Do-it-yourself oven

What else is needed besides a metal barrel?

- Sheets of iron 4-5 mm thick.

- Pipe with a diameter of 100 mm.

- A grate, better finished, although it can be made with your own hands, for example, from a corner and wire.

- Asbestos cord.

barrel construction

Now the sequence of assembly work:

A lid is cut out at the barrel with an allowance of 40-50 mm. In it, a hole is made in the center a little more than a pipe diameter of 100 mm.

At the bottom of the barrel, a rectangular hole is cut out for the firebox. Fuel will be laid through it.

A little lower, a smaller rectangular hole is made for the blower.

From the inside of the barrel, wire guides are welded between the firebox and the blower, on which the grate will be laid.

In the upper part, a hole for the chimney is cut out on the side. A pipe with a diameter of 100 mm and a length of 20-40 cm is immediately welded to it.

Now a pancake with a diameter slightly less than the diameter of the barrel is cut out of a metal sheet.

A hole is made in the pancake in the center and a pipe with a diameter of 100 mm is welded to it. The length of the pipe should be 20-50 cm more than the height of the barrel.

Rectangles 50-80 mm wide are cut from the same sheet, but their length should be equal to the distance from the edge of the pancake to the edge of the through hole in the center. These pieces are evenly welded in a circle with a rib on the reverse side of the welded pipe. This node is called a press. With its help, the fuel will be pressed down so as not to create a large space for the combustion zone.

Now we need to carry out a partial assembly. That is, a grate is installed, a press is lowered from above. A lid is put on it so that the press tube enters the hole in the lid.

Now the lid is welded to the stove body around the entire perimeter

Here it is important to weld the seam very tightly. An asbestos cord must be laid in the gap between the protruding pipe and the opening of the cover; it will become a barrier to smoke and carbon monoxide.

The door is hung on the opening of the firebox.

The gate is installed on the blower.

Everything is ready, it remains only to install the stove at the destination and attach the chimney to it

Under such a unit, a strong and refractory base must be poured, this is important

Bookmark fuel

Now to the question, how to bookmark the fuel? To do this, you will definitely need an assistant. He will lift the press by the protruding pipe. It is necessary to lift it as high as possible in order to fully open the combustion chamber. The fuel is packed tightly with minimal space between its parts. The less air inside the furnace, the longer the pyrolysis process takes.

Not everyone, probably, understood why a pipe is needed, which is welded to the press. This is a special channel through which fresh air will be supplied to the fuel combustion zone. And the ribs welded on the bottom will create the necessary space for air to enter, plus they add extra weight to the press.

This is one of the models of long-burning stoves that you can make with your own hands from a two-hundred-liter metal barrel. Let's face it, the option is not the most difficult, but not the most beautiful. No one will install a barrel in a residential area, therefore such furnaces are most often installed in utility rooms for official purposes. For example, in garages, workshops, greenhouses and so on. Although some summer residents install them inside the main building, ennobling the structure with additional elements. For example, you can install a decorative screen in front of the stove, or line it with bricks.Whoever wants, he will find options to make the stove beautiful.

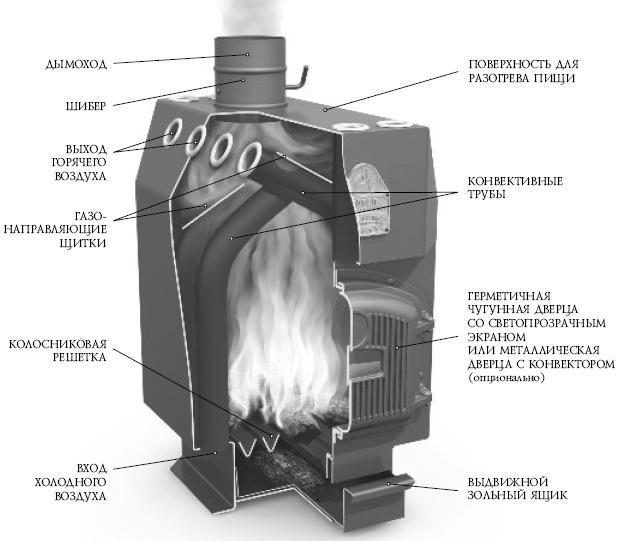

The device of gas-generating type furnaces

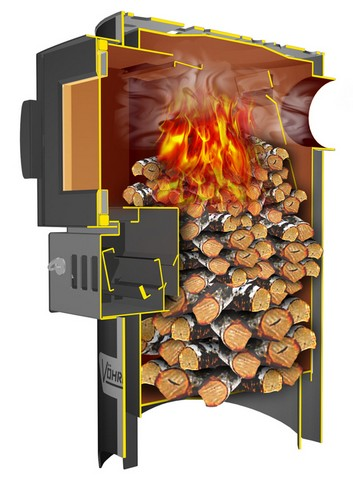

Gas-fired water heating stoves do not contain a firebox, like conventional models. The device of all pyrolysis-type furnaces is very difficult. A gas-fired wood-burning stove consists of a preliminary gasification chamber - it is directly loaded with firewood, a combustion chamber - where the fuel is converted into heat. Gases from the gasification chamber enter through the nozzle into the combustion chamber due to the action of the fan. (See also: Long-burning heating stove)

Consider the following factors when assembling and using:

- The moisture content of the firewood used should not exceed 20%. This is a fairly low figure, which characterizes the firewood as very dry. During normal storage, firewood can dry up to a level of at least 30-40%, and in order to achieve the above figure, it will be necessary to use a heat gun or another option for drying firewood.

The connection of the chimney to the outlet damper must be very easy to disassemble. The fact is that with increased humidity of firewood, condensate containing the resin of the tree will form. This same condensate, passing through the chimney, will be able to clog it - in this case, tar-like clots are formed that cannot be soaked with water, are not subject to combustion. They are not easy to remove from the chimney.

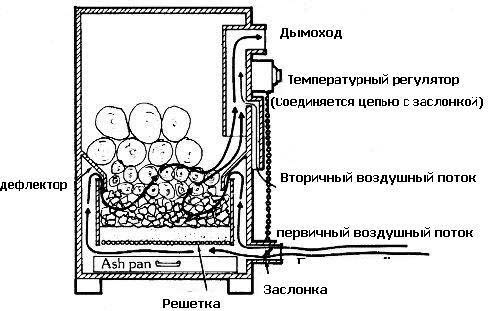

The principle of gas generation. Scheme of operation of a long-burning furnace

Gas generation is achieved by burning fuel in the smoldering mode under conditions of oxygen deficiency. At the same time, the efficiency of such a heating unit increases several times in comparison with classical furnaces.

The combustion mode is regulated by air supply to the furnace. Heat is transferred to the heated room through the heat exchange surfaces.

We will immediately clarify the terminology of the processes underlying the operation of such heating units. Without exception, all manufacturers call the furnaces they offer, operating in the smoldering mode, gas-generating. From the point of view of the formation of pyrolysis gas in this mode of combustion, this does not raise any objections. However, this is actually the end of the matter.

The principle of operation of a classic gas-generating furnace is as follows. The pyrolysis gas formed as a result of smoldering wood (mainly carbon monoxide and methane), passing through a special nozzle, mixes with air. Once in the combustion chamber, the gas-air mixture ignites in the presence of a catalyst and burns with high heat output. In this case, complete burnout of all heavy fractions and soot occurs, and the remaining flue gases are almost free of impurities.

Air is forced into the combustion chamber. The flame has a pronounced white color - a sign of complete combustion with an excess of oxygen.

Nothing like this happens in the advertised "gas-generating" stoves for heating homes. There is no doubt only that the pyrolysis gas is formed in the combustion chamber. But it is not used, but leaves the stove through the chimney turn. those. simply "flies into the pipe."

The color of the flame in the furnace is red. and soot and tar deposits quickly form on the pipe walls, which indicates incomplete fuel burnout. It would be more correct to call such furnaces smoldering or slow burning furnaces.

In this regard, many advertising claims of manufacturers, such as ultra-high efficiency, are at least questionable.

Despite the obvious inconsistency of such furnaces with gas-generating classics, they are still not without certain advantages.

Useful tips for craftsmen needed when installing the oven

A mandatory element for the safe use of a pyrolysis oven is the foundation on which the installation is installed.

The foundation must have a high degree of reliability. The foundation base for the furnace is constructed from heat-resistant building materials. The design of the furnace has a small mass, so the furnace does not create a lot of pressure on the base. During the operation of the installation, a high temperature is created, which can cause damage to the base, in order to prevent the destructive effect of high temperature on the foundation, heat-resistant materials should be used in its construction. As such a material, refractory bricks are used, which are laid out on a pre-prepared concrete base.

Read also our article Installation of the heating system of a private house: basic schemes.

Pouring a concrete base for installing a long-burning furnace should be carried out in a shallow foundation. In the process of preparing the base, its mandatory component is the reinforcing frame.

The chimney for the stove must be installed as a separate element of the heat generating plant. As a chimney, you can use a metal pipe of the appropriate diameter. When installing a chimney, it can be fixed by welding on the top cover of the furnace.

When manufacturing a rectangular oven, the chimney can only be connected to the unit from the side.

When installing the chimney, remember that immediately after the furnace body, the chimney must go strictly vertically. When designing a chimney, a minimum number of bends and bends should be used.

Since a large amount of soot is formed when using solid fuel, it is best to design a chimney collapsible, since it will periodically have to be disassembled and cleaned from accumulated soot.

After the furnace is designed and installed, it is recommended to install a reflector. With the help of this structural element, heat flows are redistributed, which contributes to uniform heating of the entire volume of the room. In addition, the installation of a reflector allows you to increase the degree of safety during the operation of the heat generating installation.

The place intended for the installation of the furnace must comply with all fire safety requirements, since the furnace body, heated to a high temperature, is a potential source of fire if the rules for operating such equipment are violated.

(Visited 1 614 times, 1 visits today)

Vertical option

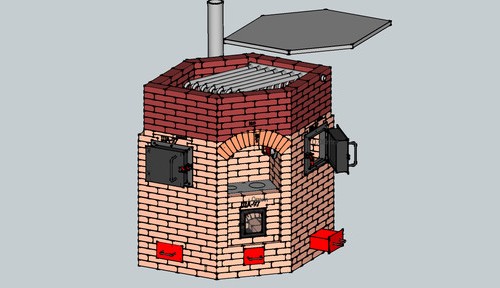

Scheme of the internal structure of a gas-generating furnace made of stone.

If you do not have space, then you can make a vertical version of the furnace body. It is slightly more complicated than the horizontal unit described above. The main body of this gas generator has dimensions of 700×510×1480 mm. This installation must be provided with a grate, which is made of steel sheet. It is installed in the gas generator housing at a distance of 30 cm from the bottom of the housing on legs made of steel pipe scraps. The grate is connected by welding with a box installed inside the unit.

A deflector is welded to the side wall of the gas generator, holding the box with the grate and giving air a free passage to the burning fuel. All these parts are made of steel sheet (thickness 4-5 mm). As a chimney, a steel L-shaped pipe is welded into the gas generator housing (above the box at the side wall of the installation). On the same wall (in the lower part of the housing at the level of the grate), make a hole with a diameter of 10 centimeters for air to pass into the unit.

Drill a 6 cm hole at the level of the lower part of the chimney pipe (in the housing). In this version of the gas generator, a fan is used to force air into the furnace, mounted on the lower opening of the duct. For normal use of the boiler and good thermal control of the installation, an automation system is installed on the side wall of the gas generator. Its actuator in the form of a chain is connected to the fan switch button.

If you want to use this boiler not only for heating, but also in conjunction with water heating, then you will have to make a heat exchanger with your own hands. It is made from sheet steel and is a casing larger in diameter than your furnace, put on top of the body of your gas generator. This casing is carefully wrapped with thermal insulation using glass wool or other similar thermal insulation material.

To enter cold and output hot liquid into a system with water heating, inlet and outlet pipes are connected to the heat exchanger. Valves and other necessary equipment are mounted according to a typical scheme for heating a home with water heating. The water boiler you have assembled can work not only on wood, but also on coal. If you have problems using metal, then the gas generator body can also be assembled from bricks, but such an installation will have large dimensions.

Furnace prices

The market is quite competitive and you can find a unit for your budget and for your parameters. You can buy a stove both in the online store and in specialized points / stores in your city or region. Here is an example of a couple of popular models.

Fire - Battery 7B anthracite

- Room volume, m³: 150

- Firebox volume, l: 45

- Dimensions, (HxWxD) mm: 760x370x680

- Furnace weight, kg: 54

- Chimney diameter, mm: 120

- Heat exchanger tank volume, l: 1.3

- Price: 16-19 thousand rubles.

Furnace - fireplace Angara Aqua

- Room area up to 90m²

- Gross power, kW: 18

- Water circuit power, kW: 9

- Heat exchanger volume: 4 l

- Furnace dimensions: HxWxD, mm: 1020x550x490

- Furnace weight kg: 150

- Chimney diameter, mm: 150

- Chimney connection top, rear

- Price: 32-37 thousand rubles.

Solid fuel boilers. which also have a water circuit. A combined or solid fuel type boiler allows you to heat a room up to 170 sq. m. Such boilers can operate both on wood and on electricity. They are made mainly of strong steel. A fireplace stove with a water circuit (they are also available with a stove and grill). Such thermofireplaces do not have a high efficiency compared to stoves, but they can also be connected to a heating system and heat several rooms of small areas. Read more in the article about fireplaces with a water circuit.

In order not to make a mistake in choosing and to purchase a really reliable and convenient long-burning stove with a water circuit in all respects, you should study all kinds of information provided by trading companies or reviews

But if you are not confident in your abilities or want to save your time, then contact the professionals, they will draw up a project for a moderate fee and offer various options for implementing your idea.

Do-it-yourself gas generator assembly

- Assembling a gas generator (furnace) with your own hands

- Vertical option

- Applied materials and tools

Various types of heaters are used to heat a room in modern conditions. Basically, these are converters with various heat carriers (gas, water, electric current). But if you have a plot or cottage in an area where there is no way to supply gas heating, and heating your cottage with electricity is expensive, then you will have to install a conventional wood-burning stove. To reduce costs, it is desirable that it uses as little wood as possible and gives a large amount of heat.

A gas generating (aka pyrolysis) furnace is used in country houses, summer cottages, private houses, that is, where there is no central gas main and central heating.

More economical installations were used in the early and mid-20th century.They are called gas-generating boilers (furnaces), have a high efficiency (up to 75%), and using a non-standard method of combustion in such installations, fuel savings of up to 50% are possible.

You can make such a gas-generating furnace with your own hands from improvised materials, if you have the skills to handle the tool. This device can be used in conjunction with water heating. Here is a diagram of the device of gas-generating heating installations, recommendations are given for assembling them with your own hands.

A gas-generating stove (boiler) using firewood as fuel consists of the following parts:

- fan (in samples of vertical furnace design);

- gasification preliminary firebox (firewood is laid in it);

- the combustion chamber.

Gases from the furnace through the nozzle enter the combustion chamber of the furnace with the help of pressurization by a fan, where the main heat is released from the fuel. Firewood must have a moisture content of at least 20%, that is, be very dry. If this condition is not met, then the tar condensate formed during the combustion of firewood will clog the chimney.

For long-term burning of fuel, such an amount of firewood is laid in the furnace (in the gasification furnace) that they occupy 85-90% of its volume. The area heated by the unit is from 8 to 90 square meters. The time it takes to reach the desired room temperature directly depends on the design of your installation. It is also possible to use the boiler both for simple water heating (for bathing), and in conjunction with water heating.

The principle of operation of this type of heating devices

For most heating devices, the heating function is realized by heating the device itself, heating the surrounding air and subsequent heat transfer by its walls. This occurs as a result of the rapid and intense combustion of fuel. This method is not very convenient for several reasons: these are “jumps” in the temperature in the room, incomplete combustion of the fuel, resulting in a lot of soot and soot, the need to constantly add coal or firewood to the furnace and adjust the draft. In long-burning furnaces, everything happens a little differently.

Pyrolysis boilers are especially economical: in addition to the principle of slow combustion of fuel, they also burn gases resulting from combustion. Thus, the efficiency of such a heating device is significantly increased, reducing costs.

"Pros and cons"

Undoubtedly, the high efficiency (up to 85%!) And the small size of such units have earned them great popularity, especially where there are no other heating resources - natural gas, electricity. It attracts the opportunity to load the fuel once, after which it is enough just to adjust the draft in the furnace when the required temperature in the room is reached. It remains stable for quite a long period of time - depending on the model of the device - and can reach 30 or more hours.

A variety of models allows you to organize both air and water heating at home - in this case, a water circuit is connected to the stove. You can also connect a container for heating water for domestic needs to such an oven, you can even cook and heat food on it - in a word, this device turns out to be truly multifunctional.

The relative disadvantage of this device can be called a utilitarian appearance: such a stove is unlikely to decorate the interior, but this is not required of it. It can rightfully be called a "workhorse" among heating stoves.

The gases leaving the furnace into the chimney have a low temperature (compared to conventional furnaces) - about 2000, which leads to the formation of condensate in the chimney. Such a furnace cannot be connected to a curved, multi-pass pipe, since the draft in it is very small, and the combustion products will not be brought out.

The long burning mode does not start working immediately - first, the temperature in the room should be brought to the required level, only after that the draft is reduced and the stove is switched to an economical mode. In this case, the temperature no longer rises, but is only maintained at a given level.

Types of fuel used in furnaces of this type

Another advantage that a long-burning furnace has is the ability to use various types of fuel - solid, liquid and gaseous. True, each of them has its own device model - there is no universalism here. By choosing a model that runs on the most affordable and profitable type of fuel in the area, you can fully ensure efficient and economical heating of your private house, cottage, industrial premises.

How to make a gas furnace yourself

Gas generators, which are also called pyrolysis boilers, are increasingly used in everyday life. They are used for heating residential and commercial premises, cooking, obtaining hot water, captivating with high efficiency, environmental friendliness and ease of maintenance. However, industrial designs are expensive, so the best solution for a zealous owner will be a gas-generating stove, made from improvised materials with his own hands.

Functioning and design features

The main principle underlying the work is the gasification of solid organic fuel when it is burned under conditions of oxygen deficiency. In the process of its decomposition (pyrolysis), solid organic matter in a gas-generating furnace does not burn, but slowly smolders, forming a large amount of combustible gas, which mainly consists of methane and carbon monoxide. The resulting gas from the combustion chamber enters the afterburning compartment, where it mixes with heated air and burns, releasing a lot of heat. Depending on the design features, the gas generator can heat the coolant jacket, give off heat to the environment, or perform both of these tasks.

Such furnaces demonstrate high efficiency, which is several times higher than traditional ones in terms of efficiency. Unlike classic solid fuel boilers, the owner of the pyrolysis boiler is able to flexibly control the operating modes and change the heating temperature of the coolant. To do this, it is enough to increase or decrease the amount of air supplied to the furnace of the gas-generating furnace. Combustible gas can be extracted from almost any solid fossil fuel: firewood, coal, peat and even linoleum. But in everyday life, the first and wood processing waste is most often used. The most common type of wood-burning gas generator is a pyrolysis oven, from which gas is not taken, but is burned to produce thermal energy.

The main design feature is the presence of two combustion chambers. In one, the process of decomposition of organic fuel takes place, and in the other, the resulting gas is burned. Moreover, the afterburner in the first case is located in different ways: under the gasification compartment, above it, or on the side. The internal structure and scheme of a gas-generating wood-burning stove for domestic needs are simple, and any home craftsman can do it.

Classic pyrolysis equipment should include:

- The body inside which the working elements of the furnace are mounted.

- A filling chamber (bunker) for placing firewood or wood waste.

- Compartment for afterburning the gas emitted by the furnace.

- Grate for holding solid fuel and coals.

- Doors for loading firewood and removing ash from the gas generator.

- Air damper system to control the supply of oxygen to the working area of the device.

What you need to make

Since home-made options are usually made from available materials at hand, they cost the owner much cheaper than their industrial counterparts.To create the simplest do-it-yourself wood-fired gas generator, you will need: metal sheets with a thickness of at least 3 mm or a piece of iron pipe (barrel), steel corners 5x5 or 4x4 cm in size, hinges and latches for doors, a chimney of the required dimensions and configuration. The number of elements and dimensions of these materials will depend on the volume of the room to be heated and the additional tasks of the stove (heating water, cooking).

Comparison of gas generating and conventional boilers.

If we compare gas-generating boilers with conventional heating or heating boilers for solid fuels, then the following nuances can be distinguished.

The relatively low autonomy of the gas-generating boiler, which is the Achilles' heel of all solid fuel heating installations, can be corrected with the introduction of an automatic loading system. In this case, a kind of conveyor starts working in the gas-generating boiler, which, depending on the temperature in the device and the burning time, can send new portions of fuel to the furnace. In addition, the gas generating device can operate autonomously during the day only on one tab, which, in general, removes the question of the need for the constant presence of a stoker-operator.

gas boiler operation

In any case, the efficiency of gas generators significantly exceeds the achievements of all their counterparts. If conventional solid fuel boilers are unlikely to show an efficiency above 85%, then for gas-generating equipment this figure can reach 95%.

But a wood-burning gas-fired boiler is still a rather complex technical device. Unlike a conventional wood-burning boiler, it requires even simple, but still regular maintenance, in addition, there are certain requirements for the qualifications of personnel who work on gas generating installations.

The gas-generating boiler most critically perceives the humidity of the fuel entering it. Therefore, only pre-dried firewood is required for the efficient operation of a gas generating installation.

Selection criteria for a wood-fired gas generator

It is recommended to select a gas-fired boiler on wood based on the following criteria:

- First of all, it is necessary to take into account the degree of automation of the boiler, its non-volatility. You may want to purchase a boiler that can work for a long time without human intervention, or perhaps a gas-generating boiler will be enough for your purposes, which should independently, autonomously work out only one bookmark.

- For space heating, heating installations must generate at least one kilowatt for every 10 square meters of heated area. Based on this, you can choose the required power of the heating gas-generating boiler.

- In addition, wood-fired gas-fired boilers may have various additional equipment. It can be intended, for example, to ensure the forced circulation of liquid through the heating control or to automate the regulation of the combustion processes of the resulting gas.

In any case, consultants in specialized stores will help you choose a gas-fired wood-fired boiler to your liking.

Pellet stoves

A pellet stove is a type of gas generating device. It is designed to work on pellets - wood pellets. The difference between such furnaces is the presence of a bunker for loading fuel

And an important advantage of such models is a high degree of work automation. The supply of granules is carried out as they burn through using a self-regulating pneumatic or screw device

You can regulate not only the fuel supply, but also the operating modes.

The hot water tank is made of steel resistant to high temperatures and aggressive environments.There are no restrictions on the size of the tank. In fact, they depend only on the dimensions of the cast-iron plate. The hot water tank is connected to the general system by branch pipes. It can be installed in two ways - as close as possible to the chimney or at the junction of the combustion chamber with the chimney.

Blog of stove-maker Alexander Zalutsky

Very often, customers ask to fold the oven for a summer residence with an oven, but the oven is not intended for baking, but for quickly heating the room. Here is one example of such a furnace: here is a project, and here is a photo

I believe that a stove with calorific pipes for quickly heating a country house is a better option. Here is an example of one of these ovens.

We need fast heating of 3 rooms. Two small 16 m2 and one 40 m2.

The stove will be in a large room, and for quick warming up - a hob. The area of the furnace, which goes into small rooms, is approximately 1 m2.

The photo cuts out the corner of the inner walls, where the stove will be located

This is the view from the small room.

Well, these are the heater pipes themselves. Sometimes they are also called "dry pipes"

When installing pipes at the point of contact with bricks, they must be wrapped with non-combustible heat-insulating material. In this case, cord asbestos.

Pipes are hung on ropes

The furnace is two-coloured. Pipes are installed in the bottom cap

The stove is 4.5x4.5 bricks in size, similar to the Swedish Alexander Batsulin, only the exit from the furnace is made not to the back, but to the side. Usually, opposite the hail, the stove overheats and cracks appear in the seams. Here I made a brick column opposite the hail. The main heat will be directed at him.

This photo is before installing the hob.

Here you can see how the upper ends of the pipes are embedded in the brickwork.

The bottom cap is closed. At the top is the lifting channel, at the bottom is the forward channel.

View of the chimney from the room. The pipe protrudes slightly from the plane of the furnace for tiling.

Passage through the ceiling. A LSU sheet is fixed to the beams in two layers.

Fluff 250 mm "from smoke"

The pipe above the roof is made of facing bricks. It is more resistant to atmospheric precipitation, compared to the one from which the furnace is built, and it looks better.