Installation of a gas stove and convectors

It is forbidden to install the convector at a distance of less than 4 meters from open sources of fire, including a gas stove. The hose suitable for the convector must have a dielectric insert, this will prevent a fire in the event of a short circuit in the wiring in a wooden house.

An important factor is the grounding of sockets located near the gas stove and convectors, although in a wooden house they must be grounded a priori.

There are three types of supply hoses that are allowed to a gas stove in a wooden house, namely:

- Rubber fabric - its plus is that it does not conduct electric current, but it is more susceptible to mechanical damage compared to analogues;

- Metal sleeve - when using it, a dielectric insert is necessarily inserted from the gas stove to the main, and otherwise it has the best performance among analogues. In addition, it is recommended by the latest approved standards. Its only disadvantage is the price, it bites;

- Rubber with a metal braid - it is more able to withstand severe shocks, and also, thanks to the rubber core, does not conduct current.

When buying a metal hose, you should pay attention to its coating, some manufacturers oriented to other markets, with other standards, use yellow insulation, which does not fulfill its main functions. Always ask for supporting documents when purchasing, and keep them in a safe place

How to choose a gas convector

When choosing equipment, you will need to consider the following:

- Power calculation

. When heating the room, air convection is used. Therefore, heaters are only effective in limited spaces. For each room you will need to install a separate convector. The power calculation is carried out according to the formula 100 W per 1 m². - Housing type

. For an apartment, heaters with a closed combustion chamber and the output of combustion products through a coaxial chimney are suitable. You can put any type of equipment in your house. But when installing a heater with a closed chamber, it is necessary to take care of a constant and intensive supply of fresh air. - Fuel type

. It is forbidden to install a gas heating convector on liquefied gas in an apartment of a multi-storey building, due to the high explosion hazard of cylinders.

All convectors are initially manufactured with the ability to connect to the main gas pipeline. If you plan to connect the gas convector to the cylinder in the future, you need to purchase a special gearbox (in some modifications it is included).

Mounting the gas convector on the wall

The installation of the convector should be carried out in the place of the greatest heat loss in the room, ideally under the window. But here one important nuance arises: there should not be flammable objects and structures near the device. It is strictly forbidden to hang it with curtains, curtains, etc., since the body of the device heats up significantly during operation.

Some manufacturers include a wiring diagram (template) with the convector, which shows the places where the device is attached to the wall and the place for the exit of the coaxial chimney

When choosing a mounting location, it is important to ensure that the distance along the outer wall between the coaxial chimney and the ground level is at least 0.5 m, and from the nearest window - at least 0.25 m. It is also necessary to take into account the possibility of snow drift, which can block the outlet combustion products

Indoors, the device must be installed in such a way that the distance between the lowest part of the convector (usually the rear wall) and the floor is at least 0.10 m; for the highest quality convection, this distance should be 0.20–0.25 m. The distance between the device and the side wall should be at least 0.18 m. 10 m (Fig. 1).

Radiators for water heating

First, we examine radiators designed for operation in central and autonomous heating circuits.

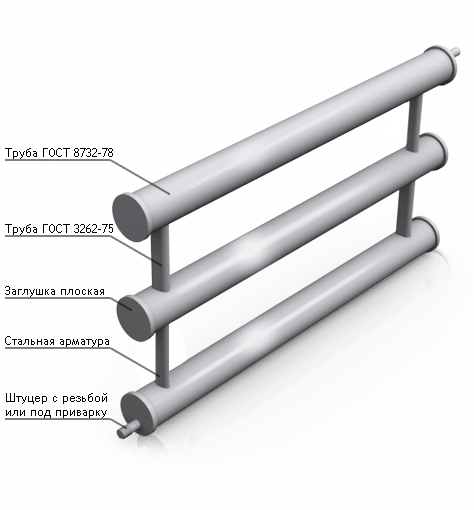

Register

The simplest and most affordable home-made heating radiators are made from pipes of large (100 - 250 mm) diameter, muffled at the ends and connected by jumpers. These devices - the so-called registers - have a large internal volume and, accordingly, a significant thermal inertia, which makes them an ideal solution for systems with solid fuel boilers.

How to make a simple horizontal register?

-

Pipes are cut into segments of 1.5 - 4 meters

(depending on the expected length of the register). -

Holes for jumpers are drilled or burned with a gas cutter in them.

. An important point: the configuration of the jumpers should create a closed circuit inside the device, excluding stagnation of the coolant in dead ends. -

Pipes are connected by jumpers

- pipes of size DN20 - DN32. -

Pipe sections of the same length are welded parallel to the jumpers, but already welded to blank walls

. They will give the structure rigidity. -

The ends are muffled with bottoms cut from a steel sheet 4-5 mm thick

. -

Branch pipes are welded into the lower and upper sections

, which will later connect the register with the eyeliner.

In most cases, an ordinary round water and gas pipe is used as register sections. It is attractive for its low price per linear meter and maximum tensile strength with a minimum wall thickness, which is ensured by a round section.

However, sometimes you can also find home-made heating radiators from a profile pipe - square or rectangular. Its advantages are the relative compactness of the register and a slightly larger surface area with the same cross-sectional area.

Convector

The simplest convector is a coil of pipe with plates pressed onto it, increasing the notorious heat exchange surface. The most accessible material is steel. Homes - new buildings often act as sources of ready-made convectors for garage owners: the owners of apartments in them massively change the heaters installed by the builders for sectional radiators that are more attractive in appearance and have a greater heat transfer.

However, steel has a serious drawback - low thermal conductivity. In order not to be unfounded, we will give the values \u200b\u200bof thermal conductivity for three metals, most often used in the manufacture of heating appliances.

Obviously, when creating a convector, it is beneficial to use non-ferrous metals: their thermal conductivity will dramatically increase heat transfer, making the heating of the fins more uniform.

Home-made copper heating radiators are all kinds of designs based on and plates - copper and aluminum. Aluminum fins are much more affordable than copper fins; some difference in heat transfer is compensated by its increased area.

To assemble the convector, solder intended for copper water pipes is most often used; somewhat rarer plates.

Is it possible to put a convector in a residential area

Heating a house or apartment with gas convectors is completely safe. In doing so, several aspects must be taken into account:

- Models with a vertical chimney, equipped with an open combustion chamber. The operation of convectors of this type is allowed in private and country houses, but is prohibited in multi-storey buildings. In apartments, installation of systems without a chimney is recommended.

- It is somewhat easier to obtain permission to install a convector than to obtain documents for the operation of a gas boiler. The gas service allows the use of heaters for heating industrial and domestic buildings.

Pros and cons

The convector cannot become a full-fledged replacement for a gas heating boiler. Only in a limited number of cases is its use justified.The advantage of the convector is that there is no need to lay heating water pipes around the house, but instead it will be necessary to lay gas pipes, which is associated with a great risk.

One or two gas convectors will cost less than a gas boiler, so in this aspect they may be preferable for a small house. The cost of piping is approximately the same, but you do not need to spend money on heating radiators.

The main advantage is the quick heating of the room and the easy start of the heater, even if the temperature in the room was negative initially.

Of the important features of gas convectors should be considered:

- The high temperature of the heat exchanger causes the decomposition of dust in the air, which requires constant ventilation so that the well-being of the residents does not deteriorate.

- Active convection flow covers the entire volume of the room.

- Since the convector is installed alone per room, a noticeable temperature difference inevitably arises directly near the heater and away from it.

- To install a convector, it is required to drill a hole in the wall for a chimney and a gas pipe, which affects the appearance of the building and is not always possible.

The convector is best identified under the window opening. At this point, it is easier to drill a wall to install a chimney, and the heat from the heater will form a thermal curtain for the window. It is desirable to make the distance from the extreme points of the opening at least 30 cm, the rise above the floor - at least 15 cm.

The instructions indicate the dimensions, as well as the plan for the distribution of the chimney and the connection of the gas pipe. However, it is better to remove the protective cover of the heater on site and record the actual values and transfer them to the installation site. You will need two/four heater mounts. From them, the position of the through hole for the chimney is already measured.

The hole should be drilled at a slight angle with an inclination down and to the street. This will protect the device from rainwater. The slope is maintained at an angle of approximately 15 degrees.

Once the hole is prepared, the coaxial chimney is inserted and foamed. If the walls of the house are made of flammable material, a larger hole is prepared, and refractory heat-insulating material is laid around the chimney. Basalt wool is perfect.

The wiring of the gas pipe and the connection of the convector is carried out only by employees of the gas facilities. These works require increased attention and appropriate permission. It is enough to bring the pipe to the convector at a distance of no more than half a meter and install a shut-off valve. The remaining section is easier to form with a flexible hose. This will allow you to remove the heater if necessary.

Installation of a gas convector

It is very easy to install a gas type convector on your own

But before moving on to the installation process, it is important to choose the right model of the device. On sale there are both domestic inexpensive options, and foreign ones, the cost of which is higher.

The most important thing is that the product is of high quality and reliable.

Convector Alpine air

Of the imported devices, one can name the Alpine air gas convector from a Turkish manufacturer. This is a high-quality series of devices with a cast-iron heat exchanger. The appearance of the unit is quite attractive. The heating power ranges from 2.5-9 kW. There are products equipped with a fan.

Convector Akog

When gas equipment is purchased, it is necessary to determine the location of its location.

It must fit the size of the device. It is allowed to place convectors only under the window.For installation, you need to prepare the following tools: an electric drill, a pipe cutter, mounting foam, silicone, a wrench, a metal-plastic pipe, a set of screwdrivers, a gas valve, plastic dowels and self-tapping screws.

When the place is chosen, mark the output of the coaxial pipe. Using a perforator, a hole with a round crown is cut. It is necessary that there is a slight slope towards the street. This will avoid problems in rainy weather.

When the place is chosen, mark the output of the coaxial pipe. Using a perforator, a hole with a round crown is cut. It is necessary that there is a slight slope towards the street. This will avoid problems in rainy weather.

The dimensions of the pipe offset are made taking into account the characteristics of the model. The device is attached to the wall with four dowels. Studs may also work. It all depends on the weight. A gap is formed between the pipe and the wall. It must be filled with special mounting foam. Gas is supplied either by a flexible gas hose or a rigid pipeline

It is important to check the tightness of the connection. The fan and automation are powered by the mains, which must be connected individually

But you can connect and.

Despite the fact that gas reviews of all users converge on heating convectors on such an advantage of these units as ease of installation, it is advisable to trust the installation to specialists with a license to carry out such work. This is especially true for connection to the gas pipeline. After all, the safety and durability of the operation of the equipment largely depends on the quality of the installation.

Our engineering and installation company "Seti Service" solves the problems of Muscovites, as well as residents of the region, who are associated with heating, water supply and sewerage. We are ready to offer you many options for solving your engineering problems with communications. For instance, installation of convectors

will help to quickly heat your home and maintain the required temperature level.

One of the advantages of this equipment is the absence of noise during operation. Such characteristics can also boast, which is in demand among our customers. But it is also worth mentioning that installation of heating convectors

will be convenient anyway. After all, it is absolutely easy to control the operation of these units - they have a simple and understandable control.

Convectors of the latest generation are produced according to the most modern designs. Therefore, this equipment can be described as energy-saving. Russian manufacturers offer units that are best suited for our conditions. By the way, the convector can be used as the main heating device, and auxiliary. Only high-quality ones compete with convectors.

Advantages and disadvantages of gas convectors

Among the advantages of gas heaters, the following factors can be distinguished.

But such devices also have certain disadvantages of using them.

- Insufficient compactness. The higher the power of the heating unit, the larger its dimensions, especially if it is a floor-standing option.

Poor heating of the room if the room has many doors or windows. In this case, you have to put a heater under each window, which is not justified from a financial point of view. If you install one heater, then the air will remain cold in the corners of the room.

Rapid cooling of the heat exchanger. This disadvantage applies only to cheap models with a steel heat exchanger.

Homemade convectors

It is also easy to create with your own hands. It is enough to make a case with holes for air movement, and place an air heating element in it. The main disadvantage of this design is air drying.

The oil cooler has a fairly simple design and can be easily repeated with your own hands.

Since the opportunity to install high-quality double-glazed windows has appeared in the Russian regions, a fashion has arisen for French balconies. The only drawback of full-height windows is the inability to put radiators under them to remove the cold bridge. They were replaced by floor convectors. These are heating devices that operate on the principle of circulation, taking in cold air and giving warm air back into the room. Convection can be carried out naturally or forced - with the help of a fan.

- It is justified to use a floor system convector if you plan to install panoramic windows and glass doors.

- When there is no room for radiators in the apartment.

- If the flooring is wooden, because it does not allow the installation of underfloor heating (it has high thermal insulation properties).

- These devices are also appropriate in rooms where humidity is high, for example, in swimming pools.

Battery Disadvantages

Due to the characteristics of the devices (they are walked on), dust (sometimes dirt) collects in them, and you need to get rid of it in time, otherwise it starts to circulate along with the air. From this point of view, a convector built into the floor is considered less environmentally friendly than a radiator hanging on the wall.

Warm floor

House owners use heated water floors with their own hands, in two versions.

Underfloor heating evenly warms up the room, increases the level of comfort and does not require additional energy costs, since the batteries and the floor circuit are powered from one boiler.

Ways to create a warm floor

The most popular ways to install underfloor heating:

Pipes used for underfloor heating

Gas supply to the convector

- GOST requires that the pipe suitable for the convector run along the street. We will act in accordance with it. If the gas pipe has a previously removed threaded connection, then we screw a gas valve onto it, which shuts off the gas supply to the convector. If the pipe does not have such a branch, it will be necessary to make it. Such work should be carried out by a gas welder. Preferably a specialist from Gorgaz or a similar office.

- When the gas cock is installed, a metal-plastic pipe should be laid to the convector.Using a tape measure, we calculate the length of the pipe, determine the presence of fittings.

- We buy pipes and fittings. When buying a pipe and fittings, find out if these pipes and fittings have a certificate of conformity for this type of work.

- Now lay the pipe, fasten it to the clips every meter. To install the clips, drill holes in the wall.

- When installing fittings, lubricate the pipe and fitting with silicone. This will provide additional sealing. In addition, the silicone will serve as a lubricant and facilitate pipe installation.

The result of the work should be a convector hanging on the wall, an exhaust pipe with a cap and a gas pipe laid and connected to the convector.

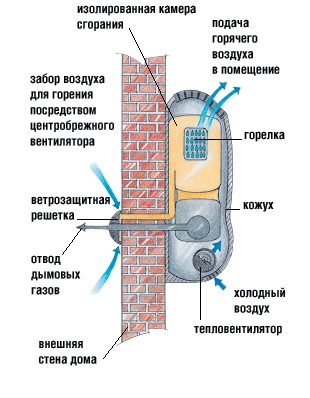

Principle of operation

Heat enters the room through the convection method, when warm air flows from a heated heater. The gas convector is equipped with a special hermetic combustion chamber, it is its surface that heats up during the combustion of gas.

The convection method is based on the fact that warm air coming from a heat source, as lighter, rises. Cold air (heavier) falls down the room and comes into contact with the convector, heats up and rises. Thus, due to the continuous circulation of the flow, all the air in the room warms up.

In order to increase the efficiency of a gas convector and heat a room of any size with the highest quality, a fan heater is built into some units. It forcibly accelerates convection, and this, in turn, significantly reduces the time to heat the room to the required temperature.

Scheme and principle of operation of a gas convector

Types of gas convectors and their advantages

Heaters differ from each other only in the presence or absence of a fan blowing the combustion chamber, and design.

Gas heaters vary greatly in terms of power. This factor is influenced by the volume of the heated room.

Many sellers of convectors often argue in favor of their own product, declaring its compactness. At the same time, doubts immediately arise, since the convector looks more like a large fireplace than a miniature heating device.

Another indicator is the relatively low cost of production, which, of course, can also be argued with. After all, this price is much higher for a standard convector used for a conventional heating complex.

Among the real and worthy advantages of a gas convector, it is worth highlighting the absence of water as a coolant in the heating complex. This represents a great level of convenience in the winter, when you can not be afraid of freezing water in the pipes (this is beneficial to summer residents). Nevertheless, such changes in the temperature regime adversely affect the interior decoration of the house, there is a risk of dampness and frost, which can ruin the furniture. Accordingly, it is better not to use convectors in houses for permanent residence (even summer cottages). Such devices are more useful in non-residential premises (sheds, workshops, garages).

In terms of environmental friendliness, some questions may also arise. The advantage is that the convector does not absorb oxygen. The temperature of the heating device (boiler or convector) should not exceed 60 degrees. Otherwise, the process of dust decomposition will begin, and you will have to forget about environmental friendliness.

However, can a gas convector maintain such a rather low temperature? If the convector performs a similar function, then this is quite important, otherwise it is also better to use it in non-residential premises

coaxial chimney

Installation of a coaxial chimney is carried out in a pre-punched (drilled) hole in the wall. Here, problems of a purely technical nature may arise, because the removal of combustion products and the intake of combustion air in gas convectors occur naturally, and in connection with this, the outer diameter of the chimney is quite large. Basically, the diameter of the hole in the wall, depending on the requirements of the manufacturer, should be 0.16–0.20 m. Punching such a hole can be a difficult task if the wall is made of durable material.

Video. Gas convector installation

The length of the coaxial chimney in most models is a maximum of 0.59 m, i.e.the thickness of the wall on which the unit is installed must not exceed this value. The minimum wall thickness may be less than 0.20 m, but the manufacturer does not guarantee the normal operation of the convector and the achievement of the parameters specified in the technical data sheet, due to the large heat losses of the building. The chimney must be mounted in such a way that the air intake pipe is located on the same level with the plane of the outer wall and protrudes 0.035 m into the room. In addition, in order to avoid moisture entering the apparatus, one should take into account the slope of the coaxial chimney by 2–3 degrees. Outside, a protective cap is attached to the chimney, which, firstly, prevents foreign objects from entering, and secondly, serves as protection against wind blowing and knocking down the burner flame.

Gas convector installation, gas pipeline connection

Installation of a gas convector is strictly linked to the implementation of a gas project. Any equipment that uses natural gas in its operation requires a permit and the implementation of a gas project.

To obtain permission to install a gas convector, you must submit an application to the organization responsible for the operation of the gas pipeline to which the equipment is planned to be connected. Independent re-installation of gas pipelines is strictly prohibited.

The operating mode of this type of installation is characterized by a high heating rate and cyclicity, so installing a gas convector in an apartment or private house most likely will not create comfortable living conditions. Temperature fluctuations in the time interval will reach decent values.

It will also not be possible to install a gas convector with your own hands - you need to have a special license for this type of work. The installation of convectors in wooden houses requires compliance with measures to protect building structures made of wood from contact with elements of the device that have a high temperature. This interaction of wood and hot metal can lead to fire.

The most popular area of application for gas convectors is the heating of large volumes of premises - production workshops, hangars, warehouses, and so on.

After receiving the application and processing it, technical conditions for connection to the gas pipeline are issued. They indicate the connection point, gas consumption and other indicators. Based on the technical specifications, a gas project must be executed.

The gas project indicates the installation locations of the devices, the methods of their connection (subject to the requirements for the installation of gas convectors), the configuration of the supply gas pipeline. The project is coordinated with the organization - the owner of the gas pipeline. Only after that proceed to the installation of equipment.

The installation process itself is quite simple. Holes for coaxial or separate chimneys are equipped in the wall; when supplied from an external gas pipeline, there is a hole for gas inlet. The convector body is mounted on the brackets. Smoke exhaust structures are connected to the body.

The holes through which the chimneys pass are sealed with non-combustible material. In the case of wall-mounted installation of the device (not on a remote bracket), the wall is also insulated from the convector with fireproof materials with low thermal conductivity (asbestos cloth, and so on). Electrical wiring (220 V) is supplied to the convector. The electrical connection of the convector is carried out (the built-in fans are powered by electric motors). A remote control panel for convector operation is installed in the accessibility zone.

For the installation of a gas pipeline, you need to attract an organization that has a license for the corresponding type of work. The installation of the gas pipeline is carried out by electric arc welding, the laying of the gas pipeline is carried out in compliance with the requirements of the project.

After carrying out the installation work on gas, pressure testing and delivery of the gas pipeline to a representative of the organization of the owner of the gas pipeline is carried out. Checking the joints of pipelines for tightness is carried out by washing. If leaks are detected, they are eliminated and a new tightness test is performed. After the successful completion of the work, an act of acceptance of the gas pipeline is drawn up.

Autonomous heaters

What to do if there is no central heating and gas in the garage, and the frequency of your visits to the premises does not allow organizing a scheme with a solid fuel boiler?

In this case, it would be quite logical to use electricity for heating.

Oil radiator

The simplest homemade oil cooler is a welded register already familiar to us with several modifications.

- There are no welds for connecting to the piping.

- The register, as a rule, is made portable, which implies the presence of legs.

- Jumpers between sections are present on both sides. Their diameter is made somewhat larger than when assembling a register for water heating. The instruction is related to the fact that natural convection implies a minimum hydraulic pressure, and if so, the hydraulic resistance should also be minimal.

- A heating element or several parallel connected heating elements are installed at the end of the lower section.

- Oil acts as a heat carrier. Ideally - transformer, but even working out will do.

- The register is supplied with a small open expansion tank. As an option, the oil is not added a little to the top of the register, and the weld on its upper section is equipped with an automatic air vent.

car radiator heater

Another interesting solution is a homemade garage heater from a radiator.

Numbered on the diagram:

- Radiator.

- Expansion tank.

- Forced blower fan.

- A casing that protects the fan blades.

- Water pump.

- Pipe for oil supply.

- Actuator.

- Fan drive belt.

- Electric motor.

- Frame stand.

- Drain tap.

- Block of heating elements.

- Blinds to adjust the direction of the air flow.

- Partially clogged radiator tubes are not a hindrance. They will miss the oil.

- Optimum motor performance - 300 - 500 watts at 1500 rpm.

- To heat the oil, heating elements with a total capacity of up to 3 kW are used. It is better to provide for stepwise power adjustment by switching them on separately.

- Due to the small diameter of the radiator tubes, it is not worth using mining in this design. Suitable transformer oil or antifreeze A-40.

- The most efficient operation of the heater will be at an oil temperature of about 80C. The temperature is regulated by the selection of the power of the heating elements and the fan speed.

Purpose

The convector working on natural gas is intended for heating of premises for various purposes. In this case, combustion takes place in a closed chamber, air is supplied from the street and combustion products are discharged there. The heat released during the combustion process is transferred to the combustion chamber body and heat exchanger, and then to the indoor air. Due to the rapid heating, the air rises, making room for the colder one, maintaining an active convection process throughout the room.

A gas convector warms up the air faster and more actively than its electric counterparts, or even more so converter-type radiators for a water heating system. This is due to the higher surface temperature of the heat exchanger and the increased rate of heat transfer from the combustion chamber.

A gas convector is an excellent solution in the following situations:

- Primary heating for a small room or cottage with one or two adjoining rooms.

- As a replacement for the solid fuel stove, which was previously used to heat the house.

- For quick heating and maintaining a comfortable temperature in the garage, utility room, small country house.

- As an addition to the central heating system in rooms where the installation of a water radiator is difficult (basement and semi-basement, attic, veranda, etc.).

- For heating greenhouses.

As a replacement for the main heating, a gas convector is only suitable for small houses or individual rooms. The effectively heated area is easily calculated based on the models of gas convectors available in terms of power. On sale, devices with a power of 2.5-6 kW are more common, less often up to 12 kW. In the first case, the convector is enough to heat a room up to 50 m2. The most powerful models are only in demand for industrial and public premises up to 100 m2.

Results

Convector heating is a very good option for space heating. Convectors can be recommended for installation both in small apartments and in large country houses. They have good performance and efficiency. published

Homemade - this word means that the product is made by hand, but sometimes it is used with some kind of dismissive connotation. Meanwhile, this is far from being the case. The most expensive hand-built cars in the world are created according to individual projects. How to call them? Homemade? Everything that provides the life of mankind is created by human hands.

Most often, craftsmen begin the creation of a heating system by determining the type of boiler, creating drawings and subsequent construction of the boiler. This work is not easy, therefore, without good knowledge of the device and the principle of operation of the selected type of boiler, experience, the availability of the necessary tools and materials for its installation, it is difficult to perform it.

Most often, craftsmen begin the creation of a heating system by determining the type of boiler, creating drawings and subsequent construction of the boiler. This work is not easy, therefore, without good knowledge of the device and the principle of operation of the selected type of boiler, experience, the availability of the necessary tools and materials for its installation, it is difficult to perform it.

Most often, the following types of boilers are independently manufactured:

Gas boilers are difficult to manufacture on their own, because this is equipment of increased danger and special technical requirements are imposed on it. Attempts to make homemade are limited by the need to obtain a quality certificate and permits from supervisory authorities. It is problematic to pass all the required checks for compliance with quality parameters. But do-it-yourself repair of the convector is acceptable. Most often, the central pipe of the coaxial output burns out and it can and should be replaced.

Electric boilers

Oil boilers

Boilers using liquid fuels are also easy to manufacture. The high price of injectors can serve as an obstacle to manufacturing.

Solid fuel boilers

Pyrolysis boilers

Craftsmen learned how to make a pyrolysis boiler from a gas cylinder with their own hands, economical and perfectly working. The easiest way to make a boiler is from a gas cylinder with a capacity of 50 liters.