Installation of a warm and self-leveling floor

After the preparatory work, the installation of plastic pipes begins. They are laid out in a zigzag in such a way that one end of the system is connected to a heat supply source, and the other to the water inlet to the general heating system.

The distance between the pipes must be at least 10 cm. At the bends, the pipes are fixed with mounting tape using dowel-nails.

Upon completion of the installation of a water-heated floor, it is necessary to make a rough concrete screed. The solution must completely close all gaps, as well as the upper parts of the pipes. At the end of the work, you need to take a two-day break in work, let the cement grab and dry.

Then a liquid self-leveling mixture is poured over the concrete pavement. It should be creamy consistency, thoroughly mixed.

The self-leveling floor is poured under a warm one, starting from the farthest corner of the room. In order for the mixture to be evenly distributed, it is necessary to direct it with a staple. The surface is also treated with a spiked roller. Thus, air bubbles are eliminated, any flaws disappear. The bulk floor for a heat-insulated floor is ready in 6 hours after filling.

Do not turn on the heating system immediately after its installation.

The structure of the flooring may be disturbed. Let it dry completely for 2 weeks. After that, the floors can be painted.

Choosing a heating system

In order for the created structure to serve for a long time and perform its duties with high quality, it is necessary to choose the type of heating used correctly. In addition to the fact that different heating systems will heat a room with different efficiency, each of them fits in its own way and requires different installation costs. The following options are suitable for pouring self-leveling floors:

- A classic water system, proven over the years and quite effective. However, in combination with filling, this will not be the most rational solution. The diameter of the water pipes is quite large and it will take a lot of mixture to fill. At the same time, it will take a lot of time to fill, since it will be necessary to carry out layer-by-layer laying of the solution.

- Electric heating cable. The optimal solution for obtaining an additional source of heat. The cost of the cable is low, the thickness of the poured solution will also be small and the heating efficiency will be at its best. At the same time, a fairly simple and reliable technology is used, in contrast to structures with water tubes, which can leak over time.

- Infrared and film heating. The most modern type of heating, which has a lot of positive qualities and requires a minimum thickness of the poured solution. However, due to relative novelty. Such heating options will be quite expensive and not everyone can afford.

The final choice will depend on several parameters: the height of the room, the ability to spend a lot of time on all the work and the budget allocated for repairs.

The device of warm self-leveling floors

There are two types of warm bulk floors: electric and water. In our country, the first type is more common, largely due to the simplicity of its installation. At the same time, water self-leveling floors, popular in the West, are more economical, although they are difficult to install and operate: pipes for hot water are laid in the base (a rather laborious and technically difficult task), then a standard screed is made, leveling is performed, and the last step is pouring the self-leveling floor .

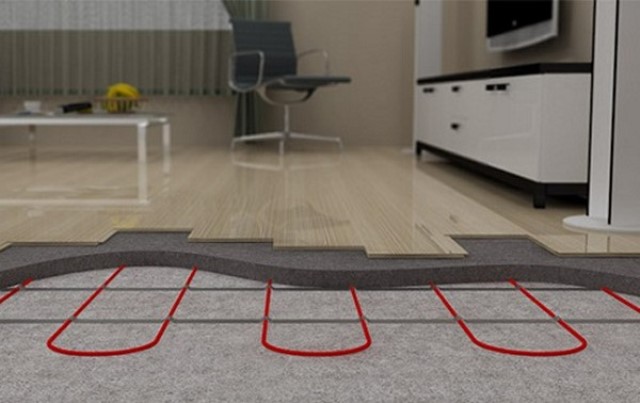

Both water and electric bulk underfloor heating are arranged in the same sequence: first - the "warm floor" system, then - pouring the finish coating.Let's consider this algorithm in more detail on the example of laying electric warm self-leveling floors. They are arranged using a cable that carries heating elements under the coating. These elements are absolutely safe and easily heat the floors to a temperature comfortable for a person. They are connected and carried out with special single-core and two-core cables.

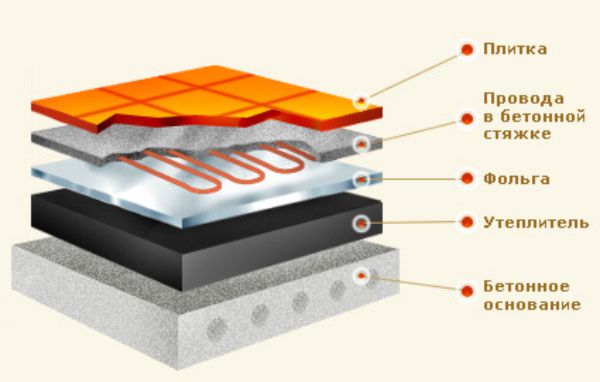

The "warm floor" system is controlled through a thermostat connected to the mains. Heating is possible up to 70 degrees, and the floor is protected from fire by a reliable protective sheath and insulation. Electric underfloor heating can be installed in different ways, but the principle by which they are arranged is the same. The first stage is a screed, insulation is laid on it, then a cable is laid, and heating elements are mounted. After the screed has completely dried, which usually takes a long time, up to a month, the finishing coating is poured - the self-leveling floor. This is done according to standard technology: the finished mixture is poured and immediately after that it is leveled with a spiked roller (this is how air bubbles are squeezed out of the coating and it becomes homogeneous). Sometimes special chips are placed on the freshly poured floor for decoration. The coating dries in 12-20 hours. From above bulk floors become covered with a protective transparent varnish.

Important nuances

In operation, a bulk underfloor heating made on the basis of an electrical system is not much different from conventional electrical appliances that are powered by wall wiring. Before laying the cable in the floor, it is necessary to plan the subsequent arrangement of the furniture (if the floor is laid in the bathroom, take into account the location of the plumbing and washing machine). The cable should be laid in places where it is guaranteed not to be threatened with overheating. Experts consider it expedient to draw and save the layout of the cable in the floor, as in the future, if repairs are necessary, this can help in detecting the damaged area.

Installation procedure

Having decided to arrange a bulk warm floor with your own hands, follow the following sequence of actions:

- Pouring concrete screed;

- Laying a heat-insulating layer. For this purpose, various heaters are used. More often, preference is given to expanded polystyrene, penofol or mineral wool. However, it is permissible to use other types of heat insulators;

- Installation of heating elements according to the chosen scheme;

- Preparing the mixture for pouring. To do this, the components of the composition are mixed together and thoroughly mixed. When doing work on your own, you can use a drill with a mixer nozzle;

- Pouring the mixture on a pre-prepared base;

- Removal of air bubbles from the surface by processing with a spiked roller;

- Surface drying. Depending on the composition, it will take up to 24 hours;

- Applying a layer of protective colorless varnish.

Advice

To extend the life of the formed floor covering, it is worth adhering to certain construction tricks and taking into account a number of technical points. In this case, the warm design will surely last a long time, providing coziness and comfort in the house. When starting installation, you should decide in advance on the following points:

- Placement of furniture. Before starting work, it is worth developing a project in accordance with which the furniture will be placed in the room. The heating circuit is placed at least half a meter from the wall. In this case, you can avoid the negative impact on furniture due to constant heating and cooling and reduce operating costs, since heat transfer in these areas is still minimal;

- Doorways. It is worth abandoning the laying of the heating circuit through the doorway. When installing the door frame, there is a risk of damaging the pipe. Recovery will be time-consuming and energy-intensive.

- Places with significant heat dissipation to avoid strong temperature fluctuations. This includes areas adjacent to walls, balconies or unheated rooms. In these places provide for the laying of insulation of greater thickness compared to the rest of the surface

Self-leveling floor heating can become a suitable type of flooring for rooms for various purposes. It is only necessary to properly prepare the base and pour the mixture. Using the advice of professionals and following the manufacturer's recommendations, you can achieve the formation of a strong, even and durable floor covering.

Varieties of self-leveling floors

The classification is based on the materials used for the device. Self-leveling floors are divided into polymer concrete and polymer. The former are formed from a mixture consisting of cement, sand and plasticizers. The formed floor covering becomes strong already in half an hour. However, its full operation is permissible only after two days.

Polymeric floors differ in high operational characteristics. They, in turn, are divided into types:

- Epoxy. With a small thickness, they have high strength characteristics and resistance to chemical reagents. They are presented in a wide range of colors, which allows you to choose the right option for a particular room. However, such a floor does not tolerate heating above 25 degrees C, which must be taken into account if a heated floor and a self-leveling floor are formed;

- Polyurethane. High plasticity and adhesion to the bases of various types. Differ in resistance to vibration. Compatible with various types of heating structures;

- Methyl acrylate. Eco-friendly, durable type of flooring. Allows operation in a wide temperature range. It quickly hardens and seizes with the base. Allows laying on the heating circuit of various types.

What systems are suitable for self-leveling floor

There are three main underfloor heating systems that you can choose from when arranging space heating. This:

electric, the main energy resource of which is electricity;

infrared, working on the conversion of radiation energy into heat;

water, where heat is transferred through heating and further movement of water.

All these systems have both disadvantages and advantages, and one must always choose carefully, taking into account the characteristics of the object to be heated.

Electric

A high-quality and reliable self-leveling floor in combination with warm electric floors is one of the most effective solutions for arranging underfloor heating. Heating electrodes have a sufficiently small diameter, which allows the use of a relatively small amount of the mixture from which the corresponding coating is made. This means that installation costs, as well as further repairs and maintenance, will be relatively small.

It should be noted that this type of underfloor heating is the most popular among residents of post-Soviet countries. This is due to both the moderate cost of the structure and the ease of installation.

Electric underfloor heating has a number of significant disadvantages. For example, if any element of the installation fails, then in order to dismantle and replace it, it will be necessary to remove the self-leveling floor at least partially. And this is an unnecessary expense, both financial and time.

Infrared

A warm floor, the principle of which is based on the use of infrared radiation energy, is characterized as the most productive system, if we take into account the heat output. Another important advantage is that the thickness of such a floor is much less than electric, and even more so water.

This difference significantly affects the cost of installation / dismantling and the cost of further maintenance.

A significant drawback is the price of the infrared variety of underfloor heating. This is due to the relative novelty of the product. Over time, the cost of the product will become more adequate.

Water

Can a self-leveling floor be combined with warm floors that use water as a heat carrier? How effective and expedient is it? It turns out that the question here is rather ambiguous, and when choosing such a heater, all the nuances must be taken into account.

Firstly, the operation and maintenance of such a floor is much cheaper than electric and infrared. Secondly, it has a high thermal efficiency.

But that's where the advantages end and the disadvantages begin. The fact is that a warm water floor has a rather bulky design. The tubes are thick enough that a large amount of solution is needed to fill them. On the one hand, this increases the cost of the system, on the other hand, the pouring height.

Basic care and safety precautions

At the moment of mixing the mineral-based mixture with water, an alkaline reaction can be observed. If the finished solution gets on the body, redness may appear. For work with mix it is recommended to use protective gloves and glasses. In case of contact with eyes, rinse them with plenty of water and immediately go to the hospital. Please follow the attached instructions regarding safety when working with such materials.

Tools should be used with extreme caution. The entrance to the construction site must be closed to children

Wet or dry cleaning is carried out without changes. The top layer of the flooring repels dust, so it is extremely easy to clean. For cleaning, you can use both washing vacuum cleaners and steam mops. No special detergents are required.

The advantages of self-leveling floor

This type of flooring has undeniable advantages:

- Formation of a flat floor surface. The coating does not have seams and joints that are formed when pouring the screed, which acts as the base for most other types of flooring;

- Human safety. The composition of the mixture used to form the floor surface uses substances that are not harmful to human health. During operation, the bulk surface also does not emit toxic substances;

- Hypoallergenic. At a self-leveling floor the surface is flat and without pores. Therefore, you do not have to be afraid of the accumulation of dirt or dust, which causes allergic manifestations in people;

- Attractive appearance. The aesthetic value of such flooring remains consistently high. They are given any desired color. Modern technologies make it possible to form realistic 3D images on the surface, selected for each room depending on its purpose and stylistic design;

- High strength. Such floors are allowed to be used in conditions of increased mechanical impact created by furniture or objects falling on the floor;

- High level of crack resistance. The special composition of the poured mixture gives it plasticity and prevents shrinkage after solidification;

- Long service life. A floor covering formed in accordance with all the rules will last at least 40 years, retaining its presentable appearance throughout the entire period of operation;

- Chemical resistance. Self-leveling floor is resistant to a number of aggressive compounds;

- Fire resistance, allowing the formation of such a floor covering in rooms for various purposes;

- Moisture resistance, allowing the installation of such flooring in rooms with a high level of humidity.

Design features

Like any system, self-leveling floor has both a number of undeniable advantages and significant disadvantages.

Advantages:

- complete absence of seams;

- such material is able to level any type of surface;

- high rates of fire safety, while the elements used do not emit toxins that could harm the human body;

- high service life, which can be calculated in decades;

- the absence of seams eliminates the accumulation of dust and fungi;

- it is possible to use detergents containing chemical elements;

- allowed for use in kindergartens and medical institutions, due to the absence of toxic substances;

- even after a strong blow, cracks will not appear.

Flaws:

- making a bulk floor on your own is simple, but it is difficult to dismantle it;

- a rather small selection of textures and shades, compared to other floor coverings;

- polymer filling will cost several times more than any other coating;

- installation will take a lot of time and money;

- preparatory work requires special care and compliance with all necessary conditions for their implementation;

- repair work is very problematic;

- constant humidity control;

- the surfaces of some types of self-leveling floors may turn yellow over time when exposed to direct sunlight.

Types of heating elements

Various types of heating structures are used for underfloor heating devices. Each of them has its own installation and subsequent operation features, which you should learn about in advance.

- A water circuit inside which a heated coolant circulates. The pipeline is laid in the form of a snake or spiral. When performing installation in an apartment of a multi-storey building, there will be difficulties with connecting to central heating. To control the degree of heating, a collector assembly is mounted. With a high installation cost, such a floor is characterized by minimal operating costs. When it is installed, it will require pouring a sufficiently thick layer of solution to prevent displacement of the pipeline during operation;

- Electric underfloor heating, formed by laying an electric cable. Installation is carried out according to a certain scheme. The cable can be one- and two-core of various capacities. To simplify the installation, special bases are often used. Manufacturers offer ready-made electrical mats in which a cable of a certain power is initially laid with a predetermined pitch. In this case, the installation consists of a simple laying of the finished product on a carefully prepared base. A thin layer of mortar is used to fix the mats. The thermostat, which is part of the system, allows you to control the degree of heating of the floor covering;

- Thermal film. Allows you to abandon the device of a thick screed. An adhesive tape is used to fix the thermal film. Maintain the temperature at the set level.

The choice of mixture for pouring

In addition to the fact that it will be tedious to choose the best heating method, when the desired option is selected, it is necessary to decide what the heating element will be filled with. The choice of the poured mass also depends on the type of heating system. Most often, a self-leveling warm floor is a combination of the lower layer, in which the heating elements are located, and the external, decorative one.

If your renovation involves the laying of traditional floor coverings, such as laminate or linoleum, there will not be much difference here - any composition designed to be used in conjunction with a heating system will do. However, if you want the fill to act as a topcoat, you will have to take the selection more carefully.

- Polyurethane mixtures are perfect for arranging such a room heating system.They are not afraid of temperature changes, tolerate heat well and have excellent elasticity combined with high strength. However, not too wide possibilities in terms of design slightly reduce the attractiveness of this solution.

- Epoxy resins, poured as a decorative coating, have high strength, but do not tolerate heat above 25 degrees very well. Therefore, in combination with such a coating, infrared film mats that do not directly heat the floor surface will be the best option.

- Methyl acrylate mixtures have very good characteristics in terms of resistance to different temperatures, are durable and beautiful. In addition, they dry in a minimum time - about two hours. However, the choice of decor for them is limited and this can be a disadvantage. At the same time, during pouring, the solution emits a very unpleasant odor, which soon disappears.

The cost of the styling solution also matters. If you need the most economical solution, then nothing is better than a conventional cement screed. The cost will be only slightly higher than standard cement mixtures. However, such a floor will not have decorative properties - you will have to lay a top coat on top. The remaining options allow you to get a ready-made solution that simultaneously heats the room and looks beautiful.

Installation feature

Installation of a self-leveling floor is carried out in several stages. Each of them is important, and work should be carried out carefully and accurately. So, the algorithm for arranging the heating system, based on the use of electric, infrared or water heated floor:

-

Preparatory stage. During its implementation, it is necessary to carefully level the surface on which the warm floor will be laid, clean it from dirt and various deposits. It is also necessary to eliminate irregularities and repair defective areas.

- When it comes to laying an infrared floor, a number of nuances should be taken into account. Among them is the need to determine the location of heavy objects in the room, mainly furniture, and do not install the system in these places. Determine the distance of the working elements to the walls and strictly adhere to it during installation. The presence of a number of heating devices is a hindrance to the placement of infrared floor heating films. The design under heating may well fail. We must not lose sight of the need for laying a thermal insulation layer made of materials with a low level of thermal conductivity. Particularly effective is a foil product located upwards with a metal part.

- The process of installing the film floor. Films are laid independently or using eyelets. The structural elements are interconnected by wires and connected to the thermostatic equipment at the output. At this stage, you must carefully monitor that there are no breaks in the electrical circuit, otherwise the installation will not work. The sensors are installed in a corrugated pipe that protects this type of equipment from damage. To check the correct installation, the installation is started even before pouring the mixture of the self-leveling floor. If the elements of the system begin to slowly warm up, everything is done correctly and you can continue to work.

-

In approximately the same way, cable electric floors are laid. However, there are some technological differences. For example, it is forbidden to lay one cable on top of another. Starting the system, including a test one, is allowed only after pouring and complete drying of the self-leveling floor. Otherwise, the system may fail.

-

Installation of a water heated floor is simple. Structural elements are laid on a previously prepared surface, interconnected.After assembly, the entire structure is tested, poured with a mixture of self-leveling floor, and put into operation.

As the main structural material from which water-heated floor systems are made, special types of plastic or copper and its alloys are used.

Each of the options has its own advantages and disadvantages. Plastic is much cheaper than copper, with similar thermal efficiency. But its service life is relatively short, and the mechanical characteristics leave much to be desired. In turn, copper options are durable and effective, but are expensive. Experts advise the latter, considering the investments quite effective.

The next is the process of pouring the mixture of self-leveling floor. It is necessary to additionally test the performance of the system and only then proceed to work.

The mixture is prepared for pouring according to the instructions on the package. Proportions should be maintained accurately enough, then it will be possible to achieve the desired result.

After pouring, it is necessary to dry the floor, achieving complete drying. Depending on the composition and characteristics of the mixture, this process can take from several days to several weeks.

After completion of these works, the system is ready for operation. In this case, it is also necessary not to forget about the instructions and follow all the recommendations of the manufacturers.

We have briefly defined how to pour a self-leveling floor layer on underfloor heating, achieving the efficiency of their use.