LPG installations

Liquefied gas boilers have their advantages, for example, there are no problems with pressure in gas pipelines, there is no need to worry about increasing the cost of heating, and you can also set standards and limits yourself. This class of equipment is also autonomous.

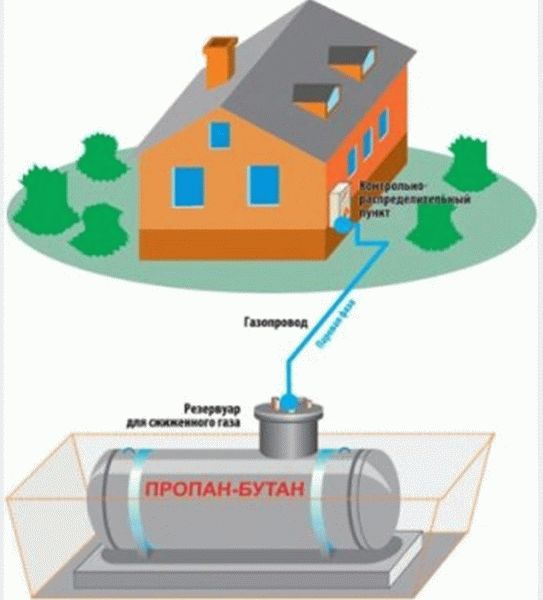

But when designing and installing a liquefied gas boiler house, additional cash investments should be spent on the design (diagram). Since the design requires the installation of a special fuel tank. This is the so-called gas tank, which can have a volume of 5-50 m2. Here, additional gas ducts of the boiler room are installed, that is, those through which liquefied gas enters the boiler plant. This class of gas supply looks like a separate pipeline (gas duct). The frequency of filling the tank with liquefied gas depends on what its volume is, this can happen from 1 to 4 times a year.

Refueling of such equipment with liquefied gas is carried out by companies that are licensed to carry out work of this class on a turnkey basis. Their licensing also allows for technical inspection of gas ducts and gas tanks. Be sure to hire craftsmen who have permits and licenses, as these are works with a high level of danger.

The construction on liquefied gas is no more different from that running on natural gas. This class of equipment also includes radiators, valves, pumps, valves, automation, etc.

A gas tank with liquefied fuel can be installed in 2 versions (diagrams):

The design of both options should be carried out subject to certain conditions and calculations, which, among other things, are indicated in SNiP. The tank for liquefied fuel, which is located above the ground, must necessarily be enclosed by a fence (from 1.6 m). The fence should be installed at a distance of 1 meter from the tank around the entire perimeter. This is necessary for better air circulation during operation.

There are also other standards for the design and location of a ground gas tank (to avoid danger) - this is the calculation of the distance from different objects:

- At least 20 meters from residential buildings;

- At least 10 meters from roads;

- Not less than 5 meters from all kinds of structures and communications.

As for the design of the reservoir underground, all of the above standards are reduced by 2 times. But there is a calculation of the depth of immersion of a tank with liquefied gas and a flue. These design standards must be calculated individually according to the volume of the tank and its design.

But equipment of this class also has its drawbacks during operation, since if the quality of the gas is poor, then the boiler room will not function in the specified mode. Refilling the tank must be done by a company with all permits and licenses.

Turnkey gas installation design

The design of gas boiler houses with a license consists in drawing up and calculating a scheme for heating, gas supply and gas ducts. To do this, you must definitely familiarize yourself with the norms of SNiP "Gas boiler houses" and take into account the characteristics when installing heating units and gas ducts.

The design of a gas boiler house should take place in a certain sequence and in accordance with the following points (norms):

- Architectural and construction schemes and drawings are carried out in accordance with the norms of SNiP. Also at this stage, the wishes of the customer (in the calculations) are taken into account.

- The calculation of the gas boiler house is carried out, that is, the amount of necessary thermal energy for heating and supplying hot water is calculated.In other words, the power of the boilers that will be installed for operation, as well as their emissions.

- The location of the boiler room. This is an important point in the design of gas boilers, since all working units are located according to the standards in one room with a certain calculation. This room can be in the form of an extension or a separate building, it can be inside a heated facility, or on a roof. It all depends on the purpose of the object and its design.

- Development of schemes and plans that help gas boiler equipment to function. Consideration should be given to the class of automation and the heating system. All gas supply schemes for the boiler room must be equipped in accordance with the norms of SNiP. Do not forget that these installations are quite dangerous and proper development is very important. The development must be carried out by qualified turnkey specialists who are licensed for this.

- It is necessary to check the object for safety, by conducting a special examination.

With improper, unlicensed design of gas boilers, you can incur large financial costs (fines), as well as be in danger during operation. It is better to entrust the installation of equipment of this class to companies that install turnkey gas boilers. Companies are licensed to perform these works, and this guarantees long-term operation of the gas installation and compliance with all SNiP standards.

Installation of gas boiler equipment

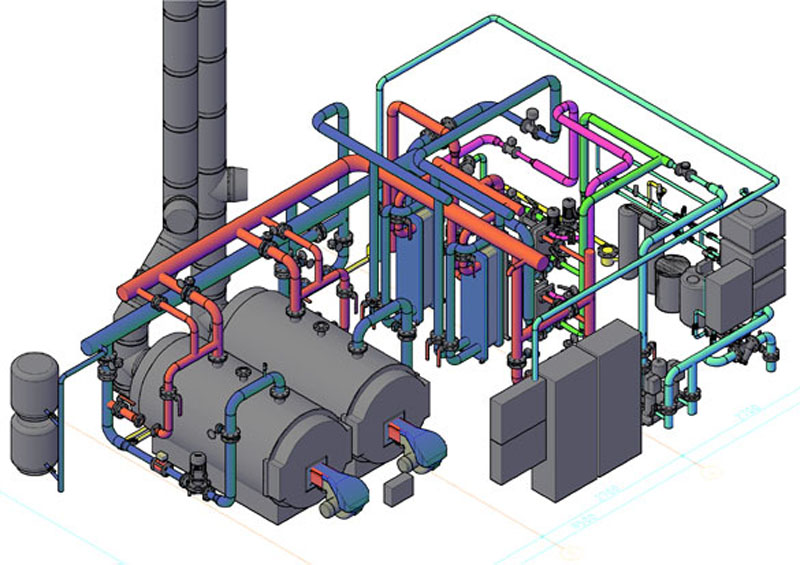

Installation of boilers is one of the most difficult and critical stages in the construction of industrial gas boilers.

At the first stage, the load that heating boilers exert on the base is calculated. When installing powerful boilers, the construction of a reinforced foundation is required.

In the room, the boilers are placed in such a way that the equipment is easily accessible for further maintenance.

In the process of construction work, heat exchangers are selected based on the parameters of the DHW system, boiler and network circuits. The main purpose of heat exchange equipment is to prevent hard water from entering the boilers from the network, thereby increasing the operational life of the installations.

The final stage of the installation of an industrial boiler house is its commissioning.

Since the boiler house is a production facility of special danger, the procedure for handing it over to the supervisory authorities is quite complicated

This is due to the increased attention of inspectors to the quality of components, materials, the correctness of the work, compliance with standards, norms and rules. Contacting a reliable partner who performs the work with high professionalism is a guarantee that the relevant regulatory authorities will issue a positive resolution for the commissioning of the boiler house

Installation of block-modular gas boilers

The work is carried out by specialists of our company at our own production site in the factory. Cases are envisaged when it is possible to assemble units at the customer's site in strict accordance with the project.

Design of TGU 100-200 kW on gaseous fuel

TGUs are small-sized boiler rooms of a modular type. The modules are made in the form of block-boxes - metal containers with fixed sandwich panels 80 mm thick. Sandwich panels are installed from the outside as wall and roof panels. The color is selected in accordance with the wishes of the customer.

The modules are provided with a supply and exhaust ventilation system, which is carried out through easily removable ventilation grilles. Air is supplied in sufficient quantity, providing the necessary air exchange in the room and stable operation of gas burners.

Equipment and pipelines are coated with an anti-corrosion compound, which increases their strength and resistance to negative chemical attack. Heating surfaces with temperatures above 45°C are additionally thermally insulated.

Types of gas boiler installations

According to the type of installation of gas boilers, they are divided into floor and wall. Floor-standing boilers, even with small dimensions, occupy a certain space in the room, and for floor-standing boilers it is necessary to install a chimney. But if you want to heat large rooms, then floor-standing boilers are the only option, because. the power of such boilers is much greater than wall-mounted ones.

Gas floor-standing boilers, the technical characteristics of which are able to meet the needs of small and medium-sized rooms, due to their dimensions and installation method do not have a big impact on the interior space of the room. Also, for the most part, this type of gas boilers is equipped with a forced draft system, which allows them to be used in rooms where it is not possible to install a chimney with passive air draft.

The use of materials is allowed only if there is an indexed link to the page with the material. For all questions, please contact dom@otopimdom.ru

Chimney design

It is important to remember that incorrect design (calculations of parameters) and operation, non-compliance with the norms when connecting a chimney to a boiler of this class leads to a dangerous situation.

When designing a gas heating installation, special attention must be paid to the chimney and flue. The installation of the chimney must take place in accordance with all norms of SNiP

That is, you should make a correct calculation of all the characteristics and norms that will meet the parameters of the boiler. Since the operation of the installation and the quality of emissions of combustion products depend on this design.

Flue is a pipeline that is part of the chimney. Combustion products move through the flue to be discharged into the chimney.

Depending on the functionality and location, the design of gas ducts can be:

- Vertical flue;

- Horizontal flue;

- Lifting flue;

- Lower gas duct;

- Rotary gas duct.

The design of the gas duct is made (designed) from steel 3-8 mm thick (the calculation depends on the power of the boilers). At very high emission temperatures, the pipes should be protected with a lining or similar. This is necessary in order to protect the pipes from the aggressive emission environment and danger during operation. Gas ducts in licensed installations must be laid above ground.

Characteristics of gas boilers

- Boiler power for home

- Fuel types

- Characteristics of gas boilers designed for heating a cottage. country house or apartment

- Wall mounted gas boilers

- Floor standing gas boilers

- Heat exchangers of floor gas boilers

- How to choose a boiler for your home, given the dependence of the gas boiler on electricity

- Other types of heating boilers

- electric boiler

- Liquid fuel (diesel)

- solid fuel

- Combined

- Boiler for home heating: prices

There is a huge selection of boilers in stores today, and any buyer has a question in his head how to choose a boiler for a country house, apartment or cottage.

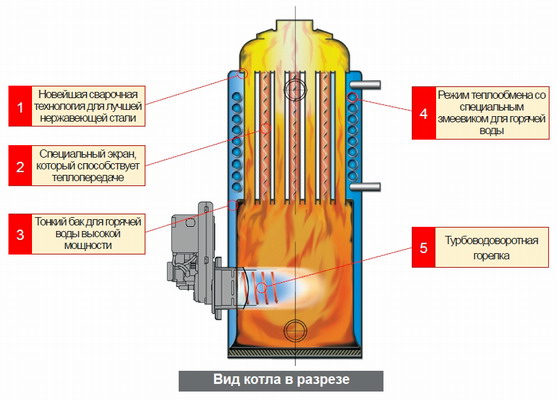

Cutaway gas boiler.

Currently, there are about a hundred different models of both foreign and domestic manufacturers. To know how to choose a gas boiler, you need to take into account several important parameters, such as the power and type of fuel in the boiler.

Gas emissions

In order for the release of combustion products to occur correctly and they do not create emergency situations, certain rules and regulations must be observed. There should be a separate channel for the ejection (removal) of spent combustion products. Two chimneys can be connected to one chimney, but a certain distance must be observed. A mandatory norm for a chimney through which exhaust fumes are emitted is tightness. Since the release of carbon monoxide is fraught with dangerous consequences for people. Therefore, when installing boilers of this class, the installation of a brick chimney is not permissible.

Carbon monoxide (CO) is very dangerous, it has a toxic effect on the body (when released into the room). Through the flue and chimney, this gas is released into the atmosphere, but this occurs in small quantities. If the room for gas equipment is not properly designed, carbon dioxide can be released, it is not dangerous to humans. It reduces the concentration of oxygen. To prevent this from happening, there must be a good ventilation system designed for certain equipment.

The operator or personnel who are responsible for the operation of the boilers must be aware of all information about the release of poisonous gases. For instance:

- The impact of gas on a person, the permissible concentration when it is released into the air;

- How to determine the release of poison gas;

- Near which unit the concentration of gas emission will be the most;

- When poisonous gases are released, the operator must know the plan and rules for evacuation from the danger zone;

- As well as the rules for providing medical care in case of gas poisoning when it is released into the air.

Requirements for buildings and premises of gasified boiler houses

Buildings and premises of boiler rooms with gas-fired boilers are not explosive. Regardless of the location floor, the boiler room, rooms for smoke exhausters and deaerators must comply with category G in terms of fire hazard and not lower than the second degree in terms of fire resistance. Under certain climatic conditions, it is allowed to install boilers in semi-open and open boiler rooms.

It is not allowed to add boiler houses, regardless of the fuel used in them, to residential buildings and buildings of kindergartens, general education schools, hospitals and clinics, sanatoriums, recreation facilities, as well as the installation of boiler rooms built into buildings for the specified purpose.

It is not allowed to place built-in boiler rooms under public premises (foyers and auditoriums, retail premises, classrooms and auditoriums of educational institutions, canteen and restaurant halls, showers, etc.) and under warehouses of combustible materials.

On each floor of the boiler room there must be at least two exits located on opposite sides of the room. Is it allowed to have one exit if the floor area is less than 200 m? and there is an exit to an external fire escape, and in one-story boiler rooms - with a room length along the front of the boilers of not more than 12 m. Exit doors from the boiler room should open outward. An exit is considered both a direct exit to the outside and an exit through a stairwell or vestibule.

The installation of attic floors above the boilers is not allowed. The floor level of the boiler house should not be lower than the level of the area adjacent to the boiler house building, and should have an easily washable coating. The walls inside the boiler room should be smooth, painted in light colors or lined with light-colored tiles or glass tiles.

The distance from the protruding parts of gas burners or fittings in the boiler room to the wall or other parts of the building and equipment must be at least 1 meter, and for boilers located opposite each other, the passage between the burners is at least 2 meters. If a fan, pump or heat shield is installed in front of the boiler front, the width of the free passage must be at least 1.5 m.

When servicing boilers sideways, the width of the side passage must be at least 1.5 m for boilers with a capacity of up to 4 t/h and at least 2 m for boilers with a capacity of 4 t/h or more. In the absence of side maintenance, the width of the side passage, as well as the distance between the boilers and the back wall of the boiler room, must be at least 1 m. (columns, stairs), work platforms, etc. must be at least 7 m.

Gas control units (GRU) are located in the boiler room near the gas pipeline inlet in the boiler room or in an adjacent room connected to it by an open opening. The GRU equipment and instruments must be protected from mechanical damage and from the effects of shaking and vibrations, and the location of the GRU should be illuminated. GRU equipment, which can be accessed by persons not related to the operation of the gas facilities, must have a fence made of non-combustible materials. The distance between the equipment or the fence and other structures should be at least 0.8 m. The GRU fence should not interfere with the repair work.

Complete set of TGU 100-200 kW on gas

Mini boilers are delivered to the facility in maximum factory readiness and can be quickly put into operation. During the production process, the modules are equipped with the necessary set of equipment, which includes:

- boilers with built-in atmospheric burners;

- boiler circulation pump;

- expansion membrane tank;

- automatic feed valve;

- internal gas pipeline;

- system of automatic control of gas content SAKZ.

At the request of the Customer, when designing, it is possible to provide for an extended configuration, ensuring compliance with individual technical characteristics. Additionally, it is possible to install make-up and anti-condensate pumps, a make-up water storage tank with a level sensor, a hot water supply unit and a diesel generator.

The operation of the equipment is controlled by the safety and regulation automation system. In automatic mode, the boilers are started and stopped, and the water pressure and its temperature before and after the boiler are controlled.

In the event of an emergency situation, the fuel supply to the burner is automatically stopped. If necessary, the project may provide for the possibility of notifying the operator on duty about stopping the operation of the boilers. Notifications are sent as a signal to the dispatcher console and/or as an SMS message to the specialist's phone (in this case, installation of a GSM module is required).

Technical characteristics of TSU mini boilers with a capacity of 100 to 200 kW

| Characteristic | Meaning* |

|---|---|

| Rated heat output, kW | 100-200 |

| Type and number of boilers | Hot water boilers with atmospheric burners, 1 or 2 pcs. |

| Boiler brand | RS-A-100, RS-A-200 |

| Boiler efficiency, % | 92 |

| Flue gas temperature, °C | 140 |

| Hourly consumption of natural gas, nm3/h | 12-24 |

| Gas pressure in front of the burner, kPa | 2-3 |

| Working pressure of cold water, kgf/cm2 | 3-6 |

| Cold water consumption for feeding the heat supply system, m3/h | no more than 0.5 |

| Electrical circuit voltage, V | 380 |

| Heat consumption for own needs, % | 3 |

| Consumed electric power, kW | 2,8 |

| Weight with chimneys and support structure, kg | 2500 |

| Overall dimensions, LxWxH, mm | 2400x4000x2500 |

| Service life of the boiler house, years | 10 |

* The data in the table are given for reference and may differ from the design values, based on the completeness (type of execution) of the TSU.

Order mini-boiler GAZSINTEZ 100 kW-200 kW on gaseous fuel in your city

You can get a preliminary cost and calculation of the production time for small-sized boiler houses TGU-100, TGU-120, TGU-140, TGU-150, TGU-160 and TGU-180 from the specialists of the Plant in one of the following ways:

- call the unified phone number for all regions 8-800-555-4784;

- call the phone number for Saratov, Engels and the Saratov region 8(8452)250-294;

- send a request by e-mail;

- leave contact details through the "Request a Quote" form.

Technical documentation of the boiler room.

Technical documentation includes:

— technical passports for boilers and pressure vessels (continuous blowdown expander and heat exchangers), forms for auxiliary equipment, drawings, descriptions and instructions from manufacturers of boilers and auxiliary equipment and structures;

- executive technological schemes of boiler house systems (feed and network pipelines, steam pipelines, blowdowns and drainages, fire pipelines, electrical cables and connections, automation, etc.), acts and protocols for installation, testing and commissioning;

- technical (production) instructions for maintenance, scheduled preventive inspections (PPO) and repairs (PPR) of boilers and auxiliary equipment;

— safety and fire safety instructions;

— instructions for using the gas analyzer;

- regime maps, load schedules (heat supply);

— magazine on instrumentation and automation;

— magazine on water treatment;

- log book of briefings;

- logbook of periodic inspections and control tests of protective equipment;

— journal and schedule of emergency drills;

— plan for localization and liquidation of emergencies;

- Journal of controlling persons of the enterprise;

- a log of bypassing the route of external gas pipelines and a route map;

- a list of works with increased danger.

Forms and drawings, technological schemes, factory and project documentation are transferred by installation, construction and commissioning organizations to the personnel of the boiler house when it is put into operation. The instructions are developed by the management personnel of the boiler house on the basis of the documentation of the manufacturers and standard instructions.

The removable log is used to record data on the operation of boilers and auxiliary equipment, switching on and switching operations, malfunctions and accidents, orders received, inspections and repairs. (Detailed data on repairs are recorded in the repair log). In particular, in accordance with the Rules, the shift log should reflect: the start time of firing up and stopping the boiler, inspection of the boiler before accepting the shift, blowing the boiler, checking the serviceability of boiler pressure gauges and water indicating devices, safety valves and feed pumps.

A repair log is entered for each boiler, in which the Responsible person enters information about the repair work performed, the materials used, the welder and welding, about stopping the boilers for cleaning or washing. The replacement of pipes and the rolling of pipe connections with drums and headers are noted on the pipe layout attached to the magazine. Also, the repair log reflects the results of the inspection of the boiler before cleaning, indicating the thickness of scale and sludge and all defects identified during the repair period.

Information about repair work that necessitates an early inspection of the boiler, as well as repair work to replace boiler elements using welding or rolling, is recorded in the repair log and entered in the boiler passport.

Replacement and repair magazines must be numbered, laced and sealed.

Didn't find what you were looking for? Use the search:

37.252.1.220 studopedia.ru Not the author of the materials posted. But it provides free access. Is there a copyright infringement? Write to us

Gas boiler license

In accordance with the Federal Law “On Industrial Safety of Hazardous Production Facilities” of July 21, 1997 N 116-FZ, it is required to obtain a license to operate certain types of boiler houses.

Necessity of Boiler Licensing

Factors that determine the need for Boiler Licensing are the presence of pressurized equipment and the presence / handling of hazardous substances.

- The boiler house uses equipment (steam boilers) operating under an overpressure of more than 1.6 MPa or at a working medium temperature of more than 115ºС. With the exception of equipment specified in clause 4 of the Federal Code of Practice “Industrial Safety Rules for HPFs Using Equipment Operating Under Excessive Pressure”;

- The boiler room runs on natural gas (gas boiler room). In the event that the HPF includes gas pipelines with a pressure above 0.005 MPa;

- The boiler house provides heat supply to the population and socially significant categories of consumers;

- The boiler house has reserve fuel, which belongs to the category of combustible liquids in the amount of more than 20,000 tons or more.

If the boiler house is assigned the 4th hazard class, then Licensing is not required.

Obtaining a license to operate a boiler house

Obtaining a license for a gas boiler house

In cases where a boiler house is assigned 2 or 3 hazard class, it is subject to mandatory Licensing. Obtaining a license is regulated by Decree of the Government of the Russian Federation No. 492 dated 06/10/2013 “Regulations on licensing the operation of hazardous production facilities of I, II and III hazard classes” and Federal Law No. 99-FZ dated 04/22/2011 “On licensing certain types of activities”.

License for maintenance of a gas boiler house

The activity of servicing a gas boiler house is not a licensed activity and a license is not required. The organization servicing boiler houses must have a permit from the SRO and certified personnel in accordance with the relevant industrial safety rules.

Answers to frequently asked questions

1. Question: I am an individual entrepreneur, do I need a license to operate a gas boiler plant with a capacity of up to 100 kW?

Answer: The operating organization, regardless of the form of ownership (LLC, IP, CJSC) must obtain a license to operate this facility. It is not the gas boiler house itself that is subject to licensing, but a hazardous production facility (Gas consumption network) consisting of: external and internal gas pipelines, GRPSh (if any) and gas-consuming equipment (boilers, regardless of their power). It is necessary to obtain a license from Rostekhnadzor, regardless of the capacity of the gas-consuming equipment (boiler). A sign of danger in is not the power of the boiler, but the presence of a hazardous substance - natural gas. In the event that there are no gas pipelines with a pressure above 0.005 MPa in the HIF, this facility does not fall under the definition of a hazardous production facility - only in this case licensing of the gas boiler is not required.

2. Question: If the boiler house does not actually function, can a fine be imposed for the absence or non-renewal of a license?

Answer: In short, Yes, you can be fined for violating industrial safety requirements. After all, you legally operate this facility. If the facility is not in operation, then it is required to conserve or liquidate it.

3. Question: Can our organization, having received a license to operate HIFs, operate other boiler houses?

Answer: No, it doesn't. Because in the License for the operation of gas boilers, the addresses of specific boilers are prescribed. In the event that you plan to operate boiler houses at new addresses, you need to enter new addresses of the places where the licensed type of activity is carried out in the existing License.

Obtaining a license to operate a boiler house

Topic 1. General characteristics of the boiler unit, boiler plant

Definition of KA, KU, steam (hot water) boiler, waste heat boiler;

main and auxiliary elements that are part of the spacecraft and CU; fundamental

Scheme of a CHP with a natural circulation drum boiler on solid fuel.

General characteristics of boiler plants

and boiler units.

Boiler house

installation (boiler room) (KU)

called a set of equipment designed to convert chemical

fuel energy into heat. CU, in turn, may be part of

industrial or energy enterprise.

On fig. 1.1, 1.1 are two

principal schemes for the production of thermal energy from fossil fuels:

heat-only production scheme and co-production scheme

thermal and electric energy.

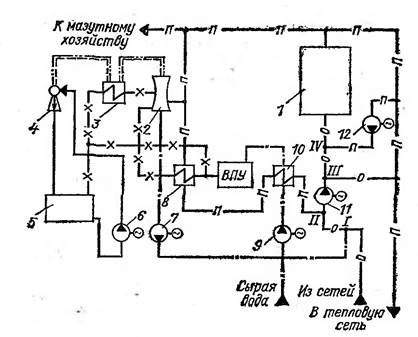

Rice. 1.1. Thermal diagram of the boiler room

with hot water boilers: 1 - hot water boiler; 2 - vacuum deaerator; 3 -

vapor cooler; 4 - ejector; 5 - tank of working water of the ejector; 6 - pump

working water; 7 - make-up pump; 8 - chemical heater

purified water; 9 - raw water pump; 10 - raw water heater; 11 - pump

network; 12 - recirculation pump.

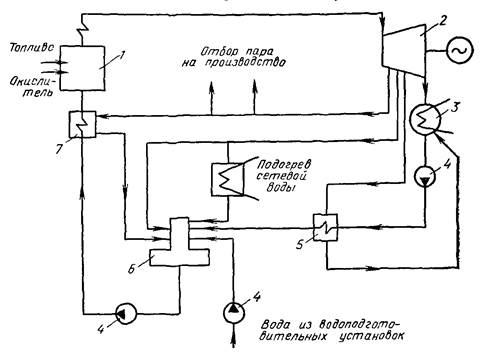

Rice. 1.2. Boiler plant in

industrial CHP system: 1 - steam boiler; 2 - steam turbine; 3 -

capacitor; 4 - pump; 5 - low water heater

pressure; 6 - atmospheric deaerator; 7 - water heater

high pressure.

The CU includes boiler units (boilers), and

also auxiliary mechanisms and devices.

Steam (hot water) boiler - a device in which to obtain steam (hot water)

required parameters uses the heat released during combustion

organic fuel or waste gases (Fig. 1.3).

Boilers that use the heat of waste from

other gas devices are called waste heat boilers.

boiler house

unit (KA) includes a furnace

device (combustion chamber), a pipe system with drums, a superheater, a water economizer, an air heater, as well as a frame with ladders and platforms for maintenance,

brickwork, gas ducts and fittings.

Rice. 1.3. circuit diagram

boiler unit (boiler): 1 - combustion chamber; 2 - evaporative

heating surfaces; 3 - steam heater; 4 – economizer; 5 -

air heater; 6 - brickwork; 7 - drum; 8 - superheated collector

pair; 9 – feed water collector; I - fuel; II1, II2 - saturated and

superheated steam; III1, III2 - feed and boiler water; IV1, IV2 - cold and

hot air; V - outgoing (flue) gases; VI - air suction through

brickwork leaks; VII - heat loss

On fig. 1.4 is given

schematic diagram of a boiler plant with a drum boiler

natural circulation on solid fuel.

Rice. 1.4. Scheme of a boiler plant with a drum boiler

natural circulation on solid fuel: 1 - coal conveyor; 2 - raw fuel bunker; 3 - coal feeder; 4 - mill; 5a, 5b —

supply of primary and secondary air; 6 -

lower collectors of combustion screens; 7 -

common hot air duct; eight -

burners; 9 - combustion chamber; 10 - downpipes; 11 - brickwork; 12 - pipes

furnace screens; 13 - top

combustor screen collectors; 14 -

drum; 15 - festoon; 16a, 16b - ceiling and convective superheater;

17 - feed water supply; 18 — economizer; 19 - air heater; twenty -

blower fan; 21 - ash catcher

(electrostatic precipitator); 22 - smoke exhauster; 23 - chimney; 24 - slag removal device; 25 -

frame columns; 26 - channels

hydrosol (slag) removal; 27 - intake

duct; I - feed water; II - superheated steam

Installation of internal gas pipelines for industrial boilers

The initial stage preceding the installation of the gas pipeline is the development of a project, its approval by the relevant supervisory organizations, registration with the regional gas services, and the appointment of technical supervision that controls the construction process.

An industrial gas boiler house is an energy facility of increased responsibility, therefore, at each stage of installation, strict control must be exercised over the equipment used, materials for quality and compliance with project documentation, standards, regulations and rules in force in the industry.All work performed is carefully monitored. One of the main requirements for the installation of an internal gas pipeline is strict adherence to the necessary tolerances for the distance from ceilings, supports, door and window openings, and existing equipment.

What requirements must be taken into account when installing an internal gas pipeline:

- Laying is carried out in an open way. Detachable assemblies are available for repair and inspection.

- Flange or threaded connection is acceptable in the installation segments of control devices, gas devices, fittings. The rest of the pipes are welded.

- Each faucet and valve has a 90° rotation limiter. Gate valves with a fixed stem are equipped with an opening degree indicator.

- Gas pipes do not run near aggressive media, hot metal surfaces, do not cross windows, doorways.

- Proper installation of the gas pipeline ensures its own removal of combustion products for all units.

- The slopes of the gas pipeline, the vertical position of the risers, the distances from the walls - in strict accordance with the design indicators.

Prior to the start of work, the fittings are tested and audited by the manufacturer.

Gas pipeline installation technology

After the registration of mandatory documents and marking, the construction of the gas pipeline begins.

- Devices are installed to which pipes will be connected.

- The device of supporting elements. The wider the pipe, the farther apart the brackets, hooks or fastening collars are located. The distance between them depends on the diameter of the pipes.

- The inside of the heat pipeline is checked, if necessary, cleaned of snow, ice, foreign objects. Laying before welding is carried out using centralizers on special gaskets.

- Connection of pipe blanks and factory assembly units. The system of turns and compensators levels out structural shifts under the influence of temperature changes.

- Connecting the gas pipeline to the equipment.

- Trial gas supply - leak test.

- Final connection.