Device and principle of operation

The device of the crane-valve, as well as the principle of its operation, depend on the type.

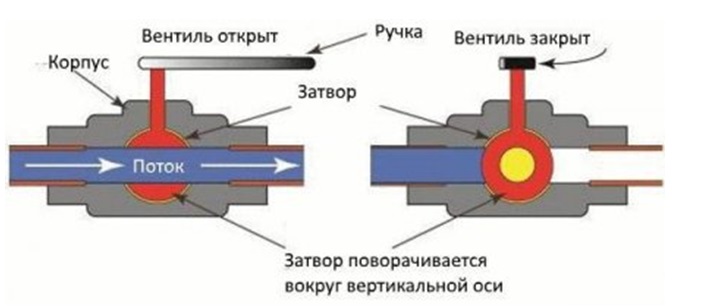

The device and principle of operation of the ball valve

How does a ball valve work? The main elements of the device are:

- valve body (1). The body can be made of materials such as brass, bronze, stainless or structural steel, silumin. The body can be integral, that is, manufactured by welding, or collapsible. The collapsible body has some advantage - if necessary, the valve can be repaired. If a ball valve with a one-piece body is installed, then if there are malfunctions, the device must be replaced;

Main elements of a ball valve

- locking element - ball (2). In most cases, the ball is made of brass, as this material is considered stronger and more durable. The ball has a through hole for liquid (gas);

- sealing rings (3) are installed between the locking element and the body, ensuring the tightness of the device. Gaskets can be made of Teflon, PTFE or rubber. Teflon seals are considered the most durable, which are practically not affected by temperature and chemical environment;

- the valve can be connected to the pipeline using nuts (couplings), flanges or welding (4).

In domestic pipelines, a coupling connection is most often used, and in industrial pipelines, a flange connection. Welded valves are rarely used today, as they require special equipment and certain skills during installation.

Flanged valve

- the locking ball is driven by a rod (5), which is connected to the control handle (6). Sealing elements are also installed between the stem and the handle;

- the handle is attached to the body with a nut (7).

The principle of operation of a ball valve is as follows. When the handle fixed on the body is turned, the locking element of the device - the ball - rotates. If the orifice of the ball is turned in the direction of the flow of the passing substance, then the valve will be opened. If the orifice is turned perpendicular to the flow, the valve will be in the closed position.

The principle of operation of the ball valve

The device of the ball valve, as well as the points that you need to pay attention to when buying a product, are discussed in detail in the video. https://www.youtube.com/embed/mMhsfT41gU8

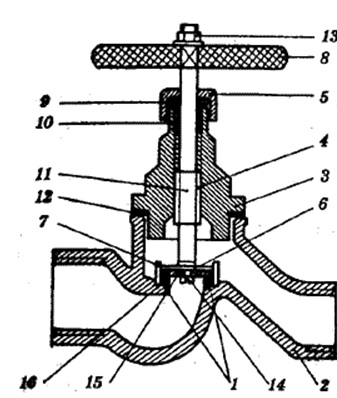

The device and principle of operation of the valve valve

Now let's figure out how a valve equipped with a valve works. The device consists of the following elements:

- the valve body (2), made of various materials, is equipped with a cover (3). A gasket (12) is installed between the body and the cover for tightness. As a rule, the gasket is made of durable rubber, but can be made of other materials;

The main operating elements of the valve with a valve locking element

- the body is equipped with a seat (1) for the valve (6), which is the locking mechanism of the device. For complete shutoff of the flow and sealing, the seat is supplemented with a sealing gasket (16);

- a seal (15) is also located on the lower part of the valve;

- the sleeve (7) and the spindle (11) are attached to the shut-off valve with the help of a nut (14);

- on the spindle body there is a thread (4), which serves to control the locking cone;

- the spindle is combined with a handwheel (8) that drives the valve. The flywheel is fixed on the body of the device with a nut (13);

- for hermetic connection of the flywheel and the valve body, an oil seal (10) is installed, fixed with a separate nut (5), supplemented with a sealing ring (9).

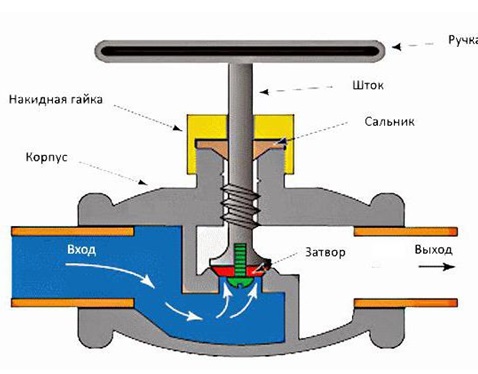

The device of the valve determines the principle of its operation.When the handwheel is rotated, the spindle moves up or down in translational movements, which lowers or raises the valve.

The principle of operation of the valve

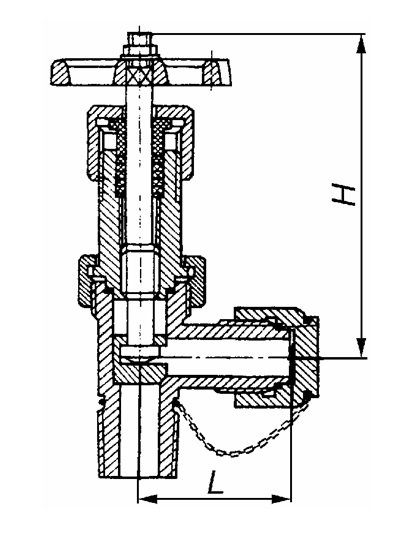

The valve valve can be a through passage (in the figures above) and an angle valve. An angle valve is recommended to be installed on the bend of the pipeline. The device and principle of operation of the angle valve practically do not differ from the passage device. The main difference is in the shape of the body and the location of the saddle.

Valve Type Angle Valve Device

Ball and valve valves have a different design and differ in the principle of operation. However, both types of products can be installed on domestic pipelines for various purposes.

Types of valves

There are the following types of valves:

- ball;

- valve.

The advantages of a ball valve are:

- simplicity of design;

- ease of use;

- durability of the device.

The only significant drawback of a ball valve for water or gas is the impossibility of using the device as a control valve. That is, the ball valve can only completely shut off the flow of the substance passing through the pipeline.

Shut-off valves for the pipeline

The valve valve is used as shut-off and control valves, that is, it serves both to shut off the flow of a substance and to restrict the passage of a liquid (gas). This factor is a significant advantage of the device compared to a ball valve.

The disadvantages of the valve valve are:

- short period of use. The shut-off valve is constantly in contact with the liquid, which leads to its natural wear;

- a more complex control system.

Shut-off and control valves for the pipeline

Both ball and valve valves can be installed on various types of pipelines.

Replacing a faucet with a riser shut-off

In order to understand how to properly replace a faucet under water pressure, you need to figure out how to do it under normal conditions - with the water pressure blocked. First you need to fix all the pipes on which the meters are installed. After that, it is worth blocking the riser.

The riser needs to be blocked, because it is often necessary to solder some pipes - sometimes for convenience, more often out of necessity. The clamp is needed in order to apply force in the opposite direction, if you need to unscrew the meter or the old tap.

To the basic rules and tips for replacing a faucet with my own hands, I would also add the sealing of all joints, which should not be forgotten.

Water valve replacement

To replace the valve in the water supply system of an apartment or other residential premises, it is necessary to shut off the water supply.

If a faucet is being replaced, which is part of the wiring in the apartment, for example, a toilet faucet or a washing machine, then you can turn off the faucet located on the riser.

How to turn off the water supply of the apartment

If it is necessary to replace the tap located on the riser, then it is necessary to shut off the water supply in the basement of the house. This will require the assistance of an employee of the management company or housing office.

Preparing for a replacement

At the first stage, you need to prepare:

new valve;

It is more expedient to select a new valve in full accordance with the old device. Parameters such as valve diameter, throughput, diameter and thread pitch must match.

two adjustable wrenches or wrenches

When selecting wrenches, it is important to choose their dimension correctly (in accordance with the dimensions of the fixing nuts);

sealing material. For water, FUM tape or Tangit Unilok thread is most often used.

Thread sealing tape

Replacement procedure

Replacing a valve on a riser or water supply distribution is carried out according to the following scheme:

- after shutting off the water supply, it is necessary to open all the taps in order to drain the remaining liquid from the pipes;

- the old valve is dismantled:

- if the valve is installed on a threaded connection, then with the help of keys it is necessary to loosen the fixing nuts;

- if a valve with a flange connection is installed, then to remove the device, it is necessary to loosen the bolts fixing the mounting flanges;

- if the valve is soldered into pipes, then when replacing, additional equipment will be required for cutting pipes, since it will not be possible to dismantle the valve in any other way;

Plastic Pipe Cutting Tool

- pipes at the valve installation site are cleaned of various types of contaminants;

- a new locking device is installed:

How to wrap sealant tape on threads

FUM tape or Tangit Unilok thread is wound clockwise. For sealing with tape, it is enough to apply 3 - 5 turns. For sealing, the entire thread is covered with a thread.

- if a flanged valve is mounted, then additional sealing is not required;

- the welded tap is installed using a special apparatus for soldering pipes;

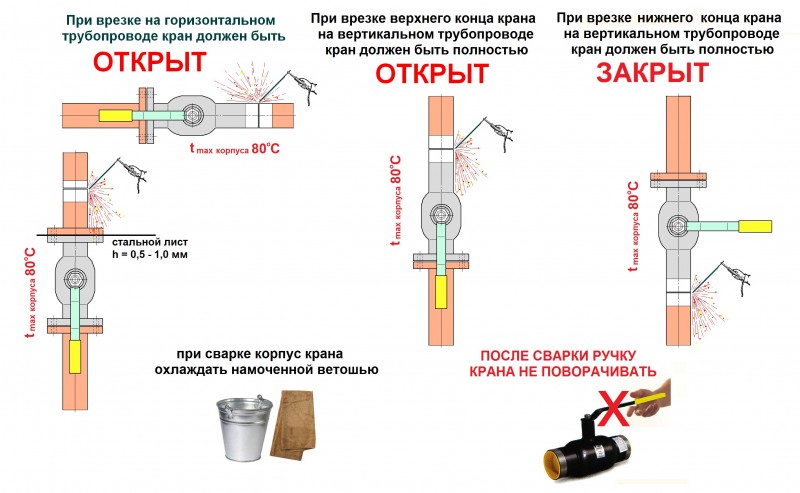

Valve installation by welding

- the tightness of the connections obtained is checked.

How to replace a tap installed on a thread, see the video.