Drywall constructions are very often used in apartment renovations. Many owners seek to save on the services of professionals and try to do the installation themselves. In order not to be disappointed in the end result, you need to know how to fix the drywall profile to the wall. After all, not only the appearance, but also the durability of the structure will depend on the quality of the frame.

Commonly used types of metal profiles

When attaching drywall to walls and ceilings, use the appropriate metal profiles:

- PS - rack;

- PN - guide profile;

- PP - ceiling;

- PPN - guide ceiling.

Guide profiles are attached directly to one of the surfaces of the room (floor, wall or ceiling) and do not have additional stiffeners. The rack and ceiling metal profiles have special sides, so they are more resistant to bending. These elements are inserted into the guides and fixed there most often with special screws.

Installation of a drywall profile may also require the use of corner or beacon profiles. But in the vast majority of GKL designs, they will not be needed.

For reliability, it is recommended to use a profile made of metal with a thickness of at least 0.55 mm.

The length of the products can be 3 or 4 meters. To get fewer trimmings when installing drywall profiles, you should carefully calculate the number and dimensions of individual frame elements, and only then go to the store.

Surface marking

An important and painstaking stage. The appearance of the entire structure will depend on the thoroughness of the markup. An incorrectly set metal profile may not be immediately noticeable, but it will definitely appear after the work is completed.

- On the surface of the wall, the most protruding point is searched. The distance from it to the inside of the drywall must be no less than the width of the metal profile used.

- A line is drawn on the floor, indicating the outer border of the guide profile.

- With the help of a plumb line, this line is transferred to the ceiling. Such marking is required when attaching drywall to the wall on the profile, since it is necessary to obtain a single plane.

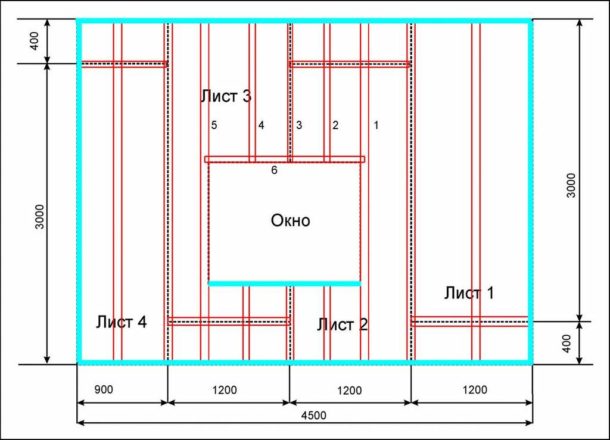

- Markings are made on the wall for the installation of rack profiles. The drywall sheet has a width of 1200 mm. Their docking must be carried out on the surface of the metal profile, so each sheet must be screwed to 3 or 4 racks. Accordingly, the step between the rack elements of the frame should be 40 or 60 cm. In most cases, preference is given to the option with three profiles per sheet: two along the edges and one in the middle.

- On the lines marking the center of the vertical rack profiles, every 60 cm, mark the installation sites for direct suspensions.

- Places are marked for horizontal jumpers and suspensions for their fastening.

Mounting the profile to the wall

The rooms in the apartment, and, accordingly, the walls can be different: they differ in size, surface curvature or the presence of windows. In each case, there will be a different algorithm for fixing drywall, but the general rules will remain unchanged. Consider the simplest option - leveling a wall without windows.

Do-it-yourself installation of a profile for drywall begins with the installation of guides on the floor and ceiling. Before that, on the surface of the metal profile adjacent to the floor or ceiling, glued sealing tape. The algorithm for further actions is as follows:

- You can fix the bottom rail on a wooden floor using self-tapping screws.Holes are drilled in the ceiling or concrete floor surface with a perforator and the guides are attached to the dowel-nails. Usually, the profiles already have ready-made holes, but they can be made independently in increments of 25–30 cm.

- With the help of dowel-nails, direct suspensions are attached. Their "wings" are bent in the form of the letter "P". With their help, in the future we will expose vertical racks.

- Vertical profiles are inserted into guides.

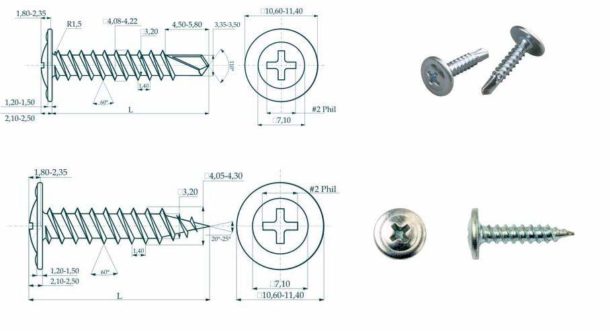

It is better to connect the elements of the crate using cutter: the heads of small self-tapping screws for metal (they are also called "fleas", "bugs" or "seeds") can interfere with the tight fit of the GKL to the frame.

- "Beds" of the rack are attached to the suspensions.

In order to set all the racks in the same plane, they do this: they install two extreme profiles, controlling their deviation with a level or plumb line. Then 3-4 nylon threads are pulled between them. They carry out the installation of the remaining racks.

- The hangers have a number of holes for self-tapping screws, with which it is easy to achieve the required position of the metal profile. After that, the "wings" of the suspensions are gently bent to the sides so that they do not interfere with the further installation of the GKL.

- In places of horizontal joints, transverse crossbars are made. They are attached to suspensions, and for connection with vertical posts, the side walls are cut off at a distance of 5 cm at the profile. Another option is to use a single-level crab connector.

- After mounting the frame, you should once again check whether all the elements are in the same plane. It is much easier to correct flaws at this stage than after fixing the drywall.

Helpful Hints

And a few more recommendations:

- After the markup is completed, communications should be dealt with, which will later be hidden under drywall. The first is electrical wiring. The applied markings will help to lay it so as not to damage it during the installation of the frame. But laying it after installing the profiles can be inconvenient.

- It will be useful to draw up and save a plan for the location of profiles with dimensions. After fixing the drywall and its high-quality putty, the joints of the sheets will no longer be visible. Especially if there is some kind of finishing coating on top of the GKL, such as wallpaper. It is not worth relying on your memory or on the marks on the wall: who knows when there will be a desire to fix a lamp, a mirror or a shelf on the wall? By this time, the marks will definitely be eliminated, and getting into the profile, wanting to mount, for example, on a butterfly dowel, will be very unpleasant.

- If the profile is not long enough, it can be increased. You can connect products "overlap" or "butt". In the second case, an additional piece of the profile is used, or the end of the guide plays its role. The junction is fixed on the sides with self-tapping screws, which will not interfere with the tight fit of the drywall sheet to the frame.