Drywall is widely used in the renovation of apartments. With its help, walls and ceilings are leveled, niches and boxes are constructed, doorways are modernized, and many decor elements are performed. There are certain rules for the installation of these structures that must be observed. Leading drywall manufacturers have developed entire kits for the convenience of consumers. The Knauf technology has gained particular popularity in our country.

Benefits of Using Technology

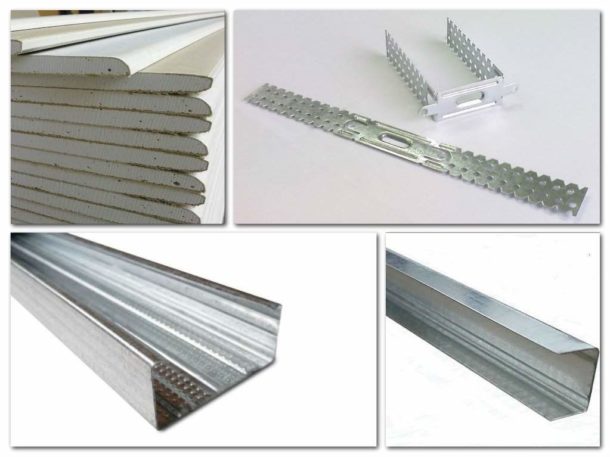

Knauf produces a whole line of ready-made kits that differ depending on the type and size of the structure.

The main advantage of the Knauf kits: they include everything you need to mount a wall or partition, from drywall to fasteners. This provides the consumer with several benefits, including:

- Guaranteed to use only high quality materials. This is facilitated by a strict system of company control, designed for minimum tolerances in the manufacture of plasterboards and other elements.

- Ease of calculating the consumption of drywall and other parts of the structure. A simple online calculator available on many sites is enough. You need to enter the dimensions of your wall or partition into it, indicating the number of doors and windows, and it will give a complete list of all the necessary elements, indicating their number.

- The manufacturer provides each kit with detailed assembly instructions, so that even an unprepared person can carry it out.

- Buying materials separately, you can forget some details. Using the kit solves this problem.

The procedure for installing Knauf kits

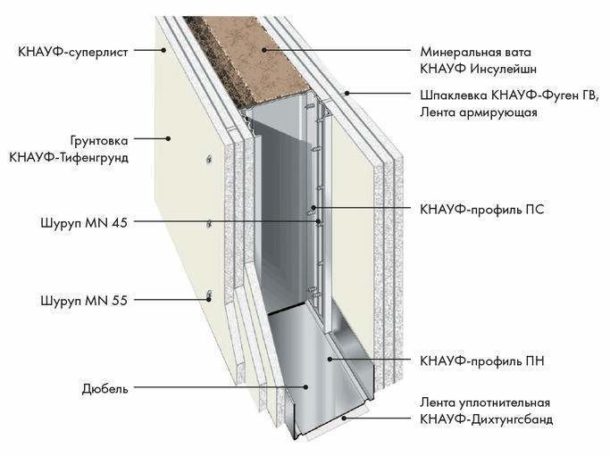

Mandatory preparatory work: alignment and marking. After that, a partition is placed:

- Guide profiles are attached to the dowels.

- Vertical racks are installed at selected optimal intervals. Their fixation is recommended to be done using a cutter with a bend.

- Horizontal jumpers are mounted.

- If necessary, communications are stretched, insulation is laid.

- GKL frame is sheathed with special proprietary self-tapping screws.

- Carry out finishing processing of corners and joints of sheets.

Mounting Features

The system for assembling walls and partitions using this technology has its own nuances that must be taken into account in order to achieve the optimal result:

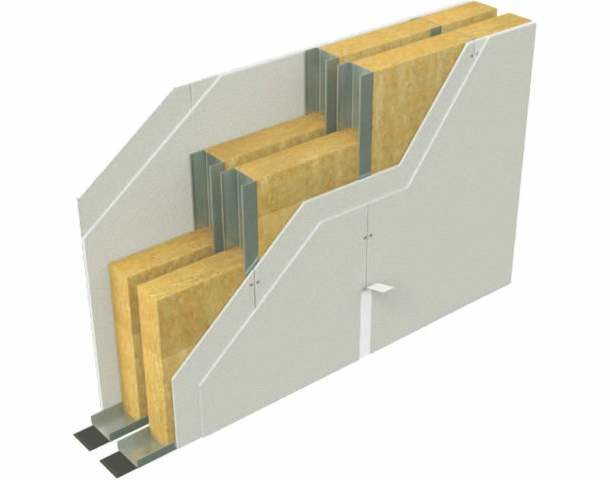

- To ensure high strength, individual frame elements are reinforced by nesting one profile into another.

- The guides are attached to the dowels at least three points. The plane of the profile adjacent to the base is preliminarily pasted over with a damper tape.

- Often it is necessary to join insufficiently long elements of a metal structure. In this case, you should space out the junctions, for example, place them in a checkerboard pattern. This will reduce the likelihood of vibrations or various deformations of the structure.

- Racks are placed at a distance of 600 mm from each other. Thus, each sheet will be fixed on three profiles. If necessary, the step between the racks can be reduced.

- The profiles are fastened together with a cutter or branded self-tapping screws. Crab connectors are used at intersections.

- GKL sheathing elements are fastened end-to-end with the necessary gaps to compensate for the thermal expansion of the material. In the future, they are filled with a special compound produced by the same Knauf company.

- When building partitions from gypsum boards with window niches or doorways, it is forbidden to join sheets above them. Otherwise, there is a risk of seams coming apart due to vibrations that occur when using windows and doors. Docking of elements is carried out closer to the corners of the room.

Types of structures provided by Knauf

The sets differ from each other in the number of skins, thickness and frame design. All partitions use branded insulation based on mineral wool. There are the following kits:

- C 111 - with one layer of sheathing. The minimum thickness and instability to loads do not allow such a design to replace a full-fledged wall, its function is decorative and zoning.

- C 112 - sheathing in two layers on each side on a single frame.

- Sets C 121 and C 122 are similar to the two described above. The difference is that instead of profiles, they use wooden beams for battens.

- C 115 - a set with a double frame, lined with two layers of drywall. This allows, by increasing the thickness of the partition, to place a double layer of mineral wool in it. According to its characteristics, this design is close to a conventional wall.

- C 116 - also performed on a double spaced frame. The internal cavities remaining inside it allow for hidden installation of communications. The two-layer sheathing removed from the wall is implemented in the C 626 kit.

- C 113 or C 367 - sets with triple skin. Designed for those cases when it is necessary to use drywall of different types: moisture resistant, fireproof and ordinary in many combinations.

- C 118 - used for extra strong walls and partitions. In it, sheets of galvanized steel 0.5 mm thick are laid between the layers of drywall.

- C 361, C 362, C 363 - sets on a single frame, sheathed, respectively, in 1, 2 or 3 layers of Knauf gypsum fiber super sheets. C 365–369 - modifications of partitions with gypsum fiber on different frames.

- C 386.1 and C386.2 - kits that provide for the laying of ventilation or other communication channels.

Various combinations of frames and skins are possible. All of them are presented in the Knauf product line.

A single frame is used when it is not planned to hang anything heavy on the wall, and also if significant insulation or soundproofing is not required. But in order to attach household appliances that have a solid weight to the wall, you will have to make a double frame with reinforcement.

Features of the formation of corners from drywall

Corners play an important role in the installation of drywall construction. If they are assembled incorrectly, then after a short time cracks will appear in these places, and the fastening of the sheets will be unreliable.

GKL structures can have both internal and external corners. For the formation of each of them, their own methods are used. First of all, the frame is assembled.

External corners are made as follows:

- Two vertical posts forming a rib are installed in the rails so as to form a single angle. It is unacceptable to mount them with an offset: in this case, there will be a void under the junction of the drywall sheets.

- The racks are fixed in the guides with a pair of self-tapping screws at each attachment point. Professionals prefer to use a cutter: such a connection does not contain bulges that interfere with the tight fit of the GKL.

- Fragments of plasterboard sheathing are screwed end-to-end, so that the plane of one element overlaps the end of the other, and are reinforced with a special corner profile. You can fix it with putty or PVA glue.

Curvilinear ribs are reinforced with a flexible plastic corner.

Internal corners are formed a little differently:

- At the initial stage, an angle is made from the profile, twisting two racks so that the side back of one is attached to half of the back of the other. In this case, self-tapping screws LB19 mm or similar are used. Fastening is carried out every 25–30 cm.

- This design is inserted into the guides on the floor and ceiling and fixed with metal screws.

- Before installing drywall, chamfers are made with a slope of 45˚, they will facilitate the puttying of the corner.

- Internally, the rib is glued with a reinforcing mesh and puttied. After drying, it is treated with a primer for drywall.

The Knauf company recommends using a slightly different scheme in its designs:

- First, a GKL fragment is mounted, forming one of the sides of the corner.

- A vertical guide profile is attached to it directly through the drywall with a self-tapping screw.

- The necessary horizontal jumpers are fixed in it, after which the drywall is screwed.

The result is a T-shaped connection of sheets. Further processing of the inner corner is carried out similarly.

If the design uses several layers of drywall, then they are offset. In this case, it is important to place the fastener points correctly.

Kits for the construction of walls and partitions from the company "Knauf" are deservedly popular in the market. Ease of assembly and high quality material will ensure the achievement of the desired result.