Types of expansion tanks

The location of the tank is determined by the type of heating system itself. She may be:

It looks like a closed expansion tank in an already installed heating system.

Important! An open-type heating system is used very rarely today. In everyday life, they are used only in old buildings.

The expansion tank in open heating systems is made in the form of a container, the top of which does not close. Its connection to the heating system is carried out using a threaded connection located at the bottom of the tank.

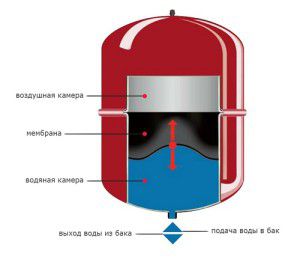

The installation and operation of a closed-type expansion tank in a heating system also has its own characteristics. The design of the closed type tank is made in the form of a hermetically sealed capsule, which is divided into two parts using a rubber membrane.

Technical advice

membrane tank installations

Before you start connecting the accumulator to the water supply system, you should:

- Carefully study the instructions supplied with the equipment.

- Carry out technical calculations of pressure and compare with those indicated in the regulatory manual for operation.

- In order to carry out the installation with high quality, you need a wrench for detachable connections and plastic pipes, a wrench of the right size.

- Special brackets will be needed to mount large volume equipment.

Note! Measurements and calculations of the operated equipment should be carried out by a highly qualified specialist. The quality of the water supply system depends on the accuracy of the calculations and measurements performed.

Many years of experience in using membrane tanks for water supply has shown that horizontal models are the best option. If you have a submersible pump connected, purchase and install vertical accumulators.

Purpose and features of membrane tanks for heating

Membrane tank design

First you need to know the functional qualities of this device. When water is heated in pipes, natural expansion and pressure increase occur. If the value exceeds the normalized value, a stabilization mechanism is needed. This is what membrane tanks for heating systems are designed for, which may differ in technical and design characteristics.

They are a sealed container, divided into 2 areas - water and air chambers. Between them is an elastic membrane. An appropriate branch pipe is provided for connecting the water supply, and a pressure injection system is located in the air chamber. The principle of operation of the expansion membrane tank for the heating system is to increase the usable volume as a result of the displacement of the elastic membrane towards the air chamber. To do this, it is necessary to connect the water pipe to the heating pipe, and create a pressure in the air chamber, the value of which should not exceed the nominal value for the heating system.

Installing a membrane tank in a heating system has the following advantages:

- Automatic stabilization of the critical expansion of the coolant;

- No water loss due to evaporation;

- Possibility of installation both for system with distilled water, and with antifreeze;

- Simple installation and replacement of the membrane when its service life is exceeded.

But how to choose the right membrane tank for heating, the principle of operation of which is so simple? To do this, you first need to familiarize yourself with its varieties.

The membrane tank for heating according to the principle of operation is similar to that for the water supply system. But the design of the latter is not designed for high temperatures.Manufacturers mark them in blue, and heating ones in red.

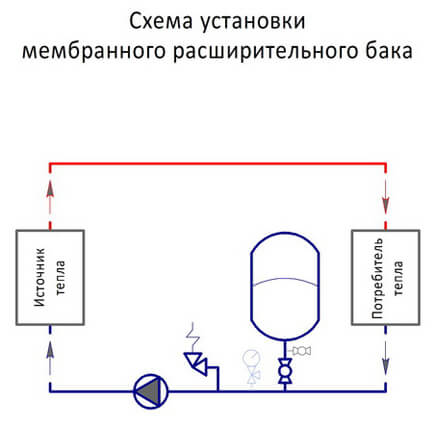

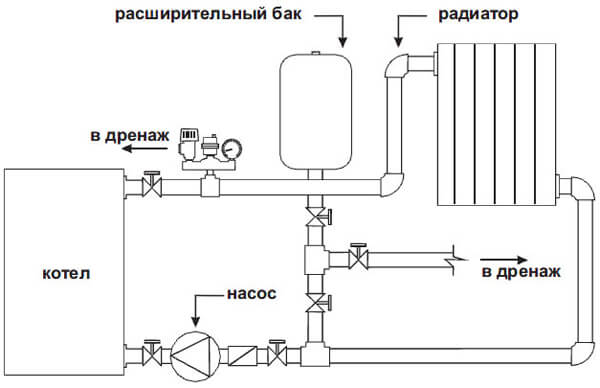

Installation of membrane expansion tanks

Before installing an expansion membrane tank, you must read the instructions that came with the device, which are included in the technical documentation. Initially, it is supplied with an overpressure of gas, which completely fills its entire volume. Before installation, the tank is pumped under a pre-calculated pressure.

A safety valve must be installed. As a rule, the connection diagram of the membrane expansion tank provides that drainage is equipped in front of the device. The installation should be carried out by a specialist, in extreme cases, his consultation is needed.

When installing, there are a few things to consider:

It is imperative that the expansion membrane tank for water supply or heating must be grounded to avoid electrolytic corrosion. A check valve is installed at the inlet to the device when it is not provided for in the design of the circulation pump. At the outlet, a pressure gauge and an autovalve for air release are mounted.

Types of membrane tanks

Expansion tank with non-removable membrane

At first glance, the design of the device is quite simple. However, for different heating systems with specific technical characteristics, the correct model of the membrane expansion tank for heating should be selected. Consider the most popular models that can be installed in both domestic and industrial systems.

Fixed tank

Their feature is that the membrane tank for heating is not collapsible according to the instructions. those. the elastic membrane cannot be dismantled and replaced with a new one. Despite this seemingly disadvantage, these models have one significant advantage - affordable cost. That is why they are installed for small heating systems with relatively stable pressure in the pipes. Often, the calculation of a membrane tank for heating implies a constant pressure indicator in the air chamber, which the manufacturer specifies additionally. But if there is a possibility of exceeding the critical expansion rate of the coolant, it is necessary to install another type of structure.

Flanged with replaceable diaphragm

Expansion tank with replaceable membrane

To install a new membrane, the design provides a flange on which it is mounted. Thus, it is possible to regulate the volume of the membrane heating tank, install elastic lotions with different elasticity indicators. Similar models are mounted for heating systems with a high probability of excess pressure in the pipes. First of all, this applies to solid fuel boilers, where it is impossible to quickly adjust the level of water heating. Tanks can be made of horizontal and vertical type. To replace the membrane, it is necessary to remove the flange, dismantle the old one and install a new one in its place. The most popular manufacturer of such models is Wester, a membrane heating tank, which can be found both in a small private house and in the heating system of a production workshop.

The usable volume of a membrane heating tank depends on its shape. For large systems, it is best to choose cylindrical structures, and flat models will be optimal for heating with a small length of pipes.

Expander operation

Maintaining a membrane-type expansion tank in working condition includes:

- regular visual inspection for corrosion;

- checking the integrity of the membrane;

- air (gas) pressure check.

Maintenance of open type tanks provides for an external inspection of the condition of the body and thermal insulation, as well as checking the liquid level, which should not fall below the minimum mark.

Expansion tank on the bracket.

The correct choice and installation of an expansion tank in the heating system is one of the components of a reliable, uninterrupted and safe operation of the entire heating system of a residential building. Today, a closed-type expansion tank with a diaphragm-diaphragm is more often installed, combining an affordable price and a high level of ease of use.

Interior solution: decorative grilles for heating radiators

Optimal thermal insulation for heating pipes

Independent insulation of heating pipes on the street

Design features

The purpose of the membrane expansion tank is that at all operating stages the device must maintain a balance between the pressure of both parts and, if necessary, level out excessive pressure or regulate its differences in the heating structure. Thus, the installation of a membrane expansion tank prevents the occurrence of increased loads in the heating circuit and in emergency situations in the event of a malfunction.

The device comes with a replaceable or non-replaceable membrane. In the first case, the coolant is completely in the capacity of the flexible membrane and cannot interact with the steel inner surface. All work related to the dismantling and subsequent installation of a new product is carried out through a bolted flange.

If you purchased a device with a fixed iris, it has a two-part internal cavity. In this case, a non-replaceable diaphragm membrane is used, which is rigidly fixed. A membrane tank for a heating system is selected directly for a specific heating structure, taking into account the amount of coolant. If the volume of the device turns out to be insufficient, then the consequences can be the most negative - cracks often appear and water can leak through the thread. In addition, often in the system the pressure drops below the permissible norm, as a result of which air enters the tank. Therefore, the choice of device must comply with the necessary design parameters (in more detail: “We make the selection of an expansion tank for heating“).

An expansion membrane tank for heating systems is used when creating a circulation of a closed-type coolant in order to compensate for its thermal expansion as a result of an increase or decrease in the temperature of the liquid, thereby preventing water hammer. In constant mode, both chambers of the device - water and gas - have the same pressure, which allows maintaining the tightness of the system. Such a device for an expansion tank of the heating system has been time-tested and recognized as the most practical.

The water circulating along the circuit does not contain aggressive gases and therefore corrosion will not render the tank unusable, which allows it to be operated for a long time. The pressure expansion device is placed in the boiler room, and for this reason there is no need to protect it from freezing.

Despite the fact that the selection of a tank for a heating structure is individual, one should not forget that:

- the initial pressure in the membrane tank for heat supply, connected to cold water supply, must exceed the static pressure in the system by 30-50 kPa;

- the device must have a spare amount of coolant to compensate for possible leaks.

To protect the system with a closed circuit and an expansion tank from too high pressure, safety valves are installed.

Popular tank manufacturers

1. Wester heating tanks are recognized as one of the best in Russia for home use. The domestic manufacturer produces vertical and horizontal models based on volume from 8 to 500 liters. Their rubber is made of a particularly durable heat-resistant material that can withstand heating up to 100 ° C.Plus, the expansion tank is equipped with a replaceable membrane, which increases the service life.

The body is made of durable steel. The heaviest barrels are equipped with supports. The warranty covers 3 years. The price of Wester WRV 80, the most popular model, is about 2,500 rubles.

2. The next interesting brand is Reflex from a German manufacturer. Differs in the high durability and long term of operation - till 12 years. The Reflex expansion tank for heating of any model is made according to the famous technology of the Krupp dynasty, famous for high-quality steel.

Volumes are very different: from 8 to 1,000 liters. The tank is equipped with a replaceable membrane designed for temperatures up to 70 °C. The cost of this line is from 1,520 rubles.

3. Very often found in the sale of a series of Chinese manufacturer Zilmet CAL-PRO. The market offers tanks with a capacity of 4 to 900 liters. Their body, made of carbon steel, is either ringed or welded together. The membrane is made of synthetic rubber. The device can operate at temperatures from -10 to 100 °C.

The cost of a membrane expansion tank of the CAL-PRO series for heating starts from 1,170.

How to choose for home

When heated to 70-90 ° C, all water increases in volume by 4-5%. Without a buffer, it creates high pressure in the pipes, which can cause them to burst. Therefore, the correct choice of a membrane tank for a heating system is very important. It should be done on the basis that the expander should take on all the excess volume of liquid. Therefore, before buying, it is necessary to correctly calculate this amount, and it is even better to consult with the designers.

It is also desirable to ensure that the tank is made of high quality materials, otherwise it simply will not withstand the loads.

Very often, inexperienced or unscrupulous sales assistants try to sell customers devices intended for water supply instead of the required ones, believing that there is practically no difference between them, except perhaps in color (blue and red). In fact, hydraulic accumulators are used in heating systems, except perhaps through an oversight. In this case, since their rubber is not designed to withstand heat, they quickly fail.

Brief instructions for DIY installation

- First you need to decide on the location of the device. According to the instructions, the expansion tank can be installed anywhere in the heating system, but in order to avoid sudden pressure surges, it is better to place it immediately after the circulation pump.

- It is necessary to place the device so that there is access to the air valve, drain cock, shutoff valves and other important details.

- During installation, the room must be at least 0 °C. The safety valve must be installed in the direction of the flow.

- There is nothing complicated in the installation itself, you just need to follow the instructions and use the proper tools, in particular the wrench for metal-plastic pipes and connectors. The nozzle must match the pipeline.

- Tanks with a large capacity must be mounted on additional brackets. To do this, first mark the place, then drill a hole and attach the hangers with anchor bolts.

- After the equipment is fixed, a pipe is brought to it so that it does not interfere and does not put pressure on the tank.

- Then a pressure reducer is mounted, it must be installed after the meter.

- If everything is done correctly, you can start setting up - pump in air and water, observing the pressure. When it is balanced, you can start turning on the heating.

- It is better to entrust the installation of a tank in a multi-boiler system to specialists who have been tested and received the appropriate license.

Moscow prices

You can buy a membrane expansion tank at the estimated cost indicated in the table.

| Brand | Cost, rubles | |||||||||||

| Volume, l | 8 | 12 | 18 | 24 | 35 | 50 | 80 | 100 | 150 | 200 | 300 | 500 |

| Wester | 790 | 860 | 900 | 1 000 | 1 650 | 1 900 | 2 500 | 3 500 | 5 200 | 9 500 | 11 500 | 18 100 |

| Volume, l | 8 | 12 | 18 | 25 | 33 | 60 | 80 | 100 | 140 | 200 | 300 | 500 |

| reflex | 1 520 | 1 600 | 1 980 | 2 300 | 3 070 | 4 900 | 5 900 | 6 700 | 9 060 | 10 860 | 15 000 | 23 000 |

| Volume, l | 8 | 12 | 18 | 25 | 35 | 50 | 80 | 105 | 150 | 200 | 250 | 500 |

| Zilmet CAL-PRO | 1 170 | 1 230 | 1 300 | 1 630 | 2 100 | 3 100 | 4 200 | 6 100 | 7 600 | 9 480 | 12 200 | 22 200 |

What is the function of an expansion tank in water supply

A membrane tank for water supply is a multifunctional device; not a single autonomous system, with the exception of those using expensive frequency-controlled submersible electric pumps, can do without its use. To answer the question of why a tank is needed in the system, one should consider its structural design and principle of operation.

All membrane tanks consist of two main parts, including a metal tank and an internal elastic membrane with an inlet fitting pressed into the housing cover. During the operation of the electric pump on closed taps, water enters the inner elastic shell and it is stretched (expanded), at a certain moment the water supply stops and the hydraulic tank remains in a filled state.

When the taps are opened, water from the accumulator enters the system at a certain pressure by compressing the elastic membrane until the pump restarts, which again pumps water to fill the tank. The process of turning on and off the electric pump is controlled by a pressure switch; to adjust it to the operating thresholds, a pressure gauge built into the system is used.

Rice. 2 Structural arrangement of the horizontal tank

Expansion tank for water supply as a hydraulic accumulator

From the principle of operation of a hydraulic tank, it is clear that it accumulates (accumulates) a certain amount of water in its internal elastic balloon or part of the body. Due to this, the required pressure is maintained in the system for a certain time, and a certain supply of water is also created, which is useful in emergency situations with a short-term power outage, damage to the water supply system, and failure of the electric pump.

Some homeowners install large volume hydraulic tanks inside the house - this allows you to make significant reserves of water resources.

Hydraulic tank to stabilize the pressure in the system

Since the tank filled with water gives off water resources for a long time, depending on its volume and consumption, even pressure in the water supply system is maintained for a long period of time. In the absence of a storage tank, the pipeline would be freed from water resources faster - this would cause a rapid drop in pressure in the system and frequent switching on of the electric pump.

Rice. 3 The principle of operation of the accumulator

Expansion tank for water hammer protection

Protection against water hammer is one of the answers to the question of why a hydraulic tank is needed. The principle of compensating them for water hammer in the system is as follows: when the electric pump is turned off and on, there is an abrupt stop or movement of water flows. At the same time, due to inertia, water has a physical effect on the pipeline shell, shut-off and control valves, transferring its kinetic energy to them. The nodes and parts of the plumbing system begin to shift, as a result of which the threaded and compression joints, pipeline fasteners loosen, and automation malfunctions.

An elastic storage tank for a water supply system in the form of a shell inside a hydraulic tank, when the water flow moves and stops, it expands or contracts first of all - this helps prevent physical impact on other water supply units.

Hydraulic accumulator to increase the service life of pumping equipment

The principle of operation of the automatic switching on and off of the electric pump consists in the reaction of the relay to the filling of the hydraulic tank with water - as soon as the inner rubber shell begins to stretch and resist the pressure of water masses, at a certain moment the pressure switch is activated and turns off the electric pump. It is clear that the longer the inner shell of the hydraulic tank is filled with water, the longer the pump is in the on state.

Similarly, during water intake, water leaves the tank more slowly and, accordingly, the relay to turn on the electric pump is activated after a significant period of time.

Rice. 4 Hydraulic tanks for heating systems - popular brands

Expansion tank functions

What is the purpose of the expansion tank? The heating system is filled with a fixed amount of fluid (water or antifreeze) that is prone to thermal expansion. This means that an increase in the temperature of the coolant inevitably leads to an increase in pressure in the system. Since pipes, radiators and other elements of an engineering structure are inelastic, increased pressure will lead to depressurization of the system - a breakthrough will occur at the weakest point.

Water is characterized by low compressibility, so a special device is built into the system - a membrane or open tank. Its function is that when the pressure rises, air will be compressed. This makes it possible to provide protection against water hammer. The installed expansion tank protects the system from excessive pressure increase.

Membrane tanks are designed for a closed-type heating system - they are a container with an elastic waterproof membrane inside, which divides the internal volume into two parts. The membrane is needed so that air does not come into contact with the coolant. Otherwise, airing the network and increasing the risk of corrosion of the steel elements of the system cannot be avoided.

In an open type system, the tank communicates with the atmosphere, due to which air is bled from the pipes. For this reason, the installation location of an open tank is strictly regulated - it must be located at the highest point in the system.

Choosing a membrane tank

In heating systems, the membrane load, as well as the expansion of water, does not change very significantly, but the temperature of the heating liquid can be approximately 90 ° C.

When choosing an expansion membrane tank, special attention should be paid to the material from which the membrane is made. The material must be of high quality, reliable and resistant to high temperatures and extremes.

You should also pay attention to the following characteristics of the membrane:

- Operating temperature range;

- long service life;

- sanitary and hygienic requirements;

- resistance to high temperatures;

- dynamism.

Advice. When choosing an expansion membrane tank, it is necessary to select tanks with a durable and reliable body so that it lasts longer.

Benefits of closed tanks

Important! The power of the boiler and the volume of liquid used affect the volume of the tank, the installation of which is carried out when creating a heating system in country houses. Unlike open tanks, closed tanks have a lot of advantages:

Unlike open tanks, closed tanks have a lot of advantages:

Two types of closed expansion tanks.

- high reliability, safety and efficiency;

- no need to add coolant to the heating system;

- eliminating the likelihood of air pockets due to the lack of pressure at the top of the system;

- the ability to install anywhere in the house;

- no possibility of water pouring out of the tank, which allows you to no longer worry about damaging the finishes of walls and floors;

- lack of contact of the coolant with air, due to which the evaporation of the coolant is completely excluded. Due to this, radiators and pipelines are not subject to oxidation, which means that the service life of such a heating system will be much longer.

Expansion tank for water supply in various systems wiring diagrams

In addition to working as equipment for an autonomous water supply system, a membrane expansion tank for water supply is often used for other purposes, installing it in heating, drainage and water supply systems of various engineering designs. At the same time, the main selection criteria are the temperature characteristics of the inner shell, the volume of the tank and the method of its placement on the surface.

Rice. 11 Hydraulic tank with indirect heating boiler - diagram and placement example

Boiler piping for indirect heating

An indirect heating boiler is designed to create hot water supplies in the house; structurally, it is made in the form of a metal insulated tank for collecting water, inside of which there is a heating pipeline. Incoming cold water into the boiler it is heated by pipes through which the heat carrier of the heating system circulates - thus the installation does not consume electricity, and the consumer always has a supply of hot water. Also, the loop connection of the broiler pipeline with recirculation does not allow the water in the pipes to cool.

It is well known that when heated, water expands and in a closed broiler, pressure increases because of this. To compensate, a vertically installed expansion tank for water supply systems is connected to it, the shell of which takes on the increased air pressure.

Rice. 12 Vertical expansion tanks for water accumulation in iron removal systems

Water supply

To ensure autonomous water supply, it is not at all necessary to install submersible or surface electric pumps in water sources and produce continuous water intake. An alternative method is a short-term collection of water and storage of its reserves in a storage tank. To implement it, a storage tank is installed in the attic of the house, filled with water from any source using an electric pump, providing for breaking the power supply circuit with a float switch installed on the wall of the storage tank.

The disadvantage of collecting liquid in a storage tank is the inconvenience of placing it in the attic, as well as low pressure without a membrane at a low location height (1 bar per 10 meters of vertical water column), which is not always sufficient for comfortable water consumption.

An alternative to this option is the use of a large capacity storage tank. It can be placed anywhere in the house and even in the basement, and the element that controls the electric pump is a pressure switch. In this case, the selected hydraulic tank will provide a significantly higher water pressure in the internal water supply compared to the storage tank in the attic.

Its second important advantage is being at the bottom, thanks to which the connected pipeline will not spoil the design and aesthetic appearance of the house, unlike a storage tank, to which you will have to draw a line along the top

Rice. 13 Scheme of mounting a hydraulic accumulator in a system with a borehole pump

Water intake from a well

The technology for connecting a hydraulic accumulator to an autonomous water supply line with water supply from a well was discussed above, in this case the accumulator is usually used as part of a pumping station or placed separately, next to the well pump. The tank can also be located in the house, much less often it is placed on the surface in a separate extension.

Taking water from a tank

Water intake is not always carried out for domestic needs and drinking, often water is needed on the farm for irrigating gardens, car washes, filling pools or man-made ponds. In this case, its purity does not play a big role, and it can be taken from various types of sources or containers - lakes, ponds, roofs, barrels for collecting rainfall. The use of surface pumps in this case requires constant supervision, therefore it is rational to use automatically disconnected pumping stations for the catchment, which necessarily include a horizontal hydraulic tank. The device will prevent unwanted hydraulic shocks and ensure the operation of the shutdown automation from the pressure switch, if it is not suitable, it is disconnected from the power supply, replaced with a dry-running relay, or an adapter with a flow switch is installed at the inlet of the pressure pipe.

Rice. 14 Schemes of pumping stations for the home

Design features

The purpose of the membrane expansion tank is that at all operating stages the device must maintain a balance between the pressure of both parts and, if necessary, level out excessive pressure or regulate its differences in the heating structure. Thus, the installation of a membrane expansion tank prevents the occurrence of increased loads in the heating circuit and in emergency situations in the event of a malfunction.

The device comes with a replaceable or non-replaceable membrane. In the first case, the coolant is completely in the capacity of the flexible membrane and cannot interact with the steel inner surface. All work related to the dismantling and subsequent installation of a new product is carried out through a bolted flange.

If you purchased a device with a fixed iris, it has a two-part internal cavity. In this case, a non-replaceable diaphragm membrane is used, which is rigidly fixed. A membrane tank for a heating system is selected directly for a specific heating structure, taking into account the amount of coolant. If the volume of the device turns out to be insufficient, then the consequences can be the most negative - cracks often appear and water can leak through the thread. In addition, often in the system the pressure drops below the permissible norm, as a result of which air enters the tank. Therefore, the choice of device must comply with the necessary design parameters (in more detail: “We make the selection of an expansion tank for heating“).

An expansion membrane tank for heating systems is used when creating a circulation of a closed-type coolant in order to compensate for its thermal expansion as a result of an increase or decrease in the temperature of the liquid, thereby preventing water hammer. In constant mode, both chambers of the device - water and gas - have the same pressure, which allows maintaining the tightness of the system. Such a device for an expansion tank of the heating system has been time-tested and recognized as the most practical.

The water circulating along the circuit does not contain aggressive gases and therefore corrosion will not render the tank unusable, which allows it to be operated for a long time. The pressure expansion device is placed in the boiler room, and for this reason there is no need to protect it from freezing.

Despite the fact that the selection of a tank for a heating structure is individual, one should not forget that:

- the initial pressure in the membrane tank for heat supply, connected to cold water supply, must exceed the static pressure in the system by 30-50 kPa;

- the device must have a spare amount of coolant to compensate for possible leaks.

To protect the system with a closed circuit and an expansion tank from too high pressure, safety valves are installed.

Scope of the membrane tank

The use of an expansion tank is possible not only in the heating system, but also in water supply and water treatment. In this case, hydraulic accumulators, which are water tanks, are used as an accumulation of liquid in order to supply it under the required pressure at a certain moment. Hydraulic tanks are often used in the construction of industrial and agricultural water supply systems.

Expansion tanks can also be used to prevent complete destruction of the system in the event of water hammer. In addition, they are indispensable when used as a container with water in the fire extinguishing system, as well as in the form of reserve tanks in the event of a power outage.

Design features

The purpose of the membrane expansion tank is that at all operating stages the device must maintain a balance between the pressure of both parts and, if necessary, level out excessive pressure or regulate its differences in the heating structure. Thus, the installation of a membrane expansion tank prevents the occurrence of increased loads in the heating circuit and in emergency situations in the event of a malfunction.

The device comes with a replaceable or non-replaceable membrane. In the first case, the coolant is completely in the capacity of the flexible membrane and cannot interact with the steel inner surface. All work related to the dismantling and subsequent installation of a new product is carried out through a bolted flange.

If you purchased a device with a fixed iris, it has a two-part internal cavity. In this case, a non-replaceable diaphragm membrane is used, which is rigidly fixed. A membrane tank for a heating system is selected directly for a specific heating structure, taking into account the amount of coolant. If the volume of the device turns out to be insufficient, then the consequences can be the most negative - cracks often appear and water can leak through the thread. In addition, often in the system the pressure drops below the permissible norm, as a result of which air enters the tank. Therefore, the choice of device must comply with the necessary design parameters (in more detail: “We make the selection of an expansion tank for heating“).

An expansion membrane tank for heating systems is used when creating a circulation of a closed-type coolant in order to compensate for its thermal expansion as a result of an increase or decrease in the temperature of the liquid, thereby preventing water hammer. In constant mode, both chambers of the device - water and gas - have the same pressure, which allows maintaining the tightness of the system. Such a device for an expansion tank of the heating system has been time-tested and recognized as the most practical.

The water circulating along the circuit does not contain aggressive gases and therefore corrosion will not render the tank unusable, which allows it to be operated for a long time. The pressure expansion device is placed in the boiler room, and for this reason there is no need to protect it from freezing.

Despite the fact that the selection of a tank for a heating structure is individual, one should not forget that:

- the initial pressure in the membrane tank for heat supply, connected to cold water supply, must exceed the static pressure in the system by 30-50 kPa;

- the device must have a spare amount of coolant to compensate for possible leaks.

To protect the system with a closed circuit and an expansion tank from too high pressure, safety valves are installed.