Principles of installation and connection of the pump

To prepare the heating system for pump installation, the heating fluid is first drained and the entire system is cleaned if it is contaminated. The system is filled with water only after the pipes are fixed, after which they are carefully checked for faults for their further elimination. Using the central screw, excess air is removed from the system.

In order for the installed pump to interact with the cooled coolant, and to extend its service life, the unit is mounted in the return line pipeline. When installing in a forced circulation system, the connection of the expansion tank should not be made to the main riser, but to the return pipeline.

Having placed the pump strictly horizontally, it is attached to the pipes. As an additional device, the circulation pump can be mounted in a natural circulation system. In this case, the pump must be equipped with a filter and a detachable thread. The filter diameter must match the pump diameter. The operation of the pressurized system must be supported by a conventional valve that matches the thread diameter of the unit. When using an open system, it is not required.

After the pump is mounted, a valve should be installed on the main and return pipelines. To allow air to be bled from the system, a special device is installed on the bypass.

Where it is planned to install the pump, a pipe is cut off and a special connection for shutoff valves is welded to it, it is installed before and after the pump unit. This must be done for ease of removal, cleaning and repair of the device. Having blocked the water with taps on the outlet and inlet pipes of the pump, the heating boiler is turned off, then the nuts are unscrewed, on which the pump is attached to the pipes.

It is necessary to connect the pump after starting the entire system and filling the pipes with water. Air should not remain in the pipes, so it is released every time before starting the pumping unit. To release air manually, use special valves installed on both sides of the pumping unit.

Selection criteria for circular pumps

Taking into account the features described above, the consumer, when choosing the equipment he needs, should pay attention to:

Performance

This indicator is calculated at the minimum level of system load is directly related to several parameters that can be combined in a single calculation formula: Performance \u003d Q. (1.16 x DT)

measured in kg/h.

Each indicator needs an explanation:

- Q is the heat consumed by the room. Measured in watts (W). For each type of premises, SNiPs define their own norms for such consumption. The indicator depends on the region of location and the type of building. For example, in Europe, 100 W are allocated for heating 1 m² of a private house, and 70 W for an apartment building. For the countries of the former CIS, the norms established in 1986 apply, which are: - 173 - 177 W per sq. m. in buildings up to three floors; - 97 - 101 W per sq. m. in buildings with more than 3 floors.

- 1.16 - an indicator of the heat capacity of water. For other liquids, this number is different.

- DT - the difference in temperature values of the return and supply branches of the pipeline.

Pump selection by power:

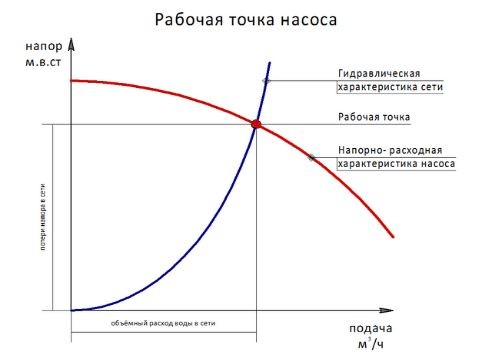

This characteristic shows the ability of the device to overcome resistance:

- pipeline;

- locking system;

- fittings;

- appliances;

- height differences.

To calculate the indicator, the formula is taken:

Head = (R x l + Z) / p x g

In it: R - the value of the resistance of a straight pipe, measured in Pa / m; I - the length of the entire system, shown in meters; Z is the resistance of the fittings, indicated in Pa P is the density of the coolant, given in kg. US.cube; g - free fall acceleration, which is indicated in m / sq. With.

The final head of the pump is taken into account in meters. The heating systems installed in specific buildings cannot be accurately measured for the specified values, therefore, average values are taken in the calculation: R = 100 - 150 PA per meter; Z = 30% of the R value. The latter indicator can be increased due to the presence in the system :

- thermostatic valve, which will increase the number by 70%;

- three-way mixer, giving an increase of up to 20%.

When calculating the pressure, it is recommended to use another formula in which the pressure is equal to:

R x l x ZF The last two letters (ZF) define the safety factor of the circuit, which is not equipped with additional devices.

- The base loop safety factor is 1.3.

- If there is a thermostatic expansion valve, then the ZF value is 2.2.

- When adding a three-way mixer, an indicator of 2.6 is taken.

This indicator greatly simplifies the calculations.

Video instruction for calculating the required pressure and volumetric flow:

Calculation of pump parameters

The main tasks of the pressure pump:

- creating such a pressure in the system that will overcome the hydraulic resistance;

- ensure sufficient heat transfer.

Based on these prerequisites, pumps for heating in a private house are selected only after calculating the required amount of heat for the house and the hydraulic resistance of the circuit. Based on the calculations, circulation pumps for heating private houses are purchased, the price and quality usually correspond to the best ratio.

To calculate the performance, a formula of the form is used - Q \u003d 0.86R / TF-TR, where:

- Q is the required consumption of cubic meters. m/hour;

- R is the selected heat demand, kW;

- TF - TR = 20.

The value (R) can have the following values:

- standards for private houses - 100 W / m2;

- for multi-storey buildings - 70 W / m2;

- factory premises - 30-50 W / m2;

- rooms with very good thermal insulation - 30 W / m2.

Calculation and selection of the circulation pump

- Types of circulation pumps

- Pump Installation Recommendations

- Pump Selection Recommendations

- Calculation of the performance of the circulation pump

- Calculation of hydraulic resistance

- Video: calculation of the required pressure and volumetric flow

Most heating systems in private homes have forced or combined water circulation. An integral part of such a system is a circulation pump that ensures the movement of water through radiators and pipes. In order for its work to be as efficient as possible, it is necessary to make the correct calculation and choice of the circulation pump for the heating system.

What is a circulation pump for?

Open heating systems, in which the coolant circulates in a circle, work according to the following scheme: chilled water enters the boiler, and after heating, due to thermal expansion, it rises up through the heating pipes, heating the radiators. Further, along a closed circuit, it goes down and through a horizontal pipeline with a slight slope again falls on the heating elements of the boiler.

To move water through pipes, an electric pump is installed in the main, which pushes the heat carrier with the blades of its impeller. The temperature in heating radiators is adjusted by changing the temperature of the water in the heating boiler, the second method is to regulate the speed of the water flow through the pipes.

Many types of circulars have 2 or 3 (rarely 4) speeds, which make it possible to increase the heating properties of radiators by increasing the speed of the coolant.

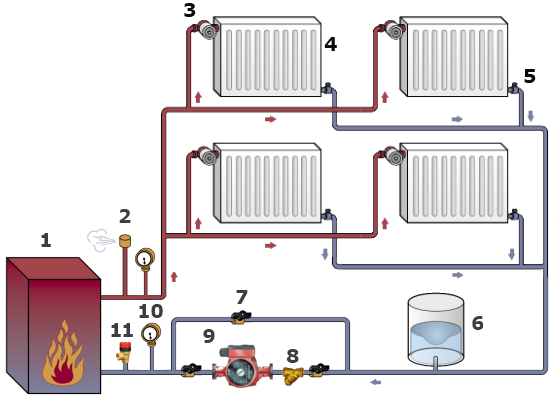

Fig. 2 Heating system with forced circulation of the coolant

How to install a circulation pump for heating

Circulation pumps are installed as part of heating systems to increase heat transfer, even distribution of heat between heated rooms, as well as to increase the efficiency of the system. The installation of a circulation pump for heating can be done by hand, which will save on paying for the services of heating installation specialists.

Unlike heating boilers that are difficult to install, the circulation pump can be installed and connected by yourself, with only minimal knowledge about the procedure, features of its installation and connection. Circulation pumps from different manufacturers have a similar design, so the installation sequence will not differ for different models.

The procedure for installing the pump depends on whether it is installed in a heating system that previously worked on the principle of natural circulation, or whether the unit is being installed to replace the failed one.

Connection

Use the central screw to remove excess air from the pipes. If the work is done correctly, liquid will begin to ooze from a special hole. For a manually operated pump, air must be bled before starting work: it must be turned on for a couple of minutes and the valve opened, repeating the steps a couple of times.

The pump unit is connected after the system is started, when the pipes are filled and all the air has been released. This must be done before each start of the device.

In systems with natural circulation, when connected to the mains, an automatic fuse is used so that a shutdown can be performed. It is installed at a distance of at least 0.5 m from the boiler.

In designs with forced circulation, the device starts working when the thermal relay is turned on. When an additional pump is installed in the home heating system, it is necessary that it and the built-in device work simultaneously. To do this, also connect the new unit to the relay or to the built-in in parallel.

If you have an electric boiler, connect the pump directly to it. This will allow the circulation device to operate only when the water is heated.

Safe operation of the circulation unit is possible when using a grounded socket.

Self-installation of the pump in the heating system of the house is possible only by observing all the rules of installation and taking into account the nuances of connection.

This issue should not be taken lightly, relying on "maybe" so as not to put your family at risk. Exact adherence to all requirements will provide your home with warmth and comfort.

Calculation of the performance of the circulation pump

Before choosing the right model of the circulation pump, you should do the hydraulic calculation of the system. The value of the operating performance of the pump is closely related to the thermal power of the heating system in question. Therefore, the volume of coolant pumped by such a unit must provide heat energy to radiators in all rooms. Therefore, for calculations, the value of the thermal power required to heat the premises and the entire building will be required.

As an example, you can use a private house, the area of \u200b\u200bwhich is 100 m 2. The value of the thermal power will be within 10 kW, respectively. Further, the pump performance is calculated according to the following formula: G= 3600Q/(c∆t), in which G is the required amount of heat carrier (kg/h), Q is the heat output of the system (kW), s is the specific heat capacity of water equal to 4.187 kJ/kg ºС,Δt - is the temperature difference in the supply and return pipes.For calculations, its temperature is taken, which is 20 0 С. Thus, in accordance with the initial data, the performance of the circulation pump will be equal to: 3600 x 10 x 4.187 x 20 = 429.9 kg / h or in larger units - 0.43 t /h.

When choosing a pump, you can notice that in the technical data sheet, instead of mass flow units, volume ones are indicated. In this case, it is necessary to convert the mass of water into its volume using a density of 0.983 t / m 3 at t \u003d +60 0 С: 0.43 / 0.983 \u003d 0.44 m 3 / h. The resulting value will be the calculated operating performance of the device.

Features of the operation of heating systems equipped with a pump

Country houses equipped with a separate heating system can be unevenly heated due to the distributed thermal energy in all rooms. The smallest amount of heat will reach those rooms that are farthest from the boiler. To solve this problem, it is possible not only to stop at the creation of new heating systems with a pipeline with a large diameter, but also to tie the pump into the heating system. currently present.

Typical scheme for installing a circulation pump: 1 - boiler, 2 - air vent, 3 - thermostatic valve, 4 - radiator, 5 - balancing valve; 6 - membrane tank, 7 - ball valve, 8 - filter, 9 - circulation pump, 10 - thermomanometer, 11 - safety valve.

Connecting a pump to a heating system is not as expensive as connecting a new pipeline.

At the same time, the dismantling procedure is applied to the old heating systems in this case, which cannot be an easy task. It is much cheaper to install a pump, especially since its installation can always be done by hand. The pump avoids the formation of air locks inside the pipes, ensuring its normal circulation through the pipeline. With the help of the pump, stabilization of temperature indicators in each room of the house is achieved. The device as a whole serves to optimize the operation of the heating system of any residential area.

Scheme of the piping of the circulation pump.

The type of sealed throttleless pump for heating system is the most common because of their simple operation and convenient design. The body of this type of pump is made of cast iron. In this case, plastic or steel can be used as a material for such a part as a rotor. The operation of such devices is silent. In this case, it will not be necessary to replace the gaskets in the heating system, which will be filled not with a cooling element and lubricant, but with water. During the entire period of operation, the unit will be distinguished by high reliability. The main condition for this is the correct connection of the pump to the heating system.

What are water pumps

The circulation pump is a small device with a metal case. The following materials can be used in the manufacture: cast iron, aluminum, bronze, stainless steel. A rotor is attached to the body of the device from the inside, and an impeller is attached to it. The rotor rotates thanks to the bearing system. All these elements are driven by electricity.

Hot water, falling on the impeller blades, is transferred by them through the pipe. This increases the efficiency of the heating system.

It is important to install the water pump vertically, otherwise its performance will decrease by 30%

There are two types of devices - with a wet and dry rotor.

Wet rotor pumps are used in heating systems of private houses. Such devices are in contact with water, so their parts need to be lubricated infrequently. The advantages of these models include simplicity of structure, long service life without maintenance, low cost of repairs and low noise level.They also consume a small amount of electricity, while their efficiency does not exceed 50% - for this reason they are not installed in large buildings.

Pumps with a dry rotor have a high efficiency and are used in heating systems of apartment buildings and high-rise buildings. In this case, the rotor does not come into contact with water, so the parts of the device need regular lubrication and service. Also, the device makes a lot of noise, so the installation of a circulation pump in the heating system is performed in a separate room with good sound insulation.

The market offers equipment with various characteristics, so the choice is not so easy to make. You also need to consider that in order to install a pump for heating of sufficient power, you will need to allocate a separate room.

With the right choice, you will be able to:

- maintain comfort and coziness in the house;

- increase heating efficiency, regulate the flow rate of water in the system;

- reduce the cost of electricity, with the help of which the pump works, and sometimes the entire heating system.

Before you go for the water pump, you need to draw up a detailed diagram of the entire heating system of the building. You also need to decide where the pump will be located and how it will be connected to the water source (read: "How to connect the pump to heating: installation and tie-in")

When choosing a device, it is necessary to pay attention to its most important characteristic - the pressure of the coolant. This indicator does not depend on the power of the heating system.

The water pressure can be 2-4 meters - when choosing, you need to take into account that the minimum indicator will not be enough for an apartment building. Thus, the greater the length of the heating system, the stronger this indicator should be.

When calculating the pump for heating, you need to focus on the maximum operating mode. All auxiliary elements (docking, plugs, fittings), and not just the circulation pump, must correspond to the functioning of the system to the maximum

In this case, errors are unacceptable, depressurization of the structure will be very expensive, so it is important to make the correct calculation of the circulation pump for heating. Also, experts recommend installing a critical pressure drop sensor in the heating system together with the water pump, so that in an emergency you can immediately turn off the pump

Useful tips from experts

Expert advice to help you make your choice:

- wet rotor pumps cope better with the load;

- models with bronze, brass or stainless steel cases last longer;

- in case of noise in the system, it is necessary to check the absence of air in the system;

- when starting, turn on the maximum speed of the pump motor.

What materials are needed to connect the restrictions when choosing a pump

The device of a heating system with water heating, operating on the basis of natural or forced circulation, will allow you to create the necessary level of heat in the room. This process will not depend on central heating. So that the circulation pump correctly moves the water in the forced heating system. it must be installed correctly. The installation of the pump structure does not require much space. According to the connection diagram, among the components of the heating system, along with the pump, there must be such parts and tools as:

Correct installation of the circulation pump.

- membrane tank.

- Mesh filter.

- Clutch connection.

- Control block.

- Signal system.

- Valves.

- System make-up line.

- Grounding.

- Circulation pump.

- Alarm and temperature sensors.

- Wrenches (19-36 mm).

- Check valve.

- Bypass.

- Stop valve.

- Plug.

- Electrical cord.

- Welding machine.

The forced circulation system allows you to hide the main pipeline deep into the wall.

In order to optimize the heating system, it is necessary to carefully consider how it will function using the installed pump. The correct selection of the device, that is, equipped with a detachable thread, will speed up the installation of the pump. This will allow you not to purchase connections separately. After carrying out the preparatory work, you should read the instructions for the purchased pump and the diagram of its device in order to confidently proceed with the installation yourself.

Connecting the circulation pump to the heating is a popular procedure necessary to create the required pressure during the operation of the entire system. In this case, it becomes possible to create structures, the principles of connection and operation of which are different.

The natural circulation system, unlike the forced one, will not make the return and main pipeline invisible, that is, hide it in the lower part of the wall. With a low height of the rooms, part of the window will be blocked by the injection pipe, so the appearance of the room will be disturbed.

Technical specifications

When deciding how to choose a circulation pump for a heating system, consider its physical and technical characteristics, the main of which are:

- throughput. Measured in cubic meters per hour or liters per minute, it shows the volume of liquid that the electric pump pumps per unit time, the flow rate is greater, the higher the flow rate. The indicator depends on the diameter of the pipeline used and can reach values up to 15 cubic meters / hour.

- Head. The value is measured in meters of water column and indicates the height to which the electric pump can push liquid through a vertically installed pipeline. The maximum pressure of the circulation pump for varieties with a wet rotor is about 17 meters, although there may be units with higher pressure characteristics, but they are inefficient in operation (they have large overall dimensions and too high a cost).

- Temperature Range. It is clear that in the heating system, pumping equipment must withstand the maximum heating temperature of the coolant with a margin, commonly used modifications are designed for a maximum temperature of up to 110º C, some types can work with liquids with temperatures up to + 130º C.

- Noise level. Basically, for use in individual homes, devices with a low noise level are chosen, pumping equipment with a wet rotor has such features, the noise characteristics of which do not exceed 35 - 40 dB.

- Compound. In residential individual houses, a heating main of a small section up to 1.5 inches is used - in this case, all pumping equipment is installed in the main through threaded connections (designed for pipelines with a diameter of up to 2 inches). The outlet fittings of most household electric pumps are equipped with external threads and are easily integrated into the line using American couplings.

- Dimensional parameters. The installation length is the main indicator of the device when built into the pipeline (for circular types, the standard sizes are 130 and 180 mm.), The diameter of the inlet and outlet pipes is also taken into account (standard 1 and 1.25 inches).

- Protection class.According to the international classification, the standard class of protection for pumping equipment of heating systems is IP44 - this means that the unit is protected from solid mechanical particles with a diameter of more than 1 millimeter (the first digit in the marking) from entering the housing, and its electrical part is completely closed from drops and splashes, flying at any angle.

In the characteristics of many centrifugal electric pumps for water supply systems, such a parameter as particle size is also indicated. For pumping devices of a closed heating system, this factor does not play any role (if the materials of the pipeline and plumbing fittings have not been destroyed) - the liquid in a closed pipeline is always in a consistently clean state.

For this reason (an open liquid-cooled rotor is designed for a clean coolant), wet rotor electric pumps are not used in the hot water supply lines of individual houses, where the intake is from wells or wells.

Fig.7 An example of a symbol for Grundfos electric pumps

Comparison of some manufacturers

To do this, you can take the most popular models of brands such as:

All of the devices listed below have a wet rotor.

Grundfos UPS 32-80

This device has:

- head 7.5 m;

- productivity 11000 kg/h;

- power consumption up to 220 W;

- liquid temperature - 2 - 110 ° C;

- price from 13800 to 16000 dew. Rubles.

Reviews speak of very high reliability, power and, as a result, price.

SPERONI SCR 25/60-180

The indicators of the device are as follows:

- head up to 6 m;

- passes about 4000 kg/h;

- withstands media temperatures up to 110 degrees Celsius;

- costs about 3600 rubles.

Reviews are generally positive.

Belamos BRS 25 / 4G

Device with the following characteristics:

- head 4.5 m;

- throughput 2800 kg/h;

- power 72 W;

- admissible temperature of the carrier from 2 to 110 ° C;

- cost from 2 to 3 thousand rubles.

According to reviews, the product is not very high quality, but quite acceptable for its price.

JILEX Compasses 25-40

This device has:

- pressure up to 4 meters;

- productivity about 3000 kg/h;

- power 32 - 65 W;

- permissible water temperature from 10 to 110 ° C;

- the price is 3600 rubles.

Given the general trends, it can be noted that the numerical value of the parameters and the reliability of the equipment grow with the price. Which manufacturer to give preference to will be decided directly by the future owner of such devices. In the meantime, we need to consider how to connect them correctly.

Which pumps are suitable for residential installations

Installation of a circulation pump.

The optimal temperature of the heating system of a country house is achieved using built-in thermal valves. If the set temperature parameters of the heating system are exceeded, this may lead to the fact that the valve will be closed, and the hydraulic resistance and pressure will increase.

Using pumps with an electronic control system helps to prevent noise, as the devices will automatically follow all changes in water volumes. The pumps will provide smooth adjustment of pressure drops.

To automate the operation of the pump, a model of an automatic type unit is used. This helps protect it from misuse.

The pumps used may differ according to the type of application. For example, dry ones do not come into contact with the coolant during operation. Wet pumps pump water when they are submerged. Dry types of pumps are noisy, and the installation scheme of the pump in the heating system is more suitable for enterprises rather than residential premises.

For country houses and cottages, pumps designed to work in water, having special bronze or brass cases, are suitable. The parts used in the housings are stainless, so the system will not be damaged by water.Thus, these structures are protected from moisture, high and low temperatures. Installation of such a design is possible on the return and supply pipelines. The whole system will require a certain approach in its maintenance.

In order to increase the degree of pressure attributable to the suction section, you can install the pump so that the expansion tank is nearby. The heating piping must be descending at the point where the unit is to be connected. It will be necessary to make sure that the pump can withstand strong pressures of hot water.

How does the principle of operation of the heating system affect the choice of pump

It is not enough to know that the operation of a circular pump can significantly reduce the cost of heating a house, it is necessary to take into account all the necessary criteria when choosing it. And first of all, you should decide on the type of the heating system itself, its characteristic features.

This work can be done independently, but given that the pump is selected for more than one season, it is better to contact a specialist.

So, before dwelling on a specific brand of pump, you need to decide on:

type of heating system. If the existing network has natural circulation, then it is recommended to install a "wet" pump with a power of up to 50-60 W

For systems with forced operation, a more powerful apparatus will be required - up to 80 W, and then, subject to the presence of a slope, and without it, attention should be paid to devices over 90 W;

heated area and volume of coolant circulating in the system

Naturally, with the growth of these parameters, it is necessary to pay attention to more powerful pumps. But in order to calculate the exact power of the device, you will need the help of a heat engineer.

Sometimes the organization of the heating system assumes that an additional pump will be installed in the heating system. for example, to increase power or separately for underfloor heating;

restriction on the maximum noise level - it is precisely because of this parameter for private houses, without the possibility of installing a pump in a separate room at a maximum distance from living rooms, it is not recommended to use devices with a "dry" operation cycle;

the technical condition of the existing heating system. Any device can be connected to the new system, but for networks that are 15-20 years old or more, the presence of impurities in the coolant should be taken into account. An additional 25-35% should be added to the calculated power, especially if it is planned to install a pump with a “wet” engine. But, if possible, pumps with a dry motor are better suited for older systems, since, due to the closed design, they are less sensitive to the quality of the coolant.

It is imperative to take into account the type of fuel on which the boiler operates, as well as its design features, including the temperature level of the coolant at the outlet and inlet.

2 Types of pumps and their features

Various circulation units can be mounted in the heating system of a private house. They are divided into two large groups. The circulation pump can be "dry" or "wet". When installing devices of the first type with your own hands, it should be borne in mind that their motor is separated from the working part by sealing rings. They are made from stainless steel. During the start-up of the installation, the process of movement of these rings begins, which leads to the sealing of the connection with a water (very thin) film. The latter is located between the seals.

Circulation pumping unit

High-quality sealing in this case is ensured due to the fact that the pressure in the external atmosphere and in the heating system itself is characterized by different indicators. A “dry” pump makes quite loud sounds during operation. In this regard, its installation is always carried out in a specially soundproofed separate room of a private house.The efficiency of such a circulation unit is at the level of 80%.

There are three types of "dry" devices for connection to the heating system: horizontal, vertical, block. The electric motor in the units of the first type is placed horizontally. The discharge pipe is attached to them on the body of the apparatus, and the suction pipe is mounted on the shaft (on its front side). In vertical installations, the nozzles are on the same axis. And the engine in this case is located vertically. In block circulating units, heated water exits radially, and enters the system in an axial direction.

Caring for a "dry" unit is objectively difficult. Its elements must be regularly lubricated with a special compound. If this is not done, the end seals will quickly fail, causing the pump to stop. In addition, in a private house, “dry” devices should be placed in rooms where there is no dust. Its turbulence during equipment operation often causes pump depressurization.

In "wet" units, the coolant itself performs the function of lubrication. The impeller and rotor of such installations are immersed in water. "Wet" devices are much less noisy, they are easier to mount with your own hands. And their maintenance is simpler compared to "dry" pumps.

The body of the "wet" installation, as a rule, is made of brass or bronze. Between the stator and the rotor there must be a special separator made of stainless steel. It is called a glass. It is necessary to give the required tightness to the engine (more precisely, its elements under electrical voltage). It is the “wet” units that are most often mounted in a private house in the heating system.

They do a good job of heating relatively small areas. For large objects, such devices are not suitable, since their performance usually does not exceed 50%. The low efficiency of "wet" installations is due to the impossibility of high-quality sealing of the glass placed between the stator and the rotor.

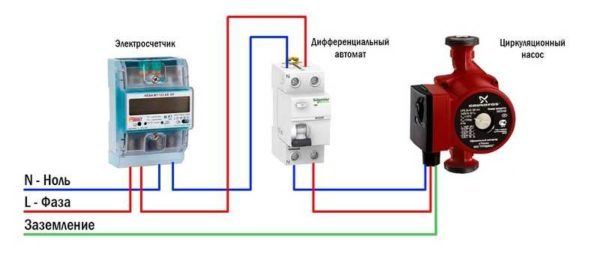

Power connection

Circulation pumps operate from a 220 V network. The connection is standard, a separate power line with a circuit breaker is desirable. Three wires are required for connection - phase, zero and ground.

Electrical connection diagram of the circulation pump

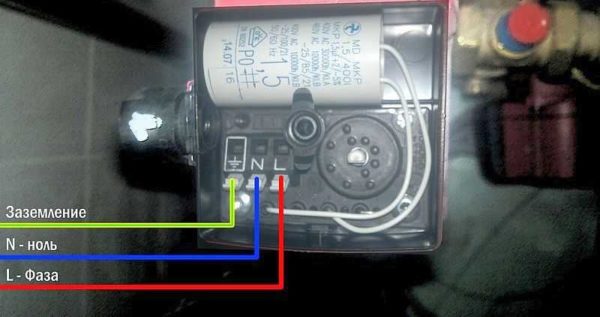

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power cable. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing a few bolts, we find three connectors. They are usually signed (pictograms are applied N - neutral wire, L - phase, and "earth" has an international designation), it is difficult to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - put a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pull” electricity to a maximum of 250-300 watts. But when organizing, you need to calculate everything and select the capacity of the batteries. The disadvantage of such a system is the need to ensure that the batteries are not discharged.

How to connect a circulator to electricity through a stabilizer

Hello. My situation is that a 25 x 60 pump stands right after the 6 kW electric boiler, then the line from the 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, the branch goes up, then 4 m, down, rings the house of 50 sq. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bath branch 40 mm up, leaves the bath, enters the 2nd floor of the house 40 sq. m. (there are two cast-iron radiators) and returns to the bath in the return line; the heat did not go to the second floor; the idea to install a second pump in the bath for supply after a branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

Choosing a pump for a heating system in a private house

In heating systems, the circular pump was almost never used before. The boiler was located at the lowest point of the heating system, and the water moved through the pipes under the influence of the laws of physics.

With the advent of powerful heat-generating units, which are designed to work in large areas, it has become important to accelerate the passage of the coolant through the system for a more uniform heat supply. Another aspect was the popularity of arranging underfloor heating, which in buildings without basements is always located below the level of the boiler.

A properly selected pump will not create unnecessary noise, save money and ensure high efficiency of the entire heating system. The main parameters, features of choice and the most popular models of such devices will be described below. When choosing a drainage pump, the selection principle is significantly different, it is described in a separate material on our website.