Types of vapor barrier materials

Several basic types of materials can be used to create a vapor barrier layer. This is a polyethylene or polypropylene film, the so-called diffuse membrane or liquid rubber. Previously, only roofing felt, roofing material and other similar materials were used.

Polyethylene film

Polyethylene film is the cheapest and easiest material used to create a vapor barrier layer.

It is quite thin, and therefore during installation it is important to be careful not to tear it. The film may or may not have fine perforations.

On a note! There is an opinion that a perforated film is used for arranging waterproofing, and without it - for vapor barrier. This is due to the presence of small holes in the material.

Vapor barrier film "Yutafol H 110"

However, in any case, whatever the film, when using it, you will have to equip the ventilation gap. And since you still have to do it, many do not think about the presence of perforation and simply buy the material that is cheaper.

Now another subspecies of films made of polyethylene has appeared - it has a reflective layer coated with aluminum. Such material has a higher vapor barrier and is usually used in rooms where high levels of humidity and air temperature are noted.

Foil-coated vapor barrier film

The film polypropylene differs in high rates of quality and durability. It is easy to install and can last for years. Polypropylene film is made not only from polypropylene - it also has an additional cellulose-viscose layer, which is able to absorb a lot of moisture and retain it. At the same time, during the decrease in the level of humidity, the layer dries up and is again ready to absorb it into itself.

Polypropylene vapor barrier

When laying this type of film, it is worth remembering that the anti-condensate absorbent layer must be turned away from the insulation. And between the layer of vapor barrier itself and the insulating material, a small gap is left for ventilation.

Diffuse membranes are perhaps the most expensive vapor barrier option. They are considered the highest quality, are called "breathable" and are able not only to protect building materials from excess moisture, but also to regulate the moisture index.

The membranes are divided into one- and two-sided, and the materials are mounted differently - if when laying a one-sided version of the membrane it is important to observe which side it will be turned to the insulation, then the two-sided one can be laid as you like

Such membranes are characterized by significant vapor permeability. They are made from a special non-woven artificial material and can have several layers. When installing, leave a gap for ventilation is not necessary.

diffuse membrane

On a note! Among the membranes there are those that are called "intelligent". They combine several properties at once - they are able to work as a vapor barrier layer, provide waterproofing and are also a heat-insulating material. This type of membrane is able to regulate the level of steam depending on the levels of indicators such as ambient temperature and humidity in the room.

Liquid rubber, when creating a wooden floor cake, is used extremely rarely for vapor barrier; it is more suitable for concrete bases. However, it is still a fairly common option to talk about it. Such rubber is a polymer-bitumen composition prepared on the basis of water.It is applied very simply - it is sprayed on the base, moreover, it forms a seamless and durable coating - a kind of rubber carpet. When the polymerization process is completed, the material will not be able to pass any substances through itself.

Liquid rubber

Liquid rubber can be applied automatically and used to process spacious structures, or manually - this option is suitable for small rooms.

Brands of materials for creating a vapor barrier

There is a wide variety of various brands of vapor barrier materials on the materials market. They have a lot of differences and may differ in price, quality and other factors.

Table. Material brands.

| Brand | Information | Manufacturer | Price |

|---|---|---|---|

| Tyvek | Good protection against steam and moisture | Denmark | 5500 rub./50 sq.m. |

| Izospan | Protects from moisture, wind, steam | Russia | 13 rub./sq.m. |

| Brane | Excellent protection against steam, moisture, wind | Russia | 1100 rub./70 sq.m. |

| Domizol | Excellent protection against steam, moisture, wind | Russia | 13 rub./sq.m. |

| Polyethylene | Tears, but protects well from steam | Russia | No more than 10 rubles / sq. m. |

"Izospan V"

Isospan is especially popular. There are several subspecies of it, and it is recommended to purchase Izospan V for floors. It is a two-layer version of the membrane. It is smooth on one side and slightly rough on the other. The rough side retains capillary moisture well, absorbing it.

waterproofing material

Long gone are the days when only the “classic” roofing material came to mind when the word waterproofing came to mind. Modern industry offers a number of materials that differ in their characteristics, installation method and price.

sheet material

The features of this material are clear from the name - these are rolls or sheets, which are a polymer, fiberglass or paper base impregnated with special compounds. The canvases are overlapped on the base, the joints are glued using mastic compounds. Next, the finished surface is heated, achieving gluing of the insulation to the base.

Such material can cover not only the floor, but also the walls. With proper installation, the surface is reliable and durable. It is worth noting that laying such insulation is a laborious process, experience is needed for a good result, it is better to entrust the work to specialists. This is a significant disadvantage, as is the high price of the material.

Painting with mastic

A fairly simple way to create waterproofing of the floor and walls is the painting method. To obtain a coating that is resistant to excessive moisture, mastic is used. Its consistency is similar to that of ordinary paint, so the methods of working with it are similar.

Mastic is equally well applied to the floor and walls. To get a high-quality coating, you need at least three layers, between applying each of them the wall is allowed to dry for 3-4 days. After hardening of the last layer, a surface with excellent water-repellent properties is obtained. The only thing that can be written down in the cons of this type of waterproofing is a short service life. The coating will last no more than 5 years.

Coating waterproofing

Another simple and effective waterproofing option. According to the method of application, it resembles mastic, but differs in composition. This material is sold in dry form, diluted with water before use. The application method is completely identical - a roller or brush is used. It is easier and faster to work with a roller, the corners are smeared with a brush.

As a rule, two layers are applied. The first is allowed to harden for 5-6 hours. The second is applied with movements directed perpendicular to the first layer. Leave until completely dry. As a result, the surface of the floor or wall will be covered with a film that has good water-repellent properties. In addition to ease of operation, this method is characterized by a fairly long service life.

How to install vapor barrier

Vapor barrier must be laid in compliance with the technology, although in general this process is quite simple and understandable to everyone.

Step 1. Windproof material is spread over the subfloor.

Laying wind protection material

Step 2. The film is laid so that its edges go over the wooden logs.

The film is attached to the logs

Step 3. The fixation of the material is carried out using a construction stapler along the logs.

A stapler is used for fixing

Step 4. After that, insulation boards are laid on the laid material. They should cover all the space between the lags.

Insulation laying

Step 5. Adhesive tape is glued along the perimeter of the wall in its lower part before installing the vapor barrier layer.

Adhesive tape around the perimeter

Step 6. The vapor barrier layer is laid. Pieces of the desired size are laid across the log with a slight overlap on the walls. The film is laid so that in the middle it sags a little.

Vapor barrier installation

Step 7 Fixing the film is carried out using a construction stapler on the logs.

Fastening the vapor barrier material with a stapler

Step 8. The edge of the vapor barrier film wound onto the wall is glued to it on the adhesive tape installed earlier.

The vapor barrier film wound on the wall is glued to the adhesive tape

Step 9. The junction of the next layer of film is sealed with adhesive tape, which is glued along the edge of the previously laid layer.

The joints between the pieces of the film are sealed with adhesive tape

Step 10. The new piece of material is laid so that it overlaps at the location of the adhesive tape. The rest of it is again fixed on the logs with the help of a construction stapler.

The second piece of vapor barrier film is laid

Step 11. The floor is being installed.

Floor installation

Video - Vapor barrier films for the floor "Ondutis"

https://youtube.com/watch?v=zBeuVSLaQ34

Vapor barrier is a layer in the floor cake, which should not be neglected, and even more so - replace it with a waterproofing material. It is thanks to the vapor barrier that it will be possible to create a microclimate favorable for life in the house.

Anton Svistunoveditor-in-chief

Author of the publication05.11.2017

What is the difference between hydro and vapor barrier

Vapor barrier is a thin film that is mounted inside the floor pie. However, quite often it is confused with waterproofing, but these are completely different materials. So, the waterproofing layer is designed to keep moisture out of the room from the outside. If water still gets to the insulation, then its characteristics will deteriorate significantly - it will no longer retain heat. This will be especially felt in winter, when the water inside the insulation layer will turn into ice crystals. The floor will become colder, and in general it will not be so comfortable to be in the room. To prevent this from happening, it is necessary to lay a layer of waterproofing. In general, it does not allow precipitation, groundwater to pass through and is laid outside the floor cake.

Floor waterproofing on the ground

The vapor barrier is laid inside the floor pie. And it will protect the materials included in the structure of the base, no longer from moisture from the outside, but from the condensate coming from inside the room, which is formed due to breathing, cooking and other processes, accompanied by the release of steam and moisture.

Scheme of the floor device on the beams

The main difference between these two types of materials lies in their structure. Waterproofing coatings do not allow moisture to pass through, but they are quite capable of passing evaporation through themselves. But vapor barriers retain both moisture and steam, thereby protecting the insulation. Thus, the vapor barrier does not have a membrane structure as such.

Vapor barrier laid on the floor

On a note! Not all types of waterproofing materials are vapor permeable.

Wall and ceiling waterproofing

In the bathroom of a wooden house, the waterproofing of the walls and ceiling is given no less attention than the processing of the floor. Protection against moisture is required not only in places prone to ingress of water, but also in areas relatively remote from its sources.

Do not forget that the bathroom gives off steam, which will certainly condense on any surface.

To reduce the amount of condensate, it is recommended to choose a room for the bathroom that is surrounded by other rooms, where no wall is a side wall of the building. If this is unrealistic, then it is necessary to ensure maximum thermal insulation of the outer walls.

Before laying the waterproofing, it is necessary to complete the installation of water supply and sewage pipes. Wooden walls and ceiling are sheathed with rolled waterproof material.

Work begins with cleaning the surface, it must be dry and clean. The ceiling and walls are covered with a primer. Next, sheets of waterproofing material are overlapped, the joints are fixed with construction tape, and the coating is allowed to dry.

Instead of roll materials, you can use special moisture-resistant mastics for wood. They are easy to work with, they do not require a preliminary primer, you just need to apply an even layer of the composition and let it dry.

After a few days, you can move on to the interior decoration. The choice of material depends entirely on the wishes of the owners. You can use lining, you can use familiar tiles, the interior looks great, in which wood and tiles complement each other.

Dear partners and customers

We are glad to see you on our site!

We draw your attention to the fact that recently there have been more cases of counterfeit products appearing on the market, as well as fake Izospan materials that clone their appearance, symbols and use consonant names. Being deceived by the external similarity of products, buyers acquire low-quality goods, and as a result, problems arise with its use.

Being deceived by the external similarity of products, buyers acquire low-quality goods, and as a result, problems arise with its use.

Hexa-Nonwoven Materials LLC, a manufacturer of Izospan TM materials, has been working on the Russian construction market for 17 years, constantly developing its range, improving technologies and equipment. We carefully control every stage of the creation of films and membranes so that the quality of our materials always remains at a high level, allowing you to create and maintain an atmosphere of comfort and coziness in your home.

Please be careful when choosing and purchasing materials! Remember that the joy of a low price is quickly replaced by disappointment from a low-quality product.

How to distinguish a fake can be found here ...

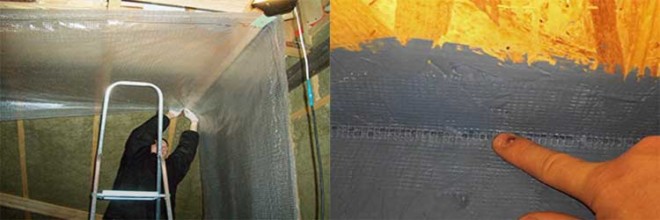

A note about my cant and a couple of questions for you.

My head was spinning from all these steam-wind-hydro-thermal insulation. Decided to load you up a bit. It so happened that in our team, at the same time, three people (including myself) are building (or completing) wooden houses. And at the same time, all three had the same problem. Water leaked from the ceiling. Everyone is different, but the same principle. At the first, a tub of water spilled out when the vapor barrier was pierced. The second screwed a screw into the ceiling and dripped from it. The third one (that is, me) has only a little dampness so far.

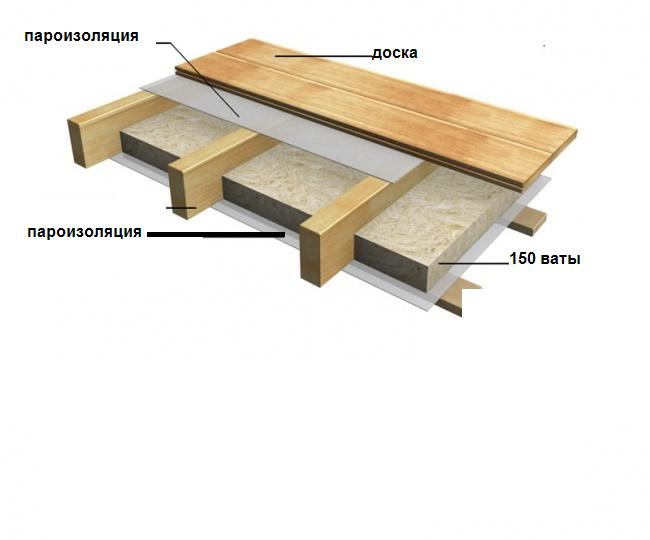

We all made the same mistake. We made this cake.

I also wrapped the beams. Well, nothing else for me, the ceiling of the first floor has already been finished.

Then a hundred and fifty rocklight.

And wrapped everything with vapor barrier.

Well, at least I didn’t have time to nail the board.

Three weeks have passed.

First, the first colleague reported the leak. I did not attach any importance to this.

And a couple of days ago, the second one announced drops from a self-tapping screw screwed into the ceiling. After that, I sounded the alarm. Together we went to my construction site of the century, threw back the boards, pulled back the film

And they found drops of condensate.

Actually, after reading more than one volume of all sorts of forums and scrolling through all my work in my head, I came to some conclusions and even more questions.

1. I did not make a ventilation gap between the cotton wool and the top layer of the film. I will.2. In vain I wrapped the beams on top. They will rush from the steam rising from the first floor. What to do with it is not clear. After all, the ceiling has already been finished and painted.

3. It was impossible to put a vapor barrier on top of the cotton wool, this is understandable. Question. Does the second layer have to be a two-three-layer membrane or can you throw a windscreen, it seems to let the steam through?

Of the materials available: megaizol D, which was just stretched, as a vapor barrier. And megaizol A, which I want to use as the top layer.

Yes, addition. The second floor will be heated, but not soon. Now the task is to launch the first floor. But also throw in the draft floor of the second floor so that you can walk on it and, preferably, not open it in the future.

General recommendations for installation

Vapor barrier of the ceiling is recommended to be performed from the inside of the room. Exceptions are regions where the air temperature in winter can reach -32°C. In such climatic conditions, it is recommended to install a vapor barrier on both sides.

Ceiling vapor barrier features

The method of installation of the vapor barrier material depends on its type and the surface on which it is attached. But in any case, you must follow the general recommendations.

Before laying the vapor barrier, all surfaces are carefully sealed.

Particular attention should be paid to joints near the chimney, ventilation ducts, etc.

Vapor barrier is laid between the room and the insulation layer.

The material must cover the entire surface without gaps or gaps.

The fixed material should not sag, but it is also impossible to stretch it too much, since it will break due to temperature changes.

When working, the strips of material are overlapped (approximately 10 cm)

Joints in the corners are unacceptable; a solid canvas is laid in them for high-quality overlapping of the entire surface of the corner.

The vapor barrier material must be laid overlapping (approximately 10 cm)

The allowance along the perimeter of the ceiling must be at least 20 cm.

Before laying the ceiling surface is cleaned of dirt and dust, then thoroughly dried.

Penofol and Izolon product characteristics

Representing foamed polyethylene, with one- and two-sided foil coating, the material is used for indoor work.

There are several types of products:

- Marking A - insulation, supplemented with foil on one side.

- Marking B - products with double-sided foil.

- The letter C means that one side is covered with foil, the second with adhesive.

- Letters ALP show products with a double-sided foil layer. Moreover, one layer of foil is additionally protected by a film.

- The letters R, M - products with one-sided foil coating, relief structure of the insulation layer.

In residential premises, the first three types of insulators are used, and A is a vapor barrier material that should be used in conjunction with other heat-insulating coatings, and types of goods B, C are used as independent materials.

On a note! In order for the insulation of the ceiling with Penofol from the inside to be of high quality, the foil layer turns inside the room, and not vice versa. In this case, heat losses are reduced. The strips are laid end-to-end, without overlapping one another, the seams are fastened with adhesive tape.

Experts advise to additionally form a crate - this increases the energy efficiency of buildings. An air cushion on both sides of the insulation reduces heat loss. The sheets are mounted on the frame, pressed on top with another crate, and then the ceiling is sheathed with polystyrene foam, polystyrene foam.

What is the difference between materials

Isolon is a closed-cell product used for thermal insulation and noise reduction in rooms.

Several types are offered for sale:

- self-adhesive tapes;

- products marked 100 - non-crosslinked polyethylene foam;

- products marked 300 - chemically cross-linked polyethylene foam;

- goods marked 500 - physically cross-linked polyethylene foam;

- reflective type insulation - foil polyethylene foam or lavsan metallized film.

According to its technical parameters, Izolon differs from other products with a density of 20-100 kg / m3, a high reflectance of UV radiation (up to 97%). In addition, the materials do not absorb water, have low thermal conductivity and are protected from steam penetration.

Penofol is a layered polyethylene foam product with different density, thickness and porosity. Light and thin products are supplemented with a foil layer, used for heat, vapor and waterproofing of rooms. It is easy to install and low cost, which makes Penofol the most popular product for do-it-yourself work.

The main difference between the goods is only in the structural structure of the insulation: Penofol is a layered product made of polyethylene foam, and Isolon is a cellular polyethylene foam product, crosslinked by physical or chemical means.

Pros and cons of insulating material

The advantages of foil insulation include the following qualities:

- A light weight. Materials will not overload even thoroughly worn floor slabs.

- Small thickness. The use of products will not reduce the useful area of \u200b\u200bthe room.

- Flexibility, elasticity. The property provides ease of installation on any surface.

- Multifunctionality, versatility. There is no need to buy additional waterproofing, carefully align the ceilings.

- Efficiency of coverage of areas of different sizes. The work will not take long.

- Ease of processing. Materials are easily cut with a sharp knife.

- Water resistant. Foil insulation does not absorb moisture, which means that it can be laid out in bathrooms, on open verandas. In addition, the layer protects the base and structures from mold, decay, and corrosion.

Minus one - flammability. Foamed polyethylene burns itself and spreads combustion, so products need additional protection.

TechnoNicole

An international company offering products with an extended service life. Warranty for vapor barrier - several decades. The range includes the following products:

- Universal vapor barrier film. Suitable for interior work. It can be applied to any surface, be it walls, ceilings or roofs.

- diffusion membrane. It is intended for protection of a subroofing heater. On both sides it has a protection in the form of a polypropylene sheet. Breathable for good ventilation.

- Non-perforated vapor barrier film. A specialized material designed to protect the roof. Equipped with reinforced mesh fabric for increased durability.

Choose any of the presented brands in accordance with your current tasks, and the building structures of your house will be reliable and durable, and your stay will be comfortable.

Perforation of fabric and skin what is it and how is it done

- home

- Youth News

- Blogs

- Contacts

Main Youth news — Business — Health and sex — Internet — Society — Incidents — Sports and extreme — Photo news Blogs — Personal —- Oleg is a great person — Blog about sports and a healthy lifestyle —- Supergirl —- Life is good —- 4 С : Sport, Sex, Style, Crazy — Thematic —- Auto-, moto —- Home, family, children —- Health and beauty —- Internet blog —- Interior, furniture —- Fashion and style —- Real estate —- Leisure and tourism —- Work, business —- Religion, unidentified —- Sports blog —- Construction, repair —- IT-technologies —- Humor —- Miscellaneous — Press releases Contacts Published: October 19, 2018 203 times

- font size decrease font size increase font size

- Email mail

Perforation is a figured slotted pattern made using a laser beam. Previously, it was used for bags and shoes. Today it is fashionable to decorate clothes with perforation: women's dresses and skirts, tunics, vests, jackets, trousers, etc.This technique appeared in the 70s of the 20th century and then it was called guilloche. The craftsmen used an electric tool with a long thin needle, which resembled an ordinary soldering iron, and performed lace trim on the fabric. To do this, a sheet with a pattern and a cloth were placed on top of the glass, and a lamp was placed below, which illuminated the pattern. Next, holes were burned into the fabric with a needle.

Mounting Features

The floor cake is made of several layers, including logs, a layer of waterproofing material, a subfloor, a layer of insulation, a vapor barrier layer, a layer of soundproof material and a finishing coating. Before installing the vapor barrier, it is imperative to prepare the surface. If the building is being built from scratch, then there will be no problems with the installation of this layer. The boards of the subfloor are simply treated with antiseptic preparations, leveled, and vapor barrier material spreads over them. It is also recommended to cover the logs with protective compounds.

Floor insulation with mineral wool

If the house has already been built, it is being overhauled, then for a start it is important to remove the old flooring and other previously used materials. Next, it is important to check the strength of the logs, the rough base - if they bend or rot, they will have to be dismantled and replaced with new ones.

All debris is removed before further work, the smallest specks are removed with a vacuum cleaner.

The vapor barrier layer must be laid on a flat base without protruding nails. Otherwise it may be damaged

Immediately before installation, it is important to determine which side the vapor barrier material will be mounted on. As for a conventional polyethylene film, there is no need to determine the side

If Isospan is used, then it is important to look at its color on both sides. It is laid with the bright side to the insulation. If the material has a pile, then this side is mounted in the direction of the room - the pile will absorb excess moisture.

Laying vapor barrier "Izospan"

On a note! To work with a vapor barrier, a material such as adhesive tape is useful. With its help, the joints of the individual strips of the coating are connected. This is necessary to improve the tightness of the vapor barrier layer. In this case, individual strips of material are overlapped by 15-20 cm on top of each other.

Installation of vapor barrier does not require special knowledge. The material is rolled out on the surface of the prepared floor and fixed on it with the help of small nails, a construction stapler. However, the easiest way is to use a special adhesive tape.

Hard-to-reach or unusually shaped places are best treated with a bitumen-based coating agent. The reason for these actions is that in such places it will be quite problematic to lay and properly fix the vapor barrier material.

The process of laying "Izospan"

The insulation itself will be laid directly on top of the vapor barrier if the material is used to protect it from moisture not only from the inside, but also from the outside. Styrofoam, mineral wool or expanded polystyrene can be used as an insulating layer. It should fit very tightly to the wooden joists so that cold bridges do not form.

On top of the insulation layer, another layer of vapor barrier is mounted. He will no longer allow moisture coming from inside the room to get to the insulation and soak into it.

On a note! Foil film perfectly reflects infrared radiation. Therefore, it is laid with the shiny side in the direction of the room.

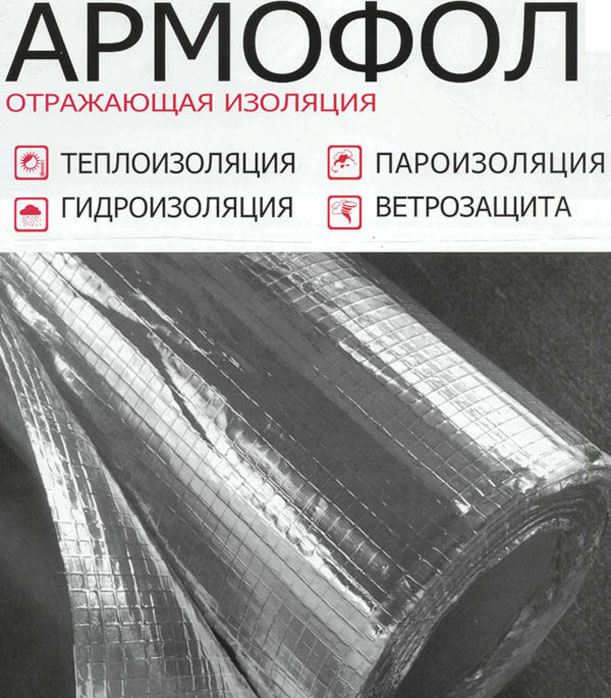

Description of ceiling vapor barrier Armofol

Materials of this brand are divided into two types, some have one-sided foiling, others have foil on both sides.

Vapor barrier "Armofol A" is a rolled material with a single foil layer based on fiberglass mesh. The main purpose is vapor barrier and thermal insulation of rooms with a high level of humidity and high temperature values. Such premises include baths, saunas and catering establishments. In addition, "Armofol A" may well be used to create a vapor barrier in private houses with wooden ceilings.

"Armofol V" is a roll-type material consisting of three layers, two of which are made using foil, the third layer is a glass mesh. High efficiency has been noted for vapor barrier and thermal insulation of attic spaces, as well as on the ceilings of wooden floors.

Other brands of this brand have a higher cost, so they are rarely used in the private sector. They are more suitable for industrial premises in which the air space is filled with vapors of acids, alkalis and other aggressive chemicals.

Which vapor barrier is better for the ceiling of a wooden house

For wooden houses, as a rule, a vapor barrier membrane or polypropylene film is used.

As for the first type, you should pay attention to the "intelligent membrane" - a modern material that can independently regulate the level of humidity in the room. But its cost is much higher than that of others, but maintaining the correct microclimate is ensured.

Experts advise choosing the following types of vapor barrier materials when forming a ceiling in a wooden house:

- Penofol A is an easy-to-install vapor barrier due to the presence of a self-adhesive layer.

- Penofol B has a foil side for better heat retention in the room.

- Penofol C is a vapor barrier for a ceiling in a wooden house, similar to the first two groups with a self-adhesive layer.

- Izospan is a material with two layers and an improved system for evaporating moisture from the surface.

- Alucraft is a vapor barrier film with three layers, used in rooms with high humidity.