TD Gofra House

We are glad to welcome you on our site! We will be happy to help.

The modern market offers a lot of types of pipes, but corrugated pipes are currently recognized as the best. Corrugation for pipes is used in the laying of telecommunication networks, electrics, sewer systems. Why corrugation? First of all, it is strength and reliability. In every house you can find telephone, computer, electrical networks, and the basis of each of them is a strong and reliable corrugated pipe. This material allows you to protect the cable from damage, especially during installation, meets the most stringent fire and electrical safety requirements.

Stainless Steel Corrugated Pipe Fittings

Mounting elements, without which it is extremely difficult for both a professional corrugated pipe installer and a novice master, are fittings.

- This is what the elements of connecting fittings that perform various functions were called, for example:

- implementation of a hermetic transition between two branches of the pipeline;

- creation of a strong connection of pipes of various diameters;

- adjusting, stopping or changing the direction of the flow of the working fluid in the system;

- increasing the length of the circuit without stopping the entire system, it is convenient when working with stainless pipes;

- changing the gasket geometry and upgrading the existing system;

- replacing part of an outdated system. Laying a new heating or water supply circuit with steel corrugated pipes.

In addition, the corrugated stainless pipe fitting is responsible for creating branches from any circuit in the system.

- With all the variety, the fittings are conventionally divided into two categories:

- Seamless elements. They are a one-piece fitting, extremely reliable, but installation may require specialized tools, such as crimping pliers.

- Electrical part. This type of reinforcement consists of several elements precisely fitted together to ensure a minimum gap.

- The principle of installation is easy to understand and quite simple, and a variety of fittings for stainless corrugated pipes is an excellent solution for assembling the system yourself. If all technological steps are followed, a strong and durable connection is formed.

As a rule, manufacturers of stainless corrugated pipe are not eager to launch fittings for their products. Economic calculations have shown that this is not a priority task for large enterprises. The growing demand in the market for corrugated steel pipes provides the manufacturer with a stable profit.

Various countries are involved in the production of fittings. Components from European manufacturers have proven themselves well. Domestic manufacturers are increasing production volumes while tightening quality control of their products.

Depending on the task set for the installers and the overall project estimate, taking into account the installation conditions and the diameter of the pipes, the most suitable type of fittings for stainless corrugated pipes is selected: brass, plastic or steel fittings.

Installation of a box for an asbestos-cement chimney

Consider how the casing is installed on the asbestos-cement chimney pipe:

- First of all, it is necessary to prepare the pipe for the installation of heat-insulating material and the box. To do this, it is necessary to clean it from dust and dirt.

- At the second stage, you need to place the heat-insulating material in a case made of galvanized steel or roofing iron. Mineral wool can be used as a heat insulator. The heat-insulating material is located along the entire length between the casing and the pipe.

- The upper part of the pipe is mounted with a slight slope.

- The niche between the asbestos-cement chimney and the pipe must be filled with cement mortar. For these purposes, concrete grade M-150 is perfect.

Mineral wool can be used to fill the space between the pipe and the casing

Such a case is recommended to be assembled from several parts. This is a necessary measure to simplify the installation of a heat insulator.

Mounting the steel case

A steel case is the most common option for organizing a protective casing for a chimney. Consider the process of installing a steel casing on a chimney:

- The case can be purchased or made with your own hands, using a steel sheet, profiles and ordinary self-tapping screws.

- The steel casing is mounted on the main pipe.

- At the third stage, the space between the main pipe and the case is filled with heat-insulating material, which must be selected based on the heating temperature of the chimney.

- At the end, the case (made of galvanized or stainless steel) must be painted with oil paint.

You can fix the casing with self-tapping screws, and to protect against rust, it is recommended to paint the finished structure

Painting the steel case is necessary in order to give it a presentable appearance. As mentioned above, for this you can use a more expensive, however, and more beautiful option - a polymeric decorative coating.

Decorative rings for pipes

Collapsible decorative rings for pipes are used in cases where it is desirable to mask the contact point between the pipe and the floor covering. Proper installation requires maintaining a 10 mm gap, which compensates for the contraction/expansion of the flooring material. Therefore, the existence of a joint is inevitable; it will not be possible to hide it with the help of a hole made. In such cases, they remember decorative rings, which are distinguished by their simple design and ease of installation.

With the help of collapsible contours, put on the girth of the pipe, the gaps are closed. After that, it remains to slam the ring, press it firmly against the floor surface and consider the installation of the decorative masking element completed. Specialists recommend gluing the junction of the ring with the floor covering for greater reliability. The overlay can be removed, if necessary, and reinstalled in a new place. To do this, it will need to be washed first.

Pipe lining is a fairly simple, in most cases collapsible, design.

Stroke for pipes is distinguished by a variety of assortment:

- it can be selected for products of half-inch and three-quarter diameter (these are the most popular sections), inch and inch and a quarter;

- it is made both from plastic or MDF (budget option), and from wood of different species - oak, beech, ash and others, as well as from bamboo;

- performing imitations in different styles allows you to combine rings with parquet, laminate, artificial stone and other types of coatings;

- additional variety is created by an abundance of colors, shades and textures.

Decorative rosettes for heating pipes or cups, as rings are also commonly called, are distinguished by a whole bunch of wonderful qualities that contribute to the spread of their use:

- extraordinary ease of installation. A collapsible socket for pipes is put on in a girth, snaps into place (if the diameter of the sockets is correctly selected), pressed against the surface of the coating - the process is unlikely to take more than one minute;

- versatility of use. Cups can be used on any type of flooring;

- a decorative cup is inexpensive;

- the ring can be easily selected not only in diameter, but also in color, shade, texture, imitating the surface of different types of tree species;

- aesthetic appeal, which, in general, is the main factor in creating interior design.

The use of various kinds of decorative overlays on elements of the heating system is becoming more widespread. This phenomenon is based not so much on blind adherence to fashion trends, but on the high additional functionality of products, combined with aesthetic appeal and the fulfillment of the main purpose - to hide unattractive designs. Practicality and beauty are the main advantages of decorative overlays for heating pipes, contributing to consumer demand.

An "Online Consultant" is available on the seller's website. To go to the site, click "To the store"

A toll-free number 8-800 is available on the seller's website. To go to the site, click "To the store"

An "Online Consultant" is available on the seller's website. To go to the site, click "To the store"

A toll-free number 8-800 is available on the seller's website. To go to the site, click "To the store"

A toll-free number 8-800 is available on the seller's website. To go to the site, click "To the store"

A toll-free number 8-800 is available on the seller's website. To go to the site, click "To the store"

A toll-free number 8-800 is available on the seller's website. To go to the site, click "To the store"

A toll-free number 8-800 is available on the seller's website. To go to the site, click "To the store"

A toll-free number 8-800 is available on the seller's website. To go to the site, click "To the store"

An "Online Consultant" is available on the seller's website. To go to the site, click "To the store"

On the seller's website, "One-click order" is available. To go to the site, click "To the store"

An "Online Consultant" is available on the seller's website. To go to the site, click "To the store"

A toll-free number 8-800 is available on the seller's website. To go to the site, click "To the store"

On the seller's website, "One-click order" is available. To go to the site, click "To the store"

Types of corrugated pipes

Today on sale you can find different types of metal corrugated pipes, but according to modern requirements, not all of them can be used for chimneys.

Aluminum

Previously, an aluminum corrugation for the chimney was used everywhere to remove combustion products from gas heaters and columns. This is a flexible pipe made of laminated multilayer aluminum foil with a diameter of 100–150 mm. quite durable and inexpensive. A steel wire is inserted inside the pipe to give it shape and direction.

Having an initial length in a compressed state of 65 cm, the aluminum corrugation stretches up to three meters, which allows you to vary the length of the chimney or air duct within these limits. And if necessary, building pipes are fastened together with metal tape.

Aluminum corrugation

On stoves, fireplaces and solid fuel boilers, an aluminum corrugated chimney pipe is not installed, as it does not withstand high temperatures. And now, gas service specialists strongly do not recommend using them for gas water heaters and boilers.

Advice. If you have already purchased corrugated aluminum pipes, use them for ductwork. For example, to connect a kitchen hood to a ventilation system.

stainless steel

Corrugated stainless steel chimneys are similar in design to aluminum chimneys, but their characteristics are much superior to them.

Without serious damage to the material and design, they can operate at very high temperatures (up to 900 degrees), effectively removing combustion products not only from gas appliances, but also from boilers, stoves and fireplaces for liquid and solid fuels.

Corrugated PVC pipes

This type of corrugated pipes provides protection against mechanical damage to cables and electric shock, so they are used for laying computer, telephone, television networks.Pipes are made from a composition of non-combustible polyvinyl chloride or polyethylene, low and high pressure. The metal wire in the composition provides flexibility and ease of installation. Corrugated PVC pipes can be installed under concrete pouring or in a cement screed, which is why they are so popular among consumers. Pipes are easy to store, their shelf life is at least two years, and there are no difficulties with delivery, they are transported in the form of cellophane coils.

Box for pipes made of metal, MDF, solid wood

4 624 rubles

6 155 rubles

Box for MDF pipes

$5,796

Box for MDF pipes

7 748 rubles

Box for MDF pipes

7 747 rubles

Box for MDF pipes

9 134 rubles

A metal decorative perforated box is a good option for decorating heating pipes. A perforated box for heating pipes is made individually, on order, according to drawings (sketches) specifically for each customer. Any color according to RAL classification. The base color is white. The box for heating pipes is made both entirely from perforated metal and from combined metal, that is, one part of the box is made of solid metal, and the other part is made of perforated metal of any perforation.

Types of perforations:

Various perforation of the box for heating pipes solves not only a decorative task, hiding from the eyes passing pipes and other plumbing elements - valves, branchings, counters, etc. but also supports the circulation of warm air in the room coming from the heating pipes. Perforated and combined boxes for heating pipes not only perfectly retain their shape and color when exposed to temperature changes, when heating is turned on and off, but when used correctly, they are reliable and durable. They are used for decorating pipes in various premises - apartments and private houses, kindergartens and schools, cafes and restaurants, shops and public buildings, as well as in any other premises for various purposes.

What are decorative boxes for heating pipes:

Decorative boxes for heating pipes are made of perforated metal of various perforations and colors. If necessary, cutouts are made in them for pipes or hatches for access to valves. Pipe boxes are of the following types:

- Rectangular - U-shaped with right angles. Scheme (A)

- U - shaped with rounded corners. Scheme (B)

- rounded. Scheme (B)

- L-shaped, for pipes in the corner of the room. Scheme (D)

If necessary, a hatch can be mounted in a perforated box for heating pipes for easy access to plumbing valves, pipe branching, meters and plugs.

|

U-shaped metal box

U-shaped boxCorners inside

U-shaped boxOutside corners

U-shaped box Mesh hem

U-shaped boxCorners inside

U-shaped boxOutside corners

U-shaped box Mesh hem

L-shaped metal box

L-shaped boxCorners inside

L-shaped boxOutside corners

L-shaped box Mesh hem

L-shaped boxCorners inside

L-shaped boxOutside corners

L-shaped box Mesh hem

Docking of metal boxes

|

Methods for fastening boxes for heating pipes made of metal:

Depending on the desire of the customer and the constructive technical feasibility, there are the following ways of fastening perforated boxes for heating pipes:

- corners inside. (The corner is solid metal.)

- corners out. (The corner is solid metal.)

- Armstrong hem. (Perforated metal is bent.)

These fastening methods are used for any ducts for heating pipes of all types - "L" shaped, "P" shaped - rectangular, "P" shaped - with rounded corners and rounded. The choice of mounting method is agreed with the measurer during the measurement when drawing up the terms of reference and must be indicated in the drawing (sketch).

Product colors:

As we said above, different colors according to RAL. The powder coating method is used, which has several advantages:

- withstands high temperatures

- does not change color under the influence of ultraviolet (does not fade)

- environmentally friendly and safe for health.

Pipe installation

Installation of a warm floor is carried out in several stages:

- choice of piping scheme;

- calculation of the length of pipes and the number of fittings;

- pipe laying.

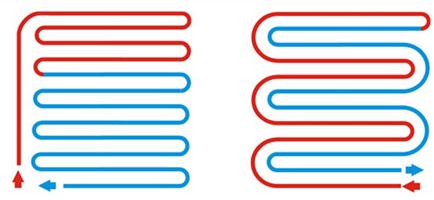

Pipe laying plans

Before proceeding with laying, it is necessary to determine the layout of the heating elements, which will help to calculate the number of pipes and fittings. Pipes when arranging the floor can be located:

in the form of a "snake";

The first way to arrange floor heating pipes

in the form of a spiral.

The second way of arranging pipes for underfloor heating

Spiral laying of the pipeline contributes to a more uniform heating of the floor and minimizes the number of kinks.

Calculation of the length of pipes and fittings

After choosing the layout of the pipes, you can begin to calculate the required materials, which is performed as follows:

- To calculate the length of the pipes, it is recommended to draw up a diagram of a warm floor on graph paper.

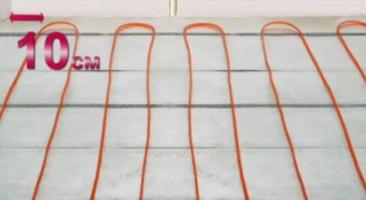

- When calculating, it must be taken into account that the smaller the distance between the turns of the pipes, the more the floor will warm up. It has been proven that a pipe with a diameter of 16-20 mm is capable of heating a layer of concrete of 10 cm. Thus, for normal heating, it is enough to make a distance between the turns of 10 cm and retreat the same distance from walls and furniture that is not planned to be moved.

It is recommended to reduce the distance between the turns in the areas of the external walls, since it is there that the greatest heating is required.

Recommended distance between pipes

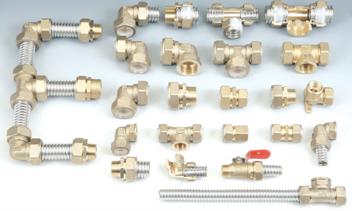

Corrugation for underfloor heating is sold in bays of a certain length. Fittings are used for pipe joints. The number of required fittings is calculated based on the required number of connections.

Various fittings for assembling corrugated pipes into a single structure

Pipe laying

Installation of pipes of the underfloor heating system is carried out according to the following scheme:

- heat-insulating material is laid on the concrete slab around the entire perimeter, it is advisable to use foil insulation. The joints of the heat insulator are glued with a special tape;

Laying thermal insulation material

- it is recommended to install a damper tape along the perimeter of the room, which helps to compensate for the expansion of the floor;

Floor Expansion Tape

- a reinforcing mesh is laid on the prepared floor. It is recommended to use a grid with a cell of 4-5 mm. Between themselves, the mesh cuts are fastened with a metal wire;

Installation of reinforcing mesh around the perimeter of the room

- corrugated pipes are attached to the grid with clamps according to the selected scheme;

Device for fixing the pipe to the grid

- floor is being poured.

The final stage of manufacturing a warm floor

The technology for installing pipes for underfloor heating is presented in the video.

Before pouring the floor, it is required to connect the pipes to the heater and test the system.

Making a warm water floor from corrugated pipes is a fairly easy procedure and can be done by non-professional craftsmen. When arranging a warm floor, the main thing is to correctly calculate the amount of materials and follow all the rules for laying and connecting pipes.

Varieties of casings on the chimney pipe

To date, the most popular two options for the execution of such casings. Consider them:

- galvanized casing for pipes;

- corrugated cover, which is made of stainless steel.

The chimney case made of galvanized steel sheet is the most popular. Galvanization has high fire resistance, corrosion resistance and long service life. The galvanized casing is easy to install, which is also a very important factor influencing the popularity of this product. Such products are made from a sheet of galvanized steel with a thickness of 0.45 mm.

The corrugated stainless steel case is also easy to install and has one very important advantage - the design of the corrugated box allows you to bend it, give it the desired shape, which is very convenient. Such a casing is resistant to corrosion and temperature extremes.

It is best to use chimney casings, which are made of metal that is resistant to corrosion.

Protective cases can perform the function of organizing thermal insulation for the chimney. Casings for thermal insulation of chimneys can be made from different materials with your own hands.Consider these materials:

- galvanization;

- roofing iron;

- aluminum;

- plastic;

- profiled sheet;

- slate.

When insulating the chimney on the roof, a suitable thermal insulation material must be used. The heat insulator is selected individually for a specific situation. When choosing a thermal insulation material, it is worth considering the following indicators:

- chimney pipe material;

- the heating temperature of the chimney on the roof;

- temperature stability of the insulating material.

The thermal insulation material must be resistant to the heating temperature of the chimney in order to avoid ignition. Particular care must be taken when choosing a heat insulator if you install a casing made of polymer material. A plastic pipe box is easy to install, however, it is considered the least safe option, so you need to provide the necessary thermal insulation for the chimney, taking into account all fire safety rules and regulations.

The protective structure can have a decorative finish

What are the protective covers for chimney pipes

Galvanized pipe casing

Will last a very long time. Such a casing is fire resistant and fireproof. Such a pipe heats up quickly, which provides good traction. Plus, it's easy to install.

Corrugated box for chimney pipes

Very convenient for installation. It can be bent and given the desired shape. Usually made from stainless steel. Resistant to temperature extremes, it is not afraid of corrosion.

Pipe insulation shell

Can be galvanized, aluminum, stainless steel. Such a metal casing has a number of advantages. For example, it is completely ready for installation, it is easy to install, durable and aesthetically pleasing.

It is best to order a protective casing for the pipe from professionals who can be contacted through the website on the Internet. There you can also see photos of finished products and read reviews from other buyers.

The casings designed by us will hermetically protect the pipe and give a beautiful appearance to the entire roof. Pipe covers are perfect for any roof structure; whether it is metal, profile, soft roofs, copper or galvanized roof coverings, natural tiles.

Order aprons and casings for pipes

At your request, we measure, design, design, order the necessary materials, both in Russia and abroad (if necessary), deliver and install on a turnkey basis.

Thanks to the pipe covers, a spectacular and quick finish around the chimneys is possible.

Decorative overlays for pipes are details that allow you to turn engineering communications elements that do not fit into the interior of the premises into an organic component of the overall design. For various reasons, it is necessary to resort to decoration in order to hide protruding structures that violate the overall impression of the room without interfering with their normal functioning.

Decorative strips are used to close the passage of the pipe through the floor or ceiling.

Heating how to achieve decorative design

To decorate the pipes in the toilet, you can use several methods:

- install false walls. Plasterboard panels are installed on a metal or rack frame, which close the pipeline. For pipes in the toilet, in this case, you will also need an overhead decorative element to ensure air circulation. You can use simple ventilation grilles;

- apply universal overlays. To install a plastic box or decorative panel, you can use commercially available ready-made models or make your own design. If a minor modernization is necessary, designed to hide irregularities, they resort to using a decorative bypass for heating pipes.Decorative rings for heating pipes were originally used for the sole purpose of covering an uneven undercut on a stretch ceiling. It turned out that the decorative pipe bypass can be used in many other situations, due to the fact that it is easy to install, and the appearance is very attractive;

- decorative coating can be created from heat-resistant fabric;

- the pipe is wrapped with hemp or jute rope;

- painting is considered a universal option for decorating pipes for all occasions, opening up considerable scope for the manifestation of imagination when combining colors and / or choosing a plot and color scheme for a picture.

The battery is easiest to hide behind a screen made of wood, fabric or metal

To hide the radiator, which is a requirement in many public places such as hospitals and schools, the following can be used:

- Metal panel, for the manufacture of which galvanized or stainless steel is used. The panel is installed front or with side walls.

- Installation of a wooden decorative screen that does not come into contact with the battery, or a designer decorative radiator.