Installation subtleties

Thermal insulation using technoplex is not a complex procedure that requires special skills and knowledge. Such work can be performed by anyone, even those who are not familiar with the basics of finishing work. The plates are put on glue, or fixed with plastic dowels, which greatly simplifies the installation process. However, for high-quality wall insulation, experts recommend following these rules:

The heater is laid only on a flat surface. Therefore, before starting work, it is necessary to knock down all the protrusions of the solution from the walls.

In order for the row to lie flat, it is recommended to mark the starting line on the wall using a laser level. Further slabs will be easier to set up - technoplex is characterized by ideal geometry.

The first plate must be aligned strictly along the marked line, drill a through hole for the dowel in the center. Having achieved absolute symmetry, the corners are also fixed with fasteners.

The seams between the insulation elements can be filled with silicone sealant.

Before finishing the walls, the insulation is covered with a fiberglass reinforcing mesh and a layer of plaster.

Technical characteristics of the technoplex

Visually, the material is made in the form of a smooth plate, somewhat similar to foam. In the section you can see many small pores.

Technoplex is distinguished by its thermal insulation properties and durability, which means that the insulation will turn out to be of really high quality. Moreover, the material tolerates a huge range of temperatures without losing its qualities.

Technoplex is not subject to decay and is resistant to various chemicals. Since its structure is represented by tightly pressed cells, the thermal conductivity of the plate will remain even at high humidity.

It should be noted that the strength index of the technoplex depends on the thickness, but freezing or thawing does not affect the basic properties. Technoplex processing before installation will not cause any difficulties. The material can be cut using a construction knife. The installation work itself is carried out in all weather conditions, but only the appropriate glue is suitable for fixing the material.

The main characteristics of the technoplex:

- increased strength;

- a large assortment;

- resistance to moisture;

- non-combustion;

- excellent thermal insulation properties.

Manufacturers

There is fierce competition in the construction market, however, not as many companies are engaged in the production of technoplex as the consumer would like. Consider a list of the main suppliers of extruded insulation in the Russian market.

TECHNONICOL. The company is included in the TOP-100 largest enterprises in Russia, and has several production lines in the country. Let out production attracts buyers by rather low price and high quality.

URSA. A relatively young brand that appeared on the market in 2003. At the beginning of its development, the company was engaged in the production of mineral wool from fiberglass. After merging with the Spanish company URALITA, lines for the production of extruded polystyrene were launched. Now it is one of the leading European brands, actively developing the Russian building materials market.

RAVATHERM. The trademark belongs to a Belgian company with production lines in the Moscow region. Finished products are subjected to multi-stage quality control, therefore, they invariably have high technical characteristics.

It should be noted that the products of these enterprises have international certificates and are absolutely environmentally safe.

1 Comparison of materials

Extruded polystyrene foam (aka Penoplex insulation) refers to the so-called "tiled heat insulators".Penoplex is made by the "extrusion" technology from polystyrene material.

Thanks to this method, it is possible to achieve a uniform distribution of the structure of the heat-insulating material, which consists of a huge number of tiny cells filled with air.

During the manufacture of granules of Polystyrene, the future Penoplex, are mixed at enormous temperatures and strong pressure. During this process, a blowing agent is added to the mixture, which, in fact, is light freon with carbon dioxide. Next, the extruder is extruded.

At the exit, we have the same Penoplex, which has quite serious thermal insulation properties.

Technoplex is produced somewhat differently and resembles a self-adhesive foil sealing thermal insulation. It, like Penoplex, is a tiled heat-insulating material. When it is created, special graphite nanoparticles are added to extruded polystyrene foam.

Thanks to them, the produced heat-insulating material decreases even more in thermal conductivity, while, by the way, its strength also increases.

In fact, both heat-insulating materials, Technoplex and Penoplex, are environmentally safe. In addition, both Technoplex and Penoplex are safe non-combustible materials. They practically do not dissolve either in water or in soil (soil).

Thermal insulation material Penoplex

1.1 Strength of materials

The strength of the described materials is easy to compare using specialized equipment.

So, in terms of the mechanical strength for banal compression at ten percent deformation, the heat-insulating material with Penoplex, type 35, shows exactly the same final results as the most popular Technoplex of the XPS30-200 Standard brand.

The final value for Technoplex and Penoplex is always the same - 250 kPa, which is better than that of foil insulation. By the way, this indicator completely depends on the density of heat-insulating plates.

The tensile strength with strong static bending of the Penoplex material is on average 0.4 - 0.7 MPa. Exactly the same parameter for Technoplex insulation is equal to 0.3 MPa.

And here we can immediately draw the final conclusion that Penoplex is somewhat more resistant to strong static bending, since, obviously, it can withstand a much more serious load than Technoplex.

1.2 Operating temperatures

The optimal working temperature of Penoplex is between -50 and +75 degrees Celsius, while the optimal temperature for operation of Technoplex is between -70 and +75 degrees Celsius.

1.3 Thermal conductivity and water absorption

The thermal conductivity parameter of Penoplex is guided by the type and conditions of its operation, but on average the indicator does not exceed 0.028 - 0.031 W / mK. The same indicator for the heat-insulating material "Technoplex" under the same operating conditions is approximately equal to 0.031 W / mK.

Essentially, both of these thermal insulation materials are equally effective in this parameter.

The water absorption of the Technoplex material does not exceed 0.2% by its own volume in twenty-four hours. Whereas the water absorption of the material "Penoplex" under the same condition is much less, and is only 0.1% (as in thermal insulation with cork insulation).

Thermal insulation boards Technoplex

In addition, Penoplex, if immersed in liquid for 28 days, after this period of time, the volume will increase by only 0.2%. And this suggests that Penoplex has an extremely low water absorption parameter.

Moreover, this heat-insulating material can retain its operational properties even after a huge number of “defrost-freeze” cycles.

1.4 Price issue

If we judge which material is better, Penoplex or Technoplex, strictly according to their price indicators, then, obviously, the heat-insulating material Penoplex wins. And this despite the fact that the difference in price between them does not exceed 10%.

However, no matter how small it may seem, in the end, when purchasing Penoplex, you can save a fairly large amount of money.

Naturally, depending on the region and country, the prices for these heat-insulating materials will differ somewhat, but in general, the trend in the price indicator is quite obvious.

Summing up, we can confidently state that there are practically no differences between the two tested thermal insulation materials.

Expanded polystyrene what is it

Penoplex is produced by the company of the same name. She creates insulation material using a special technology: extruded polystyrene is foamed under high pressure. The same applies to the technology of creating Technoplex, according to open sources. It is produced by TechnoNIKOL. As for the rest of the details of the process of creating Penoplex and TechnoNIKOL heaters, nothing is reported about them. True, fragmentary data lead us to the following thoughts:

- Polystyrene granules, which are the main raw materials, are mixed with a gasifier. The mixture is heated to a high temperature and forced through small holes. At the same time, polystyrene granules must be of high purity.

- As the mixture passes through the micro-perforated nozzle, the flow begins to break up into microscopic filaments. In this case, the polymer molecules are pulled out, which form a connection with each other. And thanks to the pressure, they begin to harden.

- When the polypropylene comes out of the nozzle, it starts to foam and forms a porous material with thousands of small bubbles.

It turns out that according to the technology of creation it is impossible to say which Penoplex or TechnoNIKOL is better. They are almost the same, the difference lies in the composition and strength. If you believe the TechnoNIKOL company, then the composition of their products, namely Technoplex, is enriched with a proportion of amphora carbon or graphite. In such a case, the rolling rolls can better form the material of the final shape and thickness.

So, Penoplex is made by extrusion. And Technoplex, due to the inclusion of graphite nanoparticles, increases the strength of the material, and its thermal conductivity decreases even more. Both the first and second material are environmentally safe. They are safe and non-flammable. The materials will not dissolve in water or soil.

The usual technology of creation involves the use of light freons mixed with carbon dioxide as a vapor-generating gas. As for the new creation methods, which are much better. For their implementation, liquid and powder gas-forming agents are used.

Is penoplex dangerous in case of fire

You need to figure out whether extruded polystyrene foam is dangerous in a fire. Previously, all types of foam plastic belonged to the group of materials with normal flammability or highly combustible properties. Such materials, in addition to their combustibility, emitted dangerous gases, which made the penoplex especially dangerous in case of fire. But recently, manufacturers have switched to the technology for the production of class G1 foam, that is, slightly combustible. The insulation received such properties due to the addition of a flame retardant, a substance that can increase the resistance of building materials to open fire. According to the statement of experts, the new penoplex does not emit harmful substances, it, like wood, emits only carbon dioxide and carbon gases. But even with such statements by manufacturers, buyers are not inclined to believe them. All due to the fact that, according to state standards, extruded polystyrene foam cannot be slightly combustible. And all its species belong to the G3 or G4 group.

Technoplex expanded polystyrene production technology and scope

Technoplex insulation has a cellular structure and is resistant to moisture. It also does not shrink, which makes it a more optimal material for insulation than ecowool.

The scope of the material is the insulation of balconies, outbuildings, private houses, renovation of residential premises and internal insulation (for example, if the facade is lined with sandwich panels, insulation is installed under them). Also, Technoplex boards are used as a substrate for a “warm water floor”. Installation is carried out on polystyrene glue. Glued insulation provides reliable thermal insulation.

To ensure the thermal insulation of foundations in cottage construction, Carbon (XPS Carbon) is used.

In the production of insulation of this brand, extruded polystyrene foam is used, the granules of which are mixed with a foaming agent. This process requires high pressure and temperature.

Styrofoam

In accordance with the generally accepted classification, it has a flammability class G1, G2. However, it has the ability to slowly smolder, releasing very toxic fumes containing styrene.

Numerous tests carried out with foam plastic allow us to draw the following conclusions:

- polystyrene foam has the property of self-extinguishing, which means that in the absence of a constant source of flame it will not burn;

- most types of foam plastic during the combustion process are deformed only in the part where the open flame was exposed;

- has the ability to smolder, emitting poisonous smoke;

- the height of an open fire during combustion reaches a maximum after 3-5 seconds, and then the process of smoldering and self-extinguishing begins.

The use of extruded polystyrene foam, installation nuances

Technoplex products are effective thermal insulation of buildings in all areas:

- foundation;

- facades and interior walls;

- overlaps;

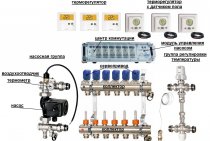

- screed floor, wooden flooring, "warm floor" system;

- balconies, garages, loggias.

High-density slabs 45 kg/m3 are used in the modernization of roads.

For outdoor mounting, sheets with a thickness of 100 mm are used. Before fixing them, the walls are leveled and treated with a primer. The insulation is fixed with a special glue for polystyrene foam. The plates are laid from below, tightly joining each other. Each next row is performed with an offset of half the sheet. After the glue has dried, Technoplex is additionally fixed with plastic dowels. Outside the insulation, fiberglass reinforcement and plastering are applied.

Durable and moisture-resistant XPS boards are used for floor insulation on the ground under a concrete screed. When installing extruded polystyrene foam under a warm floor system, energy losses are reduced. Insulation plates are laid on a screed and covered with plastic wrap. A substrate with a layer of foil is laid on top of it, and cable mats are mounted. The entire system is filled with concrete screed.

When insulating the floor along the logs, expanded polystyrene sheets are laid on a waterproofing layer placed between wooden blocks. The joints of the plates are covered with mounting foam.

Technoplex does not change its properties even in difficult operating conditions, it is installed as thermal insulation of the underground area of the blind area and the foundation of the house.

What the experts say

Of course, we would like all our reasoning to be supported by the opinion of people who are engaged in research.

Roman Eberstaller

, production manager of the Austrian Sunpor plant says:

The argument seems convincing, doesn't it? If we are not afraid to take sweets from the supermarket shelf that lie on a foam substrate, should we be afraid to insulate the wall of the house with them?

As a counterbalancing argument, the following can be cited:

- People have invented a great, economical and seemingly harmless plastic. But, the interiors of expensive cars are trimmed with natural

skin; - People came up with inexpensive chipboard.MDF, but expensive furniture is still made from natural

tree.

Did you get the gist? All modern technologies are mainly aimed at cost-effective solutions. And this means that the BEST QUALITY remains natural. It is not entirely fair to expect the environmental friendliness of linen insulation from expanded polystyrene. But, no one canceled the issue of finance. And expanded polystyrene remains the most-most in terms of price-quality ratio. This means that decisions should be made taking into account financial possibilities. If you haven't carefully chosen where you live on the planet, read books on nutrition, and don't exercise every day, foam insulation is unlikely to be your family's worst enemy. If you are scrupulous and even pedantic about health, it may be worth focusing on choosing a more natural insulation. Although the conversation about the harmfulness of polystyrene could be continued, there are already plenty of thoughts for reflection.

Please remember the example about children at the beginning of the article. Now it is clear to us that the harm of polystyrene is not a childish issue. And yet we have the principles and facts that are sufficient to decide on our own home.

The video below shows some of the properties of penoplex. In it, the guys conclude that penoplex is not harmful to health. But, when melted, its toxicity, of course, is unambiguous.

Penoleks is a type of heat-insulating materials, which is an extruded polystyrene foam. Most people, choosing the right insulation for the home, are guided by various characteristics of the material. Many are interested in low price, some prefer ease of installation, and only a small part thinks about environmental safety and fire resistance. What are the characteristics of penoplex, is it combustible or completely non-combustible? Strange, but there are a lot of opinions about this indicator, so it’s worth understanding the fire safety of foam plastic in more detail.

Easy to use, easy to buy

Penoplex is produced at factories under the same name in Perm, the Leningrad Region (Kirishi), Novosibirsk, Taganrog and Irkutsk. This manufacturer has 10 official representative offices in all federal districts of Russia.

Technoplex is produced at the enterprises of the TechnoNIKOL group of companies in Mineralnye Vody, Novoulyanovsk, Uchaly (Bashkortostan), Ryazan, Yurga (Khanty-Mansi Autonomous Okrug). And also has 10 representatives throughout Russia.

Both manufacturers have their dealers in each regional (regional) center, as well as in large cities of the regions.

Characteristics of different types of extruded polystyrene foam

If you are interested in TechnoNIKOL expanded polystyrene, then you should familiarize yourself with its main varieties that the manufacturer offers for sale. To solve everyday problems, you can use XPS Carbon Eco, which is used in the construction of private cottages and low-rise houses. You can buy this material by paying 3,300 rubles per cubic meter.

XPS CARBON Eco Drain is a slab equipped with drainage channels. These canvases are used in the construction of a flat roof and the formation of the foundation. The grooves in the material allow the removal of melt water, providing intensive ventilation.

If there is a need to carry out work in the area of \u200b\u200bthe basement or facade of the building, then XPS CARBON Eco Fas should be purchased, the price of which is 4000 rubles per cubic meter. For thermal insulation of floors, as well as foundations, you can use one of the varieties of expanded polystyrene - CARBON Eco SP, which is characterized by high rigidity and strength. For a canvas of a ten-millimeter layer, you will have to pay about 4300 rubles. per cubic meter.

Heat conduction and moisture absorption

The coefficient of thermal conductivity is one of the main parameters for a heater.The thermal conductivity parameter of the first is on average in the range from 0.028 to 0.031 W / mK, it all depends on the operating conditions. The second has an identical thermal conductivity parameter of 0.031 W/mK. It turns out that the effectiveness of materials in this area is the same.

The same applies to water absorption materials. The first has an indicator of up to 0.2% of the volume per day, as well as the second. This is really surprising and shows that each of the materials perfectly copes with moisture and resists it. So if anyone asks Penoplex or mineral wool which is better, then we can say with certainty that the first option. When wet, mineral wool loses its properties.

Internal wall insulation with technoplex

Experts recommend leaving a small gap between the wall and the insulation itself. This will help reduce heat loss, but will lead to a decrease in the area of \u200b\u200bhousing. It is better to leave a distance after all, because this will provide natural ventilation. Accordingly, the condensate will not penetrate inside, which means that the humidity level in the room will remain optimal. This will help to avoid rotting, and the walls of the house will dry out very quickly after the rain.

When the insulation work using the technoplex is completed, the wall surface must be finished. For these purposes, a wooden crate is often used. It is also allowed to use drywall sheets, which are subsequently covered with paint or wallpapered.

Among the variety of modern heaters, special attention should be paid to the technoplex. This material has excellent thermal insulation properties, thanks to which you can insulate your home both inside and out.

In this case, the help of professionals is not required.

Fire hazard and flammability group

Extruded polystyrene foam brand Penoplex 35 is produced in sheets 600 mm wide and 23 to 100 mm thick.

Penoplex, we have already mentioned this, in general, is resistant to high and low temperatures. In addition, it is also considered resistant to open fire. The declared flammability group for foam 35 is G1.

So far, no one has officially denied this, although there are other private opinions on this matter. Some experts question this figure, considering that extruded polystyrene foam, which is actually foam, a priori, can hardly have such a combustibility group, believing that the maximum that should be assigned to it is G3, G4. The logic in this message is as follows: “All materials based on expanded polystyrenes are classified as G3 or G4 in terms of combustibility. So if for some reason we saw the flammability class G1, G2 in the certificate, then this is most likely an erroneous indicator. These materials are classified as highly flammable (in the best case, moderately flammable). At the same time, they should also be considered as representing a high danger in terms of toxicity of combustion products with high smoke-forming properties. This point of view is well reasoned and has the right to exist.

At the same time, as we see in practice, foam-35 slabs are optimally suited for thermal insulation of various types of enclosing structures and structures, incl. exploited and ordinary roofs, foundations (including shallow ones), walls, floors, etc. In the manufacture of foam-35, to increase the resistance to combustion in the raw material, the manufacturer added an effective fire retardant with a special additive patented by the manufacturer.As for the results of test tests that were carried out by some fire safety centers, they showed that foam 35 foam boards correspond to low-combustible materials in their fire-technical qualities (according to GOST 30244-94). They were also classified as slow-burning materials (according to ST SEV 2437-80). Penoplex is characterized as a material that does not spread flame over the surface. Also, according to the results of the experiments, foam-35 is defined as a moderately flammable material, however, with a rather high ability to smoke.

During combustion, extruded polystyrene foam emits, as tests show, two types of gases (carbon monoxide CO and carbon dioxide CO2). Exactly like wood. This is its difference from many organic heat insulators, which emit a whole range of substances hazardous to health into the atmosphere.

I think it will be useful for someone to watch a video about using foam-35 sheets:

Insulation material made of extruded polystyrene foam is a well-known polystyrene foam. It was invented by the Dow Chemical Company in the USA in 1941 and was first used as a non-sinking component in lifeboats and boats in the Navy. Over time, penoplex began to be used to reduce the thermal conductivity of structures, it was improved and modified. To date, there are several varieties that have high efficiency, which determines the demand of consumers.

Combustibility of extruded polystyrene foam, read on penoboard.com

Fire safety when using expanded polystyrene

Today, polystyrene foam is widely used in the construction industry. Potential buyers are often interested in the level of its fire resistance. Opinions here are different - some consider such material to be slightly combustible, while others claim that it is highly flammable. What is the flammability group of expanded polystyrene actually?

Classification of heaters

- NG - surfaces do not ignite even under the influence of open fire;

- G1 - burn very weakly;

- G2 - options with a moderate level of flammability;

- G3 - with normal;

- G4 - substances that burn strongly during a fire.

In most cases, the combustibility group of extruded polystyrene foam is G3 and G4. It turns out that usually it belongs to normally and strongly combustible substances. It is worth noting that some manufacturers deliberately mislead buyers with statements that the combustion class of expanded polystyrene is G1 (low combustible). In this case, we may not be talking about an extruded version, but about ordinary foam. However, most experts are of the opinion that the flammability group of expanded polystyrene cannot be lower than G3.

At the same time, new materials are constantly appearing on the market. Manufacturers are actively working to reduce the flammability class of expanded polystyrene. The company Elit-Plast LLC relatively recently released products under the Penoboard brand. A flame retardant additive was included in the composition of such material. Due to such changes, the fire hazard class of expanded polystyrene was reduced to G1. The new product (Penoboard) received the corresponding certificate.

It should be noted that the company's innovative solutions not only reduced the flammability of extruded polystyrene foam. They also increased the degree of its environmental safety. Penoboard does not emit toxic substances during combustion - only carbon monoxide and carbon dioxide.

Several safety rules

Experienced builders recommend using structures in which polystyrene foam has a minimum chance of direct contact with an open flame. Insulation with the addition of flame retardants is considered self-extinguishing. The packaging has a special marking that indicates this.If direct contact with fire ceases, the material ceases to burn after a while. Insulation should in no case be used for thermal insulation of saunas, baths, as well as heating mains. The combustion temperature of expanded polystyrene is from 80 degrees.

As practice shows, in the event of a fire, structures for which such material was used for insulation can withstand at least fifteen minutes of flame action (without a direct threat of being destroyed). This time is enough for the safe evacuation of people. The self-extinguishing version loses its shape during the combustion process and literally flows off the surface of the structure. At the same time, its drops are not able to set fire even to flammable materials - for example, paper.

Special offer

Today, extruded polystyrene foam is increasingly being used to insulate various rooms. The flammability class of this material directly depends on its composition. If it contains flame retardant additives, then the level of fire safety increases significantly. In most cases, the combustion of extruded polystyrene foam is accompanied by the release of carbon dioxide, water vapor, and hydrogen chloride. These substances are very dangerous for humans, as they cause suffocation and pulmonary edema. The flame retardant option is much safer.

The degree of flammability of expanded polystyrene directly depends on the class assigned to it. The G1 group is very resistant to fire, while the G4 materials are highly flammable and ignite quite easily. The fire hazard of expanded polystyrene somewhat limits its scope. Many of these materials are used exclusively for insulation of the basement, foundation and floor. Expanded polystyrene Penoboard (unlike its competitors) can be used for processing walls and facades.

Buying extruded polystyrene from Elit-Plast LLC is a very practical solution. The material guarantees the safety of the structure and the person.

penoboard.com

Installation of extruded polystyrene foam

Installation of plates is carried out on glue for expanded polystyrene with additional fastening with dowel-fungi if necessary. Technoplex is warmer than foam block and other building materials, 50 mm of extrusion insulation replaces 600 mm of foam block. If we compare Technoplex with URSA XPS and other foreign analogues, then its cost is lower, with the same thermal conductivity characteristics.

Buildings should be insulated from the outside, the area of \u200b\u200bthe room in this case will remain the same. Work should begin with cleaning and surface preparation. The walls are cleaned of old paint or finishes, and then leveled with plaster. Further, starting from the bottom, the installation of insulation boards is carried out. Many put a basement starting profile, which additionally protects the insulation from rodents.

The plates are mounted end-to-end so that there are no cold bridges. After finishing the entire surface, a layer of mastic or glue for polystyrene foam is applied to the surface of the thermal insulation, on which a reinforcing mesh is glued. After drying, the surface is primed and the facade of the house is finished with plaster. Also, the facade can be sheathed with vinyl siding or decorative PVC panels.

Is foam dangerous for internal insulation

To put it simply, it all depends on the correct use. If the foam does not crumble when exposed to heat, such as batteries nearby or exposed to harmful substances, it can be considered safe. But, there are three indirect points that are worth considering when considering the use of this material indoors.

-

Styrofoam burns or not?

The flammability of polystyrene causes a lot of controversy. In short, since the material is 90% air, it does not burn. Rather, it can be said that the combustion of foam is a melting process. Of course, toxic substances are released during melting.Therefore, even non-combustible foam is a material that melts. This means that the insulation must be protected from all sides by non-combustible substances, for example, plaster or used as a filling for sandwich panels. Harmful Styrofoam - Melting Styrofoam. -

Mice and other rodents.

Although these animals do not eat styrofoam, they actively gnaw on it to create a home for themselves. - Mold.

Since the foam does not transmit heat, if cold air enters on one side, condensation forms between the wall and the insulation. A humid environment is great for bacteria and fungus to grow. It doesn't seem worth explaining that mold has a very negative effect on health.

If there is foam insulation on the walls inside, will it be harmful to be in the room? As with the use of the material, outside, its safe use inside depends on the application of the instructions.

As a conclusion: polystyrene, the harm of which is not confirmed by facts, can be considered safe.

Safe for me, safe for you

It is impossible not to compare both materials in terms of their impact on the environment and interaction with it. Whom to give preference to: penoplex or technoplex?

The fire hazard of materials is the same. They belong to the category of substances that support and propagate combustion. When they burn, a gas unsuitable for breathing is released into the atmosphere. Because of this, they are not recommended for use for insulation without taking additional measures to ensure fire safety, for example, treat thermite with a composition.

The chemical and biological activity of these heaters is the same due to the use of one source material: they are not afraid of contact with most building materials and solutions, they are not attacked by insects and rodents, they do not rot and do not spread fungus.

Both materials are destroyed by ultraviolet radiation, so their use without shelter is not recommended.

Conclusion

The main thing to remember is that the purchase of insulation treated with anti-foam does not guarantee complete fire safety. To maintain all its fire-fighting properties, the necessary installation and processing instructions must be observed. Most often, extruded polystyrene foam is used to insulate the floor, basement and foundation. It is strictly forbidden to use it for insulation of walls and facades. It is because of the fire hazard that this insulation cannot be used in all areas of construction. Fortunately, manufacturers are constantly working to improve it, using various production technologies and processing insulation with protective substances. Soon, penoplex will acquire all the necessary qualities for widespread use in the field of insulation of residential and industrial premises.

Penoplex, being literally a bright representative of a new generation of materials for thermal insulation, has already received worthy recognition in the circles of construction experts and ordinary users.

In fact, strictly speaking, penoplex is not something super-revolutionary, it is polystyrene foam in its essence. But with certain characteristic features that distinguish this material from the foam that is familiar to all of us.

The material solves the problem of heat conservation almost perfectly, according to the conclusion of construction organizations, it is optimal for solving many such problems. Many have already begun to consider foam plastic in civil and industrial construction as an almost indispensable material.And although we all know that there are no ideal materials, they all have their pros and cons, we recognize the fact of such an opinion and dwell deeper on its undeniable advantages:

- Low thermal conductivity - the most important indicator for insulation purposes;

- Minimum water absorption, which is characteristic of this material;

- High strength index.

As market statistics show, one of the types of expanded polystyrene produced under the penoplex brand has turned out to be one of the most popular among the Russian consumer from the entire product line. And it is especially popular for practical construction purposes, judging by the real requests of Internet users, its specific size is penoplex-35

. According to our research, it is technical specifications

are interested especially often and accordingly ask all sorts of questions to our specialists. We'll talk about penoplex-35 today.