Compare foamed polystyrene foam with other heaters

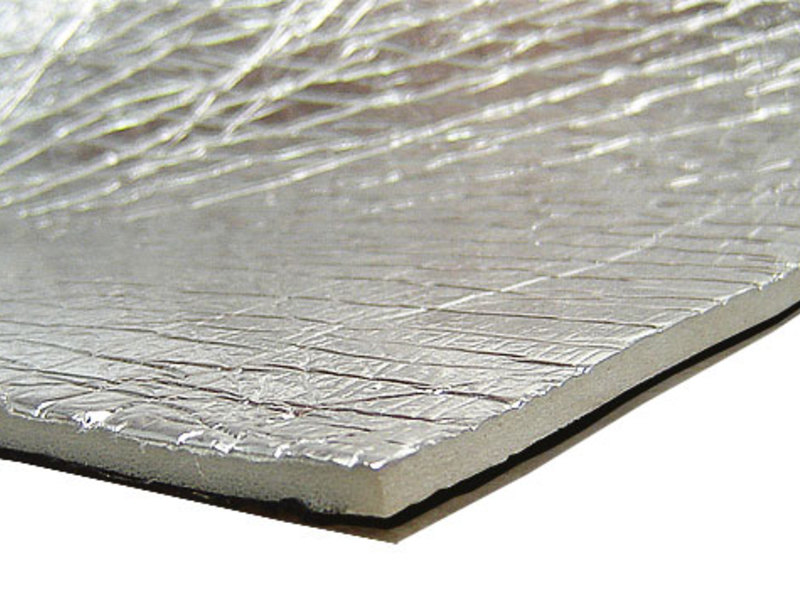

Felt and fiber insulation are considered the main competitor for such materials. Some prefer to use mineral wool, others - Technoplex or Penoplex. And which is better, foam or mineral wool for insulation? Each of the materials has its positive and negative properties. In the photo below you can see what features of expanded polystyrene foam.

Like mineral wool, they are durable, safe and environmentally friendly. True, the thermal insulation qualities and moisture absorption of mineral wool are worse.

Private one- and two-story premises are best treated with Penoplex. It's much more efficient. Mineral wool is used for finishing skyscrapers. The thing is, it doesn't burn at all. Fire retardant additives will not be able to save EPPS by 100%, mineral wool is better in this regard. However, it is not recommended to use it for wet and damp rooms.

Another competitor for EPPS is isolon. This is a heater made of foamed and modified polyethylene. Some people ask, Isolon or Penoplex, which is better? Isolon is suitable for insulating internal walls and ceilings of a building. And the thermal conductivity coefficients of the materials are almost the same. Isolon can withstand heating up to 80 degrees Celsius throughout the day. The material has excellent sound and noise insulation. It is safe and environmentally friendly. When heated, it will not emit harmful substances. The main drawback is the softness and flexibility of Izolon. Having laid it on the wall, it is required to fix it with drywall sheets or MDF boards. It is impossible to glue wallpaper on Izolon and plaster on it. That is why it is recommended to use it together with XPS insulation.

You can also find such queries on the network: Ravaterm or Penoplex which is better, Polispen or Penoplex which is better or Styrex or Penoplex which is better. It is impossible to answer the question unambiguously. All of them belong to EPPS and have almost identical characteristics. The difference is the price and some additional nuances.

Why is it necessary to make a vapor barrier when insulating with polystyrene foam

Since the humidity inside the building is higher than outside, the steam moves from an area where there is more of it (high pressure) to an area where it is less (low pressure). When it passes through a wall or insulation, on its way it can hit the dew point (the point at which the temperature of the wall corresponds to the value at which steam begins to condense, approximately 13-17 ° C).

When condensation occurs a short distance from the outer surface, this is normal. But when the dew point moves inside the structure, the wall freezes, and moisture gradually permeates the structure until it reaches the inner surface. Thus, the wall is "wet".

To avoid this, you must:

- move the dew point outside the wall. This can be achieved by insulating the walls from the outside, in which case the vapor barrier will not be needed; so that moisture does not penetrate inside the structure, when the dew point is closer to the inner surface, a vapor barrier is installed.

Advantages of sprayed insulation

A feature of the sprayed insulation is the simplicity of the insulation process. For this purpose, a high-pressure balloon installation is used, through which two structural components are sprayed, which, when combined, form a polyurethane foam.

The similarity of such a material, probably, was seen by many, using mounting foam to insulate window openings. Sprayed insulation for walls looks similar.

The sprayed insulation has a fairly light weight and can be applied with a layer of any thickness to a surface of any material without consequences.

4 Vapor barrier floor screed

With the floors, the situation is ambiguous and depends on the surrounding conditions. So, a screed on a balcony or loggia should be protected with a vapor barrier, but special conditions are formed there.

Interfloor ceilings from the side of the floor do not need to be protected. Several factors come into play here.

Firstly, the technology of installing foam on the floor itself makes it possible to fit and isolate it well. Secondly, the screed must be waterproofed, and the waterproofing layer also helps to protect against steam.

Yes, and it is worthwhile to understand that the load on the floors is very small, since according to the laws of physics, warm air and steam always tends up. At the bottom, it does not linger, being replaced by colder air.

Ceiling insulated with polystyrene boards

Again, all exceptions are the finishing of floors above a bathroom, bath, etc. Here, the amount of steam can reach critical levels and even pass through concrete interfloor ceilings.

The nuances of the use of foamed foam

Among the wide variety of modern materials, the insulation of walls, floors and roofing structures with casting foam is a fairly popular procedure. A distinctive feature that distinguishes this procedure from others is that there is no need to prepare the surface for these purposes. Transportation of equipment and raw materials to the construction site is carried out by car. For the object, the necessary conditions are the presence of a source of water and electricity.

Direct filling is carried out by means of a hose, the diameter of which should be 3.0 cm. With his participation, filling can be carried out even in the most remote and hard-to-reach places. The insulation is quite dense and of high quality. It is acceptable to apply foam on an insulated surface.

Wall insulation with this material is applicable to any surface, which will not affect the quality of work at all. It is also good to use this kind of insulation to fill voids with irregular geometry.

Wall insulation with foam

The procedure is carried out by pouring it into the space between two walls (outer and inner). This technology has 3 use cases:

- Pouring into the inter-wall space of an operated house. This procedure is performed when there is a gap of about 3-5 cm between the surfaces. Holes are formed in the surface with d 3.2 cm in a checkerboard pattern and with a distance of 1-2 mm. The solution is then poured under pressure through each hole until it is visible in the hole next to it.

- Pouring into the inter-wall space of a house under construction. Here the cavity is filled with a solution in several layers. Each layer is no more than 3 meters.

- Filling between false partitions and walls. A false partition can be a finishing coating of drywall, corrugated board, siding, plastic and others. In the same way, frame houses are insulated.

Floor insulation is carried out in the following sequence:

- Holes are drilled on the boards (diameter approximately 26 mm) through and through.

- Through the holes, the inner cavity under the floor is filled with a liquid composition.

- The foam that has come out is removed.

It is relatively inexpensive and has a sufficient number of advantages in relation to other insulating materials. This modern heat insulator stands out for its low weight, simple installation and long shelf life. Thermal insulation of apartments and houses with penoizol allows you to save the family budget when paying for heating.

Flat roof insulation

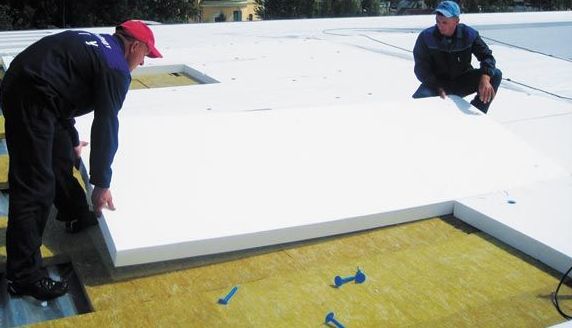

Styrofoam is usually insulated with flat roofs due to its resistance to mechanical stress.

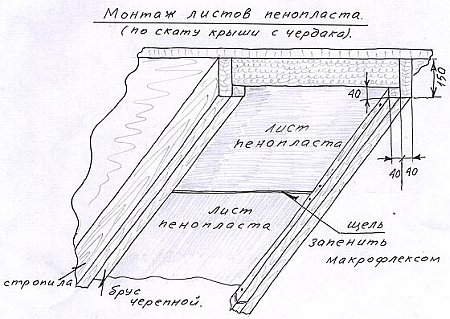

The material is also applicable for pitched roof types, but for them, experts often recommend the use of fibrous insulation. Mineral wool and glass wool better fill the under-roof space, which eliminates the appearance of cold bridges.

Preparatory work and waterproofing

Before arranging thermal insulation, it is necessary to prepare the surface to be insulated. It must be dry and clean. The old backfill is removed. Then the waterproofing film is laid.

This is necessary so that moisture does not accumulate between the insulation and the roof, which can lead to mold, rotting of wooden structures and corrosion of metal elements.

It is important to mount the film so that there is a gap of 2 cm between it and the crate to remove moisture

Insulation installation

Foam boards are laid on top of the waterproofing. You can fasten them with glue, liquid nails, anchors, dowels, flooring. For additional reliability, it is possible to mount in several ways at once.

When laying the insulation, it is necessary to ensure that there are no voids and the plates are tightly adjacent to each other.

The resulting cracks must be filled with mounting foam.

Coating with geotextile and gravel

The geotextile is laid on top of the foam boards. It protects the roof from the negative effects of the sun and reduces the effect of mechanical stress. As a result, the service life of the roof is increased.

Following the geotextile, there is a backfill of gravel, the fraction of which is 16/32. The layer thickness should be at least 5 cm. A cement-sand screed is made over the gravel.

Disadvantages of foam as a heater

Often the question arises, is it possible to insulate the roof with foam? Polystyrene vapors are toxic, but the finished material does not emit harmful substances. Polystyrene boards can present some danger when melted under the influence of an open flame. But it is worth noting that self-extinguishing foam plastic is used for the insulation of residential buildings - it does not support combustion and belongs to fireproof materials.

Expanded polystyrene sheets can be used to insulate pitched roofs, but in terms of functionality they are inferior to cotton wool insulation: rigid plates made of polymer material cannot always tightly fill the space between structures, as a result of which cold bridges form in places where there are voids and moisture condenses. Processing joints with construction foam or sealant does not guarantee one hundred percent protection. Condensation causes the destruction of wooden structures and metal fasteners.

The soundproofing qualities of expanded polystyrene are rated quite highly, but it is not quite suitable for thermal insulation of “noisy” metal roofs, as it dampens sound worse than cotton wool insulation.

Peculiarities

Expanded polystyrene is a universal heat insulator endowed with unique properties.

Advantages

The positive qualities of the material include the following:

- durability and strength (with high-quality installation, it will last at least 50 years, does not crumble, does not rot, does not decompose);

- low thermal conductivity;

- high thermal insulation (a 10 cm thick slab has the same thermal insulation properties as a one and a half meter brickwork);

- moisture resistance (the material absorbs no more than 6% of moisture and retains more than 90% of its properties);

- resistance to temperature extremes, ultraviolet, chemical and biological effects (mold, fungus does not form on it);

- frost resistance (withstands up to 50 freeze / thaw cycles and does not lose its physical and chemical characteristics);

- environmental friendliness (it is used even for food storage);

- fire safety (modern types of polystyrene do not support the combustion process, as they have been treated with fire retardants);

- simple installation technology (the purchase of expensive tools is not required, the material weighs little and is easy to cut);

- low cost.

Due to its high moisture resistance, expanded polystyrene does not need additional hydro- and vapor barrier. Unlike its main rival in the field of mineral wool insulation, foam plastic does not form dust during installation, so protection equipment (respirator, gloves, overalls) is not required to work with it.

Flaws

Styrofoam is spoiled by rodents, they make moves in it. As a protection of the house from them, even at the stage of facing, it is possible to lay poison in the form of grains or special capsules along the perimeter of the building, between the insulation layer and the facing material.

For a while, this will be enough. And, of course, it is necessary to install a base profile.

Today, customers are offered several brands of expanded polystyrene. They differ in the way of production and technical characteristics.

Pressed polystyrene

Domestic material, produced under the brands PS-1 or PS-4.

Differs in high density (60-600 kg/m3). Its area of application is radio engineering.

Non-press material

PSB, PSB-S - brands of expanded polystyrene of Russian manufacturers. The material has high physical and chemical properties. The scope of its application is the insulation of facades.

Pressed and non-pressed materials have one common drawback: at low temperatures, when moisture gets between the granules, they will begin to collapse.

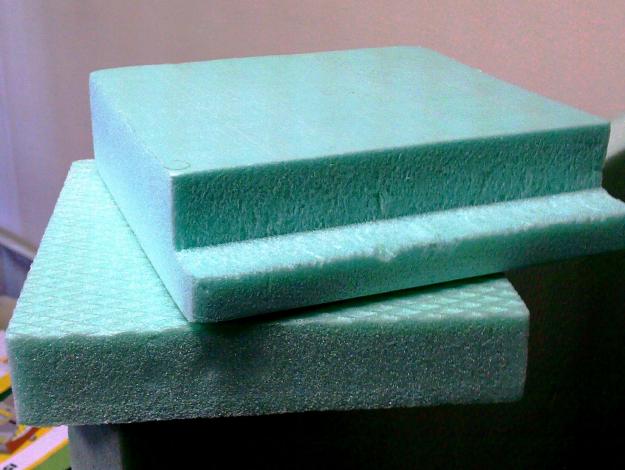

Extrusion insulation

This type of expanded polystyrene is most often used for thermal insulation of facades. It is very durable and strong, its service life reaches 80 years.

But unlike non-press material, it has a significant drawback: it contains residual styrene, which is harmful to health.

Domestic brands of extrusion insulation - Penoplex, TechnoNIKOL.

Adhesive selection options

Insulation is produced in the form of plates of various sizes. The scope of the material is extremely wide. It is used for thermal insulation of walls, ceilings, floors, as well as for insulation of roofs, facades and even foundations.

See the video for more details:

In order to choose the right way to glue penoplex, you need to take into account several parameters:

frost resistance of the composition is an important characteristic of the adhesive in cases when it comes to outdoor work;

the adhesive qualities of the composition must correspond to the characteristics of the insulated surface. Cement adhesive for foam plastic has the highest adhesion;

in rooms, the decoration of which should also perform a moisture-proof function, it is advisable to use compositions with a waterproofing function

Cement mixes in such conditions serve much less;

without the skills of installing foam, it is also necessary to take into account the rate of solidification of the composition. Polymeric materials seize in a few seconds, only experienced specialists can work with them;

the cost of the adhesive composition is also an important characteristic when choosing. In order to save money, preference can be given to dry mixes, which are significantly cheaper than a ready-to-use product.

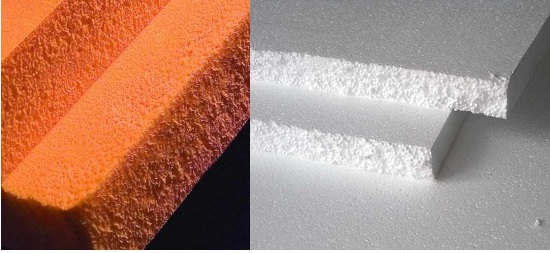

Extruded polystyrene foam

Penoplex has a bright and recognizable orange color.

Penoplex has excellent chemical resistance, but it is important to know that it absolutely does not resist gasoline (however, like Technoplex). Due to its good strength characteristics, Penoplex can be used for external insulation.

In the Penoplex line there are different types of it (their names speak for themselves):

- roofing (insulation of attics and roofs of various configurations);

- wall (insulate basement, walls, partitions, facade);

- foundation (used as a heater for the basement and the floor of the first floor);

- comfort (can be used for any work, but is especially well suited for warming apartments, balconies);

- 45 (has the best performance of all types, used in road construction and bridge building).

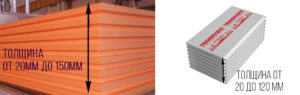

The manufacturer of Penoplex is Penoplex. Penoplex is produced in standard width and length - 600 mm by 1200 mm, respectively. But the thickness is different - from 20 mm to 150 mm.

Penoplex is operated at temperatures from -50 0 C to +75 0 C. Water absorption - 0.4% - is slightly worse than that of Technoplex, but still a very high figure. The thermal conductivity is 0.03 W/(m*K).

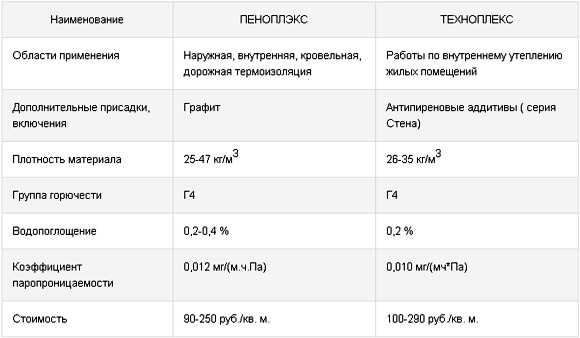

Comparison of Technoplex and Penoplex

In addition to the above, the composition of the materials includes antioxidants, stabilizers and antifoams that characterize the material. Penoplex and Technoplex what is the difference? Let's compare the specifications of the materials to answer this question:

- Area of use. Penoplex is used for external, internal, roofing and road thermal insulation. But Technoplex is used for internal insulation of residential buildings.

- The density of the material. At Penoplex, it is 25–47 kg / m 3. And Technoplex has a density of 26-35 kg / m 3.

- The flammability group of Penoplex and Technoplex is the same - G4.

- Moisture absorption. Penoplex has a water absorption coefficient of 0.2–0.4%, and Technoplex 0.2%.

- The vapor permeability coefficient is almost the same, for Penoplex it is 0.012 mg / (mchPa), for Technoplex it is 0.010 mg / (mchPa).

- Cost - the first can be bought for 90–250 rubles / m 2, and the second for 100–290 rubles / m 2.

But this is not all that can be said about the materials. Let's compare some specifications.

Advantages and disadvantages of wall insulation with liquid foam

This method of insulating houses, industrial buildings and outbuildings was made attractive and popular by the undoubted advantages of liquid foam:

- The fine-meshed, excellent steam-conducting foam texture actively passes moisture from the walls to the outside through its entire volume, making them dry and counteracting the accumulation of condensate and the development of accompanying fungal mold. This property classifies the material as "breathable", and this is a special value for any, and especially wooden, walls.

The fire safety of jellied polystyrene is quite high and has a combustibility not lower than the G-2 group. The material does not support combustion, and given the organic composition of the insulation, this phenomenon can be considered unique. In an open flame, the hardened foam is charred and loses its bulk, evaporating without forming molten drops, soot and toxic gases.

Penoizol tolerates fluctuations in air humidity and temperature perfectly, without changing its internal structure and at the same time having a rare durability. Studies have determined the service life of this insulation at the level of 60-80 years.

Like all heaters, filler foam has excellent soundproofing properties. A layer of Penoizol 5-7 cm thick reduces mid-frequency airborne noise by 3 times, and structural noise by two.

The cost of liquid foam is low and quite affordable. Using this material, you can save at the stage of building a house, but more significant savings can be obtained on heating during its operation, since this insulation has better thermal insulation characteristics.

A significant advantage of liquid thermal insulation is the absence of the need for thorough surface preparation. This circumstance significantly reduces construction costs. If a special machine is used at the facility for the manufacture of Penoizol, it will be sufficient to provide only access to electricity and water for its operation.

Like any other thermal insulation, wall insulation with liquid foam has its drawbacks:

- Compared to extruded foam, Penoizol has low mechanical strength.

When water gets on the insulation for a long time, it is able to absorb a certain amount of it, which worsens the thermal insulation properties of the coating. However, Penoizol can quickly evaporate accumulated moisture due to its capillary structure.

During polymerization, liquid foam releases a small amount of formaldehyde and water vapor into the air, but after the end of this process and getting rid of moisture for 2-3 weeks, the presence of harmful substances does not exceed their maximum permissible concentration.

In the case of injection of liquid insulation not into solid concrete or brick walls, but into frame walls, due to the problem of creating significant pressure in such structures, the filled foam plastic has an unpleasant property - shrinkage of the insulation during its polymerization and drying, which is up to 1%.

Many of these shortcomings can be corrected. Thermal insulation made of liquid foam is protected by sheathing from climatic factors and mechanical damage. It is reinforced in the frame walls, this eliminates the shrinkage of Penoizol for the entire period of its operation, and also allows you to get a monolithic coating, reinforced throughout the volume with fibers.

Roof insulation with polystyrene foam

Options for insulating a pitched and flat roof with a coating based on expanded polystyrene, the pros and cons of a protective shell from this product, the choice of components for forming an insulating layer.

- Features of the work

- Advantages and disadvantages

- Warming technology

- Materials and tools

- flat roof

- Inverted roof

- Roof space

Roof insulation with polystyrene foam is the thermal insulation of the roof with a high-quality product in order to prevent heat leakage and create a usable room or open area. Sheathing is created from different materials, which are selected depending on the purpose of the roof and its design. The article provides basic information about the rules for the formation of a protective coating.

A large piece and the wall, and the floor rejoices

In addition to hidden characteristics, externally estimated parameters also play an important role. These include, for example, linear dimensions. Due to the presence of several qualifications in this category, we will consider them separately.

The width of both heaters does not please with diversity and is fixed at 580 and 600 mm for technoplex and penoplex, respectively.

A little pleasing is another indicator, the length, especially for the technoplex. If the penoplex has a plate length of 1200 mm (2400 mm only for the maximum density plate), then its opponent has 1180, 2380, 3000, 4000 and even 4500 mm. Here is the scope!

The range of slab thicknesses makes it possible to save money when combining the thermal insulation layer without resorting to laying a large amount of excess material. According to this parameter, the penoplex shows a result of 20 to 150 mm, while the technoplex has a more modest 20-120 mm.

Durability of heaters

It is easy to compare products by density if you use the equipment for this. The mechanical compressive strength at a deformation of 10% for Type 35 Penoplex is the same as for XPS30-200 Standard Technoplex. As a result, the indicator for both one material and another is 250 kPa.

As for the limit of bending strength, Penoplex has an average of 0.4 to 0.7 MPa. With strong bending, Technoplex has a strength limit of 0.3 MPa. It turns out that the first material has better resistance to bending, which is on it, therefore, it is able to withstand heavy loads. It all comes down to the fact that the strength of the insulation directly depends on its density. And Penoplex has it higher.

What is unique liquid foam

Balloon liquid foam is a fairly light, cost-effective, durable material for sound and heat insulation, it is easy to install. Using this foam, vapor barrier is not required in addition.

They produce insulation of walls, roofs and floors of existing residential buildings and buildings under construction.

Such foam is made directly on the construction site by means of foam generators and ejector plants. The main component of penoizol is a polymeric carbamide adhesive resin. The latter may be different. When combined with a hardener, the resin transforms and becomes like plastic. Liquid foam contains other components in its composition: water and a foam-forming substance.

The solution is fed into a special installation and foamed in the foam generator with the participation of air supplied by the compressor. The power of the latter should be about 300 l / min. The material already in the form of liquid foam is sent to its destination. Primary hardening is possible after 20 minutes. Completely foam hardens and polymerizes after three to four hours. Thus, a fairly light porous insulation with small cells is produced.

Insulation with liquid foam allows you to save heat much better than mineral wool or solid types of heat insulators.

When there is an intention to insulate yourself, an injection molding machine can be rented or purchased for long-term use. Its price in various trading companies is equal to the amount, starting from 20 thousand rubles. Microprocessor mechanisms are much more expensive. But management in them is much simpler than in conventional systems. Small areas of work allow the use of cylinders with a liquid heat insulator.

Styrofoam fills the hollow structures of the house or the formwork prepared in advance. A layer of 10 cm of this material with its heat-shielding properties is equated to a layer of foam plastic of 30 cm, mineral wool - 20 cm, brickwork - 2.5 meters, concrete masonry - 2.97 meters.

Balloon foam is endowed with such characteristics as:

- long service life;

- environmental friendliness;

- fire resistance;

- immunity to the influence of organic solvents and microorganisms;

- protection against the spread of insects and rodents.

This type of insulation has an excellent price / quality ratio. Among other things, with his participation, wall insulation can be performed in already built houses without changing the entire structure.

The treatment of roofs, floors and walls with liquid foam has obvious advantages over other types of insulation:

Scheme of the foam generator.

- excellent thermal insulation properties;

- wide range of application;

- shelf life exceeds fifty years;

- wide variability of the temperature regime;

- relative cheapness;

- high degree of density;

- no voids are formed when it is filled.

Despite all the advantages, it also has disadvantages:

- linear shrinkage up to 5% when it is poured without pressure in the horizontal direction;

- unpleasant smell of formaldehyde, evaporating over time.

The difference between expanded polystyrenes

As mentioned above, the use of liquid and powder blowing agents is better, so the products obtained using this technology have stable thermal insulation characteristics. Although, it is impossible to call this the only reason why Freon is not included in the Technoplex and Penoplex. There are two more:

- Sealed cells of new material that has not yet been used have freon residues. Formally, it is called safe, but in reality it is better not to deal with it. It can cause lung problems in children.

- Over time, the gas will be forced out of the cells by air and moisture.And if dirty raw materials with the inclusion of styrene were used in the manufacture of the material, then the contents will penetrate into the external environment.

And if technical grades of EPPS, such as Penofol, are used to process the foundation, highway, basement, then the presence of freon in the composition does not affect the material in any way. But for home insulation it is better to use safe products. Therefore, the answer to the question: Penoplex or Penofol, which is better, can be answered - the first option.

And how do you know which is better Penoplex or polystyrene foam? Indeed, many recommend performing insulation with foam plastic, because it has a low price and excellent characteristics. To answer this question, you need to find out how penoplex differs from polystyrene foam. Let's start with production technology.

Technoplex, Penoplex and even that Penofol are created in the process of extrusion. This allows you to get a very dense linear structure, which affects the resistance of the material to water and humidity, as well as strength. Therefore, foam plastic is somewhat worse than materials created by extrusion methods.