Why do you need a vapor barrier for the ceiling of the bath

Vapor barrier of the ceiling and walls in the bath

Vapor barrier of the ceiling and walls in the bath

Since no one has yet canceled the laws of physics, it means that everything in this world remains the same as before.

From the school course, everyone is well aware that heat always rushes up. For a steam room in a bath, this is doubly true. If the steam and thermal barrier work poorly, then all heat and moisture losses will pass through the ceiling.

And if the ceiling is insulated with mineral insulation (basalt wool rolls, slab mineral heat insulators), what will happen to them? Just a heater saturated with moisture will stop working.

There will be practically no effect from its use. You can safely proceed to dismantle it and engage in a complete replacement of the insulation layer. This work is thankless, so it is better not to make gross mistakes during the construction of a bath and sauna.

Here is the second negative point, if the vapor barrier of the bath ceiling is not done correctly.

All wooden structures, and these are floor beams, a draft ceiling, roof elements, will be subject to premature decay. High temperature and high humidity favorably affect only a person, but for a tree this is considered an aggressive environment. Repair of the roof and ceiling is definitely provided.

Installation of vapor barrier with a furniture stapler

I recently witnessed how a neighbor was remodeling all the ceilings in a newly built bathhouse. The builders, trying to hand over the object on time, simply did not make the vapor barrier of the ceiling in the steam room. All the expensive URSA roll insulation had to be thrown away.

Literally for 3-4 times the steam room was used, it was so saturated with moisture that water simply dripped from the ceiling. It is good that all the work to correct this gross mistake was done almost immediately, and the tree did not have time to suffer much. The situation is unpleasant - money and time are wasted.

Foil vapor barrier for a bath

Modern steam rooms in the bath are heated by metal stoves with a constant firebox: the stones are heated during the firebox and if combustion is not maintained, then the stones will give off heat through the water poured on them and cool down. But the advantage of these furnaces is fast heating, the stones heat up to 300-400 degrees in a short period of time, what happens next without a vapor barrier is described above.

To keep the heat inside and prevent it from escaping, use a foil vapor barrier for the bath from the inside. The principle is to create a screen like a thermos: which retains all types of heat transfer energy: heat transfer, convection and radiant, or, as it is called: electromagnetic infrared radiation energy.

Insulation of the ceiling in the steam room should prevent the penetration of heat into the slots of the ventilation and chimney pipes and through other channels: water pipes tying the heat exchanger (register) of the furnace with a tank installed in the washing room or in the attic of the bath, electrical wiring. This also applies to the vapor barrier of the ceiling in the bath. Foil material requirement:

- High tensile strength;Low thermal conductivity;High IR reflectivity;Fire resistance;Environmental friendliness.

These requirements are met by foils from trusted manufacturers, such as Aerolam Insulation, which is one of the top ten international companies producing reflective insulating material for construction purposes.

The material contains double flame retardant and IR reflective layers of aluminum foil, between which there is polyethylene foam with air bubbles enclosed in spherical individual cells. This material structure is most suitable for creating a thermos in a steam room.

Technical characteristics of insulating materials Aerolam Insulation.

Roll Dimensions Bubble Cell Size Nominal Thickness IR Reflection Thermal Resistance Temperature Range Aerolam Premium1.2m X 30m1.2m X 30m20mm97%0.03-0.04-50 ~ 110 CAEROLAM ADVANCE1.2m X 40m10 X 30mm10mm97%0.03-0.04-50 ~ 110 CAeroalm Premium WF1.2m X 40m4 X 10mm8 mm97%0.03-0.04-50 ~ 110 CAerolam Super WF1.2m X 40m4 X 10mm4.5-5mm97%0.03-0.04-50 ~ 110 C

This is a small part of the rolled insulating material for the vapor barrier of the bath from the inside Aerolam Insulation. The choice is huge. You can choose a universal vapor barrier material for external, internal insulation.

Roll foil material can be chosen cheaper. "Alukraft" - consists of 3 layers: foil, reinforcing fire-resistant film, kraft paper. Regardless of what you choose, the foil is attached to the wall and ceiling with a stapler to a wooden crate with an overlap of 5-10 cm, the joints are glued with adhesive foil tape, included in the kit.

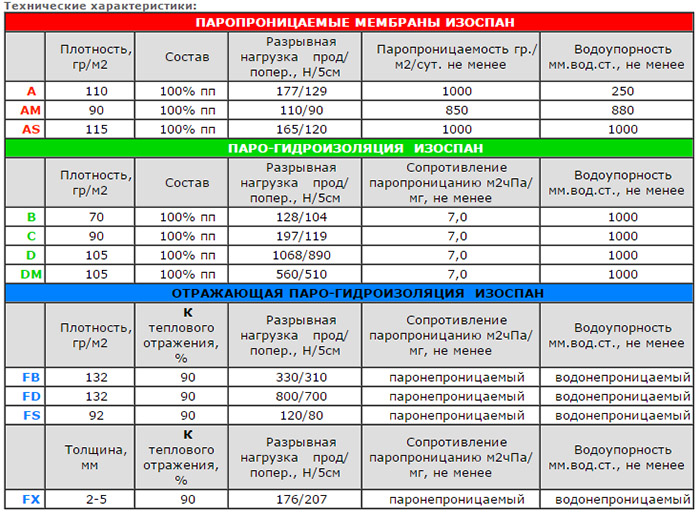

Advantages of the Izospan brand

Each of the types has its own characteristics: the possibility of installation indoors and from the side of the facade. A separate category is reflective vapor barrier for baths, which combines several functions. Foamed polypropylene with a surface laminated with foil withstands a wide range of temperature fluctuations and high humidity with absolutely no loss of quality. A bright representative is Izospan, the metallized layer of which is capable of reflecting radiation by 90%. Vapor barrier protects against steam inside rooms, resists wind and rain outside. For a bath, you can buy one of the brands, each of which is designed for different construction processes:

1. Izospan A - vapor barrier to compensate for the temperature difference between the heated room and the roof. The density is 100 g per 1 m2 with a roll width of 150 cm, length - 50 cm. It is resistant to ultraviolet radiation, mechanical damage, environmentally friendly, fireproof, thanks to the available special additives. In this group there is a brand AS, consisting of three layers, designed for wall surfaces, AM - for the bath ceiling.

2. Vapor barrier Izospan B is laid on the insulation, creating protection for all elements and structures. Density - 72 g per 1 m2 with a width of 130 cm and a length of 50 cm. It is used as a barrier in pitched roofs, attic floors, walls. Prevents corrosion, prolongs the life of all materials.

3. A distinctive feature of class C insulation is that it can be laid on a roof with a slope of less than 35. This allows the bath surfaces to remain dry, avoiding condensation. Also suitable for cement screeds and basement floors in buildings without permanent heating.

4. Izospan D - the most durable vapor barrier made on the basis of laminated polypropylene. The universal membrane is suitable for any structures, when arranging foundations, roofs, concrete bases, ceilings. DM is made from canvas with an anti-condensation coating, resistant to mechanical stress. The price ranges from 700 to 2000 rubles per roll.

Styling features

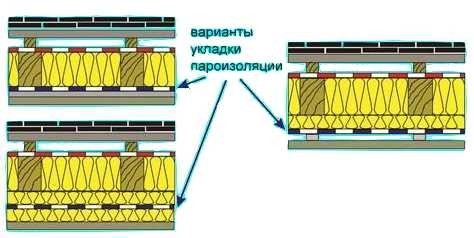

The vapor barrier of the walls of the bath and the ceiling must be mounted according to a certain scheme. Depending on the properties and purpose of the material, choose the appropriate method:

1. Creating a reliable barrier layer is the first option. To do this, prepare boards with a minimum thickness of 50 mm. So that the tree does not succumb to dampness for a long time, its surface is impregnated with drying oil. The ceiling of the bath is sheathed with dice, after which a vapor barrier is laid on top. It should be noted that the material is placed with a pile inside the room so that it absorbs moisture well. The canvases are overlapped with a margin of 100 mm using a stapler. A slight sag will prevent damage to the film during temperature fluctuations.

2. According to this scheme, clay is used, which is pre-softened for convenience, thrown over the membrane and proceed to the insulation. For greater effect and reliability, another layer of vapor barrier is mounted on top.

3. In some cases, expanded clay about 20 cm thick is additionally poured onto the canvas, which contributes to protection from the cold. This is especially necessary for arranging layers around the pipe through which the combustion products exit, since the highest temperature coefficient is in this place.

Vapor barrier of the bath ceiling is carried out according to one more scheme:

1. A grooved board is attached to the surface, on which the crate is installed.

2. Wooden elements are impregnated with an antiseptic and drying oil, a mandatory gap is made between them to remove moisture.

3. A film or foil is placed on them, then they are backfilled. In baths, it is recommended to use expanded clay, as the building is considered a fire hazard. The wall protection scheme also involves the creation of a frame with an interval corresponding to the width of the roll. This method is not applicable to thin foil.

4. The cake is mounted in the following order: hydrophobic film, insulation, vapor barrier membrane. Proper arrangement implies the mandatory provision of a ventilation cavity and a gutter with a slight slope to drain condensate.

5. The seams are sealed with mastic or metallized tape. The best cladding option is linden lining.

Bath ceiling vapor barrier

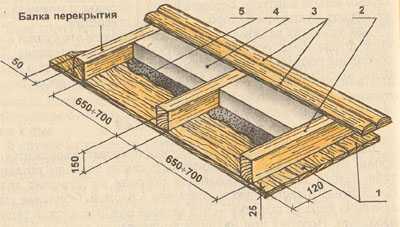

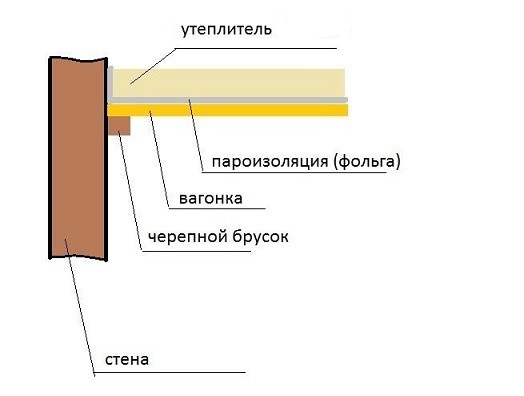

The process of vapor barrier device precedes the process of ceiling insulation.

Therefore, a vapor barrier can be installed both outside, from the attic floor, and from inside the bathhouse.

Then a layer of your chosen vapor barrier is laid on this material.

It is fixed to the floor beams with a construction stapler.

A layer of insulation is laid on top of it.

Then waterproofing and everything is sewn up with attic floor boards.

If the insulation is carried out from the inside of the bath, then everything is done in the reverse order:

- the first to mount a layer of waterproofing;

- the second install a heater between the beams;

- the insulation is covered with a layer of vapor barrier, which is securely attached to the floor beams;

- the last is mounted decorative ceiling.

Coating methods

In the construction of any bath, as a rule, the laying method using thick beams or durable boards is especially popular. They serve as supports, and sometimes the ceiling is laid on top directly on the wall trim. The installation of the ceiling in your bath begins with how you choose the installation method.

bath building process

There is no need to explain that the ceiling is erected only after finishing work in the construction of the roof, otherwise the unfavorable environment will harm the thermal insulation, reduce its effectiveness and cause the walls to slowly rot, the growth of the fungus will begin, which oh how difficult to fight.

Types of ceiling coverings

The device of the ceiling in the bath traditionally involves the laying of the base, which is the internal boards. Widely used edged or unedged board for the ceiling, which is usually sheathed with clapboard.

Between the floor beams, a layer of protection against moisture and heat preservation is laid on the inner boards. Vapor and waterproofing should not have any gaps, the joints must be sealed tightly, and the boards should be of good quality, without knots. A snug fit of the board and additional overlap will create favorable conditions and protect against the formation of water.

There are several ways to lay the ceiling:

- Hemmed, for large baths;

- Flat, for small structures;

- Panel, as an alternative to the first two.

false ceiling

Insulation for false ceilings is usually mineral wool, which has a high level of absorption and droplet absorption. It is covered with waterproofing and sheathed with boards from the outside.

If your bathhouse has an overstructure in the form of an attic, you can not be afraid for the safety of bath accessories and their drying - mineral wool, as a high-quality insulation, contributes to the rapid absorption of moisture and is ideal for such conditions. Cotton wool is produced in the form of pressed boards and is easy to install.

The deck ceiling does not need outer skin, as it is usually sprinkled with heat-insulating material. This method is not suitable if the bath has an attic. Any manipulations with the attic floor can harm the thermal insulation of the bath.

A more complex flooring option is a panel ceiling. Despite the difficulty of overlapping, the ceiling is very economical if you decide to stop at this option.

It has undeniable advantages:

- It is a prefabricated structure of load-bearing beams;

- Steam and waterproofing is installed in the construction box and, if desired, it is insulated with mineral wool;

- The ceiling can be made outside the walls of the bath.

Mineral wool

Laying a vapor barrier in the steam room

The quality and duration of the main bath procedure depends on the correct device for vapor barrier of the steam room ceiling.

A certain amount of steam is immediately formed, which effectively warms the body of people in the steam room through the skin.

But the steam tends to rise up to the ceiling and out.

If this happens, you have to hit the heater again and again to create steam.

That is, again and again you have to heat the stove.

In order to perform this procedure as rarely as possible, a barrier should be placed in front of the steam so that it does not go outside, but remains inside, in the steam room.

To do this, an additional layer is laid in the ceiling between the hemmed material and the insulation - a vapor barrier.

It prevents steam from escaping and prevents moisture from entering the insulation.

Creating a vapor barrier in the steam room is associated with a number of problems.

The fact is that quite often the air temperature in the steam room rises to 100 degrees and even more.

And the plastic film in most cases is not designed for such a temperature.

It begins to shrink sharply and very quickly fails.

It simply bursts.

Therefore, the film should be left to vapor barrier other rooms of the bath, where the air temperature is much lower.

And in the steam room for vapor barrier, modern materials should be used, which have a foil coating on one side.

For example, Stizol.

This material can simultaneously perform two functions: vapor barrier and insulation.

Stizol successfully withstands both a large amount of moisture and high temperatures.

For vapor barrier of the ceiling in the steam room - this is an ideal material.

Such vapor barrier as foamed polypropylene is also gaining popularity.

This material has a foil lamination and not only does not allow steam to pass through, but also reflects heat back into the steam room.

Video about the vapor barrier of the ceiling of the steam room in the bath:

It is easy to perform vapor barrier.

The main thing is to be careful not to damage the material.

What else to read on the topic?

Alternative materials

There is no alternative to isolone, as such, but we will be wrong if we do not briefly talk about materials that can replace it in one way or another.

cotton wool

Practically the same as isolon, cotton materials, which include mineral, glass and ecowool, have heat and sound insulation. Their manufacturers insist that their main advantages are:

- Ease and simplicity in installation.

- Low thermal conductivity.

- Strength under compression, mechanical stress, tearing.

- High soundproofing characteristics.

- Not susceptible to fire.

- Resistance to temperature deformation.

- Biological and chemical resistance.

Mineral wool is produced in the form of rolls and sheets, have different softness and thickness. Mounting structures using various types of wool is extremely simple:

- The walls must be closed with a steam or hydro barrier using a stapler.

- The next step is to assemble the frame from special metal profiles, the assembly step is 50 centimeters.

- Then cotton wool is laid, carefully distributed throughout the space, avoiding gaps.

- Then the cotton wool is fixed in any convenient way, the structure is closed with drywall sheets, plastic panels, clapboard, fiberboard.

- The final stage is the decoration of the walls, its appearance depends on what material you have chosen or is available.

The disadvantage of the material is its allergenicity, it is necessary to work in protective gloves and a mask in order to prevent contact of the material with the mucous membranes and skin of the hands. It also requires additional vapor barrier, since it loses its properties from moisture. In principle, the technology is simple and you can easily do everything yourself, without overpaying contractors.

Polyfoam or its analogues

The undoubted advantages of polystyrene include the fact that:

- Polyfoam is not afraid of moisture.

- It is a good thermal insulator.

- It is not subject to rotting, the formation of fungal or mold spots.

- Easy to install and cut.

- Has a low weight.

- Heat resistant to low temperatures.

- Does not require waterproofing.

The disadvantages of polystyrene are also many:

- Fragile, crumbling, requires additional protection with a dense base.

- Doesn't breathe.

- Easily destroyed, enters into chemical reactions.

- We love rodents.

Polyfoam is used mainly in non-residential premises or for outdoor use. Installation is carried out on an adhesive mixture, it requires additional fixing with “fungi”, careful lubrication of the seams, plaster and subsequent painting.

What happens to the heated air in the baths

The vapor barrier of the ceiling of the bath made of natural materials could not protect the wood from steam by 100%, but after washing it remained warm in the bath, and the moisture accumulated in the log evaporated during this time. The bath heated up and cooled down slowly.

There was no sharp temperature drop inside the bath and on the surface of the ceiling, just as there were no prerequisites for creating a dew point - the temperature at which moisture-saturated warm air cools down and cannot retain moisture that condenses on cold surfaces. Even if moisture appears on the surface of the ceiling, it will not penetrate deep into the wood, but will form drops on the ceiling, which will stop dripping onto the floor as soon as the bath warms up.

In modern baths, finishing materials are made of moisture-resistant wood, but the design of the stove, in most modern baths, is designed for quick heating of the steam room. Now imagine what happens during warm-up if there is no vapor barrier on the ceiling and walls.

The stove gives off heat almost instantly. The walls and ceiling that have not yet been heated up take on heated hot air; part of the wet steam finds a dew point on the surface of cold walls and ceilings, and condenses on them in the form of droplets.

The dew point does not stand still, it shifts as the walls and ceiling heat up.

What happens if there is no ceiling vapor barrier in the bath? Warm air penetrates behind the skin and meets the insulation, which has a lower temperature than the penetrating warm air. A temperature difference condition may be created at which moisture will condense directly in the insulation (internal condensation), and since the insulation has low thermal conductivity, the dew point in it can be held for a long time and the insulation will get wet like a sponge, absorbing moisture.

This is the difference between an old Russian bath and a modern one.

For the old Russian bath, there are practically no conditions for the condensation of warm air, or they are minimized (surface condensation). A modern bath should have steam protection. Moreover, this protection is based on specific conditions, which take into account:

- Furnace type: with an open-type heater and a permanent firebox, and a closed type with a periodic firebox and high heat capacity; Features of the design of the room; Construction material.

Under these conditions, choose a protection method:

- Maximum isolated room with impenetrable vapor barrier, protection against internal condensation; Partial vapor barrier, excluding the formation of a dew point in the bath structure.

Where to start warming the walls of the bath, and what materials to choose

To reduce heat loss, you will need to make high-quality thermal insulation and vapor barrier of the washing room, steam room and, if possible, the dressing room. Warming the bath from the inside, although it will require additional financial costs, but subsequently your work will pay off with interest, and you will be able to save a lot on firewood.

In the old days, the walls of the bath were insulated in the old fashioned way - with red moss or sphagnum, hemp hemp, tow. These natural materials are still used for caulking wooden baths, however, for all their environmental friendliness, they have significant drawbacks: natural materials take birds away, damage moths, they are not as convenient to use as many synthetic materials.

If you have just started building a log house from a bar, take care of the thermal insulation of the walls during the construction process by laying material made from flax or jute between the bars (flax-jute felt, linen, etc.). You will have to deal with the interior decoration of the log house approximately six months after the construction is completed. During this time, the log house will shrink, then you can carefully caulk the seams with the same flax-jute felt, treating them with a sealant on top to protect them from moisture.

Video about forcing onions on a feather

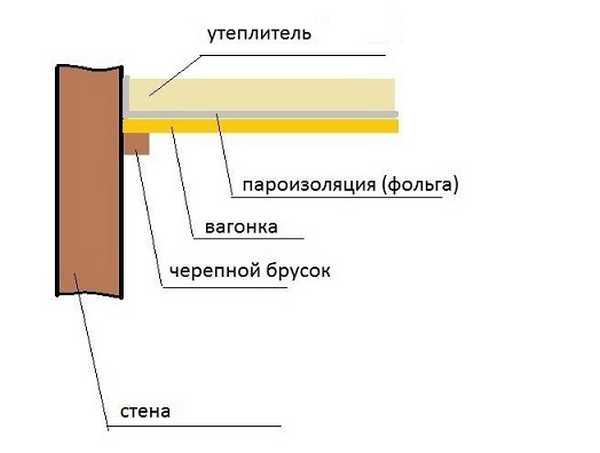

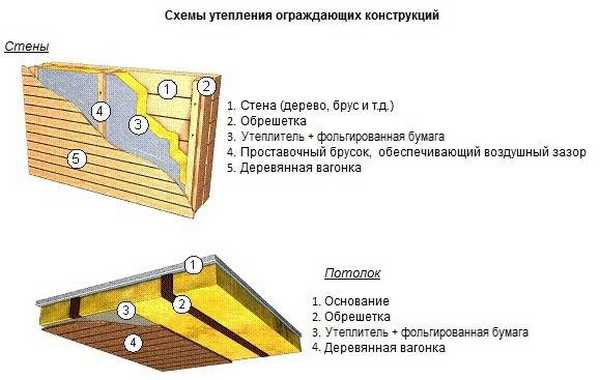

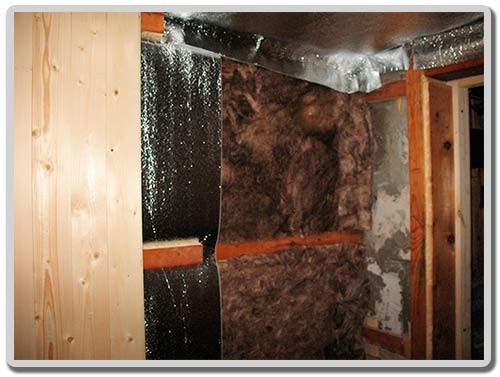

The walls in the bath are insulated according to the following technology:

- On the surface of the load-bearing walls, a horizontal and vertical crate of bars with a thickness exceeding the thickness of the insulation by a couple of centimeters is attached. Such a frame is necessary so that the insulation does not lose its qualities and does not wrinkle.

- Between the bars, glass wool or mineral wool slabs are installed as a heater.

- A foil vapor barrier is laid over the heat-insulating material with an overlap to protect the insulation from condensate.

- Joints and seams must be sealed with aluminum foil tape.

- A vertical crate of slats up to 5 cm thick is attached to the vapor barrier in order to create a ventilated gap between the vapor barrier and the finish.

- The crate is sheathed with clapboard.

Foil is typically used for vapor barriers in steam rooms and washrooms, while kraft paper will suffice in a dressing room or break room. Often, instead of foil, preference is given to dense (from 140 microns) polyethylene. As a lining material inside the bath, you can choose not only the popular eurolining, but also well-planed boards, drywall, gypsum fiber, etc.

To maximize the insulation of the bath, upon completion of work with the walls, do not forget to take care of the windows

To maximize the insulation of the bath, upon completion of work with the walls, do not forget to take care of the windows. The frames must be fitted closely to the bindings, the gaps are treated with sealant - then the warm air will remain inside the bath rooms much longer.

Vapor barrier with insulation of the bath ceiling according to all the rules

There are various variations of laying the insulated "puff" ceiling, however, when choosing the appropriate option, you must remember that the ceiling in the bath is affected by high humidity, which means that you should definitely take care of proper vapor barrier.

Often, instead of foil, preference is given to dense (from 140 microns) polyethylene

How to insulate a bath with a wooden ceiling:

- Lay fiberglass on the rough ceiling.

- Pour a layer of fiberglass with a solution of clay and sand (1: 1), mixed with fine chopped straw or sawdust. The layer of clay-sand solution should be 20-30 mm.

- Next, a 50 mm layer of clay-sand mortar (1 part clay solution, 3 parts vermiculite).

- Leave the solution layer to dry for a period of 3 weeks to 2 months, depending on the weather.

- Lay foam plastic (100-150 mm) on the clay-sand layer.

- A layer of cement mortar with the addition of foam chips (1: 3).

- If there is an attic above the bath, roofing felt or roofing material must also be laid on top of the last layer and covered with a wooden floor.

A crate is attached to the draft ceiling in the baths at intervals of 500 mm, heat-insulating material (mineral wool) is fixed between the slats, foil is lined, the slats are nailed, and the ceiling is sheathed with facing material.

Video about the insulation of the ceiling in the bath

How to insulate the ceiling of a bath from concrete floors:

- Install wooden beams 100x100 mm under the ceiling on the side walls inside the bath, maintaining a distance between the bars of 500 mm.

- Attach fiberglass to concrete slabs.

- Next, a layer of thermal insulation (100-150 mm).

- Cover with a layer of foil or foil cloth.

- Pin the crate of slats (thickness 25-30 mm).

- Attach lining or other facing material.

- In the attic, pour a layer of slag or expanded clay (150-200 mm) on concrete slabs.

- Lay thermal insulation material (thickness 50 to 100 mm).

- Lay a wooden floor if necessary.

Do not forget to provide a couple of centimeters of gaps on the ceiling inside the bath between the vapor barrier (foil) and the cladding to ensure ventilation.

Do not forget to provide a couple of centimeters gaps on the ceiling inside the bath between the vapor barrier (foil) and the cladding

Such insulation of baths allows you to achieve a "thermos effect" inside the steam room and washing room, keeping a good heat for a long time. It will take you less time to kindle the bath, and you can steam longer.

Overview of wall and ceiling materials

Previously, a coating with a mixture of clay and sawdust was used as insulation. The mix perfectly retained steam and heat, creating the so-called thermos effect. Today, well-known aluminum foil and the latest roofing films are used for these purposes.

Vapor barrier and insulation of the bath ceiling are carried out before the final fine finish. The main difference between modern vapor barriers is two-layer and special properties that prevent the accumulation of condensate, the development of dampness and the appearance of mold and rot. The most popular developments of the following manufacturers:

1. IZOSPAN FB series is positioned as a reflective (energy-saving) vapor and waterproofing. Designed for use inside baths and saunas with steam temperatures up to +140 °C. Produced on the basis of kraft paper with a protective layer of metallized lavsan. Helps to reduce heat loss through walls and ceilings, protects against dampness under the finish coat and getting wet. Used in conjunction with FL termo aluminum tape.

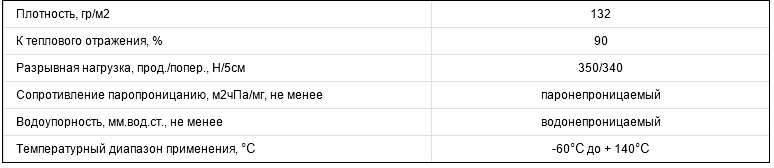

Technical characteristics of IZOSPAN FB:

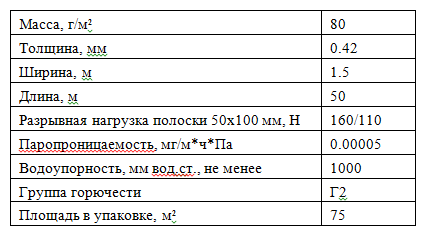

2. ISOVER VS 80 is a two-layer vapor barrier membrane with an increased level of tensile and tensile strength. It is made from polypropylene fiber, protects the insulation and load-bearing structures from moisture, mold. Buying an ISOVER vapor barrier is not enough, you need to purchase a metallized or reinforced adhesive tape for fastening in the kit. Requires during installation to observe a ventilation gap with a width of 15-25 mm.

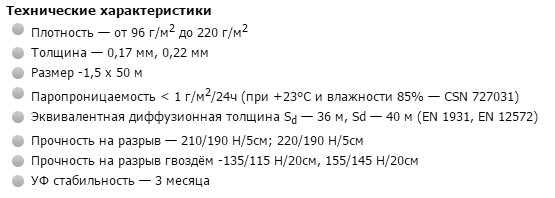

3. Yutafol series H 96 Silver and H 110 are equally well used for under-roofing and ceiling vapor barrier in the bath. Keeps heat and steam indoors, protects a heater from dampness and wetting. Produced from polypropylene non-woven fabric, H 110 is additionally reinforced with a mesh of polyethylene strips.

4. From age of series:

- B - a two-layer material for protecting walls from the inside, interfloor ceilings, roofs.

- C - a film of black or blue color with improved performance properties. Versatile, used inside and outside buildings.

- D - polypropylene non-woven with reinforcement. Differs in the increased mechanical durability, universality.

All types perfectly cope with their task - to retain steam, are applicable for baths and saunas.

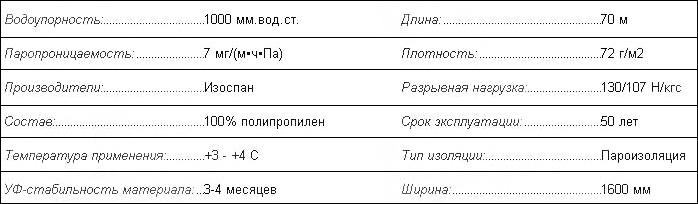

Specifications Izovek:

The vapor barrier device in the sauna during the construction of the bath requires the availability of material. The choice of brand depends not only on the buyer's confidence in the manufacturer, but also on the price.

| Name of the vapor barrier | Price per roll, rub. |

| ISOSPAN FB | 900 |

| ISOVERVS 80 | 1 100 |

| Yutafol H 96 Silver | 1 200 |

| Yutafol H 110 | 1 500 |

| Izovek V | 680 |

| Izovek S | 950 |

| Izovek D | 970 |

Installation instructions

The main advantage of modern membranes is that they do not require additional maintenance for the entire operational period. The task of proper vapor barrier is to keep heat and steam indoors

Therefore, it is so important to monitor the tightness of the seams.

Installation of vapor barrier on walls and ceilings begins with surface preparation. It is cleaned of dust, debris, cracks are puttied. A waterproof membrane is laid, then a crate for insulation is located. At the end of the work, a vapor barrier film is attached to the frame with a construction stapler. Overlap - at least 10-15 cm. The edges are glued with special adhesive tape. A counter-lattice is placed on top, on which the finishing coating is mounted. It is not recommended to stretch the material.

Bath vapor barrier installation diagram:

Sometimes, instead of membranes, heaters and substrates with an aluminum top layer (Penofol, Isolon F) are used. The most economical ones simply attach a plastic film, and foil on it. It is better to use professional products, as they are designed in such a way as to remove condensate, preventing it from settling on the finish coat. Special vapor barrier will protect your bath 100%.

Step-by-step instructions on how to insulate a bath with isolon

Before work, it is necessary to calculate the amount of isolon according to the area of \u200b\u200bthe walls, the ceiling of the bath. To do this, you need to multiply the length of the wall by the width and multiply among themselves. The resulting figure is 4. We add the area of \u200b\u200bthe ceiling to the result and subtract the doorway. The material is laid without overlap, therefore, for hermetic joining, they buy metallized adhesive tape.

For work you will need materials and tools:

- A construction stapler with 10 mm staples or a hammer with thin nails.

- Izolon.

- Foil tape.

- Scissors, clerical knife (needed to fit the insulation).

After everything is purchased, we proceed to the insulation of the walls and ceiling.

Installation of insulation on the walls and ceiling of the bath

It is necessary to insulate the walls, the ceiling of the bath with isolon between the finish and the inner wall. A ventilated gap of at least 0.5 cm must be left between them so that moisture can ventilate.

The work is carried out in the following stages:

- The walls are cleaned of dirt and dust with a brush with stiff bristles. The tree is covered with an antiseptic, lapyrimide.

- Isolon is rolled out on the wall, ceiling with the foil side inward and attached to the wooden wall with a stapler. When the bath is built of blocks or bricks, it is necessary to fill the walls with bars 20–30 mm thick, 1–1.5 m long, in a checkerboard pattern. A heater will be attached to them. Isolon does not allow moisture to pass to the tree, so you do not need to use a vapor barrier under it. If you don't have a stapler, use a hammer with small nails.

- The joints are glued with metallic tape. Also come with places where the material is attached with staples. Unglued joints will not be protected, and moisture will get inside under the insulation. The walls will start to rot.

- On top of the insulation, a crate of 40x40 mm timber is mounted, for further finishing with clapboard or other material. The step of the crate is not more than 1 m.

Warming of the steam room is ready, you can start finishing. how to insulate a steam room can be seen in the video:

https://youtube.com/watch?v=1BMehi4cwNU

https://youtube.com/watch?v=1BMehi4cwNU

Useful video

In the video, let's see a typical mistake when laying a vapor barrier:

You will not find a definite answer: which vapor barrier is better and which vapor barrier to choose for a bath. It all depends on the correct installation: you can buy expensive foil, but not get the desired effect if you install it incorrectly; and, conversely, proper vapor barrier with cheap natural materials will perfectly protect the structure from decay.

(2 ratings, average: 4.50 out of 5)Loading…

Hello dear readers! Today we will talk about one important factor, without which your steam room will not have the necessary thermal characteristics ...

A truly good bath should not only look beautiful, but also have properties specific to it. One of these properties is the rapid injection and retention of heat indoors.

Properly executed vapor barrier of the bath ceiling solves not only this important task, but also a number of others.

What? - you ask. More on that below...

Advantages and disadvantages of ceiling insulation with penofol

Today, the product is very popular because of its versatility and easy installation. Masters also appreciate it for the following qualities:

- The material is lightweight, making it ideal for work carried out at height.

- To lay penofol on the ceiling, no special tools are needed.

- The metal coating does not let steam and water through, does not absorb liquid and does not collapse under its influence, so it is indispensable in damp rooms, for example, in baths. It does not require additional protection with hydro- and vapor barrier membranes.

- The material performs several functions. After being attached to the ceiling, it not only retains heat in the apartment, but also dampens sounds transmitted through the air or through the ceiling. It is often used with other products to improve thermal insulation properties. For example, in saunas, it additionally maintains the temperature by reflecting heat.

- When heated, it does not emit harmful substances. In its production, the same polyethylene and foil are used, which are used in the food industry.

- After installation, the distance between the floor and the ceiling decreases slightly. A 1 cm thick canvas can be used instead of 8 cm thick mineral wool or 4 cm thick polystyrene foam, so insulation is often used in rooms with low ceilings.

- Sheets are sold rolled up, which facilitates installation work.

- The product does not burn and is often used in fire hazardous areas.

- Rodents don't like him.

Penofol has few disadvantages. Negative factors include the high cost of the material and the need to use other heaters to improve the result. It is also glued to the surface to ensure the integrity of the coating, which increases financial costs. The material is soft, so it cannot be used if plastering or wallpapering is planned.

Method 1 thermal insulation inside the timber frame

A bathhouse is a place that does not forgive heat leaks, everything is isolated in it - including the ceiling. Click on photo to enlarge

If you are trying in one way or another to solve the problem of how to properly insulate the ceiling of the bath, first we suggest paying attention to the following step-by-step technology:

Bar patch. The cross section of the latter is 5 × 5 cm. The step is equal to the dimensions of the insulating material made in the form of plates.

By the way, people who decide to deal with the thermal insulation of the corresponding surface of the steam room are often occupied with the question of how to insulate the ceiling of the bath. So, you need to take tile insulators.

Experts believe that rolled ones are somewhat inferior to them in terms of performance.

Heater installation. The work is reduced to laying the selected material between the blocks, which are attached at the first stage. Many recommend mineral wool, as it has good thermal insulation and sound-absorbing characteristics.

Another stripe of bars. This time, the products are mounted across, as this involves work that solves the problem of how to insulate the ceiling in the bath

Compliance with the transverse installation is quite important and should not be deviated from.

And again it is the turn of insulators.

Foil type paper stretch. It is carried out with an overlap and nothing else.It is attached to the bars with a special stapler.

Seal the seams with adhesive tape. As in the case of paper, foil products are needed.

Plank nailing. The dimensions are 2 cm. It is needed to create a finishing layer, for the arrangement of which lining is often used.