Minvata Rockwool

The main feature of the laboratory production of Rockwool mineral wool is that it is identical to natural conditions during a volcanic eruption.

This effect has a positive effect on the quality of the building material - the arrangement of the fibers is chaotic, due to which the following properties are achieved:

-

burning resistance

- at temperatures up to 1000 C they do not even melt, -

excellent thermal insulation properties

– up to 0.046 W/m K. - vapor tightness

- not affected by water

- high sound insulation

- increased resistance to mechanical stress.

The Rockwool brand has gained its distribution among construction companies and private consumers of the domestic market due to its perfect fire safety, good hygroscopicity and sound insulation, and relatively low cost. The price of different suppliers can fluctuate widely, because. some sellers offer immediately installation work and delivery to the site.

There are also different types of this insulation material, for example, the price of Rockwool Light Butts starts at 1,873 rubles for slabs 1000x600x50mm, and some facade varieties of mineral wool can reach 7,000 rubles for the same volume.

- There is no difference between URSA and Izover

If it is, it is highly conditional. Both materials are fiberglass, both have the same technical characteristics, even their appearance is so similar that not every specialist will be able to distinguish them when unpacked. By the way, their packaging is the same - a shrink film, which reduces the transport volume by up to 35 percent of the working volume, which allows three cubic meters of this heat insulator to be placed in ordinary Zhiguli.

But "Isover" we bring from Finland, and "URSA" is made in the city of Chudovo, Novgorod region. Many consumers prefer imported material (it is a bit more expensive), although the Germans, the owners of the Chudovsky plant, strictly ensure that the material produced here does not differ in any way from that produced in their homeland or at the concern's factories in other countries of the world. Another question is that the capacities of the Chudovka plant are not enough for the whole of Russia and very often people are simply forced to use imports ... - Where are these heat-insulating materials used and what are their varieties? - Between themselves, they differ in rigidity - from M-15 to P-75 (the harder the material, the higher the wall it can be laid, but the more expensive it is), in thickness - from 50 to 140 mm. On one or both sides of the material, polyethylene film, foil or kraft paper can be applied. Since they are classified as non-combustible and have excellent thermal insulation properties (their thermal conductivity coefficient is only 0.04-0.05 kcal / mchC, which means that 18 cm of heat insulator protect the house from the cold in the same way as two-meter brickwork), environmentally friendly, they can be used for thermal insulation of roofs, interfloor ceilings, and external walls, and floors, and basements, and internal partitions, and heat pipes. In short, they are universal. At the same time, such materials are very convenient to use. Install an interior partition - place between a wooden beam or a metal profile on which drywall or GWP is attached, an insulating plate of medium hardness with a thickness of only 50 millimeters. Such a partition will provide better heat and sound insulation than one laid out in one and a half bricks. But it does not need to be plastered. The labor costs for its construction are incomparably less. Due to its low weight, it can be placed almost anywhere, besides, the cost of the materials themselves is lower ...

This is probably the main advantage of modern thermal insulation materials:

You spoke about the advantages of URSA and Izover materials, but did not mention anything about their shortcomings.

Flaws? Perhaps only one. They don't like moisture. When hit, it partially loses its properties. Therefore, they cannot be wetted, and condensate should not accumulate on them inside the building structures. For this, special ventilated structures have been developed or polyethylene film, aluminum foil or kraft paper are used as vapor barriers.

Glass wool NEMAN

The products of the Belarusian glass factory meet the highest requirements. Glass wool "NEMAN" has excellent thermal and sound insulation properties, is non-flammable and durable. The raw materials for the manufacture are domestic products.

Sevenfold compression of the material reduces transport costs.

Glass wool is produced in roll form. This facilitates the work on thermal insulation of pipelines and insulation of industrial installations.

Basically, glass wool Neman finds application in the insulation of pitched roofs, with installation of hinged ventilated facades and false ceilings. It is not excluded the use of glass wool during thermal insulation works both outside the building and inside.

The topic of modern heat-insulating materials, both imported and domestic, continues to interest readers, because thanks to these materials, one can not only reduce the cost of heating housing, but also significantly reduce the cost of building construction. Leading specialist advises.

Minvata Knauf

Mineral wool brand Knauf, German production are famous for their high quality and safety for human health. This is due to the fact that, unlike many of its competitors, Knauf mineral wool does not contain phenol-formaldehyde resins, which contain harmful substances.

In order to appreciate the properties of this building material, consider its technical characteristics on the example of insulation for houses and cottages TeploKnauf in rolls:

-

Thermal conductivity

– 0.037 W/mK -

Noise protection

- 45 W -

combustibility

- not flammable -

Dimensions

- 6148x1220x50 -

The volume of one package

– 0.75 sq.m.

Knauf insulation has a number of advantages that are so valued by construction organizations and individuals:

- a small coefficient of thermal conductivity allows you to keep warm in the apartment even in the most severe frosts.

-Knauf mineral wool was widely used in houses located near tram tracks and highways.

This is due to the fact that it has excellent soundproofing properties, and provides comfort and silence in the house.

- not susceptible to the appearance of rodents and fungal formations.

- fireproof, even if a fire occurs, this substance will prevent the further spread of the flame.

- ease of transformation - mineral wool is able to shrink to sizes that are several times smaller than actual, thanks to this property it can be transported in large quantities.

- the absence of shrinkage throughout the entire period of operation will eliminate the need for repair and additional laying of mineral wool.

- light weight, easy to assemble

- safety for human health

The only drawback of the Knauf insulation can be considered its price, it is higher than that of many competitors, but Knauf surpasses them in many technical indicators. The cheapest version of Knaif mineral wool will cost the buyer 1200 rubles per roll of 18 square meters, 50mm thick.

Best Answers

Elena:

You named different brands. You have to look at the heater. If the humidity is high (or a threat). then better foam (plain or extruded). If there is no moisture, then cotton wool is more environmentally friendly. At normal humidity, all modern heaters have approximately the same heat transfer resistance coefficient.

Special opinion:

insulation is better in mats than in rolls. the rest of the parameters are almost the same.

Andrey Denisov:

there is also penoizol

Alexei:

read - what they are made of, the smelliest are those with fiber on a phenol-containing bundle.

Marina Alskaya:

The difference in cost and durability of materials. But no matter what you choose, laying insulation from any of these companies is equally difficult. If the walls are insulated, then waterproofing is necessary and

Ecowool-Voronezh:

Manufacturer. Each manufacturer has materials of different prices of different densities, someone has “environmentally friendly” someone has “noise-insulating” globally the same thing. They differ in features and density. For different applications - its own density. The higher the density, the colder. Everyone is afraid of moisture - vapor barrier is required. The coefficient of heat resistance on all is indicated for absolutely dry material.

HUMAN:

I used Rockwool to insulate the house ... a house according to Norwegian technology with autonomous heating ... permanent residence ... cool in summer in winter, warm within 22 degrees ... 100mm of insulation in terms of thermal conductivity equals 300mm of timber ...

Insulation manufacturers Knauf, Ursa, Izover

The choice of thermal insulation for your home should be approached especially carefully. And for this it is necessary to have complete information about the properties of materials. And in this we are ready to help you.

Insulation Ursa

One of the most popular materials for thermal insulation of pitched roofs is Ursa insulation. A product is made of fiberglass using binders. The technical characteristics of the material are: strength, frost resistance, increased elasticity and the ability to resist large mechanical loads.

Due to their properties, Ursa insulation completely adheres to the surface to be mounted and fills all existing gaps. This material has a high level of chemical resistance, so it can be used for thermal insulation of rooms with high humidity.

Insulation Knauf

Knauf manufacturer's heaters are made of glass or basalt fiber and have excellent characteristics not only as thermal insulation, but also as a sound-absorbing material.

Installation of Knauf insulation will allow you to feel warm during cold winters and cool on hot summer days, as well as save money on heating.

You will not be disturbed by extraneous street noises. In the event of a fire hazard in the house, the Knauf insulation will not contribute to the spread of fire, which will allow family members to safely evacuate without causing harm to health.

Izover insulation

Izover insulation is used not only in private housing construction, but is also widely used in the construction of industrial enterprises, thermal insulation of baths, saunas and heating mains. And everywhere the material is a reliable protection against cold and drafts.

Plates for external thermal insulation of the roof have increased rigidity and strength, are able to withstand strong wind and snow loads. Izover insulation as an internal thermal insulation has a soft layer that allows you to fill all the gaps and irregularities in order to avoid heat loss. The price of Izover insulation depends on the type and strength factor of the material.

As a thermal insulation for wooden houses, use a flax-based interventional insulation from a bundle. It will completely fill all the gaps between the logs, and even when the house shrinks, it will retain its excellent characteristics.

Our company offers low prices for building materials, so purchase all the necessary products from us.

Minvata Ursa

Mineral wool from URSA is designed to insulate not only walls and roofs, but it can also be used to insulate ventilation ducts and other communications. In addition, this thermal insulation material has a high level of noise absorption and long-term operation without loss of quality.All these technical characteristics have led to the widespread use of Ursa mineral wool in industrial construction and private use.

Ursa mineral wool is based on fiberglass, which has good thermal insulation properties due to the elasticity and strength of the fibers, between which air gaps are formed. The thermal conductivity coefficient of this material ranges from 0.035 to 0.044 W/mK, which is an excellent indicator for this type of insulation.

Depending on the type of mineral wool, sound insulation can be class "A" and class "B". If, along with insulation, it is required to isolate the room from extraneous sounds, class “A” building materials are used, which can replace the soundproof partition. Regardless of the type, all Ursa mineral wool is environmentally friendly and is thoroughly tested at the production stage.

Ursa pays special attention to human safety - it has achieved excellent results, for example, the content of harmful volatile compounds in Ursa mineral wool is 10-15 times less than in domestic or European counterparts

From the point of view of fire safety, Ursa mineral wool is completely non-combustible due to the use of quartz sand in its composition. The material can withstand huge temperatures and is able to prevent the spread of fire beyond its limits. As for the service life, mineral wool can be used for 50 years without losing its original properties. She is biologically stable, i.e. various rodents, microorganisms and fungi will not spread in such conditions.

Expert answers

Arthur Zarembo:

Any materials have a brand, in terms of density, thermal insulation, and so on! If the brands are the same, then I probably don’t care who the manufacturer is! As for mice, then if you have a mazov, then they will live in any heaters or without them!

LINDA ROSE:

It's the same for me

Kulyoma:

Knauf.

Elsa Weiss:

what is this?

Vladimir Petrov:

Knauf is a respectable company

sexa:

Knauf, of course!

Alexander Bykov:

Good day! It is necessary to compare technical characteristics: Thermal conductivity (the lower, the worse the material transmits heat) Vapor permeability (The higher - the better the material passes vapor molecules, the less moisture accumulates in the insulation). Fiber thickness index, the thinner the warmer the material and the sound absorption coefficient is higher, which has a positive effect on the soundproofing properties of the material. (The sound absorption is more affected by the construct (Thickness of drywall, OSB or plywood and the number of sheets.) Relative to “On does not burn” - both glass and basalt do not burn. They just have different peak application temperatures. At high, the binding fibers evaporate and the material loses its performance Glass: +200-+270, Basalt: +300 - +700, or even +1000.

ISOVER was the first company to come up with and develop the TEL technology, which is now used to produce glass thermal insulation. Knauf, Ursa.

Basalt has the main brands: TechnoNIKOL, Rockwool, ISOVER (now produces basalt, formerly Linerock), Nazarovo.

As for the harmfulness of heaters. Each product has a HYGIENE CERTIFICATE, which lists the content of harmful substances. Open and see: there is in Izover and in knauf and in basalt there are resins containing phenol formaldehyde. the content is 100 times less than the norms dangerous to human health. Each brand has a full range of products for each specific construct.

The service life of materials depends ONLY on the correct installation (selection of material, use of films, correctness of the construct, ventilation, thickness of the material in the structure) All materials are given in Russia!!

Regarding the prickliness of the material: to work with ANY thermal insulation, it is necessary to use special clothing, a mask and gloves). You don't weld without a mask!

Dima Filshin:

But I don’t know, I’ve never come across it, but I think that basalt taxis, albeit an expensive blah!

Grigory:

Basalt slab, there is a special high density, for walls ...

Natalia:

category Family, home, children Subcategory Construction and repair - did you ask there?

Alexander Bykov:

Good day! It is necessary to compare technical characteristics: Thermal conductivity (the lower, the worse the material transmits heat) Vapor permeability (The higher - the better the material passes vapor molecules, the less moisture accumulates in the insulation). Fiber thickness index, the thinner the warmer the material and the sound absorption coefficient is higher, which has a positive effect on the soundproofing properties of the material. (The sound absorption is more affected by the construct (Thickness of drywall, OSB or plywood and the number of sheets.) Relative to “On does not burn” - both glass and basalt do not burn. They just have different peak application temperatures. At high, the binding fibers evaporate and the material loses its performance Glass: +200-+270, Basalt: +300 - +700, or even +1000.

ISOVER was the first company to come up with and develop the TEL technology, which is now used to produce glass thermal insulation. Knauf, Ursa.

Basalt has the main brands: TechnoNIKOL, Rockwool, ISOVER (now produces basalt, formerly Linerock), Nazarovo.

As for the harmfulness of heaters. Each product has a HYGIENE CERTIFICATE, which lists the content of harmful substances. Open and see: there is in Izover and in knauf and in basalt there are resins containing phenol formaldehyde. the content is 100 times less than the norms dangerous to human health. Each brand has a full range of products for each specific construct.

The service life of materials depends ONLY on the correct installation (selection of material, use of films, correctness of the construct, ventilation, thickness of the material in the structure) All materials are given in Russia!!

Regarding the prickliness of the material: to work with ANY thermal insulation, it is necessary to use special clothing, a mask and gloves). You don't weld without a mask!

Minvata TechnoNIKOL

TechnoNIKOL is a domestic manufacturer of insulating materials, one of the top five European companies in the production of these products. TechnoNIKOL mineral wool is made of basalt fibers, which are distinguished by high environmental friendliness and thermal insulation performance. This material is used for insulation of both multi-storey buildings on an industrial scale, and in private housing construction.

The most common types of mineral wool produced by TechnoNIKOL are presented below:

-

rocklight

- basalt slabs with a low content of phenol in resins, due to which this material has increased safety and environmental friendliness. The main area of application is the insulation of private houses. It can be used to isolate horizontal, vertical and angled surfaces. The load on the structures is small, so they may not have high strength, which expands their scope. -

Teploroll

- a material that is long rolls of cotton wool, which have improved soundproofing properties. The greatest application was found in the insulation of roof slopes, ceilings between floors and attic spaces. -

Technoacoustic

- designed primarily for sound insulation, in addition, it has good heat-saving properties. Presented in the form of wool, made of specially arranged basalt fibers, due to which one layer of this material is able to prevent the penetration of sound at 60 dB. Basically, this type of insulation is used in the interior decoration of the building - partitions between walls, ceiling, attic. -

Technoblock

- are produced in the form of low phenolic flat boards, which are resistant to combustion, sound and heat insulation, and they are also not subject to moisture. They are used in most cases for the insulation of layered warehouses and frame buildings.

The main characteristics of TechnoNIKOL mineral wool: thermal conductivity 0.035-0.039 W / mS, vapor permeability 0.3 mg / mchPa, water absorption 1.5-2%, Density 25-50%, compressibility 8-55%.

Prices for TechnoNIKOL mineral wool are quite low and easily compete with foreign analogues. So, Rocklight slabs can be purchased for only $38 per cubic meter.

Having analyzed the main types of mineral wool presented for sale, you can make a choice in the direction of one or another manufacturer. Depending on the scope of use, conditions, prices and other nuances, you should buy a certain brand of mineral wool. Not only the comfort and warmth of your home, but also the safety of the whole family will depend on how responsibly you take this matter.

The topic of modern heat-insulating materials, both imported and domestic, continues to interest readers, because thanks to these materials, one can not only reduce the cost of heating housing, but also significantly reduce the cost of building construction. Leading specialist advises.

What are the advantages of URSA and Izover heat insulators

I had to work with Russian mineral wool. Despite a special protective suit, a respirator, particles of the material fell on the body and lungs, causing very unpleasant sensations. People who constantly work with her, often received dangerous occupational diseases. Another drawback is that this heat insulator quickly collapses in the wall, sags, as a result of which the upper part of the wall loses thermal insulation, while in the lower part it deteriorates significantly. The thermal insulation materials that we offer are completely environmentally friendly and even pleasant to the touch, durable, have the best insulating properties and, finally, are cheaper than those made in Kstovo or Vyksa.

Teploknauf or Rockwool Comparison of heaters for a country house

The choice of insulation for a private house often turns out to be that torment. All due to the fact that all experts have their own opinion regarding heaters. Because of this, it can be extremely difficult to choose between TeploKnauf mineral wool and Rockwool basalt wool, and the choice is made mainly in favor of one specific insulation.

In order to put an end to the confrontation between TeploKnauf and Rockwool insulation, we will simply compare their main characteristics and explain the differences, if any. For maximum objectivity, materials from the economical price segment were taken for wall insulation: RockWool and TeploKnauf Cottage insulation. Information taken from official sources.

Insulation TeploKnauf

Insulation Rockwool

- Not prickly

- Thermal conductivity: 0.037 W/(m K)

- Density 15 kg/m2

- Safe for health

- Not combustible

- Not designed for direct loads

- Not prickly

- Thermal conductivity: 0.039 W/(m K)

- Density 40 kg/m2

- Safe for health

- Not combustible

- Can withstand direct loads

The main characteristics of basalt and mineral wool are similar, but there are a couple of significant differences that you should pay attention to when choosing a heater for a country house

Thermal conductivity is the main indicator that you need to pay attention to. The larger this value, the more heat will leave the house, respectively, the smaller it is, the better.

A difference of a few hundredths is not particularly critical, but it is better to be sure that the insulation that you have chosen will accurately cope with its tasks.

Insulation manufacturers TeploKnauf and Rockwool consider density as one of the main advantages of their product: some argue that higher density is better, others, on the contrary, deliberately reduce it. In fact, to figure out which of these is more effective, a comparison of a sheepskin coat and a down jacket is perfect. At -30 a down jacket would be a much better solution. Than a heavy sheepskin coat that quickly freezes through.For the myth that high density protects better from the cold, you can thank the manufacturers of the same stone wool, who invented it.

Direct loads mean physical impact on the insulation. TeploKnauf Cottage without auxiliary materials will hardly survive the winter under a flat roof, unlike Rockwool, which, due to its high density, will be easier to withstand pressure.

Basalt wool due to its high density is easier to install than less dense mineral wool.

The main thing for the end user will be that the most expensive basalt wool and economical mineral wool will cope with the insulation of the floor of the walls and ceiling in the same way because of their characteristics.

A good insulation for the roof is appreciated not only in winter - it saves from the summer heat and cuts off excess noise from the outside. The range of insulating materials is large, but it is difficult for an inexperienced person to choose the best option. Too many nuances, unconvincing advertising promises and conflicting reviews. Let's figure out what the modern market offers us, and how we can insulate an attic, an ordinary roof or an attic.

It is more profitable for a private homeowner to take a reliable material that does not require replacement for at least a dozen or two years. After all, doing major repairs yourself will be difficult and expensive. That is why it is worth choosing the products of a well-known brand that protects its reputation and does not release frank marriage. But all the famous companies that manufacture heaters must have some unique production technology. So, you will have to be especially careful in choosing a decent thermal insulation for a roof or attic, correlating new items with your own requirements. We'll help you figure out the nuances.

What is better rockwell, isover or ursa

- Which is better: Rockwell, Isover or Ursa?

- How to choose a good wall insulation

- How mineral wool affects health

All these materials are high-quality heaters that are successfully used at construction sites. The structure of isover, roquel and ursa is the same: the smallest fibers of cotton wool, between which cavities filled with air are formed. It is the most effective thermal insulator. This provides high thermal insulation properties of each of these materials.

What are the differences

Roquel is made on the basis of basalt fiber, and ursa with isover is made on the basis of fiberglass. The differences between these materials are as follows:

- basalt have higher thermal insulation performance - the hygroscopicity of materials based on basalt fiber is less than 1%. (isover and ursa, since their structure contains fiberglass, hygroscopicity is 10-20% higher than that of rockwell) - basalt fibers are more resistant to alkalis and steam - during the installation of isover and ursa, the release of tiny particles of fiberglass is observed - pricklyness of rockwell much lower than that of materials made on the basis of glass fibers - isover and ursa in the event of a fire begin to burn out at lower temperatures than rockvel

What properties are similar

Each of these materials provides high-quality sound insulation, which increases the comfort of living in the house. All of them are durable and have high thermal insulation characteristics. Each of the heaters is vapor permeable. That is, in the cold season, it is able to remove excess steam to the outside, and in summer to prevent overheating of the internal space of the house.

Izover, Ursa and Rockwell are easy to install, but the latter provides greater convenience. All heaters are able to maintain the stability of their size, that is, they have a sufficiently high coefficient of resistance to mechanical stress. For vertical insulation, it is recommended to use plates, for horizontal - rolled materials.

If it is necessary to protect the house from the penetration of rodents, then it is better to use glass wool, as it is more dangerous for them than basalt fiber.There is a point of view that the advertised benefits of stone wool are just a great marketing ploy. By and large, the differences between fiberglass and basalt are minimal.

Therefore, any of these heaters will serve flawlessly for a long time.

But to ensure the maximum thermal insulation effect, when choosing materials, you need to pay attention to the degree of their density. For example, in Ursa, it may be as follows: P-15 (13-16 kg / m3), P-30 (26-32 kg / m3), M-11 (1 kg / m3), etc.

Izover insulation

The manufacture of Izover insulation is carried out using TEL technology from high-quality fiberglass.

The product obtained in this way has the following characteristics:

-

Thermal conductivity

is about 0.041 V / m K - an indicator that provides excellent thermal insulation. Over time, this indicator does not increase, keeping the room temperature unchanged for a long period. -

High level soundproofing

thanks to small air gaps between the fibers, it will not only provide protection from street noise, but also isolate the rooms inside the building from each other. -

Fire safety.

All Izover mineral wool is not susceptible to fire and complies with fire safety requirements. Therefore, its installation can be carried out in buildings of any type. -

Vapor permeability

is 0.5 mg / mchPa - an excellent indicator for this type of insulation material, however, with an increase in humidity by 1%, thermal insulation decreases by 10%. In order to prevent moistening of the mineral wool, a gap should be left between the insulation and the wall for better air ventilation. -

Life time.

The manufacturer declared figures of 50 years without deterioration in quality, this information is confirmed by the reviews of the owners who have been using this material for several years. -

Health safety.

It is believed that some types of mineral wool adversely affect human health, but scientists have proven that Izover's thermal insulation does not harm human health. -

Isover plate weight

low enough, so they are widely used for insulation of buildings with a fragile structure. -

Production form.

Isover mineral wool is produced in rolls of 16-20 cubic meters. meters and slabs, single-layer, 5-10 cm thick and multi-layer, the thickness of each layer in which is 5 cm. The cutting of the slabs can be the most diverse.

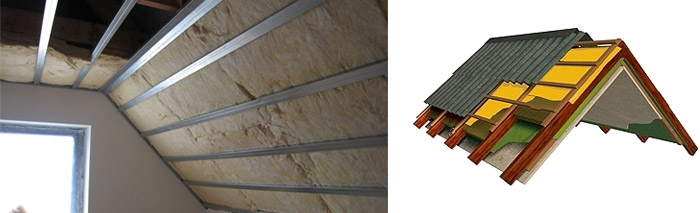

Roof insulation how to choose

The future requirements for thermal insulation depend on what type of roof your house has, since it can be flat and pitched, and it can also have a residential and non-residential attic space.

Selection principles:

- roofing insulation must be environmentally friendly;

- have excellent sound insulation;

- low thermal conductivity;

- frost resistance;

- must be fireproof;

- must retain its geometric parameters;

- have form stability;

- small mass;

- be durable.

Recommendations to follow:

- for a pitched roof, it is better to use materials with increased density;

- for unloaded structures, it is recommended to use the least rigid heaters.