Features of low pressure polyethylene

Pipelines of 2 types are made from low-pressure polyethylene (HDPE or HDPE):

- Pressure (for gas and water supply).

- Non-pressure (for the sewerage system).

Metal products give way to polyethylene pipes due to its features:

- opaque in a thick layer;

- not destroyed by biological microorganisms;

- resistant to impact (up to +60оС) aqueous solutions of salts, acids and alkalis;

- lasting;

- elastic (bends well, resistant to stretching and compression);

- does not give in to corrosion;

- durable (from 50 to 80 years in operation);

- little weight.

HDPE pipes:

- practically do not clog;

- easy to mount;

- cheaper than metal ones.

bending radius

Basically, the pipe is bent at standard angles of 90o, 60o, 45o, 30o, but if necessary, you can set any bending radius of the HDPE pipe, not exceeding 90o.

Melting temperature

At a temperature of + 80 ° C, low-pressure polyethylene softens, and its melting point is from + 130 ° C to + 137 ° C. It is at this temperature that HDPE pipes are produced.

Types of pipelines for warm water floors

Copper pipes have the best thermal conductivity

Assembling equipment for warm water floors is a rather complicated job that requires the involvement of skilled labor. Heating circuits are mounted from pipes made of various materials:

- cross-linked polyethylene pipes;

- metal-plastic pipelines;

- polypropylene systems;

- copper pipes.

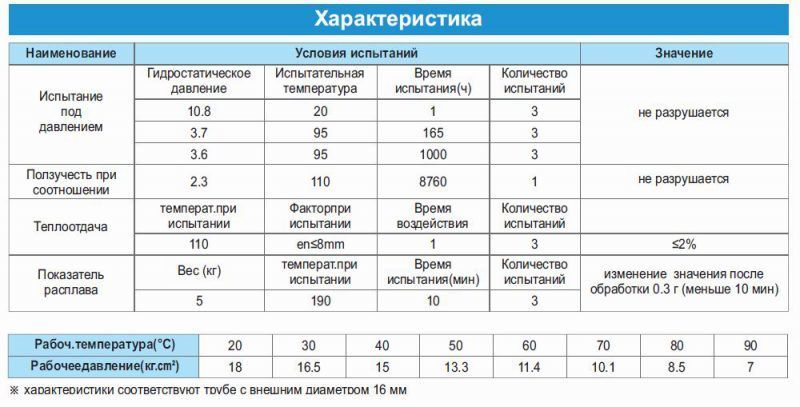

Each heating system has its own advantages and disadvantages. Compare cross-linked polymer with other pipe materials in the table:

| № | Material name | Advantages | Flaws |

|---|---|---|---|

| 1 | crosslinked polymer | Strong and durable material | Pipes are susceptible to destruction from ultraviolet radiation |

| 2 | metal-plastic | High flexibility | High price |

| 3 | Polypropylene | Low price | Pipes are bent under heat |

| 4 | copper pipe | Versatility, high thermal conductivity | The most expensive pipes |

Material production features

Cross-linked polyethylene owes its strength characteristics to a special technology for its manufacture. It consists in creating a three-dimensional molecular network, thanks to the use of various technologies:

- heating polyethylene in the presence of peroxides (PEX-a);

- treatment with moisture with implanted silane with the participation of a catalyst (PEX-c);

- electron bombardment (PEX-c);

- nitrogen treatment, which is rarely used.

Characteristics of cross-linked polyethylene

Thanks to the acquisition of new characteristics, pipes made of this material are recognized as one of the most suitable options for arranging a water-heated floor.

This is interesting: Scheme of a thermal unit: explaining the essence

Starting a warm floor

The coolant for normal operation of the system is heated to a temperature not exceeding +26 °C.

Starting heating, mounted from PE pipes, is carried out according to the scheme:

- a collector is connected to the supply pipe and return pipe;

- on the collector node, all taps from the circuits open simultaneously;

- with the designation "open", the valves of the air vents are set;

- the circulation pump is put into operation;

- the temperature is set to +25 °C;

- it is expected that the operating pressure in the heating system will increase to 1 bar;

- all contours are blocked with cranes, only one longest one remains open;

- the position of flowmeters and balancers is fixed on paper;

- the next circuit is put into operation one that is slightly less than the length of the working one, but exceeds the rest. Using a tap, the same pressure is set - 1 bar. So all circuits are connected in turn.

It will be possible to fully judge the quality of the work performed only after 3 months of the system operation.

Screed device rules

If the hydraulic tests were completed successfully, no depressurization of the pipes occurred, and the system is completely filled with coolant, then the stage of pipe installation is completed. Now you can proceed to the screed device and finishing.

For the screed device, it is necessary to use a purchased or self-prepared mortar based on M300 cement. The minimum height of the screed, which provides protection for polyethylene pipes, is 3 cm above the laid pipe. This thickness will be optimal for uniform heat distribution.

In most cases, the screed is made continuous without expansion joints. Thermal seams are needed when:

- the room has an area of more than 33 m2;

- room length more than 10 m;

- the room has a complex configuration.

A damper tape is used to create seams. Thermal seams are treated with sealant.

Do I need to do reinforcement before pouring the screed? There is no single answer to this question. Experience shows that the system works perfectly without reinforcement, but at the same time, the reinforcing layer gives the screed additional strength. For reinforcement, you can use a 100x100 mm mesh made of metal or plastic.

Also, reinforcement will be useful only if the reinforcing mesh does not just lie on top of the pipe system, but “drown” in the solution, while being solidified inside the screed.

The correct reinforcement device complicates the laying of the screed, so when there is no experience or confidence that everything can be done correctly, this step can be skipped. After pouring the screed, the system can be started no earlier than 25-30 days later.

As a finish - the top layer of the "pie" can be used any floor covering

Which pipes are better to make underfloor heating

A pipe for a warm floor must meet very specific requirements, such as:

- resistance to mechanical stress;

- long service life;

- resistance to corrosion;

- environmental Safety;

- low coefficient of linear expansion;

- elasticity;

- high heat transfer;

- ability to absorb noise.

In varying degrees, these characteristics correspond to a number of materials. Quite successfully, pipes from:

- copper;

- corrugated steel;

- metal-plastic;

- polypropylene;

- polyethylene.

Copper pipes are a high-end and time-tested option. However, their cost is high in itself. In addition, you will need to spend money on a polymer shell, which is necessary when installing copper in a screed, and on special brass fittings.

It is easier to work with corrugated steel and its consumption will be somewhat less, with almost the same performance characteristics as copper. But the price of the material will be just as high.

Metal-plastic structures are relatively "young" and perfectly serve as a transport highway when installing a warm floor. However, scale can build up inside threaded fittings over time. In addition, during installation, there is a high probability of a pipe cut.

In polypropylene pipes, with such advantages as an affordable price, simple installation and low physical weight, the indicators of linear expansion when heated are “lame”. When installed in a concrete screed, they must be reinforced with fiberglass and aluminum.

Cross-linked polyethylene pipes are considered the most modern choice for installing a warm floor, since their characteristics meet the technological requirements to the fullest extent. Among the shortcomings, one can note the insufficient flexibility of the material, due to which the pipes do not hold their shape well during installation.

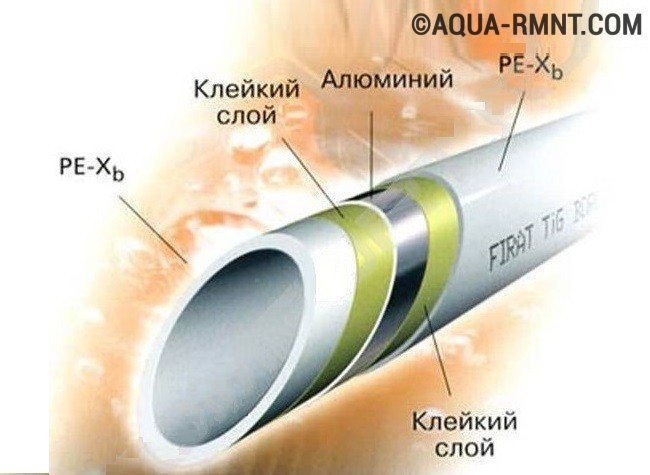

The XLPE pipe with anti-diffusion protection includes a special layer of aluminum that prevents the penetration of oxygen or water vapor through the pipe walls.

A wide selection of pipes, fittings, manifolds and other types of products for engineering networks is offered by the STOUT brand.

Stout offers a wide range of pipes

The STOUT metal-plastic pipe is designed specifically for Russian operating conditions

This is interesting: How to choose polycarbonate for a greenhouse: the whole point

Ways

All methods by which HDPE pipes are bent are based on the properties of this polymer: under the influence of high temperature, it softens, and the material is given the required shape.

The methods are divided into:

- industrial;

- non-productive (at home).

industrial or manufacturing

- Rolling around the template without filler.

- Winding on a template with a mandrel inside.

Non-productive

You can bend HDPE pipes at home. These methods can be divided into types. Depending on what tools will be used to bend.

With a building hair dryer

The method is the safest and most effective for doing it yourself. It is desirable to have a hair dryer with precise temperature control. Principle of operation: heating of the area for bending.

With a gas burner

A manual gas burner can replace a building hair dryer. The principle of operation is similar, but this option is inferior to the previous one. Since you need to have some experience, because:

- if the flame of a gas burner is far from the surface, then the specified place may not warm up to the required temperature, and when bent, the product will simply break;

- if the gas burner is too close, then the flame will ignite the polymer, which will also lead to damage to the product.

However, there are also advantages:

- accessibility in places where there is no power supply;

- the cost of a gas cylinder of 220 ml will cost ten times cheaper than buying a building electric hair dryer.

Hot water treatment

If you do not have a building hair dryer or a manual gas burner at home, and the amount of work is small, then a few liters of hot water will come to the rescue.

But this method is available only if the diameter does not exceed 50 mm. The method is used even in production. Large baths are used there, in which the liquid is heated to + 135 ° C. Principle of operation: hot water heats up the required area for subsequent bending.

Conclusions and useful video on the topic

The rules for calculating the floor heating system are given in the video:

After laying the pipe, it is important to test it before proceeding with further installation work. About it in the video: Home craftsmen often make mistakes when assembling a warm floor

The main problems of installing polyethylene pipes are covered in the video clip:

Home craftsmen often make mistakes when assembling a warm floor. The main problems of installing polyethylene pipes are covered in the video clip:

Properly selected and installed underfloor heating at no extra cost will make your home warm and comfortable. The technology for installing a floor heating circuit made of PE pipes is simple and can be used not only by professional builders, but also by ordinary people. Subject to all the rules and recommendations, the system will serve you properly for a long time.

Have you had to lay polyethylene pipes when installing a warm floor? Perhaps you know the technological nuances that are not noted in the article? Please write 0 , ask questions, post photos on the topic in the block below.