What you need to connect

To install a heating system on gas cylinders, you will need:

- Gas boiler equipped with a burner for liquefied gas;

- Gas cylinders with a capacity of 50 liters;

- Reducers;

- Ramp if several cylinders are connected;

- Shut-off valves;

- Gas pipeline in the form of pipes and hoses for connecting equipment to the system.

When choosing a gas boiler, you should pay attention to models with the lowest operating pressure and high efficiency. Many models of boilers are already equipped to work with natural and liquefied gas

If connection to the main gas pipeline is not expected, then it is better to choose just such a boiler to work on LPG.

Otherwise, additional equipment is purchased: nozzles for the burner or a complete burner for liquefied gas, and in some models a gas valve. The burner of a natural gas boiler is designed for a lower system pressure and has a valve with a large orifice, which can lead to an emergency.

Safety precautions when working with gas cylinders

Propane heating requires stringent security measures. In addition, it is impossible to place cylinders closer than 2 meters from the boiler, to prevent direct rays and overheating. Still unacceptable:

- In case of freezing, use an open fire to warm up the cylinders. In general, fire and gas containers are an explosive combination, so if an accidental fire occurs, the container with fuel should be removed first.

- When arranging a room for cylinders, care must be taken that there is no cellar or basement next to the room. The gas is odorless, but has the physical property of sinking down. Thus, a person who descended into the cellar may be poisoned. Also, with an imperceptible gas leak, large accumulations of fuel in the cellar will lead to an explosion.

- To minimize the risk of fire, a gas leak meter should be installed in the system.

- It is strictly forbidden to store empty cylinders in the house. A warehouse with full capacities should be located no closer than 10 meters from a residential building.

Performing calculations

Preliminary calculation of gas consumption for heating is made according to the formula:

V \u003d Q / (q x efficiency / 100).

- q is the calorific value of the fuel, the default is 8 kW/m³;

- V is the desired flow rate of the main gas, m³ / h;

- Efficiency is the efficiency of fuel combustion by a heat source, expressed in %;

- Q is the heating load of a private house, kW.

As an example, it is proposed to calculate the gas consumption in a small cottage with an area of 150 m² with a heating load of 15 kW. It is planned that the task of heating will be performed by a heating unit with a closed combustion chamber (92% efficiency). The theoretical fuel consumption for 1 hour in the coldest period will be:

15 / (8 x 92 / 100) = 2.04 m³ / h.

During the day, the heat generator will consume 2.04 x 24 = 48.96 m³ (rounded - 49 cubic meters) of natural gas - this is the maximum consumption on the coldest days. But during the heating season, the temperature can fluctuate between 30-40 ° C (depending on the region of residence), so the average daily gas consumption will be half as much, about 25 cubic meters.

Then, on average per month, a turbocharged boiler uses 25 x 30 = 750 m³ of fuel to heat a house with an area of 150 m², located in central Russia. In the same way, consumption is calculated for cottages of other sizes. Focusing on a preliminary calculation, it is possible to carry out measures aimed at reducing consumption even at the construction stage: insulation, selection of more efficient equipment and the use of automatic controls.

Requirements for heating a private house with gas cylinders

- Provide free access to the cylinders for their inspection and subsequent filling.

- Cylinders must not be stored in basements or on the basement of a house. This requires the organization of a specially designated space.

- Gas cylinders must not be stored in an inclined position and must not be dropped.

- The cylinder mount must be strong. As a rule, a clamp is used to fix it to the wall.

When heating the house with gas convectors or using a boiler, the cylinder should be filled to a maximum of 80-85%. As the temperature rises, the volume of the gas begins to increase. If the volume does not allow this, an explosion may occur! In addition, the installation of the cylinders must be in a place without direct exposure to UV rays.

We heat the country house with natural gas

Natural gas among other types of fuel is the leader. In the presence of a modern efficient boiler, a well-insulated house is heated at minimal cost. Of course, there are cheaper sources of energy, but they are not autonomous: solid fuel must be constantly supplied, electricity can be turned off, gas in cylinders runs out from time to time.

Features of using gas boilers

When choosing a boiler, you need to proceed from the area of \u200b\u200bthe house and the hydraulic calculation. A wall-mounted convection boiler can cope with heating a three-hundred-meter house. You can install condensing equipment. It is suitable for houses up to 400 m2. Such boilers use not only fuel energy, but also steam condensate. Their energy efficiency is much higher. If suddenly the performance of the equipment is not enough, you can use the "cascade connection" function.

Hot water can be provided by an electric boiler, but if the heating of a private house is based on the use of natural gas, it is more economical to use it to heat water. To do this, you need to purchase either a double-circuit gas boiler, or supplement the existing tank. You can choose the volume based on domestic needs. Boiler columns keep a stock of water of the necessary temperature. The flow gas boiler heats the water at the time of supply. After opening the tap, cold water will first go down, and only then hot water will come out.

Diagram of the device of such a system

The scheme of the gas heating system of a private house includes a heat source, from which the coolant first diverges through the collector through pipes to the radiators, and then, cooling down, returns to the boiler. The fluid is under pressure. The circulation in this case is forced. Additionally, air vents, stopcocks, flow and temperature sensors, thermal heads can be installed. The automatic control helps to regulate the temperature.

The system can also be designed for natural circulation, then the expansion tank at the highest point of the house is included in the circuit. Here you can save on temperature sensors, air vents and expensive pumps.

Heating wiring can be radial or tee. The first is more expensive due to the larger footage of the pipeline, but more efficient and mobile, it is easier to repair during the heating season. The second one is cheaper due to the smaller number of pipes, but it does not provide such wide opportunities for temperature control in individual rooms as radiant wiring.

The number of radiators in the system is determined on the basis of thermal and hydraulic calculations. This is the most correct option both from a technical and economic point of view.

You should not rely on the advice of unskilled sellers and outsiders: the number of sections does not need to be selected based only on the area of \u200b\u200bthe room.

Natural gas heating equipment requires minimal maintenance, which, by the way, can be done on your own. The fuel burns without forming a solid residue. In order not to install a chimney, you can purchase a boiler with a closed combustion system.

If there is no gas main by the end of the construction of the house, you can purchase a boiler for two types of fuel. After gasification, the transition to economical and efficient natural gas will not require significant material costs. The maximum will need to call a specialist from a service company.

Disadvantages of gas heating on cylinders

Like any other heating method, this one also has its drawbacks:

- if the cylinder is outside, in case of severe frost, the system may turn off - the condensate will freeze and prevent the gas from escaping;

- do not place cylinders in unventilated areas;

- since the gas is heavier than air, if it leaks, it can go down (into the basement, underground), and if there is a strong concentration, serious consequences will occur.

Thus, heating with gas cylinders, if certain conditions are not met, can be very dangerous. Therefore, they should be stored only in ventilated rooms, under which there is no basement. It is even advisable to place them in a separate extension on the site. The room must be warm so that the system does not turn off in frost. If it is cool in the annex, then you will have to make an insulated metal or plastic box for the cylinders. For insulation, the walls are sheathed with foam plastic 5 centimeters thick. Ventilation holes must be made in the lid of the box.

Heating with gas bottles

The construction of private country houses is quite actively developing in our country. Often, private houses are built far from the gas pipe, so it is impossible to connect to a centralized gas supply, and installing a gas tank is also not always convenient or profitable, and therefore heating with gas cylinders is the only right solution.

Heating with gas cylinders provides use of a gas boiler. In general, the heating system is similar to any other, the only difference will be that you will have to independently monitor the fullness of the gas cylinder. As a rule, people who own a heating system based on gas cylinders buy several cylinders at once, which makes it possible to be always sure that the fuel does not suddenly run out. If you use a special ramp, then this is quite problem-free. The ramp is connected to the cylinders with a flexible hose, which is also equipped with a safety valve and a pressure gauge. A safety valve is required when the pressure in the cylinder rises and must be deflated. The gas cylinders themselves are produced in volumes from 5 to 50 liters.

Many will have a reasonable question, “How many gas cylinders are needed, and what volume?”. Calculate will not be a problem. On average, if the area is up to 50 sq.m. then 50 liter cylinders will need approximately 56 pcs. provided that you plan to live there permanently. But we must understand that the lower the temperature outside the window, the greater the gas consumption occurs.

Among other things, it is necessary to remember the rules that apply to the heating system on gas cylinders.

- Basements and basements are prohibited from gasification.

- The gas cylinder must be freely accessible.

- The gas cylinder must be attached to the wall.

- The cylinder must be located at a distance of one meter from the gas stove, heating radiator and switch.

Heating a wooden country house with gas cylinders has its own advantages:

- Availability and cheapness of fuel,

- environmental friendliness,

- Easy to install,

- The compactness of the heating system.

The disadvantages include:

Explosiveness.

When operating gas cylinders, safety measures must be observed.

- The gas cylinder must not be tilted and stored in a horizontal position.

- Store in a separate room and it is desirable that it be located in a separate building,

- It is forbidden to bury in the ground,

- Do not store used gas cylinders in a shed or at home.

- It is strictly forbidden to self-fill gas cylinders.

To avoid problems with your heating system, only specialists with experience and special education should install it. Our specialists have both education and experience, and they also have a special permit from the relevant organization for this type of work.

Calculation of costs for an autonomous gas heating device

Comparing which of the types of heating systems will be the least expensive, you must first pay attention to the consumption of liquefied gas for heating. It is advisable to compare the upcoming costs with similar costs for other types of fuel and decide which option will be more profitable.

Initial equipment and set-up costs

The cost of purchasing equipment and installing an autonomous liquefied gas heating system in your home may vary slightly in different regions of residence. But in general, when compared with connecting to the main gas pipeline, the difference in cost will be insignificant. It will be more expensive only if you use not cylinders, but a gas tank with a volume of several cubic meters. Its cost will be more than 300,000 rubles.

It is also almost equivalent in cost to equip premises for boilers using LPG, in comparison with those that run on diesel fuel. According to reviews, heating with liquefied gas only requires higher initial costs when it serves as an alternative to solid fuel or electric heating. But in the course of further operation, the funds invested in heating a private house with liquefied gas will gradually pay off due to the profitability of this type of fuel.

Gas costs for heating a private house

A few years ago, a propane-butane mixture cost much more than main gas (methane), but over time, the price difference between them decreases. Therefore, the relative indicators of the cost and consumption of liquefied gas for heating demonstrate the feasibility of using this energy carrier.

Specific heat of combustion, mJ

The easiest way to determine the real consumption of liquefied gas for heating a house is to correlate the mass of gas in one cylinder with the technological characteristics of heating equipment. In this case, it is more convenient to calculate the flow rate precisely by mass, since the volume (in liters) depends on the density and percentage composition of the propane-butane mixture pumped into the cylinder.

A standard 50-liter cylinder is filled with 35-40 liters of LPG, which, in terms of mass, gives an average of 22 kg of gas.

Let's analyze a specific example to determine the required amount of liquefied gas in cylinders for heating a house with an area of 100 m²:

- For heating the indicated area, it will be necessary (according to the maximum standards) 10 kW of heat energy;

- However, the boiler does not operate constantly in the maximum mode, and its average load factor can be taken as 0.5. So we need 5 kW;

- With a calorific value of liquefied gas of 46 mJ / kg, about 0.1 kg of LPG per hour will be consumed to produce 1 kW of heat energy, and 0.5 kg of LPG will be required for 5 kW;

- 12 kg, or almost half of the cylinder, will be consumed per day;

- The monthly consumption of liquefied gas for continuous heating of the house will be approximately 13-15 cylinders.

The volume of the gas tank may be enough to operate the heating system throughout the season

What will be the consumption if you do not use cylinders, but pump fuel into a gas tank? How often will you have to call a tanker to replenish the gas supply in the “five-cc” tank most common among consumers? Let's figure it out:

- Any of the containers for liquefied gas is not filled “under the neck”, but only by 80–85%. Accordingly, in a tank with a volume of 5 m³ there will be about 4250 liters or (in terms of mass) 2300 kg of gas;

- We have already determined that in our case the liquefied gas heating system consumes 0.5 kg of fuel per hour;

- We divide the total mass of 2300 kg of gas contained in the gas tank by 0.5 kg / hour, and we get 4600 hours - for such a time we have enough fuel;

- Dividing 4600 hours by 24 gives us a total of 190 days. That is, one filling of a gas tank with a volume of 5 m³ is enough to heat a house of 100 m² for almost the entire heating season (in a temperate climate).

These are theoretical calculations, but in reality, fuel consumption can be significantly reduced. With the correct setting of the combustion modes, a gas heating boiler for liquefied gas is able to consume 1.5–2 times less fuel, and the temperature in the house will be maintained at an acceptable level.

To reduce the amount of combustible gas, use automation, which switches the boiler to a moderate mode at night, reducing the temperature in the system by 7–9 degrees, thereby achieving a 30% reduction in costs.

Scheme of connecting gas cylinders to a heating boiler

Accession to the system is carried out by means of a special gearbox. The device converts the fuel from a liquid state to a gaseous state for supply to the boiler. In the presence of 2 or more containers, several gearboxes are used, each of which is connected to one cylinder. This method is considered safer than connecting through a single generic reducer.

The design is formed using a ramp - a two-arm collector that distributes the tanks into two groups, the main and the backup. First, gas is taken into the boiler from the main group of cylinders, then from the reserve. Switching is automatic, the owner hears only a warning signal from the devices. As soon as the cylinders of the main group are filled and reconnected, the ramp switches back to taking fuel from the cylinders of the main group.

Attention should be paid to the installation of fuel containers - no closer than 2 m from the boiler, preferably in a separate non-residential compartment, room. Do not place the container in an open place accessible to sunlight

Using a propane-butane mixture

Autonomous heating of private houses with liquefied propane or its mixture with butane has not yet lost its relevance in the Russian Federation, although in recent years it has noticeably increased in price

It is all the more important to calculate the future consumption of this type of fuel for those homeowners who plan such heating. The same formula is used for the calculation, only instead of the net calorific value of natural gas, the value of the parameter for propane is set: 12.5 kW with 1 kg of fuel

The efficiency of heat generators when burning propane remains unchanged.

Below is an example calculation for the same building of 150 m², only heated with liquefied fuel. Its consumption will be:

- for 1 hour - 15 / (12.5 x 92 / 100) = 1.3 kg, per day - 31.2 kg;

- on average per day - 31.2 / 2 \u003d 15.6 kg;

- on average per month - 15.6 x 30 \u003d 468 kg.

When calculating the consumption of liquefied gas for heating a house, it must be taken into account that fuel is usually sold by volume measures: liters and cubic meters, and not by weight. This is how propane is measured when filling cylinders or a gas tank. This means that it is necessary to convert mass into volume, knowing that 1 liter of liquefied gas weighs about 0.53 kg. The result for this example will look like this:

468 / 0.53 \u003d 883 liters, or 0.88 m³, of propane will have to be burned on average per month for a building with an area of 150 m².

Given that the retail price of liquefied gas is an average of 16 rubles.for 1 liter, heating will result in a considerable amount, about 14 thousand rubles. per month for the same cottage for one and a half hundred squares. There is reason to think about how best to insulate the walls, and take other measures aimed at reducing gas consumption.

Many homeowners expect to use fuel not only for heating, but also for providing hot water

These are additional costs, they must be calculated, plus it is important to take into account the additional load on heating equipment

The thermal power required for hot water supply is easy to calculate. It is necessary to determine the required amount of water per day and use the formula:

- c is the heat capacity of water, equal to 4.187 kJ/kg °C;

- t1 — initial water temperature, °С;

- t2 is the final temperature of the heated water, °С;

- m is the amount of water consumed, kg.

As a rule, economical heating occurs up to a temperature of 55 ° C, and this must be substituted into the formula. The initial temperature is different and lies in the range of 4-10 °C. For a day, a family of 4 people needs approximately 80-100 liters for all needs, subject to economical use. It is not necessary to convert the volume into mass measures, since in the case of water they are almost the same (1 kg \u003d 1 l). It remains to substitute the obtained value QDHW in the above formula and determine the additional gas consumption for hot water.

Liquefied gas

Many boilers are made in such a way that the same burner can be used when changing fuel. Therefore, some owners choose methane and propane-butane for heating. This is a low density material. During the heating process, energy is released and natural cooling occurs under the influence of pressure. The cost depends on the equipment. Autonomous supply includes the following elements:

- A vessel or cylinder containing a mixture of butane, methane, propane - a gas holder.

- Devices for management.

- A communication system through which fuel moves and is distributed inside a private house.

- Temperature sensors.

- Stop valve.

- Automatic adjustment devices.

The gas holder must be located at least 10 meters from the boiler room. When filling a cylinder of 10 cubic meters, to service a building of 100 m2, you will need equipment with a capacity of 20 kW. Under such conditions, it is enough to refuel no more than 2 times a year. To calculate the approximate gas consumption, you need to insert the value for the liquefied resource into the formula R \u003d V / (qHxK), while the calculations are carried out in kg, which are then converted to liters. With a calorific value of 13 kW / kg or 50 mJ / kg, the following value is obtained for a house of 100 m2: 5 / (13x0.9) \u003d 0.427 kg / hour.

Since a liter of propane-butane weighs 0.55 kg, the formula comes out - 0.427 / 0.55 = 0.77 liters of liquefied fuel in 60 minutes, or 0.77x24 = 18 liters in 24 hours and 540 liters in 30 days. Given that there are about 40 liters of resource in one container, the consumption during the month will be 540/40 = 13.5 gas cylinders.

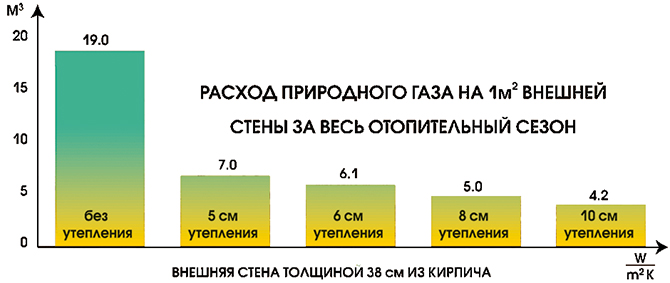

How to reduce resource consumption?

In order to reduce the cost of space heating, homeowners take various measures. First of all, it is necessary to control the quality of window and door openings. If there are gaps, heat will escape from the rooms, which will lead to more energy consumption.

Also one of the weak points is the roof. Hot air rises and mixes with cold masses, increasing the flow in winter. A rational and inexpensive option would be to provide protection from the cold on the roof with the help of rolls of mineral wool, which is laid between the rafters, without the need for additional fixation

It is important to insulate the walls inside and outside the building. For these purposes, there are a huge number of materials with excellent properties.

For example, expanded polystyrene is considered one of the best insulators that lends itself well to finishing, it is also used in the manufacture of siding.

When installing heating equipment in a country house, it is necessary to calculate the optimal power of the boiler and the system operating on natural or forced circulation. Sensors and thermostats control the temperature, depending on the climatic conditions. Programming will ensure timely activation and deactivation if necessary. A hydraulic arrow for each device with sensors for a single room will automatically determine when it is necessary to start heating the area. The batteries are equipped with thermal heads, and the walls behind them are covered with a foil membrane so that the energy is reflected into the room and does not go to waste. With underfloor heating, the carrier temperature reaches only 50°C, which is also a determining factor in savings.

Plumbers: You'll pay up to 50% LESS for water with this faucet attachment

The use of alternative installations will help reduce gas consumption. These are solar systems and equipment powered by wind power. It is considered most effective to use several options at the same time.

The cost of heating a house with gas can be calculated using a certain formula. Calculations are best done at the design stage of a building, this will help to find out the profitability and feasibility of consumption

It is also important to take into account the number of people living, the efficiency of the boiler and the possibility of using additional alternative heating systems. These measures will save and significantly reduce costs

Basic rules for heating a house with gas cylinders.

In order to correctly calculate how much a gas boiler will consume gas from cylinders, it is necessary to know the area of \u200b\u200bthe heated room and the heat loss of the room. Windows should be insulated to reduce heat loss. insulate the walls. roofs and foundations. Without these data, any calculations are not relevant. For example, for heating a standard brick house with an area of about 50 square meters, about 2-4 cylinders of 5 liters per month are needed.

Basic rules for the use of gas cylinders when heating a house with gas cylinders:

- For replacement and inspection of cylinders, free access must be provided to them.

- Gas cylinders must not be installed lying down, and they must not be allowed to fall.

- The distance from the electrical appliance (electric switch) or gas stove to the cylinders must be at least one meter.

- It is forbidden to conduct gas (including placing gas cylinders) in the basement or basement.

Important! For safety reasons, gas cylinders are filled to a maximum of 85%. This is due to the fact that in case of heating, the gas expands and the pressure inside the cylinders increases, which can lead to an explosion.

It is strictly forbidden that direct sunlight falls on gas cylinders, and cylinders should not be stored in hot rooms (for example, a bathhouse).

Gas cylinders can be filled with three types of gases:

- Technical butane is marked - B;

- A mixture of propane and technical summer butane is marked - SPBTL;

- A mixture of propane and winter technical butane - SPBTZ.

Heating the house with gas cylinders, it is desirable to use a mixture of propane and winter technical butane.

The advantages of a gas boiler on bottled gas include the following factors:

- Environmental friendliness - environmentally friendly fuel is used,

- Autonomy (compared to solid fuel boilers),

- Convenience and ease of use.

At the same time, this type of heating has a significant drawback - the cost of bottled gas.

It must be remembered that a gas boiler will not only be able to heat your house, but will provide you with hot water, in this case it is necessary to install a double-circuit gas boiler.

Important! Installation of all gas equipment must be carried out by highly qualified specialists with appropriate permits and licenses.Using gas cylinders is an effective way to heat

Using gas cylinders is an effective way to heat

Any method can be used to effectively heat a private house. Practice shows that natural gas is the most efficient fuel. If the highway does not pass to the villages, then it is always possible to heat the house with gas cylinders, reviews of which speak of their efficiency and availability.

Before direct installation of this type of heating, you should consult with professionals. They will help you choose an acceptable option based on a particular case. A consultation of this kind will provide not only theoretical knowledge, but will also allow you to organize efficient heating of a private house.