What is better foil penofol or basalt insulation

General parameters of thermal insulation:

- Weight. The insulation should not weigh much, because when mounting it on the structure there should not be any weight.

- Thickness. The thinner the material, the more space in the room remains.

- Low thermal conductivity.

- Moisture permeability. The material should absorb moisture as little as possible.

- Noise isolation. Blocks out sounds from the street.

- Environmentally friendly material. Should not emit harmful substances.

- Ease of installation.

Comparing basalt insulation and foil penofol, you need to compare their characteristics.

Basalt wool

Produced from a rock of volcanic origin. It does not burn, has good soundproofing performance, does not lose its qualities over time. It is completely safe for health.

Penofol - application

Which insulation to choose depends on the budget for insulation, as well as personal preferences.

Secret. How to glue foil insulation to the wall.

Kind. Somehow I ran into a problem with gluing foil insulation to the wall. There is a lot of information on the Internet about this. But how and with what glue I did not try - in the end, nothing happened. Everything fell off. And the secret is simple. The insulation is covered with a thin polyethylene film, to which the glue does not stick (to a smooth surface, it has nothing to catch on). The manufacturer did not take this into account, or did not want to. It is enough to make the places where the glue is applied, rough, that is, for sanding with sandpaper. You can use any glue, as well as mounting foam. And no stapler, nails, dowels, military-strategic poisonous liquids are required - as mentioned in many construction forums. Good luck everyone, keep it up.

Small observation. But many do not see the little things. Hence the big problems.

It is enough to make the places where the glue is applied, rough, that is, for sanding with sandpaper.

And most importantly - why spend money on this and other materials and stick something that will not bring any effect.

jekasus wrote: And most importantly - why spend money on this and other materials and stick something that will not bring any effect.

I will support. Apparently, the TS simply has free material and time must be killed.

jekasus wrote: And most importantly - why spend money on this and other materials and stick something that will not bring any effect.

Yes, I agree with you. But this effect is not in the preservation of heat, it is enough, water heating comes from the house. If you take a closer look at the last photo - this is an extension of the future greenhouse on the north side, of course there will not be enough light for plants. Reflective paint is not available. Here is the foil to reflect it. Even with artificial lighting, entering the room at night it is not possible to look, the eyes are hurt by a bright, dazzling, iridescent light. (Checked, a few light bulbs are enough) That's a plus for energy saving. In general, the issue was not considered on the construction of greenhouses and where, why glue the foil insulation. The meaning of how to stick!

How to fix isolon to the wall Kind. Somehow I ran into a problem **glue** foil insulation to the wall. There is a lot of information on the **Internet** about this. But how and with what glue I have not tried - in ... - photo - Mastergrad Forum

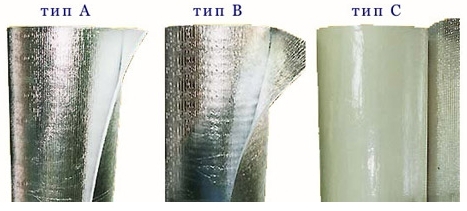

Types of foil penofol

On sale 3 types of penofol with foil.Each is labeled in Latin letters, they indicate the packaging.

Folgoizolone for outdoor and indoor use

TYPE B - the foil is located on both sides. This is the maximum protection against heat loss. Penofol type "B" is used for thermal insulation of the attic, supporting structure, basement, floor. As well as insulation of the pipeline, heating system.

TYPE C - on one side there is a foil, on the other - a thin layer of glue protected by a film. Self-adhesive penofol is easy to install without spending a lot of time. For installation, they are cut into pieces of the desired length and glued to the prepared surface.

TYPE R - full match to type "A", but with a pattern on the foil. Used as wall decor in the room. And also with multilayer insulation, creating an air gap.

TYPE ALP - high degree of reflection. This insulation is used in agriculture, for example, for warming incubators or buildings for calves.

Type NET is an analogue of type "B". Produced in a narrow roll or in coils. Used for pipeline insulation.

2000 Type C - reduced performance. The glue layer is of poor quality, having poor adhesion.

Expert answers

Grandfather Au:

ordinary food will not work - it’s metal, and if it can “reflect” some part of the radiation, then part of the convective flow will still heat it, and since aluminum is an excellent conductor ... Under the foil you need a heater! The walls themselves need to be insulated, for example .termoplex /korund.php?table=korund

*:

Try to stick with saliva ...

Marek Black:

You better insulate with pinoplast from the outside. and the floor can be insulated. You talk to those who do it.

Evil Electrician:

I think you need to consult in the building store or try the moment of installation

New:

First, prime several times with betonite, and then glue, but it is better with a heat-insulating layer, at least on PVA, but there is something that is already sold as a self-adhesive on a heat-insulating substrate.

Sergey Burmasov:

think maybe iron galvanization, but stainless steel is better because foil is weak

nina ilina:

oh, if you stick it crookedly, the receiver is a magnifying glass, with a focus like the fleet was burned in ancient Greece)

Albert Belkov:

I use Termoizol - foil on foam, it's easy to work: I insulate steel bathtubs - they turn out to be no worse than cast-iron ones, they are warm. And the food can be glued on cardboard with slots for hooks to easily insert.

Yuri Martysyuk:

Buy penofol, sold in different thicknesses. It can be self-adhesive, and if not, try double-sided tape!

Chuck Casemerczak:

If the foil sticks to the glass with egg yolk, then it will definitely stick to the concrete

Dmitry Nizyaev:

Double sided tape. He then launders. Why is he “not the best”? It will hold, but nothing more is required.

egor ag:

Why insulate at all? Never did it. Insulation only retains heat, but does not generate. And overnight, not a single heater will keep the engine warm. Moreover, the hood is not even the surface of the engine itself.

Doctor:

Bolts or rivets

Pavel Voronin:

why fix it at all, just put it in when you need to twist and remove

zheka-zloy:

narrow strips and reinforced scotch prime around the perimeter, see all this is risky ... and the thrown material is used as a reflector for radiators in apartments (it is considered the type that increases the efficiency of heating in winter)))

kurt:

called FOLGOIZOL

Engineer:

If it’s stronger, then formos /produkciya/klej_adgezivy/klej_sprei-3m/80-scotch-weld/If you stick it, peel it off, then lenta-plus m/catalog/kley/49

kenny unknown:

the material is penofol, the trouble is that, in the area of \u200b\u200bthe collector, it will definitely melt. it is glued with liquid nails of the installation company for products made of pvc and polystyrene.

2 Preliminary stage what is the main thing to do before pasting

Styrofoam can be glued to virtually any material. Bonding of concrete, wood, plastic and polystyrene foam will take place without any special adventures - virtually any adhesive composition or putty mixture is suitable. But with metal, things are not so simple.Actually, attempts to glue these materials lead workers to countless mistakes.

The most common mistake is the selection of glue, which includes acetone, gasoline or the rest of the solvent. Gluing styrofoam boards with the help of such adhesive bases leads to the destruction of the plates themselves. The type of the second error is an insufficient amount of glue. It must be applied to the back of the expanded polystyrene boards in at least five places - in the corners and in the middle. To save money, most builders apply adhesive only at three points, which is fundamentally wrong and violates the entire procedure.

It doesn't matter which adhesive base you choose - before you glue the polystyrene foam to the metal, you first need to prepare the surface. First, you should carefully clean the metal surface from rust, dirt and paint. For this, any machine for grinding work is best suited - belt or vibration. After cleaning, the surface should be degreased with any means convenient for this.

Bonding styrofoam boards is not a fast process, and very often it is necessary to ensure the stability of the material until the adhesive is slightly frozen. At first, polystyrene foam can slide under its own weight, thanks to which it is supported from below with a plywood sheet or a good-sized board.

How to glue isolon to concrete

how to glue isolon to concrete

In the construction of industrial facilities and residential buildings, modern building materials are used to meet the most important building requirements for heat and sound insulation. Such material, for example, is isolon or foamed polyethylene foam. The use of isolon reduces construction time and heating costs due to the excellent thermal insulation properties of this material.

Isolon has the following characteristics 1. Low density (light weight) and at the same time good thermal insulation properties. A layer of isolon 10 mm can replace a layer of 15 mm mineral wool, 45 mm wood or 150 mm brickwork.

This reduces the mass of structures and helps to save usable area, 2. In the production of isolon, freons and other substances dangerous to humans are not used. Izolon is non-toxic, does not affect the skin, does not emit harmful substances when applied. Has a hygienic certificate, 3.

Isolon is a chemically inert material, it is not affected by organic solvents. It is possible to combine isolon with other building materials (concrete, gypsum, cement, lime, wood). It practically does not absorb water and steam, therefore it is resistant to decay, mold and aging, 4.

Excellent shock-absorbing properties due to flexibility and uniform cellular structure. Isolon is used as a substrate for carpet, laminate, linoleum or parquet. Isolon sheets are used to separate adjacent walls, if adjacent walls are subject to movement or vibration, 5. The operating temperature range is from -60`C to +75`C, and if there are no mechanical loads, the working temperature increases to +100`C. With the exception of special isolons with fire-extinguishing additives, isolon is a combustible material. But at temperatures less than + 140`С, no harmful substances are emitted from isolon, 6.

Izolon is produced in different thicknesses and densities (with different foaming ratios) and is supplied in the form of rolls, sheets, tapes or blocks. This greatly increases the possibility of using isolon in construction. Depending on the production method, isolon is divided into cross-linked (when molecules are cross-linked, a network molecular model is formed) and non-cross-linked (there are no chemical bonds between polymer molecules).

The cross-linked isolon has improved characteristics compared to the non-cross-linked one. 1. Heat resistance increases (the operating temperature range increases by 20`C), 2.The service life of the material is increased due to increased resistance to ultraviolet radiation and organic solvents: oil, gasoline, diesel fuel, Izolon can be used 1.

For sound, steam, heat, waterproofing of walls, foundations, ceilings and roofs for country houses, cottages, garages, 2. As a sealant for slate, ribbed metal roofs or tiles, 3. Insulating tapes with an adhesive layer seal the joints of windows and doors, connections between the frame and glass, protect against dust, moisture and noise, 4. Izolon strips can be used to insulate cold and hot heat supply pipes, as well as ventilation pipes, 5. Izolon with a polymeric metallized film is used as a heat-reflecting screen to protect against heat loss through the radiator sections of the walls. When using a combined material, a double effect is obtained.

Due to the metallized film, up to 90% of the heat emitted by radiators or other thermal devices is reflected back into the room. A big plus of isolon is the ease of its use and installation. It is easy to cut and can be glued to the surface with adhesives (preliminary glued surfaces must be cleaned of dust and degreased).

To attach to a smooth surface, use screws, rails, furniture staplers. To connect the joints, use a building hair dryer. Isolon is attached to curved surfaces with double-sided mounting tape.

Thus, when using this modern material, it is possible to significantly reduce the construction time and heating costs.

How to glue isolon to concrete How to glue isolon to concrete how to glue isolon to concrete In the construction of industrial facilities and residential buildings to ensure the most important building requirements for heat and sound insulation

Best Answers

%username%:

pet doesn’t stick to anything at all, you need to put up with it

Roman Shved:

double sided tape

Dmitry Dved:

there is a special adhesive foam such as Penoplex in construction stores, but not Penoplex, it is specifically for this. Cylinders of red (more precisely, the color of cyan) color. I bought cylinders for a pistol in Castorama with a capacity of 750-800gr. I do not remember the name, it can be used as glue and as foam. Dissolves with foam cleaner. On the packaging it is indicated that before applying the foam, it is worth spraying with water from a spray bottle. Water does not improve adhesion, but is a catalyst for hardening.

Vladimir Nikitin:

88 (such glue ... ask the shoemakers)

Useful video

https://youtube.com/watch?v=RgKvM3-JFRU

Penofol was bought to insulate the loggia. How can penofol be securely glued to a concrete wall so that it holds?

Do you want to insulate from the inside? You can use penofol of all three types "A", "B", "C"

It can be glued both on the frame itself immediately, and on heaters. Used in this case, glue ceresite, dragon or titanium.

But it is better to leave a gap (air), such insulation improves air exchange and prevents condensation from accumulating.

The mounting method is as follows. Laths (crate) are attached to the wall and penofol is attached to them using a stapler. I advise you not to leave penofol as a finishing layer, but to cover it with panels or drywall.

Can be glued with glue from the "liquid nails" series, for example "Moment-Installation",

There are "liquid nails" of this brand for wet rooms (baths, saunas), there are for outdoor, for indoor work.

Also consider the surface material (metal, brick, concrete, etc.).

In general, the very idea of \u200b\u200bgluing penofol is not entirely correct.

If some air ducts are insulated with penofolm,

If the wall is insulated, then the penofol is attached with an air gap (up to 2 cm, this is enough), that is, at the beginning of the crate, then penofol, fastening with brackets (you need a stapler), then the counter-batten and finishing finishing material.

Joints are sealed with foil tape

It is not necessary to glue penofol at all, it is attached differently, without an air gap it is of no use.

On the loggia you need penofol type "B", this is penofol with double-sided foiling, one layer of foil (do not forget that penofol is reflective thermal insulation) will not release heat from the room, the other will not allow the sun's rays to overheat the room in the summer (this is true for the loggia ).

Penofol type "B" is not glued; it is attached with a gap to the brackets (see above).

In your case, the adhesive method will not work, just spoil the material and do not insulate the loggia, fasten the penofol according to the technology described above (sheathing, gaps, and all that).

By choosing the adhesive method for strengthening penofol on insulated surfaces, you will do the right thing, since it is technologically simple, does not require professional tools and skills, and is the least expensive in terms of money / time

One thing is important: take into account the bearing capacity of the adhesive in order to securely attach it by determining the maximum weight of the coating. But since foil penofol (and its analogues too) is a very light material, the main requirement for glue is its adhesion

This is the name of the ability of the adhesive to penetrate into small pores / irregularities of the material, providing adhesion to it. Any material on an organic polymer (including penofol) has low adhesion if it is not porous. Therefore, it is clear: water-based adhesives are absolutely useless for gluing penofol. The composition must contain an organic solvent; it, as it were, “dissolves” the surface a little, thereby increasing adhesion.

And since absolutely universal solvents have not been invented, it is necessary to look for a special glue for penofol. Adhesives called "universal" most often glue everything, but badly. Or they are incredibly expensive.

Advantages and disadvantages of the method

Foil insulation has a number of features and a minimum of negative sides. Advantages:

- Foil reflects heat. Thus, the heat remains in the house, on the other hand, it does not let the heat into the house in the summer.

- Increased wear resistance.

- Partially applicable as a waterproofing material.

- Easy installation, light weight, easy dismantling.

- The insulation does not let the cold wind through. Maximum isolation from external influences. It does not give in to deformation at sharp temperature drops.

- Keeps out noise from the street.

- Doesn't rot or mold.

- This material is thinner than others, but more efficient by 20-30%.

- The insulation does not emit substances harmful to health and prevents the smallest irritants and allergens from getting inside.

- There is no rigidity, so you can’t cover it with plaster or wallpaper on top.

- For fixing, special adhesive compositions are required.

- Sometimes insulation with foil is not enough to insulate the room.

Despite the shortcomings, foil material is widely used for various purposes.

The most popular type of insulation with foil for finishing inside aluform

Bestizol or alufom is a bubble base, consisting on one side of aluminum foil (outer layer) and polyethylene (inner). The foil acts as a reflector of solar and thermal rays. The polyethylene layer has a cellular structure, and neutralizes sound waves, shocks. The advantage of this material is low thermal conductivity.

Bestizol can be used both in frost and in heat. Due to the small thickness (1 cm), the material is used for hard-to-reach places:

- for winding ventilation pipes;

- pasting of air ducts;

- insulation of pipelines and other outgoing communications.

Where is the foil insulation method used?

Foil insulation reflects infrared rays, which are essentially thermal. But, it is not necessary to apply the material everywhere. In some places it will not work properly.

It is mainly mounted at sources of thermal energy:

- heating appliances - batteries, heaters. The insulation is mounted on the wall with foil in the room;

- boiler, fireplace stove.

And also it is used in the installation of "warm floor".The reflective layer will direct the heat in the right direction.

In the attic. Here the insulation is mounted on the roof. Apply 2 layers to combat heat and cold.

In baths and saunas. Heating of the room is not constant, foil material is suitable for such purposes.

Garages, hangars, outbuildings - an installed radiator or potbelly stove.

They also insulate heating pipes, air ducts, wells and wells.

1 Foamed plastic what's what and why

The correct technical name for the well-known polystyrene foam is foamed plastic. Looking closely at this material from a short distance, you will find that it is made up of a large number of small balls that are held together - these are polystyrene granules that have been foamed under high pressure and temperature and compressed in a press.

Because of this technology, in the structure of expanded polystyrene there are a lot of microcells invisible to the eye, in which air resides. Due to this, the material receives airy lightness and the properties of a very excellent heat insulator. Consumers fell in love with it for a very small price - in fact, it is a very inexpensive insulation, and workers appreciated its technical specifics. We will dwell on this in detail, because simultaneously with the demand for the material, like mushrooms after it rained, countless myths about its shortcomings grew.

Expanded polystyrene is very durable - polystyrene keeps its shape for at least 25 years in outdoor conditions and at least half a century when used in the middle. You will definitely be surprised, because some people talk about its fragility. In fact, ultraviolet radiation and the systematic influence of moisture can reduce the operating time. But only these same factors can reduce the life of virtually any building material, as well as heat insulators of various kinds.

Foamed plastic is not afraid of fungi and mold - due to this, it can also be used in a wet environment, for example, in a basement. Polystyrene granules do not actually absorb moisture. However, they say that a variety of rodents easily make holes in polystyrene foam. Again, this is only partly true - if the rodents have something to feed on, they will make holes even in concrete. deprive them of food or exterminate with poison, and you will not need to think about their relationship with styrofoam.

Expanded polystyrene does not support combustion - no matter what they say, however, this material is several times safer than the same wood. In order for it to catch fire, a temperature twice as high as in the case of wood is required, and when ignited, it releases much less heat. The material is not hazardous to human health and the external environment - among the popular myths, there is also a myth about the alleged danger of material for human health. But dozens of studies have disproved this myth for a very long time. Look behind you, there are a lot of much more harmful materials around you.

Of the bad qualities of expanded polystyrene, a small fortress should be called - it breaks off easily, and also a not very big blow can leave a dent on its surface. Due to this, it must be protected from damage from mechanical factors - classically, mixtures for plaster are used to do this. They also protect the material from the influence of ultraviolet radiation.

https://youtube.com/watch?v=Ea94bC7aIp0

What glue to use for gluing polyethylene composition

The easiest way is to purchase structural adhesive in the store, which includes methyl acrylate. Its properties provide rapid softening of polyethylene and its further bonding. The adhesive also contains inorganic and organic acids and xylene, chromic angrid and various additives.

The advantage of using a mixture is that no additional processing of the material is required. However, the adhesive for polyethylene is quite toxic, so it is recommended to work outdoors. The glue acquires its best properties at a temperature of + 35C, it is not afraid of moisture, but is easily flammable. It is better to buy it in specialized stores, so as not to run into a fake.

This technique allows you to get a strong inseparable seam. Among the shortcomings of the method, it is worth noting the deformation of the edges of the product.

On sale are mixtures for connecting polymers, which are similar in consistency to a thick paste. The kit comes with an activator. After adding it to the adhesive for polyethylene, it acquires the required consistency and can be used within a short time.

We glue polyethylene - step by step instructions

To glue polyethylene, special knowledge and skills are not required. Even beginners at home will cope with the task.

The order of work is as follows:

- Clean the surface and degrease it. Some manufacturers claim that this step is optional, but experts still recommend spending a few minutes and never skip it.

- Apply glue to the processed material. It will take only a few minutes to solidify, so the parts must be attached to each other without delay.

- Leave the glued polyethylene elements for several hours until the glue has completely set.

In general, this algorithm is similar to working with any glue. True, you should take care to use protective gloves, as the glue can cause allergic reactions and is quite toxic.

It is more convenient to apply the adhesive with a glue gun, which can be loaded with ready-made cartridges. The mixture of them is distributed evenly, so it is easy to achieve the desired dosage. If you are planning a large amount of work, this device is worth spending money on.

RELATED VIDEO

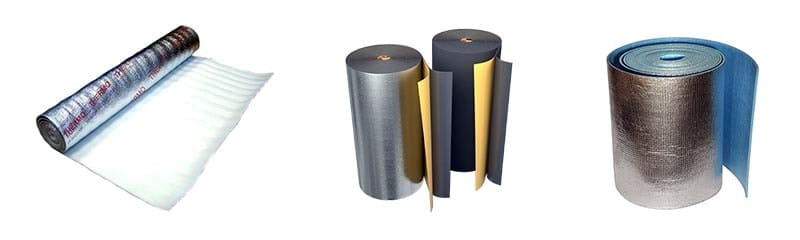

How to glue polyethylene foam

Foamed polyethylene has a porous structure, therefore it provides high-quality heat, steam and waterproofing.

Due to its low price, ease of operation and installation, it is actively used in construction. The most popular brands are Izolon, Vilaterm, Energoflex, Polifom, Temaflex.

If it becomes necessary to glue foam insulation, experts recommend two-component adhesives based on methyl acrylate. Such compounds are characterized by high adhesion and are suitable for working with polyvinyl chloride, polyethylene, polypropylene. An example is the well-known adhesive composition "Easy-Mix PE-PP" from WEICON.

Usually, in order to achieve high results in gluing foamed polyethylene, the following procedures are additionally required:

- surface treatment by sandblasting or grinding,

- physical treatment, such as thermal fire,

- chemical treatment (usually the fluorination method is used).

But when using "Easy-Mix PE-PP", you can do without additional preparation and surface treatment due to the "primer" included in the composition, which changes the structure of the materials to be glued, after which they easily adhere.

The use of Easy-Mix PE-PP glue for work with polyethylene foam both on an industrial scale and at home allows you to quickly and reliably fasten materials, while it is ready for use immediately after opening the package, it is easy to dose and mix, and also apply.

The glue has a soft pasty consistency, is not afraid of conditional "aging" and retains its properties for a long time even in open areas.

How to mount penofol

Penofol is fixed with the foil side inside the room. A greater effect of thermal insulation is created by an additional air gap 1-2 cm thick (with the help of a substrate - crates).

By watching the video you will learn more:

https://youtube.com/watch?v=zx8WiU-qxvI

Polyethylene foam adhesives of different compositions can be ready-made or require preparation on site. It is necessary to carefully read the instructions for the selected mixture:

the glue is applied evenly, paying special attention to the edges. Before sticking, it is necessary to wait up to 1 minute for the composition to be slightly absorbed.

This provides a better display of adhesive properties. Attach the processed penofol to the insulated surface. The plates are fastened butt-to-butt, but not overlapped;

the setting time varies depending on the characteristics of the adhesive (at least 15 seconds);

smooth the surface of the polyethylene foam, removing the folds. Glue the seams, you can use foil tape;

glued insulation in residential premises requires additional decorative finishing. The last layer of the structure (drywall or lining) is installed on the crate.

Nothing brings more satisfaction than the right and skillfully done work. If you follow all the recommendations, fixing the insulation will not cause much trouble.

Can you just stick it with double sided tape?

it is proved that it holds tightly if you glue it along the joints and put one strip of adhesive tape in the middle of the strip. if this does not appeal, you can try titanium glue for foam false ceilings (it is sold everywhere and is inexpensive). again, it has been proven that it does not dissolve penofol and holds well. only more trouble - you need to press the foam until it seizes

It is no longer possible to know who first came up with the idea of using expanded polystyrene instead of a building material for thermal insulation of buildings - initially its area of use was limited to furniture transportation and equipment, where it acted as a sealant. In this article, we will try to figure out how to properly glue polystyrene foam to metal and concrete.

Life time

Since foil insulation has appeared relatively recently, it is not yet possible to establish the exact expiration date. However, conducting experiments, we can say that the material does not lose its properties for 200 years.

The service life of the installed insulation depends on the adhesive used. If the adhesive composition has expired, then you can re-install with the same heat insulator.

There are many heaters on the construction market. The choice is so wide that the question arises, which one is better. To answer, you need to compare the characteristics of the heat-insulating material and the scope - a street, a living room, a garage or an agricultural building.