Pros and cons of insulating the foundation with polystyrene foam

Material advantages:

- low thermal conductivity, good thermal insulation properties;

- frost resistance;

- almost no vapor permeability;

- water resistance;

- ease of processing;

- light weight;

- ease of installation: careful alignment of the base is not required;

- affordable price.

Flaws:

- combustibility from G1 to G4. When finishing protruding parts (plinth, etc.), external cladding with non-combustible materials is necessary;

- combustion toxicity;

- in order to avoid damage by rodents, it is necessary to install a reinforcing mesh over the plates;

- the material itself is waterproof, but does not provide the necessary waterproofing. In conjunction with insulation, treatment with waterproofing materials is required;

- it is necessary to protect the material from mechanical damage with asbestos-cement or reinforced concrete slabs, wooden shields.

Preparatory stage

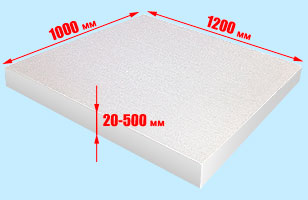

Expanded polystyrene PSB-S

First you need to calculate how many insulation boards you need for the foundation. The dimensions of a standard expanded polystyrene plate are 600x1200 mm, thickness is from 20 to 100 mm. For the foundation of a residential building, 50 mm thick slabs are usually used, laying them in two layers. To find out how many plates are needed, the total length of the foundation is multiplied by its height and divided by 0.72 - the area of \u200b\u200bone sheet of expanded polystyrene.

For example, if a foundation 2 m high is insulated in a 10x8 m house, the area of thermal insulation is 72 squares. Dividing it by 0.72, we get the number of sheets - 100 pieces. Since the insulation will be carried out in two layers, it is necessary to buy 200 plates with a thickness of 50 mm.

This, however, is a very average calculation, based on the fact that the thickness of the insulation will be exactly 100 mm. But this value can be more - it all depends on the climatic conditions of the region, and on the foundation material, and on the type of insulation.

There is a special system for calculating the thickness, for which you need to know the R indicator - this is a constant value of the required heat transfer resistance established by SNiP for each region. It can be clarified in the local department of architecture, or taken from the proposed table:

Foundation insulation thickness calculator

In order not to bother the reader with calculation formulas, a special calculator is placed below, which will allow you to quickly and accurately find the required thickness of thermal insulation. The result obtained is rounded up, leading to the standard thickness of the panels of the selected insulation:

Go to calculations

In addition to polystyrene foam, you will need:

-

mastic or roofing material;

Ruberoid

- gravel;

-

glue;

Styrofoam Adhesive

-

fungal dowels;

Fungus dowel

- putty or mounting foam;

- level;

- notched trowel;

- cement mortar;

- sand;

-

reinforcing mesh;

Reinforcing mesh

- roller

When all the materials are prepared, a trench is dug around the perimeter of the foundation. You need to dig to the level of freezing, that is, to a depth of 1.5-2 m. In order to make it convenient to work in a trench, its width should be 0.8-1 m. Of course, excavation is done exclusively by hand, since equipment can damage the foundation. The walls of the base must be thoroughly cleaned of the ground, irregularities and cracks should be repaired with mortar.

Preparation and waterproofing

The preparatory process has its own nuances for each type of foundation. A "tape" of standard depth should be manually dug in a trench up to one meter wide and to a freezing depth. The technique is not used in this case, so as not to accidentally “injure” the foundation. The surface is cleaned and leveled - the protrusions are chipped off, and the cracks are sealed with cement.

Waterproofing

Then a waterproofing layer is placed: bituminous mastic with a roller or liquid rubber - from a spray gun

It is important that the waterproofing material is applied in a continuous layer and does not contain organic solvents that have a destructive effect on XPS.

A combination of bitumen and rolled material will provide even more effective protection for the strip foundation. Ruberoid, fiberglass, etc. superimposed on the mastic in a heated state with an overlap of up to 150 mm, the joints are smeared with bitumen. In the same way, it is possible to isolate the slab foundation from moisture.

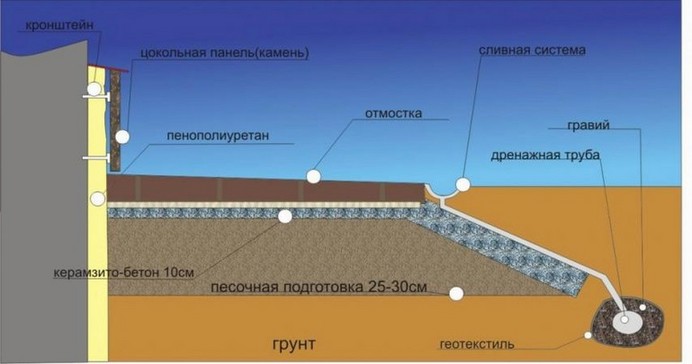

If the foundation is on piles

With a pile foundation, a combination of a waterproofing compound and a drainage system is required to protect against groundwater. Drainage is mounted in the following sequence:

- a shallow trench is dug;

- the bottom of the trench is covered with rubble;

- geotextiles are laid on top of the rubble;

- pipes for draining water are laid at an angle from the house;

- over the pipes - another layer of geotextile;

- the top layer of rubble is laid.

What is extruded polystyrene foam

Not everyone clearly understands what, in fact, is polystyrene foam. In general, this is nothing more than the usual and well-known foam used in everyday practice, mainly for packaging fragile items. It is a strong, lightweight, heat-saving, biodegradable and almost insoluble material obtained by filling styrene granules with gas and then heating them.

When exposed to temperature, the granules "swell" until they occupy the entire volume available to them and sinter together.

Extruded or extruded polystyrene foam is distinguished by a special manufacturing technology. For conventional foam, polystyrene beads are simply heated with water vapor, while to obtain XPS, several processes are used at once: the beads are mixed and heated, a blowing agent is introduced, and then extruded under high pressure, i.e. pushed through the mold hole.

This technology provides greater uniformity and, consequently, greater strength of XPS compared to foam.

Basement insulation with foam

Basement insulation technology in the same plane with the walls of the house:

- Markup. Since the insulation boards should be several centimeters higher than the waterproofing layer, horizontal markings should be made with a pencil over the entire surface of the wall.

- Wall cleaning outside. The surface of the wall is pre-prepared for gluing with polystyrene foam. To do this, it is thoroughly cleaned from the outside of dust and dirt. After that, the surface is primed. After the primer dries, you can proceed to the next event.

- Attaching plates. Pasting the walls of the house with polystyrene foam is carried out using a special glue, starting from the corner. Marking and cutting of plates with a sharp wallpaper knife is done.

- Applying adhesive to the wall and slabs. With a special notched trowel, an adhesive is applied to the surface of the base. Pre-prepared fragments of the plates are smeared with glue and attached to the wall, the joints between the plates and the ends outside the house are carefully sealed.

- Further, with the help of a perforator, drilling and inserting dowels are performed with further nailing. After covering the entire surface of the outside of the house with slabs, a special primer layer is applied to provide the basis for all subsequent layers.

- Strengthening the corner of the slope. A metal corner is fastened around the entire perimeter of the wall. For installation, the same adhesive composition is used as for the plates.

- Installation of reinforcing mesh. The reinforcing mesh is pre-cut to the size of the plates, lubricated with adhesive and glued over the expanded polystyrene. The technology of strengthening the reinforcing mesh is the same as the installation of the corner.

- Finishing work and installation of ebbs. The basement area is puttyed with materials for outdoor work.It is left to dry and primed again with subsequent staining. To prevent the penetration of moisture, ebbs are installed.

In the event of defects in the coating, they can easily be eliminated by re-priming and painting. The technology of thermal insulation with foam plastic is the same as that of foam plastic.

Expanded polystyrene as EPS or XPS insulation

As a thermal insulation, two types of expanded polystyrene are mainly used today: foamed (EPS) and extruded (extrusive, XPS). They differ not only in production technology, but also in properties. For insulation of the foundation, it is preferable to use XPS. Compared to it, EPS has a higher heat transfer coefficient (less effective as a thermal insulation material), hygroscopic, less resistant. But at the same time, expanded polystyrene stands out with a comparable low price. It is possible to level its shortcomings by installing an additional layer of waterproofing that protects the material from wet soil, as well as drainage of the foundation, which allows you to lower the level of groundwater.

Insulation of the foundation from the outside with foam

The foundation of the house, as you know, directly interacts with the external environment, as it is located on the ground. Therefore, as well as waterproofing, insulation of the foundation is an important step in construction and repair work, on which the comfort of housing in the cold season will depend. In addition, thermal insulation is of great practical importance, since it prevents the penetration of dampness into the basement floors and does not allow the resulting condensate, which appears due to the temperature difference outside and inside the house, to adversely affect the laid communications and the supporting structure as a whole.

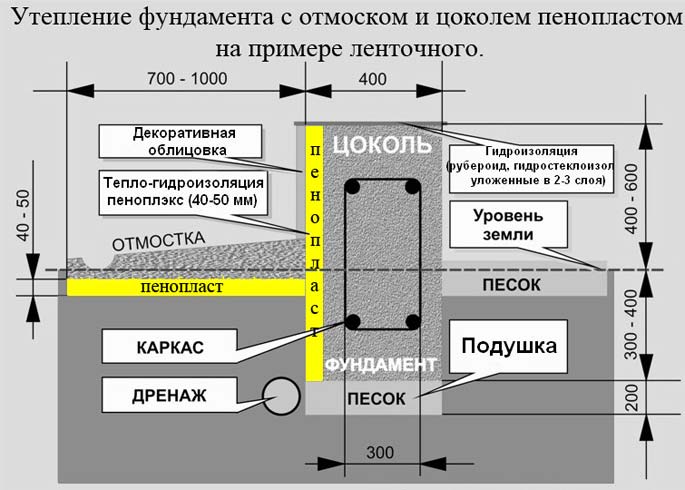

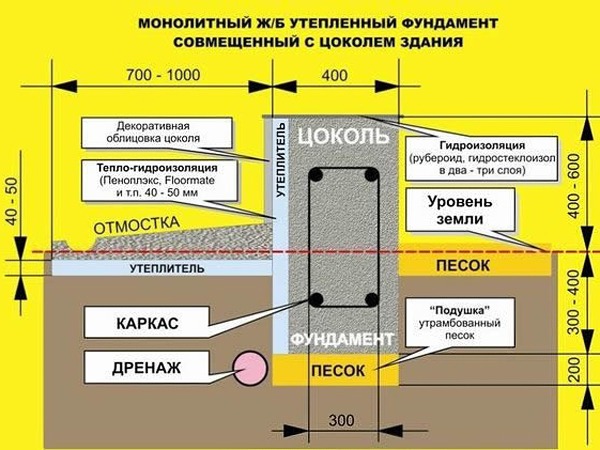

Foundation insulation scheme.

There are varieties of this material, for example, foam or expanded polystyrene, but in essence they are identical heaters, therefore, the same technology is used to insulate the tape foundation with them.

Due to the fact that such heaters are produced in the form of plates already with ready-made grooves, the installation of this material is very simple, and provided that there are skills in construction, any adult can handle it. The heat insulators listed above tend not to be exposed to water, so the plates are not deformed.

It should be noted that the insulation of the base can be done both from the inside and from the outside. The choice of option depends on many factors. So, if it is supposed to insulate the foundation from the outside, then this will allow it to be laid to a lower freezing depth, which reduces the costs allocated for building a house. In addition, in the case when the building stands on heaving soil, the thermal insulation of the supporting structure from the outside will allow leveling the effect of sub-zero temperatures on it, which will prevent the movement of the foundation, and this greatly affects its durability and strength.

Also, by making the insulation in this way, this material will be an additional waterproofing. In other words, this option is the most optimal. Now, having understood all the nuances and having decided on the material, before starting work, it is necessary to study the very process of insulating the foundation from the outside with either foam plastic, or foam plastic, or expanded polystyrene. Let's consider everything in order.

Types of expanded polystyrene

On the modern building materials market, there are two main varieties of this insulation: foamed and extruded polystyrene foam. Let's look at them in more detail.

Extruded polystyrene foam

This material is also referred to as XPS.It should be noted that this type of coating has somewhat better qualities, and therefore, many people prefer to use extruded polystyrene foam to insulate the foundation. Its main advantages include:

- good ability to keep warm;

- a high level of compressive strength, this indicator for this material varies within 0.25-0.5 MPa with a surface deformation of 10%;

- extruded polystyrene foam has a homogeneous porous structure, and its pores are closed, which ensures a good water-repellent function of the material;

- due to the fact that such a coating does not absorb moisture, it is not subject to freezing;

- another plus of this insulation is its durability, according to some manufacturers, the service life of the material is about 50 years.

Expanded polystyrene foam

It is also called foam plastic and is denoted by the letters EPS. Such material is also often used as a heater for the foundation. Like the previous type of coating, the foam has a low level of thermal conductivity. Among its main advantages, one can single out a small cost, however, in terms of its qualities, EPS expanded polystyrene is significantly inferior to XPS expanded polystyrene. The difference between these types is as follows:

- Polyfoam is able to absorb a significant amount of water, which reduces its thermal insulation properties. Because of this, after sheathing the foundation, it is necessary to create an additional waterproofing layer.

- The compressive strength of expanded polystyrene foam is 3 times lower than that of its extruded counterpart. In this regard, there is a need to protect the coating from soil pressure.

Given the above characteristics, the technology for warming the foundation with foamed polystyrene foam should include the following types of work:

- creation of a waterproofing layer of bitumen, rolled roofing felt or any other suitable material on top of the insulation;

- erecting a brick wall around the foundation or covering the structure with profiled polyethylene membranes.

Insulation of the foundation with foam

Styrofoam is not able to collapse in contact with asphalt or paving slabs

Styrofoam is not able to collapse in contact with asphalt or paving slabs

Among the many heaters for the foundation, including mineral, glass wool and expanded clay, the most suitable material should be noted - foam. Due to the ability to save its functions in any climatic conditions, the product has gained incredible popularity among builders.

The characteristics of foam are reliability, low cost and ease of operation. In addition, its main component is air, which itself has excellent thermal insulation properties.

Foam for insulation of the foundation has the following properties:

- stability when interacting with asphalt and concrete;

- resistance to water and fire;

- the ability to retain heat;

- resistance to temperature fluctuations;

- preservation of shape and volume under the influence of external factors.

A significant disadvantage of the foam is brittleness. To prevent the formation of various defects on it, the surface should be treated with glue.

Styrofoam is recommended for use in the insulation of foundations built on clay soil. In addition, it is an excellent option for insulation designed to work underground. This is due to its good moisture resistance and resistance to sudden changes in temperature.

Types of polystyrene foam for warming the bases of houses:

- press - plate, foam thickness - from two centimeters;

- tiled expanded polystyrene, parameters - 1 * 1 * 0.05 m;

- polyurethane foam (liquid);

Most often, foam is used for insulation. The reason for this choice is its size, which has a beneficial effect on laying and finishing procedures.

Foundation insulation process

Choice of plate thickness

To date, slabs of material of various thicknesses are on sale, this figure ranges from 3 to 12 cm. To determine which option is best for you, you should consider some factors, among them:

- the purpose of the basement, if any;

- the material from which the foundation and basement are made;

- basement wall thickness;

- the prevailing climate of the area in which the building is located.

For example, if a house is built in the middle lane and has a basement, then it is best to use extruded polystyrene foam about 5 cm thick for insulation. also add that the corners freeze most of all in the building, so in these places the foundation needs to be insulated with a thicker layer of material.

Work process

Insulation of the foundation with polystyrene foam from the outside consists of the following steps:

- The first step is to dig the foundation around the entire perimeter of the house. The depth of the trench should reach the lowest point of the base, and the width of the pit should be such that it is convenient to work in it.

- Adhering soil, fragments of building materials and other debris should be removed from the surface freed from soil. It is desirable that the wall is as flat as possible. If there are too noticeable protrusions or depressions on it, they must be eliminated.

- The next step is to waterproof the foundation. It can be made from coating, roll or spray products - the option depends on your desire and budget.

- Determine the depth of soil freezing. If the lowest point of the foundation is below this indicator, then the distance from the sole of the base to the soil freezing line will need to be filled with sand. It is not necessary to insulate the wall in this place, but waterproofing will have to be done.

- After the foundation is protected from moisture, you can proceed with the installation of polystyrene foam plates. It is best to fix the elements with adhesive mixtures. As mentioned earlier, the use of compounds based on organic solvents and hot mastics is strictly contraindicated, since they damage the material and reduce its thermal insulation properties.

- Apply glue to a sheet of expanded polystyrene should be pointwise. One fragment measuring 1x0.5 m will need to be spread in 6-7 places.

- After applying the composition, the insulation must be pressed against the wall surface and held in this position for 30-60 seconds.

- It is best to start warming the base from any lower corner, moving along the structure. If you plan to cover the foundation with several layers of material, then the second layer should overlap the previous one in a checkerboard pattern. So you close the joints of the first level of the plates and improve thermal insulation.

- The corners of the building should be insulated more carefully, because it is through them that the most cold enters the room. The expanded polystyrene layer in these problem areas should be somewhat thicker, so it is recommended to stick an additional piece of insulation on each side of the corner.

- The outer side of the Styrofoam usually does not require additional processing, unless the foundation protrudes above ground level. After the process of warming the base is completed, the trench around the building must be filled with sand and earth. It is better to pour the soil in layers, gradually tamping it down.

- If, in addition to the foundation, you also insulate the basement, then it is better to fix the material with the help of special plastic dowels-umbrellas - they will hold the plates more securely than glue.

Insulation of the foundation with polystyrene foam, video:

What you need to know about foundation insulation

The implementation of such work will allow you to achieve the following results:

- ensuring a comfortable stay in the room;

- reducing the cost of heating the building;

- protecting the soil around the base of the house from swelling and freezing and, as a result, protecting the foundation and the building itself from destruction;

- creating comfortable conditions in the basement of the house, thanks to which the room can be landscaped and used for various purposes.

You should know that the material for insulation of the foundation must have certain properties. The main requirements include the following:

- Low thermal conductivity, which will allow you to keep the temperature in the room acceptable for living.

- Waterproof. If the material absorbs a lot of water, its thermal insulation properties deteriorate. In addition, moisture in the winter turns into ice, which leads to damage to the insulation, its deformation and destruction.

- High strength. Since the material is used to insulate the part of the house that is underground, it will constantly be subjected to soil pressure.

Is it possible to insulate the foundation with foam

Expanded polystyrene and polystyrene are synthetic heat-insulating materials, almost entirely consisting of air bubbles, which explains their extremely low thermal conductivity. Insulation of the foundation with polystyrene foam is beneficial in many ways:

- low cost in comparison with analogues;

- a slight degree of water absorption;

- very wide operating temperature range;

- low density;

- availability of technology for warming foundations with their help.

The disadvantages include only some fire hazard and modest mechanical strength.

However, in practice, they can be ignored, since the risk of fire on the outside of the foundation is extremely small, and it is very difficult to mechanically damage the material covered with decorative trim or soil.

Meanwhile, Styrofoam and Styrofoam have slight differences in characteristics:

- expanded polystyrene has one and a half to two times lower thermal conductivity;

- polystyrene is several times stronger than polystyrene foam when compressed;

- expanded polystyrene is somewhat heavier than polystyrene and has the property of vapor permeability;

The need for thermal insulation of the foundation

Basement foundation insulation

Basement foundation insulation

Insulation of the foundation of a private house with foam plastic from the outside is mandatory. This also applies to other buildings, especially those containing a basement. To achieve a high-quality result in the installation of thermal insulation, many use foam.

A poorly insulated building loses up to 50 percent of its heat through holes in the thermal insulation coating, causing additional economic heating costs. A fatal mistake during the installation of a house insulation is the neglect of the thermal protection of the foundation, believing that it will be enough just to finish the walls of the structure.

Good thermal insulation of the base is characterized by the performance of two functions:

- minimization of heat consumption;

- preservation of the foundation from freezing and deformation.

The fact is that the predominant type of soil in our country is heaving. Due to the effect of cold, the depth of soil freezing can be several meters. During the thaw, the volume of soil changes, which in turn negatively affects the design of the foundation of the house.

Before starting installation work, it must be borne in mind that the installation of a thermal insulation coating must be complete. The presence of any gaps, defects and details in the insulation layer adversely affects the ability of the building to maintain a temperature suitable for comfortable living. Only a dense air layer containing a ball of insulation is capable of completely restraining the loss of warm air.

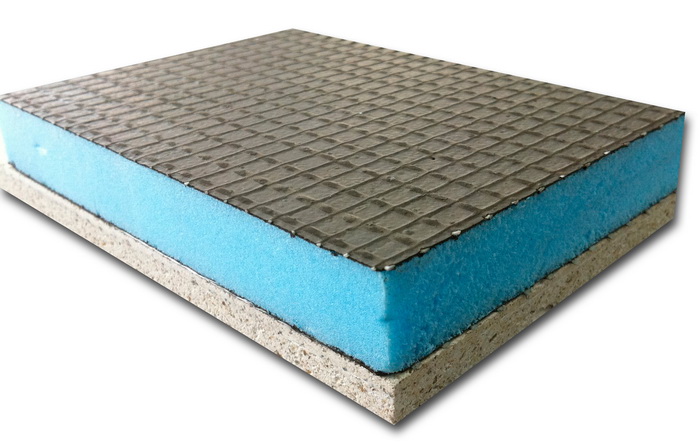

EPS installation

When the waterproofing is over, and the bitumen has completely cooled down, the insulation of the foundation with polystyrene foam proceeds to the main stage. The thickness of the insulation is determined in accordance with the parameters of the foundation and the climatic characteristics of the region.For example, if the winter in your area is harsh and long, it would be reasonable to lay the thermal insulation in two layers, five centimeters each.

Expanded polystyrene sheets are produced both corrugated and smooth. To ensure optimal adhesion to the adhesive, the former are better suited. But if you still purchased smooth plates, immediately before installation, process them with a spiked roller.

How to fix?

Fastening Styrofoam below ground level requires the use of exclusively special adhesives that do not contain organic solvents. It is applied to the insulation with dotted strokes in the corners and in the center of the sheet. Then the insulation sheet should be firmly pressed against the foundation and held so that the glue grabs.

In no case should you fix the thermal insulation in the basement with dowels, as they will damage the moisture-resistant layer. Above the ground, the sheets are attached to the wall with hardware three days after installation, when the glue is completely dry. There are about five dowels for each sheet, which are hammered into holes drilled through the heat-insulating material.

How to lay?

XPS sheets should be laid from the corner of the house, checking the correct installation using a level. At the corners, it would be better to lay the material in two layers, with a lead of a meter in each direction from the corner. The plates are mounted with each other by means of a connecting locking system at the edges. If gaps remain between the sheets, they are sealed with polyurethane foam sealant.

Thermal insulation protection

Thermal insulation must be protected from rodents and unforeseen ground movements. There are two main protective technologies: using geotextiles and roofing material or reinforced fiberglass. The cost of the glue on which the mesh is attached is quite impressive, so it is permissible to use cement mortar instead.

Trench backfill

The trench dug around the perimeter of the house, after the end of the insulation work, should be covered only when all the materials are dry, including the lining of the basement.

This process takes place in several stages:

- the bottom of the trench is covered with a layer of sand up to 150 mm thick;

- sand should be moistened, leveled and well compacted;

- expanded clay or gravel is laid on top of the sand layer, the layer thickness is from 200 to 300 mm;

- the excavated soil is poured over the gravel pad and compacted very carefully;

- the trench should not be completely buried; approximately 300 mm should remain to the ground level for the blind area.