Methods for producing hydrogen in industrial conditions

Extraction by methane conversion

. Vaporized water, preheated to 1000 degrees Celsius, is mixed with methane under pressure and in the presence of a catalyst. This method is interesting and proven, it should also be noted that it is constantly being improved: a search is underway for new catalysts that are cheaper and more efficient.

Consider the most ancient method of obtaining hydrogen - coal gasification

. In the absence of air access and a temperature of 1300 degrees Celsius, coal and water vapor are heated. Thus, hydrogen is displaced from water, and carbon dioxide is obtained (hydrogen will be at the top, carbon dioxide, also obtained as a result of the reaction, will be at the bottom). This will be the separation of the gas mixture, everything is very simple.

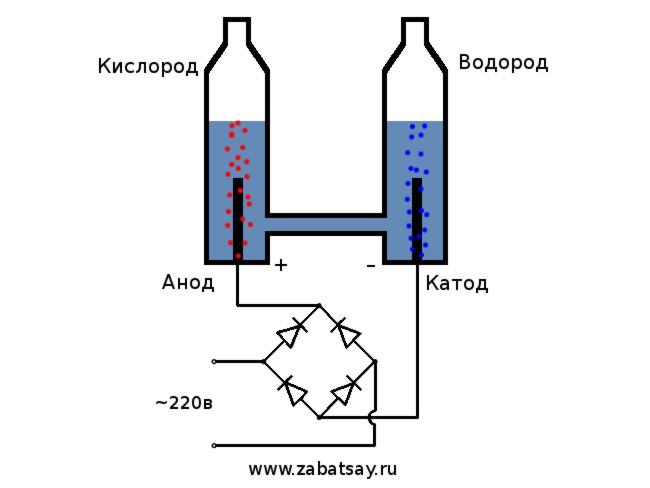

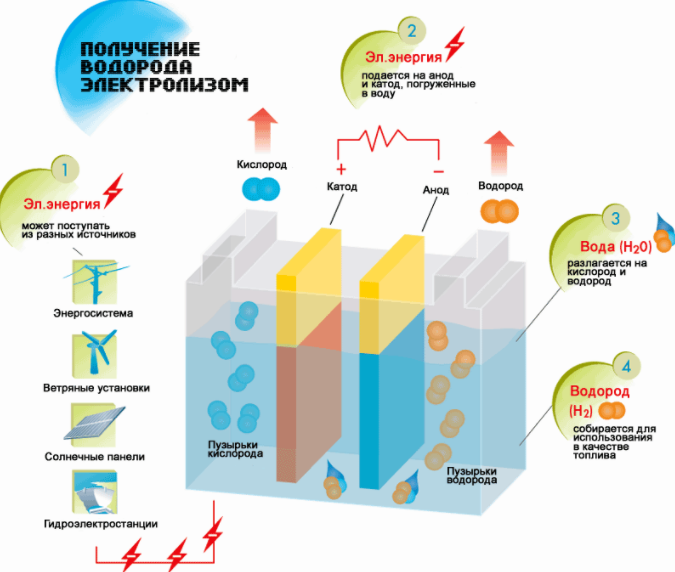

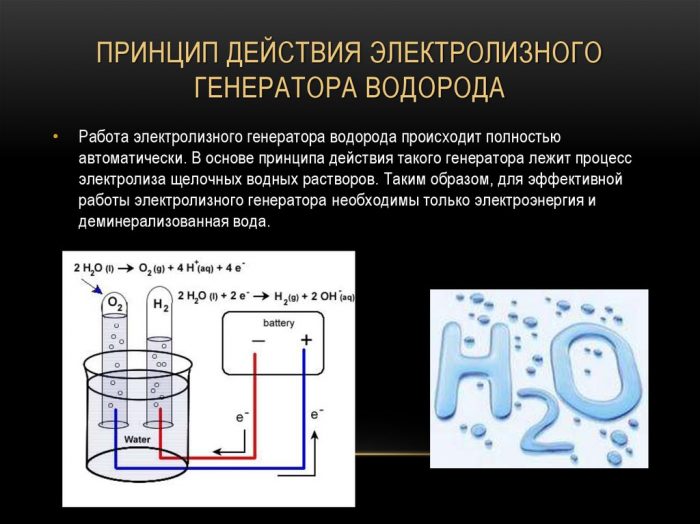

Obtaining hydrogen by water electrolysis

considered the easiest option. For its implementation, it is necessary to pour a solution of soda into the container, and also place two electrical elements there. One will be positively charged (anode) and the other negatively (cathode). When current is applied, hydrogen will go to the cathode, and oxygen to the anode.

Obtaining hydrogen according to the method partial oxidation

. For this, an alloy of aluminum and gallium is used. It is placed in water, which leads to the formation of hydrogen and aluminum oxide during the reaction. Gallium is necessary for the reaction to take place in full (this element will not allow aluminum to oxidize prematurely).

Recently gained relevance method of using biotechnologies

: under the condition of a lack of oxygen and sulfur, chlamydomonas begin to intensively release hydrogen. A very interesting effect, which is now being actively studied.

Do not forget another old, proven method of producing hydrogen, which is to use different alkaline elements

and water. In principle, this technique is feasible in laboratory conditions with the necessary security measures. Thus, during the reaction (it proceeds when heated and with catalysts), metal oxide and hydrogen are formed. It remains only to collect it.

Get hydrogen by interactions of water and carbon monoxide

only possible in an industrial setting. Carbon dioxide and hydrogen are formed, the principle of their separation is described above.

THE INVENTION HAS THE FOLLOWING ADVANTAGES

The heat obtained from the oxidation of gases can be used directly on site, and hydrogen and oxygen are obtained from the disposal of exhaust steam and process water.

Low water consumption when generating electricity and heat.

The simplicity of the method.

Significant energy savings, as it is spent only on warming up the starter to a steady thermal regime.

High process productivity, because dissociation of water molecules lasts tenths of a second.

Explosion and fire safety of the method, because in its implementation, there is no need for tanks to collect hydrogen and oxygen.

During the operation of the installation, the water is repeatedly purified, transforming into distilled water. This eliminates precipitation and scale, which increases the service life of the installation.

The installation is made of ordinary steel; with the exception of boilers made of heat-resistant steels with lining and shielding of their walls. That is, special expensive materials are not required.

The invention may find application in

industry by replacing hydrocarbon and nuclear fuel in power plants with cheap, widespread and environmentally friendly water, while maintaining the power of these plants.

CLAIM

Method for producing hydrogen and oxygen from water vapor

, which includes passing this steam through an electric field, characterized in that superheated water vapor is used with a temperature 500 - 550 o C

, passed through a high voltage direct current electric field to dissociate the vapor and separate it into hydrogen and oxygen atoms.

I've wanted to do something like this for a long time. But further experiments with a battery and a pair of electrodes did not reach. I wanted to make a full-fledged apparatus for the production of hydrogen, in quantities in order to inflate the balloon. Before making a full-fledged apparatus for water electrolysis at home, I decided to check everything on the model.

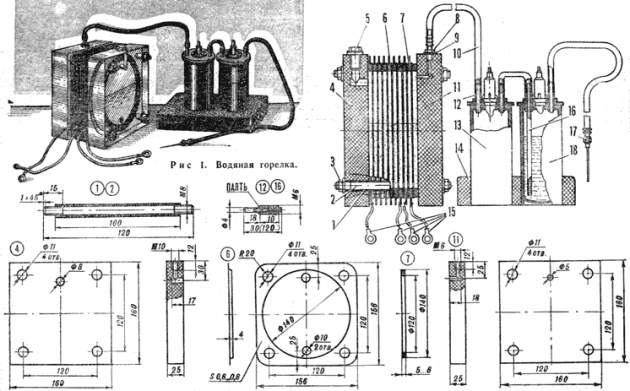

The general scheme of the electrolyzer looks like this.

This model is not suitable for full daily use. But the idea was tested.

So for the electrodes, I decided to use graphite. An excellent source of graphite for electrodes is the trolley bus current collector. There are plenty of them lying around at the final stops. It must be remembered that one of the electrodes will be destroyed.

Sawing and finishing with a file. The intensity of electrolysis depends on the strength of the current and the area of the electrodes.

Wires are attached to the electrodes. Wires must be carefully insulated.

Plastic bottles are quite suitable for the body of the electrolyzer model. Holes are made in the lid for tubes and wires.

Everything is carefully coated with sealant.

Cut off bottle necks are suitable for connecting two containers.

They need to be connected together and melted the seam.

Nuts are made from bottle caps.

Holes are made in the bottom of two bottles. Everything is connected and carefully filled with sealant.

We will use a 220V household network as a voltage source. I want to warn you that this is a rather dangerous toy. So, if there are no sufficient skills or there are doubts, then it is better not to repeat. In the household network, we have alternating current, for electrolysis it must be straightened. A diode bridge is perfect for this. The one in the photo was not powerful enough and quickly burned out. The best option was the Chinese MB156 diode bridge in an aluminum case.

The diode bridge gets very hot. Requires active cooling. A cooler for a computer processor will fit perfectly. For the case, you can use a suitable sized soldering box. Sold in electrical goods.

Under the diode bridge it is necessary to put several layers of cardboard.

The necessary holes are made in the lid of the soldering box.

This is what the assembled unit looks like. The electrolyser is powered from the mains, the fan from a universal power source. A solution of baking soda is used as an electrolyte. Here it must be remembered that the higher the concentration of the solution, the higher the reaction rate. But at the same time, the heating is higher. Moreover, the reaction of sodium decomposition at the cathode will make its contribution to heating. This reaction is exothermic. As a result, hydrogen and sodium hydroxide will be formed.

The device in the photo above was very hot. It had to be turned off periodically and wait until it cools down. The problem with heating was partially solved by cooling the electrolyte. For this, I used a tabletop fountain pump. A long tube runs from one bottle to another through a pump and a bucket of cold water.

The relevance of this issue today is quite high due to the fact that the scope of the use of hydrogen is extremely extensive, and in its pure form it is practically not found anywhere in nature. That is why several methods have been developed to extract this gas from other compounds through chemical and physical reactions. This is what is discussed in this article.

Hydrogen production in the household

Choice of an electrolytic cell

To obtain an element of the house, a special apparatus is needed - an electrolyzer.There are many options for such equipment on the market, the devices are offered by both well-known technology corporations and small manufacturers. Branded units are more expensive, but their build quality is higher.

The home appliance is small in size and easy to use. Its main details are:

- reformer;

- cleaning system;

- fuel cells;

- compressor equipment;

- hydrogen storage tank.

Simple tap water is taken as raw material, and electricity comes from an ordinary outlet. Solar-powered units can save on electricity.

"Home" hydrogen is used in heating or cooking systems. They also enrich the air-fuel mixture to increase the power of car engines.

Making the device with your own hands

It is even cheaper to make the device yourself at home. A dry cell looks like a sealed container, which consists of two electrode plates in a container with an electrolytic solution. The World Wide Web offers a variety of schemes for assembling devices of different models:

- with two filters;

- with the top or bottom arrangement of the container;

- with two or three valves;

- with galvanized board;

- on the electrodes.

A simple device for producing hydrogen is easy to create. It will require:

- sheet stainless steel;

- transparent tube;

- fittings;

- plastic container (1.5 l);

- water filter and check valve.

In addition, various hardware will be needed: nuts, washers, bolts. First of all, you need to cut the sheet into 16 square compartments, cut a corner from each of them. In the opposite corner from it, it is required to drill a hole for bolting the plates. To ensure constant current, the plates must be connected according to the scheme: plus-minus-plus-minus. These parts are isolated from each other with a tube, and at the connection with a bolt and washers (three pieces between the plates). 8 plates are placed on the plus and minus.

With proper assembly, the edges of the plates will not touch the electrodes. The collected parts are lowered into a plastic container. In the place where the walls touch, two mounting holes are made with bolts. Install a safety valve to remove excess gas. Fittings are mounted in the lid of the container and the seams are sealed with silicone.

Device testing

To test the device, perform several actions:

- Fill with liquid.

- Covering with a lid, connect one end of the tube to the fitting.

- The second is lowered into the water.

- Connect to a power source.

After plugging the device into the socket, after a few seconds, the electrolysis process and precipitation will be noticeable.

Pure water does not have good electrical conductivity. To improve this indicator, you need to create an electrolytic solution by adding alkali - sodium hydroxide. It is in compositions for cleaning pipes like "Mole".

Methods for producing hydrogen

Hydrogen is a colorless and odorless gaseous element with a density of 1/14 relative to air. It is rarely found in the free state. Usually hydrogen is combined with other chemical elements: oxygen, carbon.

The production of hydrogen for industrial needs and energy is carried out by several methods. The most popular are:

- water electrolysis;

- concentration method;

- low temperature condensation;

- adsorption.

Hydrogen can be isolated not only from gas or water compounds. Hydrogen is produced by exposing wood and coal to high temperatures, as well as by processing biowaste.

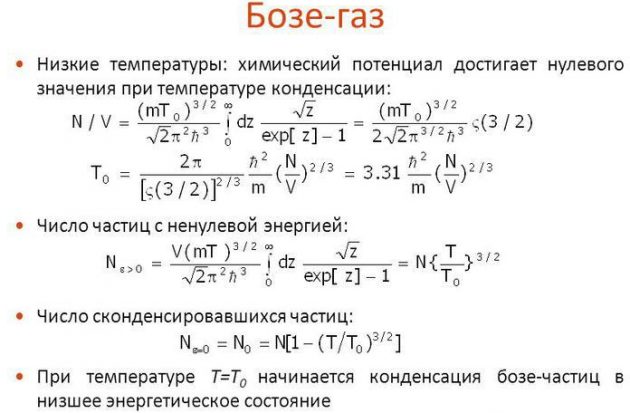

Atomic hydrogen for power engineering is obtained using the method of thermal dissociation of a molecular substance on a wire made of platinum, tungsten or palladium. It is heated in a hydrogen environment at a pressure of less than 1.33 Pa.Radioactive elements are also used to produce hydrogen.

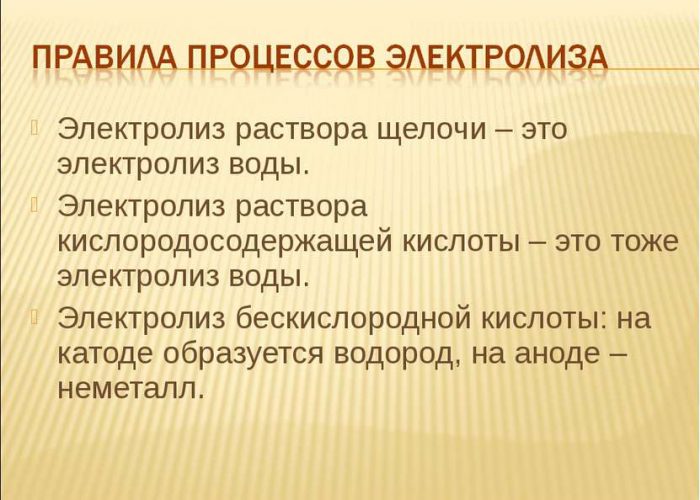

electrolysis method

The simplest and most popular method of hydrogen extraction is water electrolysis. It allows obtaining practically pure hydrogen. Other advantages of this method are:

- availability of raw materials;

- obtaining an element under pressure;

- the possibility of automating the process due to the lack of moving parts.

The procedure for splitting a liquid by electrolysis is the reverse of the combustion of hydrogen. Its essence is that under the influence of direct current, oxygen and hydrogen are released on electrodes dipped into an aqueous electrolyte solution.

An additional advantage is the production of by-products with industrial value. Thus, oxygen in a large volume is necessary for catalyzing technological processes in the energy sector, cleaning soil and water bodies, and disposing of household waste. Heavy water produced by electrolysis is used in the power industry in nuclear reactors.

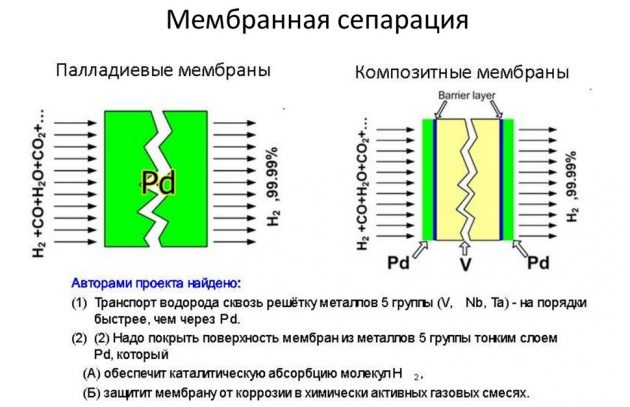

Production of hydrogen by concentration

This method is based on the separation of an element from gas mixtures containing it. Thus, the largest part of the substance produced in industrial volumes is extracted using steam reforming of methane. Hydrogen produced in this process is used in energy, oil refining, rocket industry, as well as for the production of nitrogen fertilizers. The process of obtaining H2 is carried out in different ways:

- short cycle;

- cryogenic;

- membrane.

The latter method is considered the most effective and less expensive.

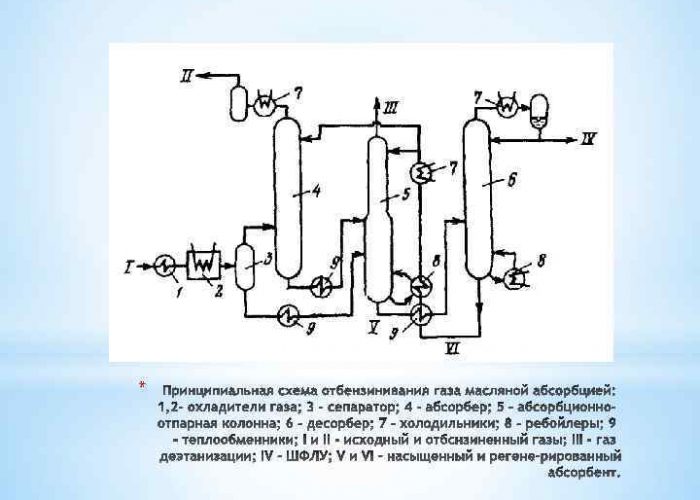

Condensation at low temperatures

This technique for obtaining H2 consists in the strong cooling of gas compounds under pressure. As a result, they are transformed into a two-phase system, which is subsequently separated by a separator into a liquid component and a gas. Liquid media are used for cooling:

- water;

- liquefied ethane or propane;

- liquid ammonia.

This procedure is not as simple as it seems. It will not be possible to cleanly separate hydrocarbon gases at a time. Part of the components will leave with the gas taken from the separation compartment, which is not economical. The problem can be solved by deep cooling of the raw material before separation. But this requires a lot of energy.

In modern systems of low-temperature condensers, demethanization or deethanization columns are additionally provided. The gas phase is removed from the last separation stage, and the liquid is sent to the distillation column with the raw gas flow after heat exchange.

Adsorption method

During adsorption, adsorbents are used to release hydrogen - solid substances that absorb the necessary components of the gas mixture. Activated carbon, silicate gel, zeolites are used as adsorbents. To carry out this process, special devices are used - cyclic adsorbers or molecular sieves. When implemented under pressure, this method can recover 85 percent hydrogen.

If we compare adsorption with low-temperature condensation, we can note the lower material and operational costs of the process - on average, by 30 percent. The adsorption method produces hydrogen for energy and with the use of solvents. This method allows the extraction of 90 percent of H2 from the gas mixture and the production of the final product with a hydrogen concentration of up to 99.9%.