Boiler installation

After the heat exchanger is manufactured and the parts for the housing are prepared, you can proceed directly to the installation of the equipment itself. It is best to do this at the place where the home-made solid fuel boiler will stand. The structure will be very heavy and unbearable.

What will need to be done:

- we lay out the brick foundation, on which we then install the bottom plate of steel sheet;

- vertically along the perimeter of the bottom plate we install the inner walls of the heat generator;

- inside this housing we place the grate and the heat exchanger itself. Here it must be taken into account that the pipe for draining water must be lower than the pipe for its supply;

- install external walls;

- between the inner and outer walls we place a layer of washed and calcined sand to increase efficiency;

- we weld stiffeners on the outside of the boiler, and attach the remaining sheet to the upper part of the body;

- we install the doors in the holes and mount the chimney.

On the surface of the structure, you can install a cast-iron stove and get the opportunity to cook. Or instead, adapt a do-it-yourself water heater. As a result of all activities, an economical and reliable home-made solid fuel boiler will be obtained.

home > Heating > Heat exchanger for a solid fuel boiler. With my own hands.

Types of heat transfer

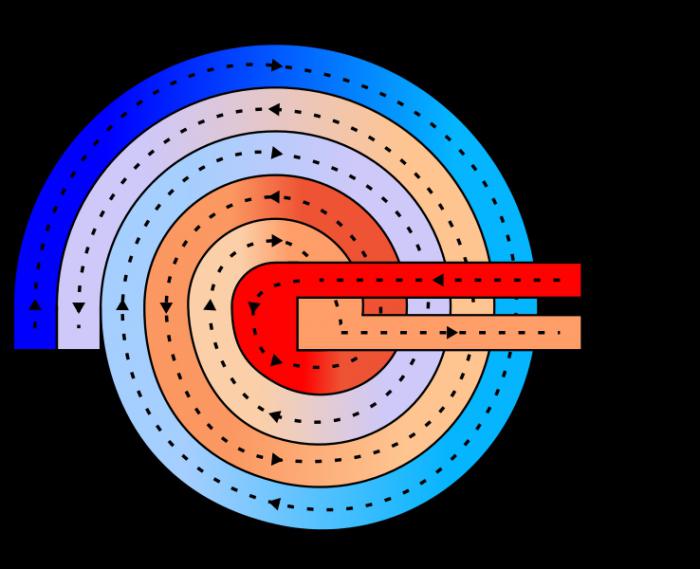

Now let's talk about the types of heat transfer - there are only three of them. Radiation - heat transfer due to radiation. As an example, consider sunbathing on the beach on a warm summer day. And such heat exchangers can even be found on the market (tube air heaters). However, most often for heating residential premises, rooms in an apartment, we buy oil or electric radiators. This is an example of another type of heat transfer - convection. Convection can be natural, forced (hood, and there is a heat exchanger in the box) or mechanically driven (with a fan, for example). The latter type is much more efficient.

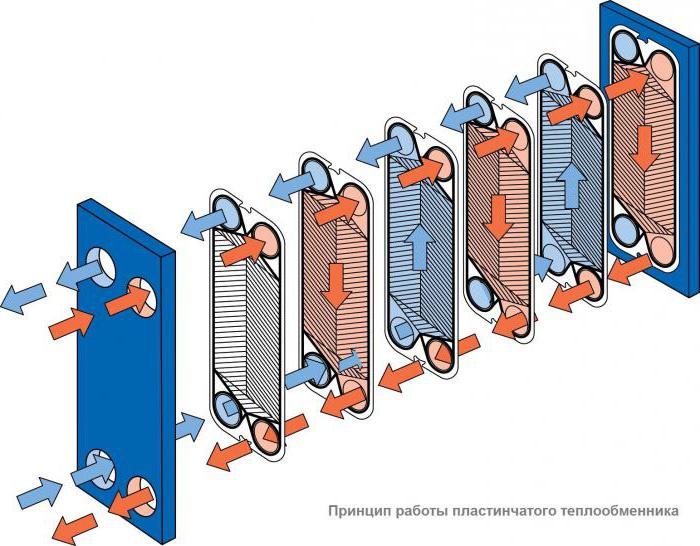

However, the most efficient way to transfer heat is conduction, or, as it is also called, conduction (from the English conduction - “conduction”). Any engineer who is going to conduct a thermal calculation of a heat exchanger, first of all, thinks about how to select efficient equipment in minimum dimensions. And it is possible to achieve this precisely due to thermal conductivity. An example of this is the most efficient TOA today - plate heat exchangers. A plate heat exchanger, according to the definition, is a heat exchanger that transfers heat from one coolant to another through a wall separating them. The maximum possible contact area between the two media, together with correctly selected materials, plate profile and thickness, allows minimizing the size of the selected equipment while maintaining the original technical characteristics required in the technological process.

Let's start installation

The sequence of work depends on the design features of the heat exchanger.

Installing a device with a register

When installing in an old furnace, you will have to disassemble part of the masonry. The sequence of work is as follows:

- We are preparing the foundation for the coil directly in the furnace cavity.

- Installing the coil.

- We lay the disassembled row of bricks, leaving room for the inlet and outlet of the pipes.

- We connect the heat exchanger to the heating system.

Before starting operation, the tank should be checked for leaks without fail. You can make sure that there are no leaks by filling it with water, preferably under pressure.

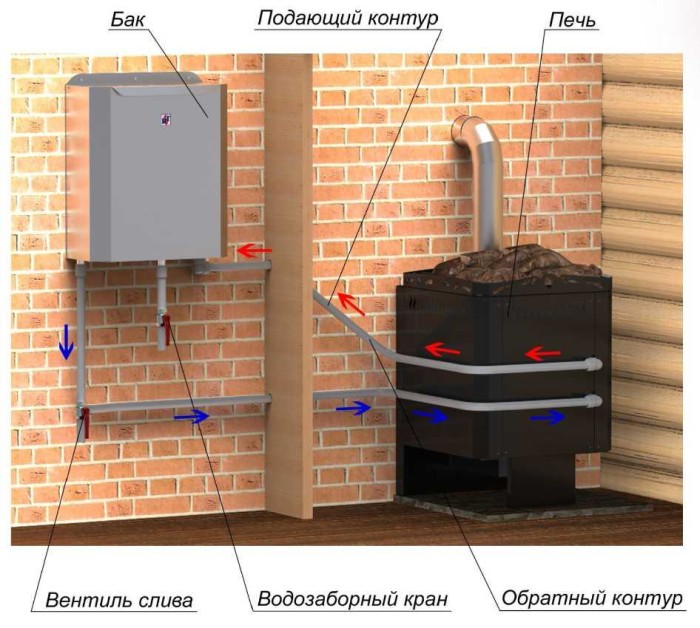

Mounting the device with a container

The best option for a stove or fireplace. It is made of a metal tank and two copper tubes. The volume of the tank, as a rule, is about 20 liters.In the absence of a finished product, a tank of sufficient volume is made by hand by welding sheet steel.

For the manufacture of the heat exchanger, a material thicker than 2.5 mm should be used. Welding should be done in such a way that the thickness of the formed seam is minimal.

The tank must be installed 1 meter above the floor level, but no further than 3 meters from the stove. Two holes are made in the tank: one near the bottom, the second - at the highest point on the opposite side. The efficiency of heat transfer depends on the location of the lines.

It is necessary to strive to ensure that the minimum deviation of the lower outlet in the direction of the floor is 2 degrees. The top one should be connected at an angle of 20 degrees in the opposite direction.

A drain valve is being installed in the storage tank. Another tap is provided to drain the entire system, which is installed at the lowest point. After checking the tightness, the system is ready for operation. The efficiency of such a furnace with a heat exchanger can be appreciated in the cold season.

What characteristics should the tools have

If your goal is to make a heat exchanger for a boiler room or a heating point, it is best to focus on the choice of plate collapsible devices or make them yourself according to the drawing. The heat exchanger diagram is shown in the photo below:

Why lamellar collapsible devices? The fact is that the liquid (in this case it is water) in heating and plumbing networks does not have particularly good qualities, which can lead to the formation of scale and other serious deposits in the system. By the way, the repair of heat exchangers consists precisely in cleaning the channels from such substances. Also, in the repair, “rolls” are changed and cracks in holes are repaired (if necessary).

Of course, the design of such heat exchangers does not allow to reduce the level of scale formation to zero. But then what are their advantages? Their main advantage is easy disassembly. The design of the plate heat exchangers is so simple that it is possible to clean the scale almost every day. Thus, the repair of collapsible type heat exchangers is carried out as soon as possible. Here, one more advantage should be noted - the maintainability of the device, because it is possible to replace the plates in it without the use of special equipment and tools.

20 photos of cats taken at the right moment Cats are amazing creatures, and perhaps everyone knows about it. They are also incredibly photogenic and always know how to be at the right time in the rules.

9 Famous Women Who Have Fallen In Love With Women Showing interest in someone other than the opposite sex is not unusual. You can hardly surprise or shock someone if you admit it.

Our ancestors slept differently than we do. What are we doing wrong? It's hard to believe, but scientists and many historians are inclined to believe that modern man sleeps in a completely different way from his ancient ancestors. Initially.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don't worry about the shape and length of their hair. It seems that youth was created for experiments on appearance and bold curls. However, already

These 10 little things a man always notices in a woman Do you think your man knows nothing about female psychology? This is not true. Not a single trifle will hide from the gaze of a partner who loves you. And here are 10 things.

Never do this in a church! If you're not sure if you're doing the right thing in church or not, then you're probably not doing the right thing. Here is a list of the terrible ones.

home > Heating > Heat exchanger for a solid fuel boiler. With my own hands.

What is it and why is it needed

A heat exchanger is a device for transferring heat from a heated medium to a colder one. The principle is one, designs + set.The heat exchanger for the chimney allows you to select part of the energy of the exhaust gases and use it to heat an adjacent room or heat hot water.

Flue gas heat extractors for the chimney can only be used if the pipe is made of steel. It will not be possible to install a heat exchanger on modern ceramic and sandwich structures, since the outer surface of the insulated pipe is cold.

The exhaust gases from modern gas and pellet boilers are not hot - about 200 ° C, so it will not work to get a lot of heat from the chimney. Hotter gases exit from solid fuel boilers - up to 600 ° C, and the recuperator allows you to get a fairly significant amount of heat for heating or heating water.

The maximum amount of heat from exhaust gases can be obtained during the operation of not too modern traditional stoves, fireplaces, home-made bourgeois stoves. The efficiency of these heaters is low, the flue gas temperature is high, so a large part of the outgoing heat can be captured using a heat sink. The use of heat sinks on the chimney of a home-made potbelly stove allows you to capture up to 30-40% of the energy additionally.

The main reason for installing a heat exchanger is to maximize the use of fuel combustion energy and save heating costs. In addition, sometimes when heating small houses it is not economically feasible to purchase a heater with a heat exchanger and install a heating system.

A modern fireplace or stove heats houses up to 70 m² and even more well, only some rooms need heating - bathrooms or distant bedrooms, rooms on the second floor or attic, so heat from the heat exchanger for the chimney can be used for heating them. Sometimes a chimney heat exchanger is used to heat water.

Production of heat exchangers for horizontal boilers

A horizontal solid fuel boiler usually has fairly significant dimensions and is intended not only for space heating, but a hob can be placed on its upper surface. The easiest way to build such a boiler with your own hands is to use metal pipes that are assembled according to a certain pattern.

Scheme of operation of a simple boiler with a heat exchanger.

The rectangular heat exchanger is made of 40 mm and 50 mm round tubes and 60×40 mm rectangular tubes. A rectangular profile is used for joining pipes with a circular cross section. For these purposes, it is also possible to use pipes with a circular cross section, but this is a very difficult process that requires a lot of experience. The wall thickness of all pipes used should be 4-5 mm.

After the required dimensions of the heat exchanger have been calculated and pipe blanks of the required size have been made, holes for round pipes are cut out in vertical racks, a square section profile. Consider an example of creating a heating boiler for a house with an area of \u200b\u200babout 100 m 2. In the front racks, as viewed from the furnace door, it is necessary to cut 4 holes for pipes with a diameter of 50 mm, in the rear racks, 4 holes are also cut in a face with a width of 60 mm. In a face with a width of 40 mm, 4 holes of 40 mm are cut.

Thus, the front post forms a hole for the furnace door, pipes run on the sides of it. The C-pillar frames and butts 40mm tubing. It must be remembered that in order for the solid fuel boiler to function correctly, it is necessary to provide pipes for the inlet of cold water and for the outlet of hot water, which will be connected to the heating system of the house. The hole for cold water is located at the bottom of the boiler, and for hot water outlet - at the top. They are cut either with a gas or welding cutter, they must be neat, you need to try to make them even, the influxes that may form are removed with a grinder.

Scheme of a homemade boiler from pipes.

The assembly of the heat exchanger of a solid fuel boiler begins with the end parts. Racks and pipes are set perpendicular on a flat surface

After the front and back parts are assembled, welding of the side parts begins, it is important to monitor the perpendicularity of the edges. It is best to do it together, someone holds the pipe, someone welds

The next step is to weld pipe sections for supplying and draining water. Then weld the end parts of a rectangular profile, this is done using pieces of metal measuring 60 × 40 mm.

It is very important after completion of welding work to check the tightness of the seams. To do this, the structure must be installed vertically, close the lower hole, and start pouring water through the upper one.

If there are no leaks, then you need to drain the water by opening the bottom hole, and you can proceed with the installation of the boiler.

Power calculations

It is almost impossible to independently calculate the power of the heat exchanger in the absence of initial data (power of the furnace, temperature and amount of outgoing gases per unit time, area of contact between the heat exchanger and the chimney metal, the speed of air or water passing through the device) is almost impossible. You can measure the power of an already installed heat exchanger.

It is tentatively worth counting on the fact that the heat exchanger on the chimney of a solid fuel stove or fireplace will warm up a couple of small radiators, increase the temperature in the garage or make the attic room warmer, the dressing room in the bath.

Manufacturing process

First of all, you need to prepare all the necessary blanks:

- Steel sheets with a thickness of 4 - 5 mm for the manufacture of fireboxes. Alloy steel of heat-resistant grades 12X1MF or 12XM (with the addition of chromium and molybdenum) is best suited, but it must be cooked in an argon environment, so you will need the services of a professional welder. If you decide to make a firebox from structural steel (without alloying additives), then you should use low-carbon grades, for example, Steel 20, since high-carbon ones can lose ductility from exposure to high temperatures (they are hardened).

- Sheet steel with a thickness of 0.3 - 0.5 mm, painted with a polymer composition (decorative sheathing).

- 4mm structural steel sheets for the hull.

- Corner 50x4 mm, from which the grate will be typed.

- Du50 pipe (flame pipes inside the heat exchanger and branch pipes for connecting the heating system).

- Pipe Du150 (pipe for connecting the chimney).

- Rectangular pipe 60x40 (air intake).

- Steel strip 20x3 mm.

- Basalt wool 20 mm thick (density - 100 kg / m3).

- Asbestos cord for sealing openings.

- Factory made door handles.

Welding of parts should be carried out with MP-3C or ANO-21 electrodes.

The best heat exchanger for hot water

The necessary element in the heating system of a private house, due to which heat is transferred from heating to cold water, thereby heating it and providing residents with sufficient hot water.

GDP 08-114-4000

It is installed in hot water supply systems, heating systems of domestic and industrial buildings and structures, in which the working medium is hot water coming from heating networks of CHP, and other non-freezing liquids. The principle of operation is that the heating medium in it passes through the inner space of the pipe, and the heated medium passes through the annular space. Due to this, the heater can also be used in other systems that require the regulation of liquid temperatures. It is also used in the petrochemical industry, pharmaceuticals, etc. for cooling and heating vapors, gases, their mixtures and condensates.

GDP 08-114-4000

Specifications:

|

Technical regulation |

TU 4933-001-65753064-2010; GOST 27590-2005 |

|

Number of tubes, DN 16, pcs. |

19 |

|

Heated water consumption, t/h |

21,5 |

|

Heated surface area, m2 |

3,58 |

|

Diameter, mm |

114 |

|

Length, m |

4 |

|

Weight, t |

97,1 |

The elements of the heater are made of L-68 brass or 08x18H10 (12X18H10) stainless steel. The device is connected to heating networks and pipelines through transition pipes coming from the body.

Shell-and-tube boiler

They are used in heat supply systems of buildings for various purposes and are used to heat network water with steam. Smooth heat exchange pipes made of L68 brass or 08X18H10 stainless steel with a diameter of 16 mm are used.

Shell-and-tube boiler

Designed for heating water in heat supply, heating and hot water systems operating according to common temperature control schedules of 70°/150°; 70°/130°; 70°/95° and 50°/60°. In order to avoid boiling water, its pressure must be at least 0.1 MPa (1 kgf / cm2) higher than the steam pressure.

Danfoss XB 06L-1-8 - Tavago

Brazed plate heat exchangers with stainless steel plates are specially designed for district heating applications. They can also be used in heating, hot water and refrigeration systems for ventilation and air conditioning installations.

Danfoss XB 06L-1-8 - Tavago

It consists of 8 reliably brazed AISI 316 steel plates. Copper soldering is performed at the edges, as well as at all points of contact of the plates - which prevents the leakage of the coolant and the heated medium. The number of plates is selected according to the specific system and individual requirements.

Among the advantages, the design pressure has been increased to 2.5 MPa (25 bar), weight has been reduced and maintenance has been significantly simplified - now it takes a maximum of 2 hours to flush.

VIDEO: Heat exchanger. Heating a tent in winter while fishing

Heat exchanger for solid fuel boiler. With my own hands.

For my solid fuel boiler, I made an efficient heat exchanger. The design of the heat exchanger is thought out in such a way as to provide the maximum possible heat exchange area with ease of manufacture. And the heat exchange area, as you know, directly affects the efficiency.

Structurally, the heat exchanger consists of three identical tube registers. All of them, during installation, are combined into one heat exchanger using welded combs. The connections are detachable, so that in the event of an accident of any of the registers, you can simply turn it off without dismantling the boiler.

Before making the registers, I first made templates from a plastic pipe, which I decided to use for marking in order to achieve the correct geometry of the welded joints.

The holes were made without drilling. First, with a large grinder, I cut off part of the metal, then with a small grinder with a grinding wheel I adjusted it to the markup, and only then I finally chose it with a cutter. An additional handle on the drill is not at all superfluous, the speed controller too. Sharoshka has been waiting for her turn in my bins for 15 years since working at the email. installation for chamfering the inner surfaces of pipes (with the industrial method of installation) .

To control the holes during processing, I also used a template. The old electrolytic capacitor turned out to be very convenient for me in this capacity.

From the remaining scraps of the profile pipe from the fence, I made a “template” for assembling the registers so that three sides become rigid, and the fourth, after laying the inner pipes, is pressed with clamps. First, I assembled everything on tacks, and only then did the final welding. Thus, according to the same template, three absolutely identical registers were assembled from profile pipes.

Then he started making combs for assembling a block of registers. The holes in the blanks were made using the same technology as when assembling the registers: grinders, a drill with a cutter. With the help of clamps, he pressed the screwed-in saddles with American women to a flat pipe and to a comb pipe, grabbed it by welding.

After twisting the Americans and the saddles of the second comb, he pulled them so that the planes of the Americans were tightly pressed, and the pipes were parallel in two planes. He grabbed it, untwisted it, everything seemed to remain in the planes. Scalding has not yet decided to the final welding registers, just in case.

Site search. You can change the search phrase.

As a result, my solid fuel boiler with a capacity of about 100 kW was equipped with an efficient and fairly reliable heat exchanger, which was later confirmed by practical operation.

Information about the assembly of registers was sent by Victor:

If the firebox design is incorrect or the stoker is not properly behaved, the firewood can burn poorly, with the formation of a large amount of soot. What is soot? It is, simply put, unburned carbon. And if it didn’t burn out, then it didn’t release heat.

A bypass is generally just a pipe connecting the output of the boiler registers to their input. It is done in order to be able to supply part of the heated water from the output to the input. It would seem that everything is simple. But gravity has not yet been canceled.

Let's talk about automatic heating for the house. And before making any choice in terms of iron for it, I will talk about the features of operating a heating system with a Water Heat Accumulator - VTA.

As always, autumn has come again unexpectedly. After the calculations, our plans to heat ourselves with electricity in winter were shrunk and we decided to install a boiler. For now, maybe.

Posted: 04/20/12Updated: 12/27/15Total views: 20802 today: 4

Egor You can fix the wire on the Krona battery terminals with a tube cut off from the cap of a medical needle.

Verification calculation

The verification calculation of the heat exchanger is carried out in the case when it is necessary to lay a margin in terms of power or in terms of the area of the heat exchange surface. The surface is reserved for various reasons and in different situations: if it is required by the terms of reference, if the manufacturer decides to make an additional margin in order to be sure that such a heat exchanger will reach the regime and minimize errors made in the calculations. In some cases, redundancy is required to round off the results of structural dimensions, while in others (evaporators, economizers), a margin on the surface is specially introduced into the calculation of the heat exchanger power, for contamination by compressor oil present in the refrigeration circuit

And the low quality of water must be taken into account. After some time of uninterrupted operation of heat exchangers, especially at high temperatures, scale settles on the heat exchange surface of the apparatus, reducing the heat transfer coefficient and inevitably leading to a parasitic decrease in heat removal

Therefore, a competent engineer, when calculating a water-to-water heat exchanger, pays special attention to additional redundancy of the heat exchange surface. A verification calculation is also carried out in order to see how the selected equipment will work in other, secondary modes. For example, in central air conditioners (supply units), the first and second heating heaters, which are used in the cold season, are often used in the summer to cool the incoming air, supplying cold water to the air heat exchanger tubes. How they will function and what parameters will give out, allows you to evaluate the verification calculation.

Calculation of a twisted heat exchanger

Calculate the length of the tubes and the number of turns of the tubes of the coiled heat exchanger of the air separation unit, in which copper tubes with an outer diameter of mm and a wall thickness of mm are wound on a core. Between the tubes are gaskets mm thick; the distance between adjacent turns of tubes is mm. The coefficient of thermal conductivity of copper W / (m K).

Inside the tubes of the heat exchanger, air moves with a pressure of MPa at a speed of m/s. Inlet and outlet air temperatures, respectively, K and K.The air consumption is kg/h = 0.314 kg/s.

From the outside, the tubes are washed by an air stream with a pressure of MPa coming from the vapor separator from the liquid. The air temperatures at the warm and cold ends of the heat exchanger, respectively, are equal to K and K.

SOLUTION.

The values obtained in the calculation according to the diagram may carry significant errors associated with the inaccuracy of determining the initial values according to the diagram, so we will specify the value of M using the tabular values of the enthalpy in the balance of the heat exchanger:

,

moreover, for low-pressure air, we will consider the enthalpy through temperature and heat capacity, which is practically constant and equal to 1.006 kJ / (kg * K)

,

error in determining M:

If this error turned out to be more than 5%, then you should look for an error in the calculations according to the diagram.

For air, at a pressure close to atmospheric, the isobaric heat capacity in this temperature range changes slightly (within 1%), therefore, for thermal calculations, we take the average value = 1.01 kJ / (kgK). The heat capacity of high-pressure air varies markedly with temperature, so the average logarithmic temperature difference formula cannot be used to calculate the average temperature difference along the length of the heat exchanger. We will calculate it step by step: we will conditionally divide the heat exchanger into several parts, within which the heat capacity will change insignificantly. It is most convenient to divide so that within each section the high-pressure air temperature drops by 10 K, and the unknown low-pressure air temperature at the end of each section will be found from the heat balance equation of the heat exchanger part from its warm end to the considered section

,

where . From here

Calculations using this formula are shown in Table 1 and Figure 5.

Table 1

|

Temperature air inside the tubes |

Enthalpy air inside tubes |

Temperature air, bathing tubes |

Temperature difference |

Working temperature difference |

|

T4, K |

,kJ/kg |

T3, K |

DT,K |

DT,K |

|

300 |

274,14 |

290 |

10 |

14 |

|

290 |

262,02 |

282 |

8 |

12,1 |

|

280 |

249,7 |

273,7 |

6,2 |

10,3 |

|

270 |

237,08 |

265,3 |

4,7 |

8,8 |

|

260 |

224,18 |

256,7 |

3,3 |

7,4 |

|

250 |

210,9 |

247,9 |

2,1 |

6,2 |

|

240 |

197,12 |

238,7 |

1,3 |

5,4 |

|

230 |

182,78 |

229,1 |

0,9 |

5 |

|

220 |

167,7 |

219,02 |

1 |

5,1 |

|

210 |

151,66 |

208,3 |

1,7 |

5,8 |

|

200 |

131,42 |

194,8 |

5,2 |

9,3 |

|

190 |

115,62 |

184,2 |

5,8 |

9,9 |

|

180 |

94,9 |

170,4 |

9,6 |

13,7 |