The tool you need to get the job done

First of all, for work, you should find out the exact dimensions of aluminum radiators. To measure them, you will need a construction tape measure or a special folding ruler. Also, if both types of devices are not available, you can use the standard student ruler. It should be noted that most rulers are only 30 centimeters long, so you will have to make notes on the radiator (it is better to use a pencil that is easily washed off the surface).

Each new mark will be the end of the previous measurement and the beginning of a new one. The resulting dimensions are added, and the true size is obtained. Dismantling aluminum radiators requires other tools that are desirable to use for dismantling, namely:

- A complete set of wrenches (socket and ring).

- Radiator key.

- Pliers.

- Screwdriver.

Step-by-step description of dismantling works

A few words about when you may need to disassemble the heating battery:

- In the case of replacing the old radiator with a new one that has better performance and better appearance.

- If you need to add additional sections for the battery.

- If it is necessary to replace a separate section or gasket that has leaked.

The instruction begins with the preparation of the necessary tools:

Step #1: Preparing the Tools

Photo of a nipple wrench

Sample gas key

Tip: taking into account the fact that it is very rarely needed on the farm, and its price is not the lowest, it is recommended not to buy a nipple wrench, but to rent it. This will save the family budget.

Step #2: Disconnecting the Battery

Before disassembling an aluminum or cast iron radiator, it must be disconnected from the heating system. To do this, it is imperative to turn off the heating and drain the water from the riser, otherwise you will simply flood the room and get burned.

Tip: it is recommended to cover the floor under the battery with a film, rags, or at least newspapers before starting dismantling, in order to avoid getting any residual liquid on it, which may be in the circuit even after draining the riser.

Further, depending on the complexity, three situations can be distinguished:

- Polypropylene pipes. In this case, the coupling connection, as a rule, is twisted with bare hands, without causing any difficulties.

- Steel new. With some effort, you will most likely be able to spin the battery inlet and outlet horns with a gas wrench.

Disconnection of new steel pipes

- Old steel or cast iron pipes. First, we try by removing the paint from the docking place with a blowtorch and a metal brush, we try to unwind the connection as described in the previous version. But in systems that have worked for a long time, most often this does not give a result, and then we simply cut off the drive with a “grinder” or autogenous.

Cutting old sgons using a grinder

After disconnecting the battery from the pipes, we remove it from the hooks and lay it on a flat plane.

Step 3: Radiator Disassembly

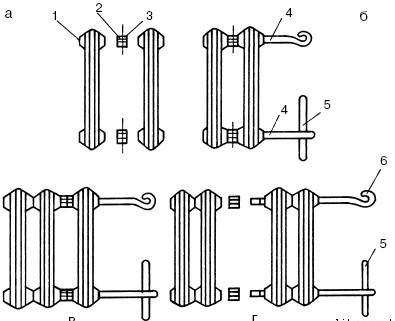

Battery section disconnect diagram

Pipe section or crowbar

The battery can be cast iron, aluminum or bimetallic.

The most difficult option for parsing is the first of the listed ones, and we will start with it:

- How to disassemble a cast-iron heating radiator on your own:

Carefully, we check the threading on the fittings or plugs, which can be either left or right.

We insert the nipple key inside, we increase its torque with the help of a piece of pipe or a crowbar.

We tear off the thread by scrolling the tool a quarter of a turn, first at the top, and then at the bottom.

Then we also alternately continue to unscrew the nipples so that the radiator does not warp.

The main problem with old batteries is that the futors can get stuck in the course of many years of operation and not give in to the key. In this case, the junction must be heated in a circular motion with a blowtorch, and then again try to unscrew the nipple

The procedure is repeated until the thread yields. If it still doesn’t work out, then you have to cut it with an autogenous.

Dismantled old cast-iron radiator

- Let's find out how to disassemble a bimetallic or aluminum radiator? The procedure is almost the same as described above, but has several differences:

-

- A smaller nipple wrench is used.

- So much effort is not required when unscrewing the nipples.

- Plugs and futurok are marked with the direction of the thread in the form of the letters S and D, where the first indicates the left stroke, and the second - the right.

- The metal spacers located between the sections are wiped, polished and stored until the next assembly of the battery.

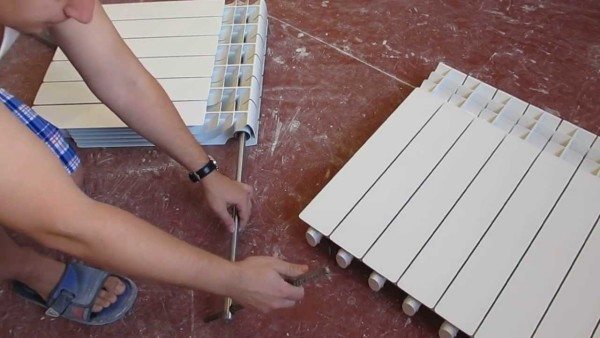

Disassembly of the aluminum battery

After completing the described tasks, you can replace the leaking part, add a section, or even install a new radiator in place of the old one.

How to disassemble an aluminum heating radiator with your own hands

Removal of the aluminum battery occurs in the following cases:

- When the system changes completely.

- It is necessary to increase or remove the extra section.

- Eliminate leak.

Before you disassemble the aluminum radiator, you need to prepare a set of wrenches and a screwdriver.

Further actions are performed in the following sequence:

The coolant is discharged from the system. If disassembly occurs during the heating season, then you should wait until the battery cools down.

Using a wrench, unscrew the coupling that connects the hose coming from the battery to the heating pipe.

The disconnected radiator must be freed from residual water and placed face up on a flat surface.

The battery filter is removed and washed thoroughly. This must be done immediately, since the dirt accumulated in it can harden and then it will be extremely difficult to remove it.

Further work is the analysis of the battery into sections. They are interconnected with special nipple nuts. To remove them, you need a wrench for disassembling aluminum radiators, by turning it counterclockwise, they can be easily removed from the radiator.

This must be done very carefully to avoid distortion.

After disassembly, the battery cells are washed and assembled in the same sequence of actions.

If it is necessary to eliminate the leak, then a special epoxy resin solution with the addition of bronze powder is suitable for aluminum radiators. You need to work with this composition quickly, as it dries up in a matter of minutes, so the leak site must be cleaned and prepared in advance.

Dismantling the old radiator

In general, the process of disassembling an old cast-iron heating radiator is carried out in exactly the same way as a new one. But the problem is that all connections eventually become covered with scale and practically solder with each other. As a result, it becomes simply impossible to get by with just a plumbing radial key.

In addition, an additional item appears in the work - flushing. The old radiator, in any case, is clogged from the inside with all sorts of dirt. Therefore, if you already undertook to improve it. then you need to take care of cleaning the equipment, this will allow it to work much longer and better.

It is advisable to flush outside, so you will save the bath from damage. The procedure is carried out using ordinary running water, there is nothing complicated about it. But the further process can be quite puzzling. If you find that the nuts are firmly attached to the radiator and do not want to be separated from it, then you can use three different methods to break this union:

- the stuck compound can be separated by heating. To do this, you will need either a blowtorch or a building hair dryer. The first option is much more efficient in work, but the second one can give the desired result. Use this accessory to heat up the perimeter connection you need, and then immediately try to remove the nut without waiting for it to cool. If it doesn’t help right away, repeat the same procedure a few more times, after each entry again trying to figure out the problem. At the same time, keep in mind that working with hot metal is very dangerous. do not forget to protect yourself with protective clothing - gloves and an apron - and special glasses;

- if the previous procedure did not help, then you will have to try to solve the problem with a more radical method - sawing. As a tool for this, you will need a hacksaw or a Bulgarian saw. The grinder does an excellent job of sawing metal, but here again the fragility of the cast-iron battery should be taken into account - if you cut the same place for too long, the material may simply crack, and you will have to throw away the entire radiator. To prevent this from happening, cuts should be made in stages, giving the battery a little rest after each call. But in general. if you have the opportunity to spend a significant amount of time and effort, then it is better to use a hacksaw for cutting. Of course, this is a much more dreary and lengthy process than in the case of a grinder. But on the other hand, there is no risk of damaging the radiator in those places where it is not required at all;

- the third option is even more brutal. If heating did not help to solve the problem, and cutting for some reason is impossible, then there is only one way out - just break the desired section. This is done with a sledgehammer. Naturally, you should not hit with all your might, because in this case you will be left without a battery. You need to act carefully and slowly, starting from the middle of the section and gradually reaching the point of its connection with the next one. As with the blowtorch, don't forget to wear safety goggles - even with careful breaking, there is a risk that one of the fragments will bounce violently.

Dear readers, now you know how to properly disassemble a cast-iron battery, even if it is three times older than you and fiercely wants to maintain its integrity. The assembly is carried out, in general, in the same way, but in the reverse order.

Even if the radiator is brand new, all joints must be carefully cleaned with sandpaper before assembly. And in the case of an old battery, this is generally a mandatory procedure. In addition, it is advisable to replace all gaskets. If before that there were rubber ones, then replace them with more modern ones made of silicone or paronite. These materials are much less susceptible to deformation and have a very long service life.

As you already understood, the most important thing in the process of disassembling a cast-iron heating radiator is accuracy. The fragility of the material requires an extremely slow approach

In addition, do not forget about safety, which, as you know, is above all. With the right approach to the process, your cast iron radiator will serve for a long time and with high quality. Good luck!

Disassembly of aluminum and bimetal radiator

Before disassembling the heating battery, prepare the necessary tools.

A nipple wrench is used as the main tool (can be rented at a specialized store for little money). It is a rod about 700 mm long. On the one hand, a key head with a size of 24x40 mm is welded to it, and on the other, a through hole is made. You can insert a metal bar into it. With it, it will be easier to scroll the nut.

This is the main tool that is used when assembling / disassembling heating radiators.

Several notches are applied on the surface of the key.The distance between them corresponds to the width of the radiator section. By inserting the key inside the battery, and counting the number of notches, you can easily find the nipple of the desired section.

Before disassembling the heating battery, it is necessary to orient with the direction of rotation of the key. The radiator is laid on a flat horizontal surface with the front side up. The right side will be a right hand thread and the left side will be a left hand thread. In order not to get confused, you can do it easier: take the nut and bait alternately on the right and left, and then we conclude in which direction to turn the key

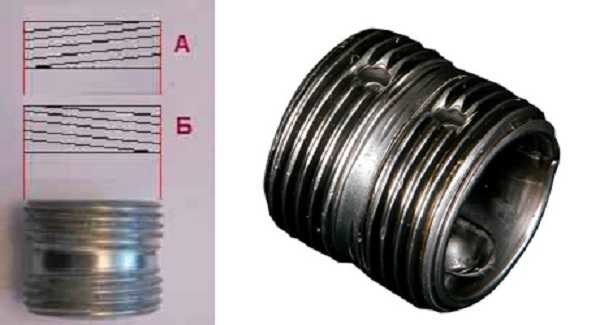

This is important because the threads are easy to break and then you need to buy two new sections. Imported manufacturers on the plugs and bushings on the front side of the section make the following designation for the thread: D-right, S-left

The thread on the nipple nut can be right or left, therefore, before disassembling the radiator, we determine in which direction to turn

Let's say you need to unscrew one section on the right. To do this, insert the key with a “blade” into the upper hole to the desired place, fix it in the groove of the nipple nut and, turning the key counterclockwise with force, “tear” it off. This is where a bar inserted into the ring on the key may be needed: a decent effort is required.

We make two full turns and rearrange the key to the bottom of the radiator. We repeat the operation by rotating the key in the same direction. We unscrew the nipple by 2 turns here. Again we take out the key and repeat the procedure for the upper part. So alternately unscrew the section completely. This is done so that there are no distortions.

Product design

The aluminum radiator is a construction of separate sections connected to each other by means of nipple nuts. In fact, this connecting element is a cylinder, on each side of which an external thread is made. The cylinder is empty inside. Radiator sections are screwed onto each nipple-nut on both sides.

The connectors are located both at the top and at the bottom of the battery. Thus, each section of the radiator is attached to the adjacent one at four points. The nipple-nut is made in such a way that it is generally invisible in the assembled product.

Inside each connecting element there are protrusions that serve for the installation procedure. A special tool clings to them, with the help of which the nut is untwisted and tightened. In this case, the direction of the thread should be taken into account - on some elements it is right-handed, on others it is left-handed.

In order not to play the "guessing game", just pay attention to the markings in the appropriate areas. If the letter D is indicated there, this means that the thread is right

The letter S indicates the left

It is very important not to confuse, since trying to unscrew the nut in the opposite direction can lead to stripping of the thread and, therefore, damage to the element.

Disassembly of cast iron radiators

Dismantling cast-iron radiators sometimes becomes a very time-consuming process, but necessary.

Scheme of disassembling cast-iron heating radiators: a - capturing the threads of sections by 2-3 threads with nipples; b - turning the nipples and joining the sections; c - connection of the third section; g - grouping of two radiators; 1 - section; 2 - nipple; 3 - gasket; 4 - short radiator key; 5 - crowbar; 6 - a long radiator key.

A new or old radiator is placed on a level place. At least on one side, you need to remove the usual futors or deaf ones - plugs. On different sections of radiators, they can be left-handed or right-handed. Usually, cast iron fittings have a right-hand thread, and plugs have a left-hand thread. If there are no disassembly skills, and there is a free section, it is better to find out what kind of thread this is and in which direction the key should be rotated before applying force. If the thread is left-handed, when disassembling cast-iron batteries, turn the key clockwise.

As with unscrewing any nuts, you first need to “break” the futors from their place, i.e.turn them a quarter of a turn on both sides of the battery. Then the futors are unscrewed so that a gap of several millimeters is formed between the sections. If you release the futorki more, the whole structure will begin to bend under its own weight and due to the applied efforts. In this case, the thread may jam. To prevent this from happening, an assistant must stand on the disassembled battery, which will prevent bending with its weight.

Usually, dismantling of old heating radiators is difficult because the fittings and sections are “boiled”. In order to disassemble such a battery, you will have to use an autogen or a blowtorch. The junction is heated in a circular motion. As soon as it is warm enough, the futorki are twisted out. If it was not possible to unscrew the first time, the actions are repeated.

If there is not enough strength to disassemble the battery, you need to increase the length of the key. An ordinary pipe is used, which serves as a lever.

Similarly, built-in nipples for airing cast-iron radiators are unscrewed.

If it was not possible to disassemble the cast-iron battery using the considered methods, it remains to cut it with a grinder or autogenous or smash it in a supine position with a sledgehammer. You need to carefully break or cut one section. After this operation, the adhesion between the sections may loosen, the battery can be disassembled, the remaining sections can be saved.

The use of a “liquid key” or WD liquid does not give an effect, since in old cast-iron batteries the futors were sealed with linen and paint, and liquids would not get on the threads.

How to disassemble cast iron batteries with your own hands

Most often, houses and apartments of the old layout are equipped with MS-140 cast-iron batteries. Nipple nuts and gaskets are also used to assemble their sections. It is especially difficult to disassemble an old battery, because. in the course of its long operation, the gaps between the sections boiled with rust. As a rule, in such cases, the key niches are corroded by the coolant.

It is also important to keep in mind a significant mass of cast iron. For example, the weight of one battery for 12 sections is 90 kg: it will be difficult to cope with such a product alone.

To implement the procedure, you will need the following tools:

- Nipple radiator wrench.

- Plumbing fixtures for unscrewing fittings and plugs.

- Small sledgehammer and chisel.

- Blowtorch (it can be replaced with a building hair dryer).

- Steel brush.

- Wooden blocks for installing the battery on the floor.

In the role of a radiator key, a round-shaped metal rod flattened at one end, with a diameter of 18-20 mm, is used. The dimensions of the flattened part are 28 × 40 mm, with a thickness of 6 mm. A ring is welded to the opposite end of the rod, through which the lever is threaded. The radiator key should be as long as half of the largest battery for 12 sections, plus 30 cm.

Disassembly procedure

It is very difficult to separate the stuck intersection joints. In some cases, they stick so much that even significant physical efforts are powerless. In such situations, the joints are heated before disassembly with a blowtorch or hair dryer.

How to disassemble a cast iron radiator:

- Cast iron is heated with a blowtorch until it begins to emit a crimson glow. After that, you can start the disassembly procedure.

- The first step is to unscrew the plugs.

- The radiator key is brought to the top of the battery: its head should fall into the area where the nipple nut is unscrewed. At the end of the section, you need to mark the circle of the tool rod with the help of chalk.

- The flattened part is inserted into the lower inner groove. Further, moving the tool in the right direction, bring it to the marked circle.

Before starting the operation, it is important to find out in which direction it is necessary to twist the sections.If there is a nipple nut, it is screwed in turn onto the right and left ends of the battery: this makes it possible to determine the direction of rotation of the nipple

If the thread moves, it should not be completely unscrewed. To avoid distortion, the upper and lower nipples must be unscrewed alternately one full turn.

From the author:

hello dear friends! Often, the owners of dwellings face the question of how to disassemble an aluminum heating radiator. This happens in two cases. The first is a breakdown of equipment, a violation of its performance or a leak in one of the segments.

The second is when the power of the product is not enough to heat the room with high quality. This, as a rule, happens if the required indicator is initially incorrectly calculated. That is why it is recommended to invite a specialist to pre-calculate the required parameter.

A professional makes a calculation taking into account even the slightest nuances. In this situation, all factors are important - for example, the climatic zone in which you live, the area of \u200b\u200bthe premises that need heating, the condition of the window frames, the presence of an insulating layer on the walls, and much more.

It is clear that a person who does not have the appropriate knowledge and experience will not be able to correctly calculate the required power. Therefore, in fact, it often turns out that an aluminum battery is simply not able to provide the required amount of heat. Fortunately, this problem can be solved quite easily by disassembling the product and adding the required number of sections. How to do this, you will learn from today's article.

The main reasons for repairing an aluminum radiator

Why do such incidents happen? The fact is that aluminum heating batteries are not quite suitable for installation and operation in such buildings, due to the limit of the permissible working pressure of the product. For aluminum radiators, the maximum (permissible) working pressure is within 15 atmospheres. Installing an aluminum radiator in an apartment, with an external source of heat supply, forces the product to work to the limit, since the operating pressure of the central heating system, as a rule, is in the range of 12-15 atmospheres, and when pressure testing (starting the system) it reaches much more.

As you understand, an accident with an aluminum battery, under such operating conditions, is inevitable and can happen at any time and it is not necessary that you stay at home and be the first to know about it. So, based on the foregoing, a sudden accident of an aluminum structure can entail large - serious financial costs that will have to be spent not only on repairing your premises - an apartment, but also on compensation for the consequences of the accident, neighbors .

But there are other reasons that force an urgent repair, interference with the integrity of the battery design, that is, to involve a qualified specialist or disassemble and assemble an aluminum heating radiator with your own hands. If you decide to get by, in order to save money or other circumstances, on your own (on your own), then you will have to thoroughly study the topic and find out: “How to properly disassemble and assemble an aluminum heating radiator with your own hands?”.

As practice shows, there are three main reasons that imply urgent, professional repair (disassembly and assembly of an aluminum heating radiator on your own) actions:

- Clogging of the heating battery. The radiator is barely warm (not all sections are the same temperature), although the pipe, the heat source, is hot. Such a defect involves disassembling and washing the product;

- Inter-sectional battery leak. Moisture appears between the joints of the sections or a liquid leak occurs - it involves disassembling the structure and replacing the sealing elements;

- The occurrence of a leak in the radiator section. The appearance of a crack or other defect, directly in the section itself, which provokes the release or leakage of the structure, implies the replacement or restoration of the sectional element, or the entire battery.

Helpful Hints

Interesting fact. Many people don't want to use cast iron radiators solely because of their appearance. But recently, it is the cast-iron retro heating batteries that have become widespread. Exactly those models from which so diligently left. Fans of retro style often specifically order such models in stores. Fans of a more modern design can be offered to decorate cast-iron radiators with special screens.

There is no heat loss from the screens, but the batteries look somehow special, simple, but stylish. For those who do not want to change their batteries, you can simply bring them back to their original beautiful appearance. Batteries can be repainted using modern materials or give them a rather unusual look yourself. When choosing materials, be sure to select those that can withstand high temperatures of more than 80 degrees. It is advisable to consult about painting materials and sellers. There are some paints that can change color when exposed to hot surfaces. In this case, by carefully painting the battery in a snow-white color, you can see a completely non-crystal white version during the heating period.

How to disassemble a cast-iron heating battery with your own hands

Sooner or later, it may turn out that even a cast-iron battery will require a complete replacement or you just need to clean it. In both options, the battery will have to be disassembled. How to disassemble a cast-iron heating battery with your own hands quickly enough and as professionally as possible? The fact is that such radiators are the best option for use in apartment buildings. These heating elements are able to withstand all the ups and downs of an imperfect heating system. Sometimes, over time, even cast iron has to be changed, because it has leaked or simply does not fit into the new apartment renovation.

Although even today, cast-iron batteries are still relevant. Many users do not want to change such good heat sources for new, but such short-lived, compared to cast iron, heat sources. Therefore, most people try to put their batteries in order by simply repainting them. Some use decorative screens for cast iron batteries. It is very comfortable and looks like new radiators and there are no problems in design. (See also: Do-it-yourself installation of heating radiators)

Any replacement of batteries can be performed only in the summer, when the heating season has not yet begun or, on the contrary, has just ended. But sometimes circumstances develop in such a way that it is necessary to change and disassemble the battery even in winter. For example, if the battery leaks, what should I do? Wait for the summer or the fact that one day the radiator will burst and the neighbors below will be flooded?

You can try to use the services of plumbers, but you can cope with the situation on your own. In order to disassemble a cast-iron battery, you need special tools and some knowledge, which we will talk about.

Battery assembly

In principle, having the necessary tools at hand, even a beginner can assemble or disassemble an aluminum radiator with his own hands.

To install a heater from an aluminum radiator with your own hands, you must:

Place the battery on a flat surface. This is necessary in order to inspect the device before installing it and check all joints for possible cracks or chips.

Before connecting the heater elements, the threads at the joints are cleaned not only of debris, but also of factory paint. This is done using sandpaper with a fine grained coating.

This is important, as the paint layer may crack later, leading to a leak. For the sake of presentation, manufacturers paint not only sections of radiators, but also their joints.

When cleaning the battery from paint, you need to make sure that the sandpaper does not leave scratches on it, which can also cause leaks in the future.

All gaskets should be washed in soapy water. and if antifreeze is supposed to be used in the heating system, then they need to be degreased, since this carrier is able to penetrate into any, even the most insignificant, irregularities.

Before connecting the sections, it is advisable to study the drawing of the key for assembling an aluminum radiator in order to know how to use it. This metal is very soft, so any too much force can damage the threads and then you will have to buy a new section.

A paronite seal is put on the nipple nut on both sides. The key is placed on top and easily rotated a couple of times, the same is done with the bottom hole. Only after the joints have been tacked can you tighten them more tightly with a lever.

The hole that will not be used is closed with a plug, and a Mayevsky crane is attached to the other and the assembly of the aluminum radiator is ready.

After all sections of the radiator are assembled, it can be connected to the heating system and checked for possible leaks. Since aluminum batteries are quite light, it is quite possible to connect them with your own hands, even if you do not have the appropriate skills for this.

How to solder an aluminum car radiator with your own hands

Let's move on to the soldering process. First, the problem area is carefully cleaned with a file and sandpaper. Before you start replacing the Peugeot 307 timing belt with your own hands, you need to prepare the tools that we need for this operation on the nfu engine. If there are lamellas on it, they must be carefully removed with pliers. Do-it-yourself aluminum radiator, a car that is like already. Next, the repair site is degreased with acetone.

Once soldering preparation is complete, flux can be applied. After that, we begin to warm up the junction. If you are using a gas torch or blowtorch, make sure that the flux does not burn out prematurely. It is easier to apply with a soldering iron. It is enough to dip its working element into the mixture and transfer it to the surface to be treated.

Now it's time to apply the solder. How to repair a toyota radiator It is better if it is in the form of a bar or wire. Solder is applied to the joint and carefully heated with a soldering iron (burner). When it spreads evenly, it is necessary to let it cool, after which it is desirable to apply a second (safety) layer. At the end of the work, the resulting sagging can be removed with sandpaper.

Do-it-yourself disassembly and assembly of an aluminum radiator

The site on which the restoration of the radiator will be carried out, covered with thick cloth

. If this is the surface of the table, then the main work will not take place on weight. The prepared place will protect the soft aluminum from getting unnecessary deformations and scratches.

Important

! Before removing the union couplings, a rag is spread under the radiator

to protect the floor from dirty liquid that may leak out during dismantling. Keep a rag handy to soak up any residual moisture remaining inside the sections

Disconnection from the heating network

Before starting disassembly, the radiator is disconnected from the heating network. shut-off valves

. If there are no shut-off valves on the radiator, then invite a housing worker

so that he turns off the heating riser for repair work.

During the heating season, after the radiator is closed, a pause is made. Because the water is still hot, wait for some time until the liquid cools down

, and then disconnect the radiator from the heating pipes.

coolant

remaining in the battery poured into a prepared bucket

and proceed to the separation of sections. Immediately after dismantling, the inner surface of the battery is washed with running water.

How to disassemble and assemble the battery

Aluminum sections, connected nipple nuts

. The inner part of such a connector has protrusions, for which the nipple wrench grabs the nut and unscrews it. The nut is similar to the clutch, only carving is external

. One nipple nut has both right-hand and left-hand threads. They are made in pairs for the top and bottom connection. When the nipple is untwisted, the sections diverge, and when twisted, they are pulled together.

Pre all plugs and adapters are twisted from the ends

. Access to the connector must be open to the nipple wrench from all sides.

Photo 1. Fastening sections of an aluminum radiator to each other: the nipple-nuts are untwisted when disconnected.

To disassemble the battery, the blade of the tool is placed through the open end of the radiator into the grooves of the unscrewed top

nipple-nuts and with some pressure make a test scroll counterclockwise

to move the connection. If the key turns the nut normally, then it is inserted into the grooves bottom

nipple nut and also, as in the first case, try to turn a couple of turns.

Important

! When unscrewing the connectors, follow the sequence of actions

to avoid distortion. After disconnection, the exposed threads are carefully examined for cracks and chips.

, for thread integrity

If necessary, the joints are cleaned with fine emery cloth.

After disconnection exposed thread carefully examined for cracks and chips

, on the thread integrity

. If necessary, the joints are cleaned with fine emery cloth.

Starting the assembly of the radiator sections, on the upper and lower nipple nuts put on sealing rings made of paronite

placed between sections. I lightly press the sections against each other and alternately screw them together. Turning nuts

, so as not to skew, is limited two turns of the key

.

If something went wrong

During operation joints between sections and steel nuts stick to each other

. This comes from the quality of the coolant supplied to the heating system. Sometimes even significant physical efforts are useless.

Despite the fact that sticking needs to be dealt with, aluminum is easily deformed

because it is a soft metal.

By heating the joints with a building hair dryer, you can overcome boiled rust

. If this also did not help, having corroded the corrosive growth too much, then the edger gets down to business.

Advice.

If the nipple nut does not loosen under high pressure, then no need to increase the applied force with excessive leverage

. In the worst case, not only the nut itself will break, but both sections that fit tightly on this nut will also crack.

Bulgarian circumcised leaky section

, moreover, from the reverse side and stepping back from the edge of the connection by at least half the length of the coupling. This protects the working section from destruction and does not cut the connecting nut. During trimming, the rust bounces off, making it easier to unwind the surviving section.