Assembly technology

Different types of connections are made according to different schemes.

How to weld plastic pipes

To weld pipes, you will need to prepare:

- welding machine with a set of nozzles of different diameters. It is not necessary to purchase the device, as it can be rented at a hardware store;

- pipe cutter;

- measuring instruments;

Welding tool kit

connecting fittings, the selection of which is made in accordance with the pipeline scheme.

Fittings for welding plastic pipes

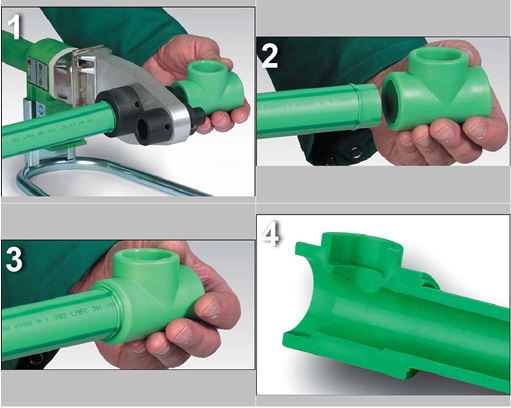

Welding assembly instructions:

- the pipe is cut in accordance with the dimensions specified by the pipeline scheme;

- heated to operating temperature (set automatically) welding machine;

- the joints of pipes and fittings are cleaned of dust, dirt and moisture;

When welding reinforced pipes, the reinforcement layer is removed from the junction.

Preparation for welding

- further, the pipe and the connecting fitting are heated. The heating time depends on such parameters as the diameter of the pipes to be connected and the depth of the weld;

The main parameters for making a strong joint by welding

heated parts are connected to each other

It is important to avoid deviations from the center. Deformed joints are the most vulnerable places and do not have high strength;

the connected parts are held in one position until they cool completely (cooling time is indicated in the table above).

Step-by-step execution of pipe welding

How to weld pipes, look at the video.

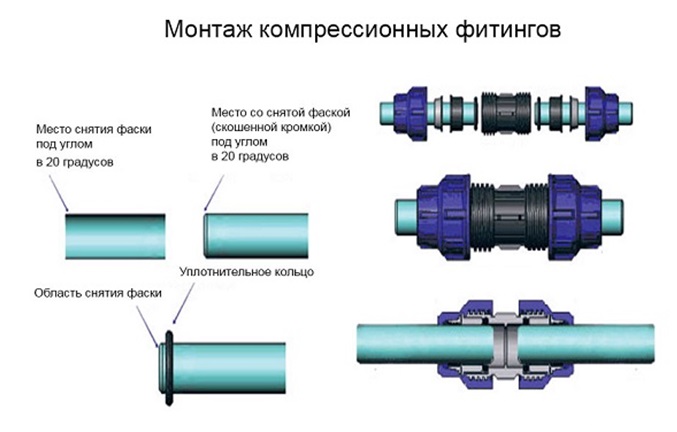

How to install a compression fitting

To install a compression fitting, you will need:

- pipe marking tools;

- pipe cutter;

- calibrator and beveler.

Fitting installation work is carried out in the following sequence:

- pipes are cut in accordance with the scheme;

It is important to cut exactly at an angle of 90º. This will ensure the strength of the connection.

- pipe ends are calibrated and bevelled;

- a fixing nut and a compression ring are put on the pipe;

- a fitting collet equipped with rubber seals is inserted into the pipe;

- a compression ring is put on the collet and fixed together with a connecting nut. Tightening the nut should not be done using any tools (wrenches), as this can damage the seals and reduce the strength of the connection.

Compression fitting installation technology

Thus, the installation of plastic pipes can be done in various ways independently. Which method to choose depends on the type of pipes and the priorities of the owner of the pipeline system.

Connection types. Their advantages and disadvantages

The main ways to connect plastic sewer or water pipes are:

- welding;

- compression fittings.

Welding allows you to get a strong connection. For welding, a special apparatus is required. A significant disadvantage of welding is to obtain a permanent connection, that is, if a leak is detected in the joint, a complete replacement of the assembly will be required.

Connection of plastic pipes by welding

Welding can be used to connect polypropylene, polyethylene and PVC pipes.

The use of compression fittings is permissible when constructing a pipeline from the following types of plastic pipes:

- metal-plastic;

- polypropylene;

- polyethylene.

The connection using a fitting is detachable, which allows periodic repairs without replacing individual elements of the pipeline system.At the same time, it turns out to be highly durable and not subject to mechanical stress.

Special fittings for connecting plastic pipes

In addition to the main ways to connect pipes, you can:

using a special adhesive that softens the top layer of plastic for a while to obtain a connection. This procedure is also called cold welding. The method of cold welding is mainly used to install polyvinyl chloride pipes in the construction of domestic pipelines;

Application of cold welding

electrical couplings (used for polyethylene pipes). The connection is made by melting the spirals located in the fitting. The use of electric couplings is permissible in the construction of both external and internal pipelines. However, expensive equipment is required to get the job done;

Connecting pipes with electric couplings

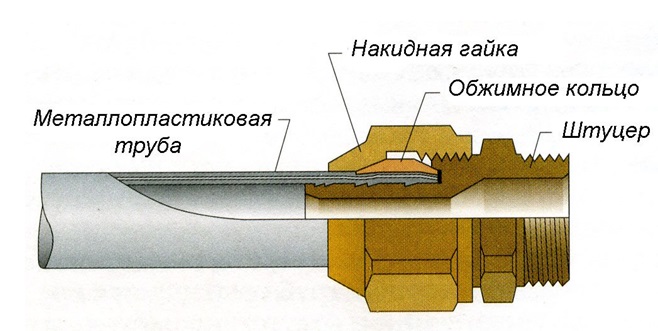

crimp fittings. A distinctive feature of this type of fitting is the presence of a special crimp ring, with which the connection of the pipe and fitting is obtained;

Using a Compression Fitting to Connect Pipes

push fittings. New fittings allow you to quickly and reliably assemble pipelines without the presence of additional equipment.

Technology for installing new push fittings

Push fittings and compression fittings can only be used in the construction of a pipeline from metal-plastic pipes. For other types of pipes, this connection is not allowed.

Methods for connecting polymer pipelines

The connection of plastic water pipes with your own hands can be carried out using different technologies. Their choice depends on the purpose of the system, the type of polymer used and the dimensions of the pipe. The main connection types are:

- In the bell. It is most often used for sewer engineering systems, where the medium moves by gravity. Also suitable for non-pressurized water supply networks.

- With the help of an adhesive. There are two options for how to connect plastic water pipes without soldering - a standard adhesive connection or “cold welding”, when under the action of a certain adhesive component the upper part of the polymer dissolves and 2 parts stick together at the molecular level. "Cold welding" is suitable for water, gas and sewer systems.

- Threaded connections. This type of installation is appropriate when plastic pipes are connected to metal pipes.

- High-temperature welding - the parts to be joined are preheated in a special installation and then joined. The technology is also called diffuse welding.

- Creation of flange connections. you can use special welded bushings for flanges or overhead metal flanges. This is the best option for combining metal with plastic.

- Docking using collets The design of the compression fitting is optimal in case of connecting small diameters. Installation is carried out by connecting crimp fittings with a rubber seal. During installation, the teeth of the metal tube "crash" into the pipe, forming a reliable joint.

- Welding with electric clutch. For connection, the parts are prepared - they are cleaned and degreased, after which they are located in the same plane, and an electric coupling is put on them. When current is connected to it, the pipes heat up - due to this, a joint occurs. The joint is formed sufficiently reliable, but not strong enough for use in the heating system.

In general, it is possible to connect plastic pipes both without welding and with it, that is, installation can be carried out in a “hot” (welding) or “cold” way.

The most rational when installing a water supply system is the collector wiring of water supply pipes in an apartment. What are its advantages and features - read in a separate article.

How to organize water supply in a private house from a well is described in this material.