Fuel from peat and sapropel is a profitable alternative

- Details

- Category: Other

Scientists from Tomsk Polytechnic University (TPU) have found a way to make fuel briquettes from low-grade combustible materials - sapropel (bottom sediments), peat and brown coal, which are equal to coal in terms of calorific value (the amount of heat released during combustion) and have the lowest cost, reported one of the developers is Roman Tabakaev.

The development was presented at the exhibition-presentation "Products, technologies and services of enterprises and organizations of the scientific and educational complex to the municipalities of the Tomsk region" for the municipalities of the southern part of the Tomsk region. Such exhibitions are held in order to acquaint villagers with the innovative developments of Tomsk companies and universities.

“We make briquettes from low-grade fuel - peat, brown coal, wood waste. Even from sapropel, which is actually earth. Several similar products are on the market. But those briquettes are destroyed by contact with water and are more expensive - they are very expensive to produce due to the need to use press machines to form briquettes. And our briquettes can be molded by hand, the equipment needs to be less powerful,” the scientist said. He also noted that the cost of a ton of fuel he developed is about 1,000 rubles, which is several times cheaper than coal. At the same time, the calorific value of fuel briquettes is practically equal to the calorific value of coal.

“The main innovation is that a new technology has been proposed. It consists of three stages. We thermally process raw materials without access to oxygen and, as a result, we get three products from low-grade fuel: fuel gas that is burned during work, carbon residue and tar, which are used directly for briquettes,” Tabakaev added.

Now the developers, funded by a grant from the Umnik federal program, are moving on to developing an industrial prototype of an automated line for the production of briquettes. The creation of a complex for the production of 20 tons of fuel per day - enough to provide heat to a small village - will cost about 6 million rubles. In the near future they plan to find investors and enter the market.

According to Tabakaev, the main consumers of the new fuel will be residents of the northern regions of the region. “It is very expensive for them to transport coal: it is already 2.5 times more expensive in Tomsk than in Kuzbass. Electricity is also very expensive - almost 5 rubles per kWh,” Tabakaev explained.

For reference

Tomsk Polytechnic University was founded in 1896 as the Tomsk Technological Institute of Emperor Nicholas II. The structure of the university today includes 11 educational institutes, three faculties, 100 departments, three research institutes, 17 scientific and educational centers and 68 research laboratories. 22.3 thousand students study at the university, including 224 students from 31 foreign countries. In 2009, TPU was among the 12 universities in the country that received the status of a national research university.

(RIA-Novosti, 23.08.2012)

Application in science

The plant origin of peat was first established.

Since peat accumulates quite quickly and is well compressed during decay, substances introduced into it are deposited in peat bogs. The surface of the peat bog is uneven, and the substances deposited on it are usually poorly blown back by the wind. Due to decay and more or less uniform compression, these substances can be clearly seen in the layers of compacted peat.

During eruptions, the fallen ash is well traced in peat bogs, and the organic matter of peat bogs above and below the deposited ash lends itself to dating. This is a common method of dating fallen volcanic ash, which is widely used in, on, on, on and. Also, sand is deposited in coastal peatlands, which is carried out by waves. In this way, volcanic eruptions and large tsunamis that occurred 4000 or more years ago can be dated.

Literature

- , , "Energy-technological use of fuel", M., 1956.

- Peat deposits and their complex use in the national economy, M., 1970.

- Use of peat and developed peatlands in agriculture, L., 1972.

- Peat in the national economy, M., 1968.

- Lishtvan I. I., Korol N. T., Basic properties of peat and methods for their determination, Minsk, 1975.

- , Peat deposits, M., "Nedra", 1976.

- A. F. Bowman, Soils and the Greenhouse Effect, 1990.

- Bezuglova O. S. . Fertilizers and growth stimulants. Retrieved February 22, 2015.

- Articles

- // Great Russian Encyclopedia. Volume 32. — M., 2016. - S. 313-314.

- Peat // Technical Encyclopedia. Volume 23. — M.: Soviet Encyclopedia, 1934. - Stb. 746-763

- Regulations

GOST 21123-85 Peat. Terms and Definitions

|

(combustible minerals) |

|

|---|---|

| Coal row |

|

| Oil and naphthoid series |

|

Main types |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fossil |

|

||||||||

| Renewable and biological | |||||||||

| artificial |

Application

As a fuel, brown coal is used much less frequently than hard coal. It is used for heating private houses and small power plants. By the so-called. Dry distillation of brown coal produces mountain wax for the woodworking, paper and textile industries, creosote, carbolic acid and other similar products. It is also processed into liquid hydrocarbon fuel. Humic acids in the composition of brown coal make it possible to use it in agriculture as a fertilizer.

Modern technologies make it possible to produce synthetic gas from brown coal, which is an analogue of natural gas. To do this, coal is heated to 1000 degrees Celsius, as a result of which gas formation occurs. In practice, a rather effective method is used: through a drilled well, high temperature is supplied to the deposits of brown coal through a pipe, and ready-made gas, a product of underground processing, is already coming out through another pipe.

As a result of prolonged exposure to elevated temperatures and pressure, brown coals are converted into hard coals, and the latter into anthracites.

The irreversible process of gradual change in the chemical composition, physical and technological properties of organic matter at the stage of transformation from brown coal to anthracite is called coal metamorphism. Structural and molecular rearrangement of organic matter during metamorphism is accompanied by a consistent increase in the relative carbon content in coal, a decrease in oxygen content, and the release of volatile substances; the hydrogen content, combustion heat, hardness, density, brittleness, optics, electricality, and other physical properties change. Coals at the middle stages of metamorphism acquire sintering properties - the ability of gelified and lipoid components of organic matter to pass, when heated under certain conditions, into a plastic state and form a porous monolith - coke.

In zones of aeration and active action of groundwater near the Earth's surface, coals undergo oxidation. In terms of its effect on the chemical composition and physical properties, oxidation has an opposite direction compared to metamorphism: coal loses its strength properties and sintering properties; the relative content of oxygen in it increases, the amount of carbon decreases, the humidity and ash content increase, and the calorific value sharply decreases. The depth of oxidation of fossil coals, depending on the modern and ancient relief, the position of the groundwater table, the nature of climatic conditions, material composition and metamorphism, ranges from 0 to 100 meters vertically.

The greatest heat transfer is obtained from anthracites, the smallest from brown coal. Hard coals win in terms of price-quality ratio. Coal grades D, G and anthracites are most often used in boiler houses, because. they can burn without blowing. Coal grades SS, OS, T is used to generate electrical energy, because.it has a high heat transfer during combustion, but the combustion of this type of coal is associated with technological difficulties that are justified only if a large amount of coal is needed. In ferrous metallurgy, grades G, Zh are usually used for the production of steel and cast iron. The fraction of a given coal grade is determined based on the smaller value of the smallest fraction and the larger value of the largest fraction, indicated in the name of the coal grade. So, for example, the fraction of the DKOM brand (K - 50-100, O - 25-50, M - 13-25) is 13-100 mm.

Peat reserves in the world

According to various estimates, there are from 250 to 500 billion tons of peat in the world (in terms of 40%), it covers about 3% of the land area. At the same time, there is more peat in the northern hemisphere than in the southern; peat content increases with movement to the north, and the proportion of high-moor peat bogs also increases. So, in the area of peatlands they occupy 4.8%, in - 14%, in - 30.6%. In the share of lands occupied by peatlands reaches 31.8% in () and 12.5% in . There are also a large number of peat deposits in the Republic of Karelia, the Republic of Komi, a number of western regions (especially in the Ryazan, Moscow, Vladimir regions). Sufficient peat reserves are available at (the Morochno-1 deposit). There are also large reserves of peat in a number of states.

According to Canadian Peat Resources (2010), Canada ranks first in the world in terms of peat reserves (170 billion tons), and Russia ranks second (150 billion tons).

The renewal of peat in Russia is estimated at 260-280 million tons per year.

Details about the methods and types of peat extraction

As mentioned earlier, most of the peat deposits are on the surface. Peat is extracted only according to two main schemes:

- from the surface of the earth (cutting the topsoil)

- from quarries (using excavators)

There are only 5 types of peat:

- milling (cutting)

- hydraulic scraper

- hydropeat

- lump

- baguette

milled peat - one of the most common types. It is mined at a depth of only 2 cm thanks to a tractor that loosens the soil, crushes the peat and turns it into fine crumbs. Then the peat dries in the sun, gathers into rolls, and then another layer is loosened. After each such process, peat is mined in the same place 5-6 more times. The collected peat is delivered to a special site and there it is collected into separate heaps. A suitable season for the extraction of such peat is the summer period, when natural drying of the mineral is possible. The milling method is also used to obtain sod peat.

Sod peat obtained by excavation. Each such piece of peat weighs at least 500 g. This method of extraction is practically the same as the previous method, but the only difference is that it needs weather conditions. Sod peat can be mined at any time of the year. Such peat is mined from a depth of 50 cm using a special disk with a cylinder in which peat is pressed.

Hydropeat obtained by hydraulic method, which was first proposed in 1914, as mentioned earlier.

carved peat mined from peat bricks by hand, sometimes by machine-forming.

As for the transportation of peat from the extraction sites, it is carried out after the final drying of the peat and is taken out by narrow-gauge railway. For agricultural purposes, peat is transported by road.

Peat fuel LAD

|

Description and scope Peat fuel "LAD" is a high-quality municipal fuel. It is not inferior in calories to firewood, brown coal, shale, low-grade coal. The calorific value of peat fuel is 3000-3500 kcal/kg. Peat fuel "LAD" does not emit carcinogenic substances, is an environmentally friendly product. Peat fuel "LAD" is recommended for heating houses, dachas, greenhouses, baths, boiler rooms, furnaces, as well as cooking. Advantages of peat fuel:

Recommendations for use:

Storage: Peat fuel "LAD" should be stored on dry sites, protected from groundwater and sewage, as well as from atmospheric precipitation, for example, on some kind of flooring, covering the fuel with plastic wrap. |

Varieties

There are a lot of varieties and varieties of brown coal, among which there are several main ones:

- Ordinary brown coal, the consistency is dense, matte brown.

- Brown coal of an earthy fracture, easily rubbed into powder.

- Resinous, very dense, dark brown, sometimes even blue-black. When broken, it resembles resin.

- Lignite, or bituminous tree. Coal with a well-preserved plant structure. Sometimes it is found even in the form of whole tree trunks with roots.

- Disodil - brown paper charcoal in the form of decayed thin-layered plant mass. Easily splits into thin sheets.

- Brown peat coal. Resembling peat, with a large amount of impurities, sometimes resembling earth.

The percentage of ash and combustible elements in different types of brown coal varies widely, which determines the merits of a combustible material of a particular variety.

Ecological features

Peat formation continues to this day. Peat performs an important ecological function, accumulating products and thus accumulating atmospheric peat.

After the peat deposit is drained, due to the access of oxygen, active activity begins in the peat, decomposing its organic matter. This process is called, during which carbon dioxide is released at a rate that is an order of magnitude higher than the rate of its accumulation in an undisturbed swamp.

The danger is that can occur in drained peatlands.

Organogenic peat soils are formed on peat deposits.Peatiness can be observed in the upper mineral soils with prolonged waterlogging or in cold climates.

When peatlands are flooded with reservoir waters, peat masses sometimes float up, forming.

What is the process of pyrolysis of peat.

The process of pyrolysis of peat is also called gasification or gas generation. This process takes place at a temperature of 800 to 1300 degrees C.

The essence of this process lies in the production of combustible gas by heating the raw material to a certain temperature with limited access to oxygen. As a result of this process, which occurs in combustion devices that restrict the flow of air from the outside, you can get substances such as:

- carbon monoxide

- methyl gas

- Hydrogen

- Methane

- Gaseous hydrocarbons

- And other components in various proportions.

Let's look at how this process differs from ordinary peat burning.

If, during the combustion of peat in a conventional furnace, an influx of the required amount of oxygen is provided, then as a result of such combustion, carbon dioxide, water, ash (the amount of which corresponds to the content of inorganic substances in the original peat) and heat are formed.

But if, after the start of the combustion process, the air supply is limited, then combustion will continue, but the combustion products will be slightly different. The result is water, hydrogen gas and carbon monoxide. In this case, heat will be released, contributing to the continuation of the combustion process. Under the influence of heat, chemical bonds are broken in the molecules of complex hydrocarbons contained in peat. At the same time, in the process of combining hydrogen atoms with carbon and oxygen, heat is released and a gaseous energy carrier is formed - generator gas.

The gas obtained by pyrolysis of peat consists of hydrogen, methane, carbon monoxide and carbon dioxide, a small amount of high order hydrocarbon compounds, such as ethane, and various impurities, such as tar and ash particles.

In contrast to the much larger volume of the original peat, the gas obtained from it by pyrolysis is more convenient for storage and transportation. Generator gas can be used to produce heat and electricity and as a fuel for internal combustion engines after its purification. In addition, after additional purification from H2S, CS2 and CO2 —generator gas can be used in ammonia production as a source of hydrogen. It is also possible to further process the producer gas in order to obtain liquid fuels from it.

Brown coal

Brown coal is in the form of a dense, earthy, woody or fibrous carbonaceous mass with a brown line, with a significant content of volatile bituminous substances. It often has a well-preserved vegetative woody structure; the fracture is conchoidal, earthy or woody; color brown or pitch black; burns easily with a smoky flame, emitting an unpleasant peculiar smell of burning; when treated with caustic potassium gives a dark brown liquid. Dry distillation forms ammonia, free or combined with acetic acid. The specific gravity is 0.5-1.5. The average chemical composition, minus ash: 50-77% (average 63%) carbon, 26-37% (average 32%) oxygen, 3-5% hydrogen and 0-2% nitrogen.

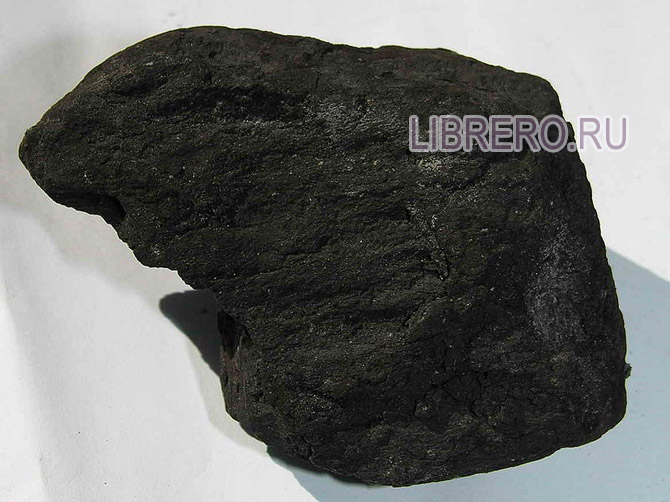

The photo below is brown coal.

Brown coal, as the name shows, differs from coal in color (sometimes lighter, sometimes darker); there are, it is true, also black varieties, but in this case they are still brown in powder, while anthracite and coal always give a black line on a porcelain plate. The essential difference from hard coal lies in the lower carbon content and the significantly higher content of bituminous volatile substances. This explains why brown coal burns more easily, gives more smoke, smell, and also the aforementioned reaction with caustic potash.The nitrogen content is also significantly inferior to coal.

Peat industry today

Peat resources cover about 400 million hectares, but only about 300 million hectares have been put into operation. Only 23 countries of the world are engaged in peat extraction. The leading ones are Russia, where about 150 million hectares are concentrated, and Canada, where peatlands make up 110 million hectares. Peat is a renewable resource and much more is produced than is consumed. The world's peat stock is concentrated in Russia, because 60% of the resources are contained there. But in terms of production, Russia is in fourth place, ahead of Canada, Finland and Ireland.

Only 30% of the world's peat is used for fuel, the remaining 70% is used for horticulture and agriculture. The upper peat layer has suitable properties for animal husbandry, floriculture, crop production and vegetable growing in greenhouse conditions. Peat plays an important role in the world market, especially vegetable peat, which is the most exported.

The largest peat deposit is concentrated in the Tver region - 21%. Thanks to this, the Tver region is fully provided with energy and soil fertility. OJSC "Tvertorf" produces the largest amount of peat products throughout Russia. In the 90s, the extraction of the mineral dropped significantly. Due to the crisis, the equipment has ceased to be updated, the capacity of enterprises specialized in peat has also decreased. Today, production rates are trying to resume, but the process requires significant funding and more labor.

The main problem associated with the peat industry is the development of a legal and regulatory framework. There are some contradictions in the legal status of peat deposits, which lacks clarity in the application of credits provided by the tax service. There are also noticeable shortcomings in the calculation of payments and taxes on land. Therefore, today the peat industry is undergoing serious stagnation.

The Russian government has set a goal by 2030 to increase the level of extraction and processing of peat to improve domestic, allied and agricultural conditions. The first necessary criterion is to improve the industrial base, i.e. to develop new equipment, only then can peat be effectively used at power plants specializing in heat supply. In the future, due to its beneficial properties, peat will be used in medicine. The peat extract is enriched with minerals, so its properties are excellent for the human body, it has a particularly healing effect on the skin and subcutaneous tissues. By 2030, it will be planned to restore the peat base, build boiler houses and thermal power plants in remote regions, the main resource of which will be peat.

peat land

From high-moor, less often from low-lying decomposed peat, they are harvested peat land and peat humusused in and decorative .

Peat improves soil fertility. For use as a component of soil mixtures for indoor and greenhouse plants, peat sods are weathered in low and wide heaps for three years, since freshly dug peat sods contain substances harmful to most plants (). To accelerate the weathering and washing out of acids, regular shoveling is carried out. Soil mixtures based on peat are characterized by significant moisture capacity. In a mixture with sand, peat soil is used for sowing small seeds and as the main component in the preparation of earth mixtures for many protected ground plants.

Mining

Methods for extracting brown coal are similar for all fossil coals. There are open (career) and closed. The oldest method of underground mining is adits, inclined wells to a coal seam of small thickness and shallow occurrence.It is used in case of financial inefficiency of the quarry device.

A mine is a vertical or inclined well in the rock mass from the surface to the coal seam. This method is used in deep coal-bearing seams. It is characterized by high cost of extracted resources and high accident rate.

Open pit mining is carried out at a relatively small (up to 100 m) depth of the coal seam. Open-pit or quarry mining is the most economical, today approximately 65% of all coal is mined in this way. The main disadvantage of career development is the great damage to the environment. The extraction of brown coal is mainly carried out in an open way due to the small depth of occurrence. Initially, the removal of overburden (rock layer above the coal seam) is carried out. After that, the coal is broken by the drilling and blasting method and transported by specialized (quarry) vehicles from the mining site. Overburden operations, depending on the size and composition of the layer, can be carried out by bulldozers (with a loose layer of insignificant thickness) or bucket-wheel excavators and draglines (with a thicker and denser rock layer).

Origin

Brown coal forms layers of deposits of sedimentary rocks - flakes, often of great thickness and length. The material for the formation of brown coal are various kinds of pyalps, conifers, trees and peat plants. The deposits of these substances gradually decompose without access to air, under water, under the head of a mixture of clay and sand. The smoldering process is accompanied by a constant release of volatile substances and gradually leads to the enrichment of plant residues with carbon. Brown coal is one of the first stages of metamorphism of such plant deposits, after peat. Further stages - coal, anthracite, graphite. The longer the process, the closer the state to pure carbon-graphite. So, graphite belongs to the Azoic group, coal - to the Paleozoic, brown coal - mainly to the Mesozoic and Cenozoic.

Peat industry

The peat industry is a category of industry that provides the country with fuel as well as fertilizer. Today, peat is used in agriculture, chemical plants, power plants.

So what is peat? Peat has a characteristic brown color. It is formed over time from the almost decomposed remains of plants, mainly mosses. Peat deposits are swamps and ponds, which are almost overgrown. In Russia, areas with peat are located in forests. In fact, peat consists of 60% carbon, which makes it the most important biomaterial. it has a fairly high calorific value. Peat is also used to make various thermal insulation materials, such as slabs.

Recall that in 2010 in Russia there was a terrible fire associated with the ignition of peat areas, as a result of which forests were damaged. After the incident, it became obvious that the peat industry would take a long time to recover.

Now around the world receive approximately 25 million tons of peat. In 1985, peat extraction reached its peak, namely, 380 million tons were obtained in a year. However, since the 1990s, the level of mineral extraction has dropped significantly to 29 million tons.