Which to choose

Expansion joints must ensure the reduction of loads arising in the longitudinal and transverse directions, as well as at an angle to the axis of the pipeline when the pipe is removed.

L-shaped, U-shaped, annular expansion joints and snake-shaped devices are sections of the pipeline (made of the same polypropylene, or materials similar in characteristics, but with greater elasticity and elasticity), which are given the appropriate shape.

They are mounted in the same way as sections of the main highway (how many layers of FUM tape must be wound, it is written here).

Fittings are included in the design to obtain a shape (for example, for U-shaped expansion joints) or achieve the desired characteristics without using them.

The range of devices that implement compensation for thermal expansion due to other materials is much wider.

These include:

-

axial bellows compensators KSO and OPN.

These devices are designed to compensate for the deformation of the pipe in the direction coinciding with its axis.

An elastic structure is used as a working element - a bellows made of corrugated sanitary rubber or thin stainless steel.

Practical note!

OPN type devices are easy to install due to the presence in the design of fasteners that serve as supports during pipeline installation; -

shear compensators KS.

The devices are designed to compensate for deformations in a direction that does not coincide with the axis of the pipe, and, accordingly, have degrees of freedom in both (vertical and horizontal) planes.The design of expansion joints includes one or two corrugated bellows.

When using a two-piece device, the reliability of the connection of the bellows is achieved through the use of connecting fittings;

-

KSP rotary compensators.

The function of these devices is to compensate for the linear expansion of both sections of the pipe at the bends of the line.They are used where, according to the laying conditions, the angle of rotation of the pipeline must remain unchanged;

-

universal compensators KSU.

The devices make it possible to compensate for all types of pipeline deviations that occur due to thermal expansion.

Accordingly, the working stroke of these devices is designed for axial, transverse and angular deviations.

The design features of these devices dictate their use in short sections of highways or in those places where the use of other types of bellows compensating devices, for whatever reason, is limited or impossible;

-

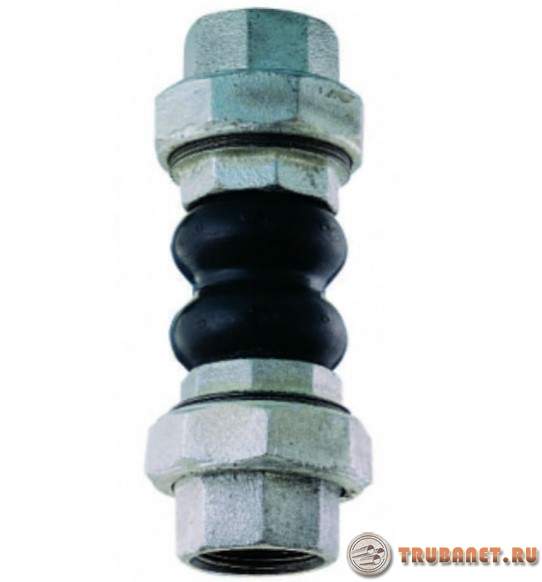

rubber bellows elements KR (flanged).

These compensators are used to compensate for the deviation of the pipeline axis.In addition, the devices act as damping devices, capable of absorbing water hammer in the serviced section of the highway.

In addition to their functional purpose, compensators are divided according to the installation method.

For polypropylene pipelines, welded and flange expansion joints are used.

In the welded method, the traditional installation method for polypropylene pipes is used using welding equipment (what tool is needed is written here).

This connection method imposes mandatory conditions for the choice of compensators:

- identical diameter,

- wall thickness,

- internal section of the compensating device and pipeline section.

The compensating device is installed by connecting the flanges on the compensator and the pipeline.

The advantage of this method is to obtain a detachable connection that is easy to maintain and repair.

The main disadvantage is the increased complexity of installation and a greater number of technological operations.

Attention! Installing a metal flange on a polypropylene pipeline is not an easy task.Therefore, it is better to entrust its implementation to specialists with relevant experience.

Therefore, it is better to entrust its implementation to specialists with relevant experience.

For your information!

Under certain conditions, the use of bellows expansion joints, in addition to combating thermal expansion, solves the problem of eliminating vortex fluid flows in the pipeline, which increases the safety of its operation.

Effective operation of compensating devices is possible only if the rules for their installation are observed.

Sources

- https://trubanet.ru/truby-dlya-otopleniya/kompensatory-dlya-polipropilenovykh-trub-silfonnye-p-obraznye-kompensator-kozlova.html

- http://HomeBuild2.ru/truby/kompensator-dlya-polipropilenovih.html

- http://ru-canalizator.com/santehnika/s-oborudovanie/kompensator.html

Advantages and disadvantages

This part assumes the most important function for any pipeline - ensuring the integrity of the structure. This makes her irreplaceable. The product is good because:

- Effectively contributes to the stabilization of the internal pressure on the pipes;

- It cuts off the so-called vortex flows;

- Promotes quick and convenient fastening (welding) with the main main pipe;

- It has a high degree of reliability due to the manufacture of high quality materials;

- It has a very long working resource and a service life exceeding 50 years;

- Provides perfect sealing when installed correctly.

Significant shortcomings in the design, device or operation of these products have not been identified. The only, and perhaps the most significant disadvantage is the possibility of combination only with those pipes that are made of polypropylene.

Types and differences

To date, several main types of expansion joints are produced, which are mounted on a polypropylene water pipe:

Loop compensator

- Bellows axial products of the KSO and OPN brands. Installation and subsequent integration of such products is extremely simple and unpretentious. This is due to the presence of special mounting guide assemblies. They are presented in the form of firmly fixed supports, which greatly simplifies their installation.

- Compensators shift brand KSS. Designed to effectively provide compensation in two areas at the same time. They are located parallel to the central axis of the highway. In addition, the design is equipped with one or two corrugations, which are made of stainless steel. The elements are connected to each other by means of connecting fittings.

- Swivel elements KSP. They are used to eliminate the consequences of linear expansion. It occurs on those sections of the pipeline where there are turns. The device rigidly fixes the angle and can follow the contours of the line at an angle of 90 degrees.

- Universal types of KSU products. They have three modes of working stroke - angular, transverse and axial. Often, such an element is used in cases where it is necessary to mount a short trunk line with a large number of branches.

- Rubber flanged bellows expansion joints are actively introduced into the structure of those water pipes, on which hydraulic shocks are often formed. These devices can compensate for small inaccuracies associated with the curvature of the central axis of the water main.

How to choose?

Before you buy a compensator, you should read a few important recommendations.

First of all, before buying, you need to correctly take into account the diameter of the product itself and the diameter of the pipe on which it will be mounted.

These figures must match. It must be remembered that the most common diameter of plastic pipes is from 20 to 40 mm. For systems located in apartments and private houses, the most acceptable diameter is 20 mm.

The heating system is not installed without compensators

Remember that using the flange mounting method, the compensator is not attached to the line, but to the counter flange.

Based on this, preference is given to the flange compensator. This product will provide a reliable, tight, and, at the same time, detachable connection.

In the event that an emergency occurs, it will be possible to quickly make an urgent replacement of the element.

In view of the simplicity of the design, the price of the compensator for polypropylene pipes is quite acceptable. It fluctuates within the following limits.

Bellows compensator, KSO:

- Working pressure: 16 atm;

- Overall length: 250mm;

- Branch pipe diameter: 21.5 mm;

- Price: 3-4 $.

Shear compensator, KSS:

- Working pressure: 12 atm;

- Overall length: 170mm;

- Branch pipe diameter: 18 mm;

- Price: 2-3 $.

Compensator flange, rubber:

- Working pressure: 18 atm;

- Overall length: 295mm;

- Branch pipe diameter: 20 mm;

- Price: 1-2.5 $.

Why is thermal expansion dangerous?

Thermal expansion of polypropylene pipes is considered one of the negative factors that must be taken into account when designing and installing systems.

Its danger is illustrated by the following figures.

For a material reinforced with fiberglass, the indicator is 0.06 mm / deg., For reinforced with aluminum - 0.03 mm / deg.

With a temperature difference of 60 degrees, the elongation of 1 meter of unreinforced pipe will be about 9 mm.

Such a temperature difference is not impossible.

An example of the conditions leading to such a situation is the design and assembly of a heating system at an air temperature of 20 degrees and the supply of coolant heated to 80 degrees into the pipes (the water temperature standard in hot water pipes is indicated on this page).

If a straight section of a heating pipe passes through 2 adjacent rooms with a wall length of 5 m, its total length is 10 m.

In such a section, the total elongation under the described conditions will reach 90 mm.

If the gaps between the pipeline and the walls are insufficient (and they should be at least 45 mm in the described case), the pipe will rest against the structure.

This will lead to the appearance of deformation forces that threaten to violate the integrity of both the fittings and the pipe walls.

Creating the necessary gaps (almost 5 cm from the walls) violates the aesthetics of the system and the interior of the premises.

Important conclusion!

The deformation of pipes due to thermal expansion leads to a violation of the tightness of the joints.

Due to additional mechanical loads, it poses a danger to the integrity of pipeline sections and connected equipment.

Compensators are used to compensate for thermal expansion.

Design features of compensators

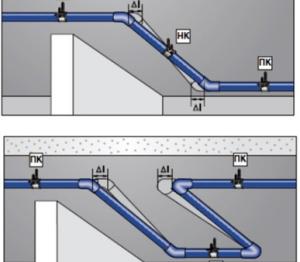

In order to reduce the risks of pipe breaks during operation, during the assembly of the water supply, it is necessary to consider the installation locations of the polypropylene compensator. Such a compensator is made in the form of a loop, its inclusion in the system allows you to compensate for the linear expansion or contraction of pipes, thereby increasing the safety and life of the pipeline.

And a little more about the design, the "loop" of the compensator is quite easy to install in the pipeline system due to its simple shape and low weight. Experienced specialists choose the middle of the pipe for the installation of expansion joints, placing it between the supports, which are motionless and, in turn, segment the pipe. Special tools for installation are not required, as well as additional sealing agents.

For polypropylene pipes, a bellows axial compensator can also be used, made in the form of a corrugated insert, which is compressed or stretched during changes in temperature or water pressure.

The advantage of using compensators

Compensating connecting devices of the type: PP (for polypropylene pipes) are used in cold and hot water supply systems, as well as when laying heating. Such devices are found both in summer cottages and in houses of sleeping areas, in addition, compensators and pipelines of large office buildings and industrial premises are not complete. Thus, there are several clear advantages of protecting polypropylene pipes with expansion joints:

- The first is the ease of installation and the comparative cheapness of the material;

- Increasing the service life of the system, by the way, the service life of polypropylene pipes, with proper assembly, reaches 50 years;

- The pressure in the pipes is distributed evenly, and vortex flows are also cut off;

- The pipeline can be vertical or horizontal, such a circumstance will not interfere with protecting the pipes from kinks, elongation and water breakthrough at the joints.

Bellows compensators are installed on a straight section. They can accept extensions that were originally included in the project. Before installation, possible deviations are necessarily checked, the compliance of all technical characteristics with those indicated in the project. In addition, you need to make sure that there is no damage to the compensator. Only one expansion joint can be placed between the fixed supports. Welding is used to connect the device to the pipeline.

Features of plastic pipelines

Among which:

- the working pressure for pipes made of this material is up to 10 atmospheres (it may be necessary to test pipelines for strength and tightness);

- the upper limit of the operating temperature range exceeds 90 degrees.

This is enough for wiring hot water and heating systems; - the material is absolutely non-corrosive, inert to most household chemicals, not biodegradable;

- the quality of the surface of polypropylene pipes and the properties of the material prevent the deposition of plaque on the walls, including lime;

- service life of polyethylene pipelines - at least 30-50 years;

- polypropylene is absolutely safe for human health, does not release toxic compounds into water and air;

- this polymer is fireproof.

Installation technology involves the use of welding (an iron for soldering polypropylene pipes) to obtain reliable connections.

With the appropriate equipment, mastering the skills of installing systems from polypropylene pipes is available to everyone.

Among the shortcomings of polypropylene pipes, experts note the impossibility of giving them the necessary shape.

Due to this, the turns of the highways are performed exclusively with the use of fittings.

Another serious disadvantage of this polymer is its high coefficient of thermal expansion.

Thanks to him, polypropylene pipes are characterized by significant elongation and / or sagging during the transportation of hot media (hot water or heat carrier of heat supply systems), and at high outside temperatures.

What is it needed for

When installing pipeline systems, a natural question may certainly arise: why do we need an expansion joint for polypropylene pipelines?

The polypropylene compensator is presented in the form of a special design of the connecting type. It often takes the form of a loop.

The purpose of the polypropylene compensator is to provide compensation for the linear expansion of the pipeline. The device prevents excessive exposure of the internal walls of the pipeline to factors such as high temperature and excessive pressure.

Thus, the installation of expansion joints on polypropylene pipes ensures optimal stabilization of the entire aquifer.

Despite the rather low cost and relative simplicity of design, this device significantly increases the service life of pipelines.

The compensator, due to the simplicity of its device, allows mounting on almost any straight section of pipelines. It provides a high degree of reliability for the entire system.

Design features

Loop-shaped expansion joint for polypropylene pipelines is often made using static polypropylene.

Modern products are manufactured using a special injection molding method.Often this item is sold in two color variations - white and gray.

Polypropylene compensator, due to the simplicity of its design and relatively low weight, is easily mounted on the plumbing system.

PVC pipe connection

To properly install this product, do not requires the use of special tools or seals.

Thermal compensators for polypropylene pipes are widely used in all types of pipelines.

By mounting this product, you thereby significantly increase its strength and protection against tearing.

This is especially true for those places where there are joints and nodal connections. Often a compensator for polypropylene is mounted in the middle of the pipe. This may be a section located between two fixed supports.

In addition, expansion joints effectively protect the pipeline from excessive stretching or sudden displacement.

This can happen when the temperature of the working medium inside the pipe rises sharply, or when a hydraulic shock occurs.

The device is widely used for a number of systems. This:

- systems and lines for cold water supply;

- hot water supply systems where expansion is unavoidable;

- heating systems.

It effectively performs its restrictive function in cases of unauthorized reduction of pipes made of polypropylene.

The device is mounted on the highways of buildings with a variety of purposes. It can be:

- Country and multi-apartment houses;

- Commercial and administrative buildings;

- All types of industrial premises.

Varieties

In practice, the following varieties proved to be the best:

Bellows expansion joints for polypropylene (PPR). They are used in the installation of heating and water supply networks made of PPR materials. The conditional diameter of bellows types is from 1.5 to 5 cm. The type of connection of bellows varieties is coupling, and the casing is made of aluminum. Their internal screen is made of stainless steel. The temperature of the working medium is up to one hundred and fifteen degrees, the pressure is up to 16 bar. The working medium for the bellows version is drinking water, air, steam.

Shear. They are designed to compensate for movement in two directions. Design features in this situation are one or two bellows corrugations. It is made of stainless steel and fastened with fittings-connectors.

Rotary. They are used to level the linear increase in the area of the turn of the highway and serve to fix the turn. Most often they are taken to change the direction of the system by ninety degrees.

- Universal. They are endowed with three options for working moves. They are placed where it is necessary to lay a short network, or in a place limited for installing a bellows type.

- Flanged. These rubber parts are placed in a place where there is a need to dampen the shock wave from a sharp increase in the average working pressure. They also smooth out axial inaccuracies of the pipeline.

- The device is in the form of a loop.

- coils

- Axial bellows mechanisms

- Flanged devices made of soft material

- Bellows

- Universal, which are effective for displacement in axial, angular and transverse directions. They are recommended for installation on a small branch line with branches

Manufacturers offer various devices that are of excellent quality. But, the do-it-yourself compensation loop in the heating system also copes with the functions assigned to it.

It is not difficult to make such a device with your own hands. A compensation loop can be made in a short time. This important detail, fastened correctly, becomes a guarantee of the perfect operation of heating or hot water supply.

Simple do-it-yourself equipment with a compensation loop will increase the working life of communication networks up to half a century.

How to choose the right device

To find out which compensating element is better to install on polypropylene, it is necessary to understand in detail the design of these devices.

Polypropylene (PP) piping is installed very often. With its help, they equip the supply of hot water, where the temperature rises to almost one hundred degrees. Polypropylene during use has shown a number of characteristics, thanks to which it is ideal for plumbing systems and heating. It is not afraid of the influence of an aggressive chemical environment, has a small weight and is quite durable.

For this reason, in sections longer than ten meters, it is recommended to install flexible expansion joints. They make it possible to reduce the expansion from thermal exposure.

In order to choose and install it correctly, it is necessary to take into account the diameter. It must match the diameter of the pipeline itself. Most often, the diameter that the compensation element has is from 20 to 40 mm. For a house and an apartment, a device of 20 millimeters will be enough.

As for the manufacturer, it is better to give preference to well-known world brands. They represent products for polypropylene networks, which are of high quality, which are successfully used in many areas.

Important additional information

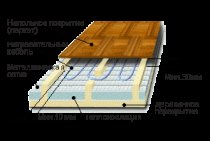

Thermal insulation PVC pipes

Some products used for thermal insulation can have a devastating effect on thermoplastic pipes.

It is recommended to insulate with the following materials (only some options are listed):

- Mineral felt

- Armaflex class 1 NT

- Foam phenolic

- Polystyrene.

Some types of foam rubber and adhesives can be toxic when used together with foam rubber. Therefore, it is not recommended to use them as a means of fastening the thermal insulation of the pipeline. Adhesives should only be used for bonding.

Pipeline heating

Thermoplastic piping can be damaged by the plasticizers used in the outer coating of some trace heaters. Do not use plasticized PVC tapes. (This comment also applies to any tapes, adhesives, and other substances used to attach trace heaters to piping.) Recommended trace heaters are silicone rubber, woven wire mesh, or woven polyester sheath heaters to minimize the risk of plasticizer interaction with pipeline material. Therefore, it is preferable to use these tapes on thermoplastic systems.

PVC pipe marking

Do not place adhesive labels directly on the pipe surface, as adhesives may damage the outer surface of the pipe. It is recommended to use a cushioning material such as aluminum foil between the pipe and the ID tag.

Foaming mastics and sealants

Certain sealants contain phthalates. Phthalates are highly corrosive to PVC-based materials, therefore, before using any sealants and mastics for PVC pipes, it is necessary to obtain confirmation that the selected sealant is suitable for the chemical composition of the unplasticized PVC pipeline.

Clamps for fixing PVC pipes

It is important that the clips and their coatings do not contain substances that can have a devastating effect on the unplasticized PVC pipe. Check selected products for compatibility with piping material

We recommend using Cobra clamps for pipes up to 160mm OD/6" nominal ID included.

Freezing conditions

Measures should be taken to prevent freezing of the contents of the pipeline, as this can lead to pipe rupture.

PVC-U contact with various fluxes

Some fluxes can be detrimental to unplasticized PVC piping.

Special precautions should be taken when brazing copper piping directly above or near unplasticized PVC piping.

Thread sealants

Some thread sealants can damage unplasticized PVC piping. Teflon tape is recommended for threaded connections.

Resistance of unplasticized PVC to ultraviolet rays

Protect from ultraviolet rays, such as sunlight, especially during storage. Their exposure can cause discoloration and deterioration of the properties of the material. And, although these are only superficial changes, it is nevertheless recommended to avoid exposure to ultraviolet radiation. For outdoor storage, cover the pipes with an opaque material. When installed outdoors, PVC pipes are recommended to be protected from UV rays by insulation or painting.

underground pipeline

It is forbidden to lay the pipeline in contaminated soil.

It is forbidden to lay the pipeline in the soil where liquid chemicals are released.

uPVC pipes and pressure surges

Unplasticized PVC pipeline is able to withstand pressure surges within the specified limits. Under no circumstances should pressure surges exceed the values of the continuous working pressure given in the graph.

Types of compensation devices

In practice, several main types of expansion joints for polypropylene pipes are actively used:

- In the form of a loop - it is the simplest.

- Serpentine or spiral.

- Bellows axial with marking KSO or OPN.

- Flanged type - allows you to soften water hammer, made of soft material and easy to mount.

- Bellows expansion joint for polypropylene pipes is a nodal device for restraining linear expansion.

- Shear - allows you to restrain linear expansion in 2 planes. It consists of two segments of stainless corrugated pipe, connected by a special fastener.

- Swivel - used wherever the pipe is bent at an angle of 90º.

- Universal - suitable for compensating shifts in cross-section, angular or axial section, especially in small sections of branched pipelines, where other types of devices are not applicable.

All these devices are united by the fact that in order to obtain the desired effect, they must be mounted only on pipeline sections made of flexible polypropylene.

It is very convenient to use expansion joints during the installation of rotary sections. Thanks to these devices, it is possible to extinguish fluid turbulence and stabilize the pressure in the pipeline.

Among the best foreign manufacturers of expansion joints for polypropylene pipes are Finnish companies, as well as the Turkish company Kayse. Among domestic suppliers, the SanTermo company can be noted.