Workplace preparation

To fix the heater, you first need to create conditions for this. One of the main prerequisites for a successful repair will be preparation for it. First of all, you need to choose a place where you will disassemble the heater. It should be spacious enough and well lit. A garage or a separate room is best suited for this.

Then the tool and accessories are prepared. Since the device of the heater does not present any complexity, then the tool will be the most ordinary. A set of screwdrivers, pliers and side cutters, a small hammer and an awl - this will be enough for repairs. Before repairing, you must have a soldering iron, a tester, WD-40 liquid, grease (Graphite or Litol-24) and a little alcohol to wipe the contacts at hand. Be sure to have a clean rag. If the cause of the breakdown is determined in advance, then spare parts are needed to replace the failed parts.

I bought a convector - turned it on - does not heat

User

I bought a convector - turned it on - it does not heat!

Good day!

Yesterday, by order of XC 300277, I purchased Timberk TEC.PS1 PGE 1000 IN Convector (1 pc.). I didn’t order delivery - let me, I think, I’ll bring it home myself. I dragged it - I’m happy to turn it on - the dashboard works, but the convector does not heat! And where is the promised express heating, if in 30 minutes the convector did not even get a little warm? And what should I do now? Should I drag this convector back to you? And then go for an exchange and start all over again? I am very dissatisfied! I ask you to exchange the convector for a working convector and deliver it to me at your expense. I am ready to write and fill out the applications that are necessary, so as not to waste time in your store signing papers that I do not need. It’s not my fault that they slipped me a defective product and didn’t let me check it in the store, under the pretext that “how can you check such a convector”. Tomorrow from 9:00 to 14:00 I expect the delivery of the chair by order COXC-208055 - I can give you a faulty convector.

The convector does not heat with heat, but with the skill of the Evening Dnieper

In anticipation of the coming winter and the expected savings on central heating, many families are concerned about buying additional autonomous heaters.

We will tell you about the different types of heaters that can be purchased in Ukraine and what you need to pay attention to when choosing this home appliance. Today we will talk about electric convectors

Externally, the electric convector looks like a flat radiator with a grate in the upper part of the body. The principle of operation of this heater is as follows: a heating element (heater) is located inside the case, due to the temperature difference, cold air is sucked in through the holes at the bottom of the case, passes through the heater, and already hot air exits through the grate at the top of the case. This movement of air is convection and gave the name to this device.

How to choose the right convector?

First, you need to decide on the power. For an average power selection, it is convenient to use the formula: 1 kW per 10-12 square meters. m of room area with a wall height of 2.7 m. In the case of a higher wall height, it is recommended to add 10% of the power for every 10 centimeters of height above the specified one. That is, to heat a room with an area of 15 sq.m, you need a convector with a power of 1500 watts. What threatens the wrong choice? With a low power, the convector will work constantly, consume electricity, but the room will not heat up to the set temperature. With increased power, a large load is created on the electrical network, and it is possible that when the convector is running, you will not be able to use other appliances, such as an electric kettle.

Secondly, you need to pay attention to the type of heating element. Heating elements are open and closed

In models with an open heating element, air comes into contact with a coil heated to 150 ° C, while oxygen burns out and moisture is burned out (the air dries out). In addition, dust burns on the heating element, which is inevitably sucked into the convector, and a burning smell appears. In closed heating elements, air is in contact with a special finned heat exchanger, which has a lower temperature and does not dry the air. It is also necessary to pay attention to the design of the heat exchanger. In the most modern (but also expensive models), the spiral is soldered into the body of the heat exchanger, which allows you to maximize the efficiency of the heater.

Thirdly, convectors come with mechanical and electronic control. An important element of the device is a thermostat with a temperature sensor. This device provides automatic control of the convector. You can set the desired room temperature and the convector will turn on and off to maintain that temperature. Convectors with mechanics have a large error (1o) versus 0.1o for the electronic one.

Fourthly, some convectors are equipped with a power regulator (usually stepped), which allows them to be used at reduced power and not to load the home electrical network.

Fifth, according to the installation method, convectors are divided into stationary and mobile. Stationary mounted with brackets on the wall, mobile equipped with wheels to move around the apartment. But, as a rule, you can remove the wheels from mobiles and install them on the wall, and on some stationary models you can buy wheels. BUT - for fire safety purposes, mobile convectors are usually equipped with a tipping sensor that turns off your heater when it falls (and even if it deviates slightly from the working position). In stationary - there is no such sensor.

Sixthly, some models of convectors are made in a splash-proof, moisture-proof version, which allows them to be safely used in bathrooms.

And finally, small "chips": some models have timers that allow you to program the convector's operating mode by hours (and even by days of the week). Some companies supply their heaters with additional options, for example, an air ionizer.

Make the right choice and have a warm winter.

The main breakdowns of oil coolers

Every repair starts with a diagnosis.

It is important to correctly determine the cause of failure and calculate the faulty part.

- Do not be afraid if the heat source began to crackle immediately after switching on. As a rule, this happens during the heating of the mineral oil inside. Crackling is considered normal and does not affect the operation of the appliance. Sometimes moving the radiator to a perfectly flat place helps to reduce noise.

- If the heater stops turning on, the first step is to exclude a breakdown in the outlet and turn on the device in another power source. The most common failure in this case is a loose contact, in second place is a plug malfunction, and in the third place is damage and breaks in the cord.

- If the heater shows signs of operation (indicators are on, fans turn on), but does not heat up, the cause should be sought in the thermal relay. This spare part is easy to buy and replace with your own hands.

- A cold case may also indicate that the heating element is out of working condition - this is a rather serious reason and it is not recommended to eliminate it yourself.

- If the device does not turn off after heating to the set temperature, this may signal a thermostat malfunction - such work becomes not only uncomfortable and dangerous, but also uneconomical in terms of energy consumption.

The device of the simplest oil heater

It is good to cover the oil heater with clothes to dry. The only type of devices where the owner will avoid fatal consequences.The only thing is that on the side of the accordion container there is an extension equipped with electronic filling, avoid hiding the compartment. The oil heater device includes the following elements:

Emergency shutdown sensor (thermal fuse, relay)

- A container filled with oil. Appearance - poured accordion, heated to a decent temperature, hold off touching it with your hand. When it comes to drying things, fearlessly put heat-bearing ones. The container is sealed, but there is 15% air inside. Try to put the oil heater upside down, fill it up on its side, return the load to the wheels. Heard thumps frighten mice: air bubbles burst inside. Water is not used by the heater, it will quickly evaporate, the corrosion of the body will become significant, the manufacturing technology would require the complete exclusion of air from the working fluid (water + oxygen = the most powerful oxidizer of wildlife). The coefficient of thermal expansion of the most common liquid on the planet is ten times higher than that of steel. It's not good if the tank breaks.

- The lower part of the end of the accordion contains a heating element, to which the electronics compartment clings. The oil heater is devoid of a pump and works by natural oil recirculation. The current starts from the heating element upwards, then at the opposite end of the battery the liquid descends. When working, it emits audible vibrations of the spiral under the influence of alternating voltage. The effect is irremovable, due to the influence of the Earth's magnetic field. The boiling point is above 100 ºС (150-200), avoid touching the container, the liquid is not brought to a change in the phase state due to the prohibition of the use of water: the container will burst. TEN double (two spirals), will allow more flexible regulation of heating.

- Not far from the heating element is a thermal fuse. The device will not allow a fire to happen, if oil suddenly leaks out, the temperature relay breaks. The oil heater would work hard when the copper heater started to melt. Oil will leak out - through the case, the high temperature will cause the sticky thermal fuse to trip. The structure distinguishes between bimetallic (reusable) or wire (disposable). The photo shows the presence of a distinctly blackening tablet above the heating element: a thermal fuse (see the first photo of the review), or a thermal relay (determined by the design).

Steel profile that connects the electronics compartment and the heater bellows

- The relay is located at the top. We see the main difference from the iron: there is no contact with the body. It can be seen that the thermal relay simply tramples the air. An oil heater with a marked feature resembles an electric kettle, in which the bimetallic plate is often exposed to steam penetrating through a special opening in the housing. The thermal relay is an adjustment mechanism, the thermal fuse is designed to localize the event of failure of standard equipment.

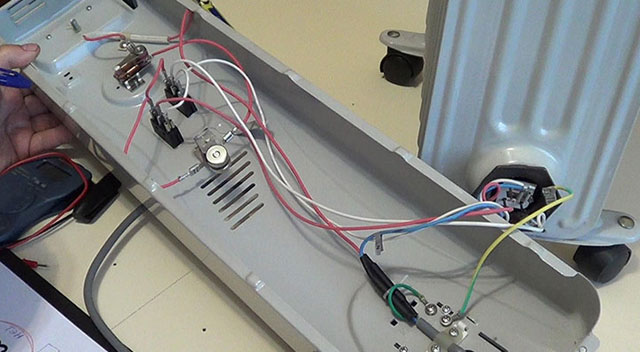

- The pictures show: there are two switches, a phase, a heating element ground, one wire of a thermal relay are suitable for each. This redundancy allows the indicator lights to glow. One phase is not enough to provide the Joule-Lenz effect. The manufacturer does not know in advance which side the user will plug the plug in, whether the blue (red) wire will be zeroed, exposed to 230 volts.

The electrical part differs little from the iron, electric kettle, water heater. You can turn on both spirals of the heater at the same time, separately. In the latter case, the oil heater will reach the mode longer. There is a chance that in a cold room the design will work without interruption at all.

Earth's magnetic field researcher listens to the buzz of an oil heater coil

Close the air passage holes in the electronic circuit - nothing will burn, the oil heater will turn off ahead of time, the restart will not happen soon, the drying woolen sock will prevent the inflow of a fresh stream.The bottom of the housing of the electronic unit is cut through with supply slots. The air leaves the floor, follows, bypassing the wires, reaching the top outlet. Along the way, the bimetallic plate evaluates the moment of termination of heating.

Dismantle the oil heater

Photos of the oil heater show: the electronic unit is rolled up as a single unit with an accordion. This is not true. The inscription "Do not cover" hides a pair of screws, the mounting bracket is held by a spring located at the bottom. It is clearly visible to the naked eye, explanations are superfluous:

- the spring is released;

- bolts are loosened.

Inside the oil heater housing, most of the electrical connections are made with plug-in terminals. If necessary, remove the switches, bimetal relay, unscrewing the screws from the inside, opening the wires

Please note: the heating element is tightly rolled. Shows the desire of the producers, not to let anyone inside

A cunning technician knows how to get acquainted

How the device works

If the heater breaks down, before proceeding with its repair, you should take a closer look at its device and the principle of operation.

The main parts of an oil heater are as follows:

- Metal case.

- Heating element - heating element.

- Control block.

- Connecting wires.

The device works according to this principle:

- The body is filled with special oil.

- When the radiator is turned on, the temperature of the heating element begins to rise.

- Accordingly, the oil also heats up.

- Gradually, heat is transferred to the walls of the case, and the room heats up from them.

- When the temperature in the room reaches the optimum value, the control unit is activated and the heating element turns off.

- The process is repeated throughout the entire period of connecting the heater to the power supply network. Thanks to this, a comfortable atmosphere is created in the room.

Repair process

Each owner, when an additional heating device fails, asks the question of how to return the broken equipment to work. The solution to the problem is quite simple and consists of several points:

Regardless of the type of work performed, before disassembling the oil cooler, it must be disconnected from the power supply.

Then the device needs to be disassembled and examined the oil cooler circuit in order to understand why it does not work. For this purpose, the control panel is disconnected from the main body

Latches, screws and staples can be used as fasteners in this case, so it is important to conduct a thorough visual inspection. After determining the type of fastening, remove the control panel

In this case, it is very important not to make special efforts so as not to break the plastic elements.

Restoring the performance of an oil heater begins with checking the power cord and switch. Sometimes the oil heater does not work due to a broken wire in the power cord. You can check the reliability of this using a tester. As for the switch, here the reason is a contact failure, which is the result of burning the wires at the junctions. To solve the problem, the wires are disconnected and stripped, and the connection point is also cleaned. Next, the switch is assembled and the restored contact is checked using a tester.

At the next stage, all contact connections of the control unit are inspected. On each contact, oxidized or burnt places are detected, as well as places of weakened fastening. Repairs are carried out with screwdrivers and sandpaper. In some cases, a soldering iron is used to solder broken wires.

- If the thermal relay or temperature controller turns out to be faulty, you need to carefully remove these elements and disassemble them. The bimetallic plate located inside is pulled out and replaced with a new element. There can be no other faults in these details.A new plate restores the functionality of the relay or thermostat.

- Thermal fuses are checked for operability using a tester, in case of a malfunction, they are replaced with new elements. Check each of the available thermostats.

- If the oil heater does not heat, then the cause may be a faulty heating element. A tester is also used to check the condition of the heating elements. With its help, resistance is measured, the normal value of which should be equal to 1 KΩ. Deviation from this value indicates a malfunction of the heating element and the time of its replacement.

Having passed all the stages of checking the electrical parts of the oil cooler, you can begin to eliminate mechanical damage.

The most pressing problem is oil leakage from the radiator housing. To solve it, it is necessary to disassemble the device and drain the remaining oil

When inspecting the housing for damage, it is important to pinpoint the exact location of the leak. Here, using a sandpaper, a stripping is performed, as a result of which the size of the hole is determined.

It depends on how the repair is done. If the size of the hole is small, and there are no signs of corrosion around, then a small self-tapping screw or screw can be inserted into the hole.

A hole formed as a result of rust is more difficult to repair. The damaged area is also cleaned with sandpaper, removing rust to the base metal. After that, an inspection is carried out and the size of the hole is determined. A small hole can be soldered using brass solder rather than tin. A patch is applied to a more extensive damage and welded using semi-automatic type welding equipment. The process is complicated by the fact that it requires special equipment and skills to work with it.

You can repair oil radiators with your own hands, for this you need to have minimal skills in plumbing and electrical engineering. Moreover, repairing a minor breakdown will cost less than buying a new appliance for space heating.

An oil cooler failure can happen unexpectedly and at a very inopportune moment. If oil leaks appear on the case, the device should be immediately turned off from the network and think about buying a new heat source. In case of other malfunctions, the device can be brought back to life with the help of a wizard or independently. It is recommended to take on the repair of an oil heater with your own hands only if you have basic knowledge in the field of electrics, while not forgetting to observe safety precautions.

Typical convector malfunctions

As a rule, breakdowns of convectors happen very rarely, because this device itself is very simple in execution. And the maximum resource of their uninterrupted operation is quite long - on average, about 20 years.

But like any equipment, the convector can also fail or perform its functions inefficiently.

Experts identify a number of reasons why the convector does not heat well and may need to be repaired:

- manufacturing defects,

- overheating of heating elements,

- power outages,

- mechanical damage,

- depreciation of equipment.

Troubleshooting the convector, despite the fact that this equipment is not particularly difficult in terms of design, it is better to entrust qualified specialists.

Especially when it comes to gas equipment, which is quite unsafe. And breakdowns of the gas convector must be eliminated by craftsmen who have permission to work with such equipment.

Split-S specialists note that most often it is necessary to repair:

- Control block,

- a heating element,

- temperature sensors,

- automation.

Very often the convector does not turn on due to the fact that there are malfunctions in the connection to electricity. Sometimes just repairing the outlet is enough and the problem is solved.

Major breakdowns of oil heaters

The heating element breaks more often, the tank flows. The oil heater is in complete disrepair. The relay will last for years. Today, Soviet irons are common, and are still operational. The mechanism cannot be repaired. You need to clean the oxidized contacts with alcohol. Repair of electronic filling is limited to the replacement of elements mainly. Thermal fuses are too lazy to repair: it is difficult to calculate the response temperature. Masters avoid taking responsibility. Keys, relays should be cleaned from time to time.

The main thing is the replacement of heating elements, oil, repair of holes. Those who wish to take it should know: they certainly store air in the tank. Acts as a cushion when the oil begins to expand. Protects the tank from bursting. When replacing, use transformer oil, the used one is not suitable, it will cause the heating element to grow scale.

Buck avoid soldering. Take non-tin solder - brass, copper-phosphorus, silver, use a burner. Suitable refrigerator repair equipment. It is recommended to pour water inside the tank to avoid fire. Accordingly, after work, the container must be dried. The oil is evaporated at a temperature of 90 ºС before filling. Beware of stubbornly heating the liquid - it will begin to oxidize, burn. Of course, you can freeze the oil. A thin stream is passed through a chute having a negative temperature. Oil is poured into 90% of the capacity of the oil heater, you can measure it in any way possible, with water.

How to remove the heating element depends on the design. There is information about collapsible and non-collapsible versions. Try to select a heating element of the same power. The shell is made of copper tubes. The tank of oil heaters is steel, there is a possibility of corrosion caused by the formation of a galvanic couple.

Small holes may be bolted. Lay the thread with putty, heat-resistant sealant is used. Difficult to avoid leaks. One sealant will not do, heating-cooling cycles will cause cracks to appear. No wonder the case is made with an accordion. The structure of the metal extinguishes the lion's share of deforming loads.

Listed the main types of faults. Self-repair of oil heaters, when it comes to holes, is a time-consuming, thankless task. However, have an inverter for welding thin sheets at hand, localize the hole

It is important to remove, repairing a layer of rust, corroded places, to allow the seam to catch on. Oil leak repair has a chance of success

The fall sensors went silent. The input of the electrical circuit of the oil heater is preceded, at a certain roll, the power to the device is turned off. Checking the operation of the element is not difficult. Lay on its side, ring the contacts. The repair of the oil heater drop sensor is not justified by the risk caused by the incorrect execution of the operations. Along with the thermal fuse, we see an element that ensures the safety of operation. The information regarding the repair is presented, we hope the story is useful for novice craftsmen. The pros themselves know how to fix the problem.