Installation and operation rules

The boilers are equipped with tanks for storing liquid fuel. These tanks can affect the performance of the equipment. It is necessary to correctly install this container, which must be set on all planes.

The tank must have a pipe for draining sediments and a fix bag. The container must be periodically emptied of fuel and cleaned; it is recommended to use only purified fuel.

Before starting the equipment, diesel fuel is initially filled into the tank, which must settle for at least half an hour.

Only after that the unit is started and the operating modes are adjusted.

In the presence of power surges, it is desirable to purchase a stabilizer to ensure the correct operation of the control and monitoring unit and safety from premature failure.

To keep the boiler working you need:

- Periodic mechanical cleaning.

- Constant monitoring of equipment performance and checking of components and parts for their leakage.

Self-installation of diesel boilers is possible with a careful study of the schemes and recommendations of the manufacturer. However, there are many operations that require the presence of highly qualified specialists, so that later the equipment does not have to be repaired. Instructions for the exact order and principle of installation and the electrical installation diagram serve to illustrate the implementation of these works.

Kiturami boilers are an economical option with a long service life. The reason for the premature repair is untimely service or low-quality fuel filling.

Error codes:

Reasons for no ignition - error code "01":

-

Jamming of the screw limiting the fuel level.

It is necessary to replace the locking element or check the injection motor; -

Injection motor failure

– it will be necessary to check the performance of the motor; -

Lack of fuel supply

- you will need to check its level; -

third party item

in a screw gate; -

Photosensor failure

- it needs to be checked for functionality.

Diesel single-circuit and double-circuit models have been developed, the latter are more convenient, but more expensive.

Choosing the first option, you need to purchase a boiler and other appliances and fixtures, but its cost will still be lower.

It is worth paying attention to the depth of the fuel intake according to the criterion for determining the deep location of the fuel and fuel tank.

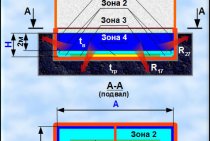

According to fire safety, fuel tanks must be dug into the ground to an appropriate depth. With low power, the depth of the fence is higher.

The cost of installing the equipment will include the price of the heater

, its installation, start-up and adjustment works, maintenance and spare parts during its repair.

Most of all, this issue is relevant for owners of suburban housing. And although modern gas boilers are the most advanced, they are inaccessible to many people due to the constant increase in the price of this type of fuel.

Heating the house in winter is a top priority for every homeowner today. Most of all, this issue is relevant for owners of suburban housing. And although modern gas boilers are as advanced as possible, they are inaccessible to many people due to the constant increase in the price of this type of fuel.

Therefore, a large number of consumers choose other alternatives, one of which is the Kiturami diesel boiler. Although they are not new on the market, they have not lost their popularity at all. They are able to provide high-quality heating in the house.

Today Kiturami is a well-known South Korean concern, one of the largest manufacturers of heating equipment. Repeatedly, the boilers of this company were awarded diplomas for reliability and technical perfection, and due to the presence of certificates that meet all international standards, the Kiturami diesel heating boiler is exported to almost all countries.

What is the peculiarity of heating equipment from Kiturami

The Kiturami concern is engaged in the production of various types of heating equipment, which includes biofuel and gas installations. But it was Kiturami's diesel heating equipment that brought the concern such great fame and a high rating. The name diesel speaks about the type of fuel on which it runs.

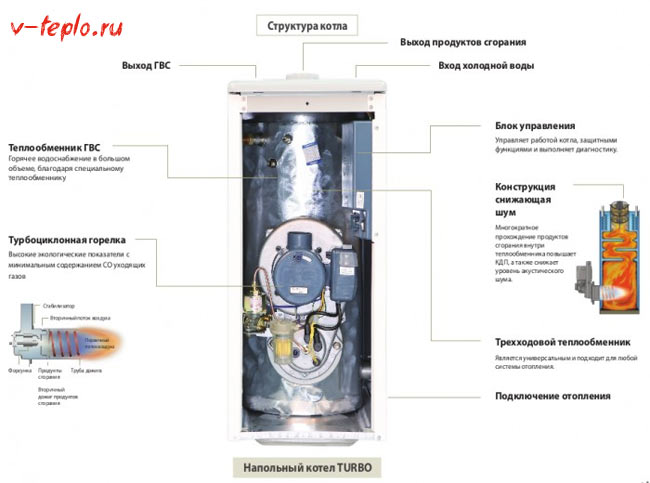

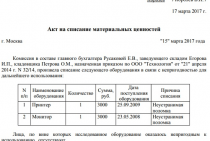

Rice. one

The most popular model in the line of this manufacturer is the Kiturami Turbo 17 diesel boiler, the purpose of which is hot water supply and heating of industrial and residential premises. Boilers from the manufacturer Kiturami are very convenient for use in country houses, when the need for hot water does not arise daily, and heating is required only during the presence of the owners there. In addition, with proper operation, repair of such equipment is very rarely necessary.

The main advantages of Kiturami diesel heating equipment include:

- the diesel copper of Kiturami is convenient in operation. The control panel allows you to set any control function. Kiturami's work on the coolant and room temperature is regulated by a thermostat built into the remote control. The boilers are independent of the size of the chimney and the presence of draft due to the presence of a turbo blowing effect, which forcibly sends the exhaust gases to the chimney;

- diesel Kiturami is highly economical. Thanks to the aerodynamic flow in the combustion chamber, maximum efficiency is achieved in terms of the amount of fuel consumed;

- setting up the equipment is absolutely simple, and you can do it yourself;

- The house has hot water all year round. Boilers of the Kiturami brand are also used at a time when the room is not heated;

- The Kiturami diesel boiler has a self-diagnosis system that informs on the display about its operation and the malfunctions that have occurred, showing the real state of the system. If you constantly monitor the display readings, then the need for repairs will be minimal.

Model Kiturami Turbo-13R comparative characteristics

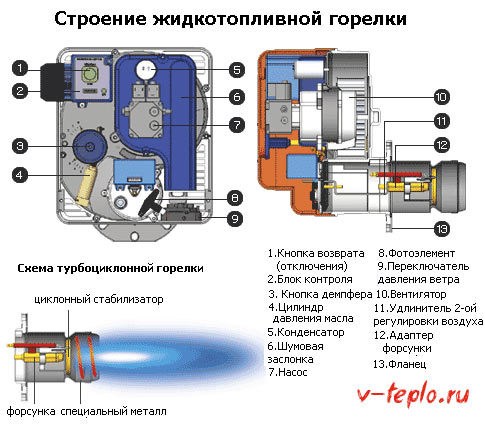

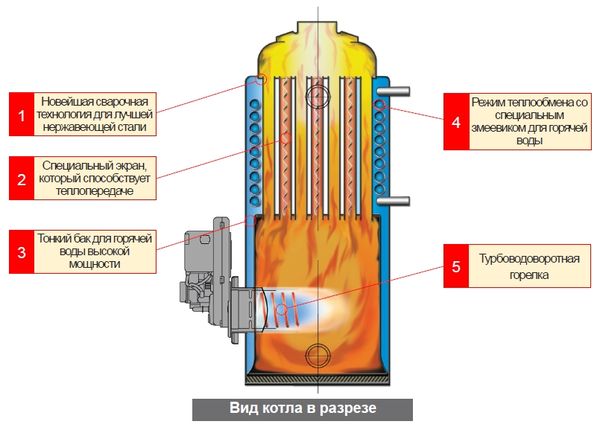

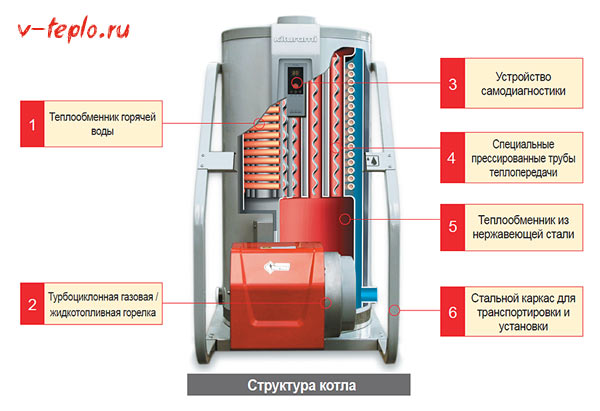

As an example, let's take one of the most popular models of boilers from this manufacturer, namely the Turbo-13R. It is characterized by the fact that it is made in the floor version and can be used both for heating and for providing warm water. The main advantage can be considered the presence of a turbocyclone burner.

How is this burner different? First of all, it functions according to the technology of a turbocharged engine in a car: due to the high temperature, which can reach 800 degrees, the gas is completely burned out in a special metal plate (the so-called secondary combustion takes place). And thanks to this, you can not only save on resources, but also significantly reduce the amount of harmful substances released into the atmosphere.

Note! To control this boiler, a special remote control is used, located on the front of the case. There is an alternative to such control - this is a thermostat installed in one of the rooms of the house.

Among the functions of this device are:

There is also an alternative to such control - a thermostat installed in one of the premises of the house. Among the functions of this device are:

- integrated security (this includes self-diagnosis, combustion sensors, fuel shortage sensors, etc.);

- programming;

- lack of people in the room.

To date, thousands of users have already tried and convinced themselves of the quality of this boiler.Many of them subsequently spoke about the high quality of not only Turbo, but of all Kiturami products as a whole.

And this is how the boiler looks from the inside in an open, disassembled form:

As a small conclusion

When analyzing some models, we found a lot of advantages for boilers of this brand over their competitors, although even here they could not do without drawbacks.

This applies in particular to liquid fuel (diesel) appliances. Each boiler that consumes diesel fuel is necessarily equipped with a special fuel tank, which in most cases has a very significant volume - from 2,000 to 5,000 liters. Boilers are equipped with such tanks, but in the absence of the latter, you will also have to fork out for the purchase of a “tank for diesel fuel”.

To install such a boiler, it is necessary to have a room with excellent ventilation, so that the user does not accidentally get poisoned by fuel combustion waste. In some cases, heat generators even smoke, which is why they need special care. Finally, one should not forget about the cost of diesel heating appliances - it is often higher than that of appliances using other types of fuel (even though Kiturami boilers are cheaper).

Despite all the strengths and weaknesses of such boilers, modern technologies make it possible to significantly increase the safety in the operation of space heating devices. And we all know that safety should come first. Moreover, this equipment can work autonomously, maintain the required temperature for a long time, even if there are no people nearby.

Video - Kiturami Turbo-30R

Assortment of Kiturami

All heating boilers from this Korean manufacturer are divided into three categories, each of which has its own characteristics, strengths and weaknesses. This:

- diesel;

- solid fuel;

- gas heaters.

Let's get acquainted with each of the types.

- Diesel devices, as the name suggests, operate on diesel fuel, which increases the efficiency of heating. The model range of such boilers will be discussed in more detail in the next paragraph.

- Solid fuel appliances are an alternative to the previous option, since they are quite capable of operating on both diesel and solid fuel, which is especially important in conditions of an unstable supply of energy resources. These boilers are made in such a way that after solid fuel is used, they begin to burn diesel itself. All diesel devices are combined into one model range - KRM. There is an automatic control, it is possible to use for domestic hot water purposes.

- Gas appliances use natural gas, which is why they are now very popular. They are floor or wall, for one or two circuits. They are quite convenient to operate, and the savings in their use are obvious.

Instructions for connecting GSM-Thermostat TS2 GSM v2.6 to gas and diesel boilers Kiturami, Navien, Saturn Update from

User manual

Operating instructions GSM-alarm "Dachnik - Informer" Before using the device, please read this manual Inside the GSM-alarm "Dachnik" there is a high

More

GSM boiler controller COMFORT

GSM boiler controller COMFORT Operating manual ODO BLOCKHOLE 2015 General description This operating manual (hereinafter referred to as the manual) is intended to ensure correct operation

More

GSM THERMOMETER. User's Manual

GSM-THERMOMETER User manual Purpose of the device: Temperature control at remote sites, notification of users on a mobile phone about temperature deviation from the norm Independent

More

ROTATION UNIT FOR AIR CONDITIONERS SB015

ROTATION UNIT FOR AIR CONDITIONERS SB015 Contents Purpose..3 Safety measures..3 Description of the device 3 Technical characteristics..4 Description of operation..4 Installation and adjustment.4 Connection options. 5 Display

More

Thermal sensor RTD-01/02 for CCU6225

R&DS Thermal sensor RTD-01/02 for CCU6225 Temperature measurement in the range -50С 116С. User manual CCU6225 input setting recommendations For controller firmware version HA.04.05 or

More

Oscar W Weekly programmer

Oscar W Weekly programmer Control buttons 1 on/off heating mode 2 automatic/manual operation 13 time (hours and minutes) 3 heating mode programming 14 heating mode deactivation

More

USER MANUAL

MULTIFUNCTIONAL CONTROLLER RT-200E "TEPLODOR" INSTRUCTIONS FOR USE 1. Purpose: The multifunctional controller RT-200E "Teplodor" is used in electric heating systems

More

The new electric boiler 28 is distinguished by its small size and new design Electric boiler K 28 ( 24,21,18,15,12 9, ) Main features Power, 9, 12, 15, 18, 21, 24, 28 Smooth power modulation

More

Installation and operating instructions

TE918WHB-0-RF wireless 24-hour thermostat Installation and operating instructions The TE918WHB-0-RF thermostat kit consists of a TE2010DE receiver and a TE918WHB room thermostat. TE918WHB-0-RF usually

More

Electric boiler ELEKTRA from

Electric boiler ELEKTRA from MORA-TOP The new standard of the XXI century Electric boiler with direct heating ELECTRA EK08SB ELECTRA EK15SB ELECTRA EK24SB main technical characteristics of the boiler ELECTRA Power:

More

User manual

Operating instructions GSM-alarm system "Dachnik" Before using the device, please read this manual. ATTENTION! Inside the GSM-alarm "Dachnik" there is a high

More

Nice Calculation TFS-CP 3.0

Universal digital timer Nice Calculation TFS-CP 3.0 User manual (instruction for solariums)

More

THERMOMETERS AND THERMOSTATS WITH 1 SENSOR AND 1 RELAY: AKO - 14023, AKO 14012, AKO 14031, AKO 14112, AKO 14123, AKO 14602, AKO 14610 CONTENTS 1 Description page 3 2 Technical data page 3 3 Installation page 3 31

More

structure or coolant;

Purpose and scope of application The room electronic chronothermostat VT.AC 709 is designed for automatic control and maintenance of the programmatically set temperature in the room, temperature

More

Recommendations for use.

Recommendations for use. GSM Alarm Sentry-1MT, the simplest in the product line. It has 2 inputs for connecting wired sensors. Any number of sensors can be connected to each input.

More

Installation and operation instructions

Installation and operation instructions Heating system controller AUTOMIX 20 AUTOMIX 20 is designed to control the temperature of the supply coolant in the circuit of heating radiators or warm

More

GSM module FACI RB800 for remote control of the boiler

GSM module RB800 for remote control of the FACI boiler

- Remote control of the state of the boiler and heating system.

Starting and stopping the boiler.

Notification of emergency situations during the operation of the boiler.

Reset errors.

Increases the reliability and safety of the boiler room, because. immediately informs you of any violations in the work.

Connection: The module is connected to the FACI boiler control panel through a special connector. A SIM card is additionally inserted into the module.

Control

Remote control of the boiler and obtaining information about its operation occurs by sending the appropriate commands in SMS messages. There is no special application.

There are currently 5 commands in use. Commands are entered in English in capital or lowercase letters.

1. The LEARN command informs the SY400 boiler control system to which telephone number to send SMS messages in case of an error in the boiler operation. The SY400 control system sends a response message via modem to the OK phone.

2. The START command starts the boiler control system if it has not been activated.The SY400 control system sends a response message via modem to the telephone from which the command was received. The message indicates the CHECK UP mode (boiler control mode) and the temperature of the heating medium. Or information about the error, if it occurred (error number). This command is applicable only in the "Pellets" operating mode.

3. STOP command. Depending on the mode in which the boiler is at the time the command is received, the transition of the boiler control system to the OFF state occurs through the Extinguishing mode (fire extinguishing). If the boiler has been de-energized for more than 20 minutes (respectively, the control system), the STOP command can only be applied after the boiler has switched to the RUN MOD mode.

4. The RESET command resets the boiler errors in the control system and unlocks the system if it is in a blocked state. The boiler control system sends a message to the number from which the command was received about the state of the system and, possibly, an error that has not been reset.

5. The STATUS command queries the SY400 control system for the status of the boiler. The SY400 control system sends a response message via modem to the telephone from which the command was received. The message indicates the state of the boiler, the temperature of the coolant and a possible error in the operation of the boiler.

Specifications

Supply voltage: ~220V

Operating temperature: -20…+60°С

Humidity: 5…85%

Attention! The device must be handled carefully, avoiding contact with the leads, as electrostatic discharges can damage the device. The same caution should be observed when working with a SIM card, carefully read the instructions for using it. Do not insert or remove the SIM card while the device is in power saving mode

Do not insert or remove the SIM card while the device is in power saving mode.

Remote control of the Kiturami boiler

Price

from

before

Name:

Vendor code:

Text:

Select a category:

Everything

3G-MMS signaling

GSM alarms

» Devices without sensors

» Wireless alarm

» Wired alarm

GSM alarm sets

» Alarm for giving

" Alarm system for home

» Alarm system in the apartment

» Garage alarm

» Boiler alarm

Wired sensors

» Security sensors

»» Magnetic contact sensors

»» Internal motion sensors

»» Vibration sensors

»» Glass break detectors

» Fire detectors

» Water leakage sensors

» Gas leak detectors

» Other sensors

Wireless sensors

» security sensors

" alarm button

» fire detectors

» key fobs

» other sensors

» Gas leak detectors

Perimeter security

» Outdoor motion sensors

» Perimeter sensors

Optional equipment

» camcorders

» power supplies

» Keyboards

» microphones and speakers

» Sirens, alarms

» Cables, wires, connectors

» Keys and readers

» Power Relays

» Actuators and valves

» Thermal sensors

» Antennas

» Active protection means

Radio relay and wireless relay

Remote control of boilers

» ARISTON

»» Wiring diagrams for Ariston boilers

» AEG

»» Connection diagrams for AEG boilers

» ALPHATHERM

»» Connection diagrams for Alphatherm boilers

» BALTUR

»» Boiler connection diagrams Baltur

» BAXI

»» Connection diagrams for Baxi boilers

» BERETTA

»» Wiring diagrams for Beretta boilers

» BIASI

»» Wiring diagrams for Biasi boilers

» Bosch

»» Wiring diagrams for Bosch boilers

» BUDERUS

»» Wiring diagrams for Buderus boilers

» CHAFFOTEAUX

»» Boiler connection diagrams Chaffoteaux

» DE DIETRICH

»» Wiring diagrams for De Dietrich boilers

» ELECTROLUX

»» Wiring diagrams for Electrolux boilers

» FERROLI

»» Connection diagrams for Ferroli boilers

» IMMERGAS

»» Connection diagrams for Immergas boilers

» KITURAMI

»» Wiring diagrams for Kiturami boilers

» KOSPEL

»» Kospel boiler connection diagrams

» LAMBORGHINI

»» Wiring diagrams for Lamborghini boilers

» navian

»» Connection diagrams for Navien boilers

» RINNAI

»» Wiring diagrams for Rinnai boilers

» ROD

»» Wiring diagrams for boilers Roda

» SAVITR

»» Wiring diagrams for Savitr boilers

» TERMET

»» Connection diagrams for Termet boilers

» THERMONA

»» Connection diagrams for Thermona boilers

» TITAN

»» Connection diagrams for Titan boilers

» VILLANT

»» Wiring diagrams for Vaillant boilers

» VIESSMANN

»» Wiring diagrams for Viessmann boilers

» WATTEK

»» Wiring diagrams for Wattek boilers

» WOLF

»» Wolf boiler connection diagrams

Manufacturer:

VseAccordTecAMCAxycamBugatti (Italy) CORNETDallas SemiconductorsDS-SystemESVIFOXGSNHiQ-ElectronicsHiWatchJ2000JablotronJSB-SystemsOubaoPower LaiPrimePROXISCCTVPyronixRViSmartecSTELBERRYAVARKOAkkumulyatory (Taiwan) Argus-spektrBastionIPRoKomplektStroyServisKomtidMagnito kontaktMikroKomServisparitetPoliservisPremer GruppRadiyRieltaRubezhSibirsky ArsenalTekoElektronmashElektrotehnika and Automation

New:

Vsedanet

Special offer:

Vsedanet

Results per page:

5203550658095

Find

Features of Kiturami boilers

Kiturami is a South Korean company with more than half a century of experience in the design and manufacture of heating boilers and related equipment.

During this time, the company has become one of the leaders in the domestic Korean market, and has also found an extensive market in North America and nearby Asian countries. In our country, Kiturami boilers have been officially distributed for at least ten years and have already shown themselves on the good side.

The main emphasis in the promotion of boilers is on the introduction of innovative technologies and, in particular, their own developments, which have no analogues from other manufacturers or determine the narrow specifics of the equipment.

Diesel boilers, by definition, are not considered as the main model range for a wide range of applications. In terms of economic feasibility, they are inferior to gas, electric and even solid-state boilers. However, they are still in demand among consumers in view of a number of reasons why liquid fuels are becoming preferable.

Diesel fuel, unlike gas, is easier to transport and store with minimal risks to life and the environment. Unlike solid fuel boilers, when burned, diesel fuel provides uniform heating and a greater degree of control over the waste of resources. And finally, the design of the diesel boiler and in particular the burner does not limit the use of other heat sources.

With minimal changes, the diesel burner can be replaced for the use of blue fuel, and boilers equipped with an extensive combustion chamber and a grate, can quickly switch to charcoal, wood or pellets.

Diesel boilers Kiturami are highly technological and are a perfectly balanced equipment for the use of diesel fuel as a heat source, and at the same time they are excellent for the above types of conversion to work on gas or solid fuel. So constructive and functional flexibility is the first significant advantage.

Kiturami boilers often use their own designs and unique layouts.On the one hand, this reduces the maintainability of heating equipment, but on the other hand, it ensures the highest efficiency of the boiler and balanced operation while observing simple and transparent operating rules.

This is the second significant reason to turn your attention to diesel boilers from South Korea.

The last advantage is the cost of boiler equipment. Even taking into account the high performance and proven quality of the boilers, their cost does not exceed the average on the market among similar offers.

So it turns out that Kiturami boilers have three features: a balanced design, high efficiency and an affordable price.

Equipment characteristics

-

The design, equipped with high-quality elements and blocks, is different from other brands.

The heat exchanger is made of highly alloyed steel, superior in physical and technical qualities to other metals, which increases its cost, offset by high quality. -

The equipment is made of copper, which does not react with water and increases its heat resistance.

The presence of internal and external control units, which contributes to the regulation and control of the operating mode of the system from various places in the boiler room. -

Coverage of the power range of floor-standing 2-loop units –

from 10 to 35 kW, sufficient for heating 250-275 sq. m. -

The dependence of the actual fuel consumption on personal settings.

The nozzle is selected from the manufacturer for the actual power parameters. -

Heating power, fuel consumption and its combustion mode are set independently.

With power parameters up to 15 kW, the expected fuel consumption is 8 liters per day, while the burner will work with a certain frequency to create the optimal room temperature. By choosing the right heating mode and installing a variable temperature controller, you can significantly reduce fuel consumption. - Boilers for gas, diesel fuel, floor or mounted on the wall are mainly equipped with a closed-type combustion chamber and a forced gas exhaust system.

A steel or ceramic chimney is coaxial so that the supply of street air flow and gas exhaust are carried out at the same time. -

It is possible to build a chimney with a slightly larger diameter - up to 120 mm.

Reducing its size and cross section is unacceptable.

turbo 13r

The model number of the boiler corresponds to the amount of heat generated per hour - 13000 kcal/hour. In terms of the usual kilowatts, the values \u200b\u200bare obtained are 15.1 kW.

The declared power is enough to heat a house up to 150 m2. Naturally, one should take into account the heat costs for the preparation of hot water supply. If a significant consumption of hot water is predicted, moreover, regularly, then the heat output for the heating circuit will naturally be lower.

Reliability and balanced operation, combined with the affordable cost of the boiler, gives a clear advantage in the case of using several boilers simultaneously in one building, for example, when dividing the heating circuit for each floor separately or when covering a large area in two more wings, directions.

Pellet boiler Kiturami Kiturami domkotel.ru

What to do if there is no main gas connection? Install a pellet boiler. It works on pellet granules, which are made from sawdust. The boiler is fully automatic, in addition to heating it has a hot water circuit (DHW).

Their operation is simple, because. it comes down to filling pellets into the bunker (once every few days) and periodically shaking out the ash box. The Kiturami pellet boiler provides for automatic cleaning of both the device from ash and from the sintering of low-quality pellets - the formation of “cakes”. All this falls into 2 ash drawers with easy access.

ADVANTAGES OF KITURAMI PELLET BOILER:

- Optional GSM boiler control module (9500 rubles).

- Compact dimensions.

- It does not depend on the quality and size of the pellets.

- Made from quality steel.

- Room control unit.

- The presence of a DHW circuit expands the options for installing, if necessary, additional equipment for obtaining hot water, which saves money.

- High efficiency - up to 96%.

- Heated area from 60 to 600 m2.

- Automatic cleaning of turbulators and heat exchanger.

- All ash falls into 2 ash drawers, conveniently located behind the door.

- Automatic shutdown of the boiler when the door is opened.

- All mechanisms are hidden behind the case.

- Room control panel.

- The compact dimensions are suitable for the smallest boiler rooms.

- Electricity consumption is not more than 82 W/h. Power consumption during ignition (4 min) up to 320 W/h.

- The presence of a built-in smoke exhauster allows you to save on the chimney.

- The flue gas temperature is not more than 130°C.

- The "absence" mode - maintains the temperature in the heating system + 8 ° C and does not allow the house to freeze.

- 3-way heat exchanger - maximum combustion heat transfer.

- Flare type burner.

- Automatic switching on when the temperature drops and switching off when the set value in the room or the coolant temperature is reached.

- Auto-ignition in 30 seconds with a ceramic heating element of the Japanese company FKK.

Fire safety system.

You can buy pellets from us.

Diesel boilers from the manufacturer

All diesel fuel boilers from Kiturami are double-circuit and are manufactured in several series, let's get acquainted with them.

- - These are devices whose power can reach 35 kilowatts. The power, as we see, is insignificant, but there is a turbocyclone burner, and the cost is low. All models are designed for use in private houses or cottages, the area of which does not exceed 350 square meters.

|

Specifications |

Unit rev. |

||||

| Power | kWh | 15 | 19.8 | 24.5 | 35 |

| Heated area | m2 | up to 150 | up to 200 | up to 250 | up to 350 |

| efficiency | % | 92.8 | 92.9 | 92.8 | 92.7 |

| Average heat consumption | l/day | 4.9-6.8 | 6.1-8.6 | 7.3-10.4 | 10.0-14.5 |

| DHW capacity | l/min at T=40C | 5.2 | 6.5 | 8.2 | 13.0 |

| Heat exchanger area | m2 | 0.78 | 0.92 | 1.03 | 1.03 |

| Heat exchanger capacity | l | 23 | 32 | 29 | 29 |

| Boiler dimensions WxDxH | mm | 310x580x835 | 360x640x920 | 360x640x920 | 360x640x920 |

| Boiler weight | kg | 64 | 75 | 85 | 88 |

| Electricity consumption energy | W/h | 120 | 170 | 200 | 280 |

Table of technical characteristics of boilers of the Kiturami Turbo model

Kiturami STS

- similar devices, differing in that they are made of stainless steel.

|

Model |

Power | Heating area |

DHW at dT 25 C |

HxWxD-mm |

Weight |

| Kiturami STS 13 OIL | 16.9 kW | 160 sq.m | 6.2 l/min | 700x325x602 | 30 kg |

| Kiturami STS 17 OIL | 19.8 kW | 190 sq.m | 6.7 l/min | 700x325x602 | 30 kg |

| Kiturami STS 21 OIL | 24.4 kW | 240 sq.m | 8.3 l/min | 700x325x602 | 32 kg |

| Kiturami STS 25 OIL | 29.1 kW | 290 sq.m | 10.4 l/min | 930x365x650 | 48 kg |

| Kiturami STS 30 OIL | 34.9 kW | 340 sq.m | 12.5 l/min | 930x365x650 | 48 kg |

Table of technical characteristics of boilers of the Kiturami STS model

Kiturami KSOG

- high-power devices (up to 465 kilowatts) of a two-coil type, also consuming diesel fuel. These Kiturami diesel boilers have a built-in turbocyclone burner and are intended for operation at industrial facilities up to 4650 square meters, as well as for supplying hot water.

Note! All mentioned boilers have an electronic control unit, which is equipped with numerous functions. In addition, the manufacturer provides for the possibility of installing a room thermostat, which allows you to control the temperature in the room directly on site.

Table - Comparison of models and prices of Kiturami heat generators

|

The lineup |

Name |

Power, in kilowatts |

Cost, in rubles |

| Kiturami KSOG | 50R | 58 | 95.5 thousand |

| 200R | 230 | 304 thousand | |

| 150R | 175 | 246 thousand | |

| 100R | 116 | 166.6 thousand | |

| 70R | 81 | 104 thousand | |

| Kiturami STS | 30R | 35 | 63 thousand |

| 25R | 29 | 55 thousand | |

| 21R | 24 | 50 thousand | |

| 17R | 19 | 42 thousand | |

| 13R | 16 | 41 thousand | |

| 30R | 34 | 52 thousand | |

| 21R | 24 | 50 thousand | |

| 17R | 19 | 40.6 thousand | |

| 13R | 15 | 38 thousand |

Features of Kiturami in operation

The diesel heating unit represented by the Kiturami concern differs significantly from other brands in its characteristics, both in terms of the method of maintenance and the need for repair. Only high alloy steel is used to manufacture the heat exchanger.

Kiturami brand boilers are made of copper, which is highly resistant to water. If we talk about the price, then in comparison with stainless steel, copper is much cheaper, and, accordingly, a diesel boiler costs accordingly.In addition, copper significantly increases the heat resistance of equipment.

The quality of work of Kiturami Turbo depends on how correctly placed the tanks in which the fuel is stored. Here it is necessary to correctly place the tank and expose it in three surfaces. It is imperative to take into account that a drain is provided in the sedimentation tank. The Turbo tank should be cleaned regularly and the sediments should be drained, and the fuel should only be filled into the diesel mechanism in a cleaned form. Such handling contributes to uninterrupted operation, and the need for repairs is not needed.

When the Kiturami diesel boiler is filled with fuel, the instruction says that you need to wait half an hour until it settles. Only after this, the Turbo diesel boiler can be started and the necessary modes can be adjusted. It is also advisable to use a stabilizer to avoid repairs from sudden changes in mains voltage. It will ensure stable operation of the control unit, as well as protect the heating unit from premature repairs.

In order for the Kiturami diesel heating boiler to work smoothly during operation, the following is necessary:

- the boiler setting must be carried out correctly and correctly, then the need for repairs will be minimal;

- a diesel boiler requires the systematic implementation of its mechanical cleaning in order to protect it from premature repairs;

- Turbo should regularly monitor the operation of all its connections and assemblies for leaks;

- the performance of the equipment must be checked regularly so that it is not necessary to prematurely repair Kiturami diesel boilers.