Equipment malfunction report

The pair of right burners of the electric stove does not heat up - the contacts on the terminal box and the fuse may have come off, it is likely that the fuse needs to be replaced. There may also be problems with the power supply, control and the block of the burner itself.

The induction hob does not turn on The power switch or fuse may have failed. Including there is a possibility that the contacts between the power board and the control unit are broken, as well as between the control unit and the touch panel. Troubleshooting - replacing the touch panel, replacing the burner unit.

Household appliances are periodically updated, becoming more advanced and smart, able to automatically support various cooking modes and report readiness. All such innovations are the result of the complication of the internal components of the electric stove in order to make operation more convenient and easier.

Info

More and more electric stoves on the modern market are touch-sensitive. Less and less you can see the stove in the classic version, where rotary switches were used to adjust the power of the burners.

Varieties of thermostats

There are three types of regulators:

- electronic;

- electromechanical;

- mechanical.

Below we will briefly discuss the characteristics of each of them.

Electronic regulators

The thermostat with electronic filling is composed of three components:

- temperature sensor;

- microprocessor responsible for processing and transmitting information;

- thermal relay, thanks to which the control switching is carried out.

Electronic thermostats are used not only in oil heaters, but also to organize the management of larger heating systems (for example, "smart home").

Electromechanical regulators

Relay-based electromechanical devices are much simpler than electronic devices. There are several types of electromechanical regulators:

- Devices of the first group include a group of contacts and a double metal plate. When the equipment is heated, the plate bends and, thus, opens the group of contacts. The consequence of the opening is to stop the supply of electricity to the heating plate. When the heater cools down, the plate returns to its starting point, and the electrical circuit starts to work in the previous mode, since the contacts are closed again. The cyclic operation allows you to maintain the temperature level at approximately the same level.

- Devices equipped with a relay operate on the principle of expansion of its elements as a result of heating. The relay is a cylindrical tube containing a heat-responsive substance. The pipe is in a container of water. When the temperature of the heater rises, the substance in the pipe expands. When the temperature reaches a certain value, the expanded content acts on the electrical circuit with the help of an actuator, resulting in the closing or opening of contacts. In this way, it is possible to avoid overheating of the equipment.

Mechanical

The most simple are mechanical regulators. Such thermostats are conventional shut-off valves. The design of the device includes a cylinder with a rod filled with a thermally sensitive substance. As a result of the expansion of the substance during heating, the rod partially or completely blocks the flow of the coolant in the system.

The burner does not heat up

The main element of any cooking surface, of course, is the burner. It is this element that ensures uniform distribution of the flame over the surface of the bottom of the dish.However, in view of the above reasons, sooner or later there comes a moment when it ceases to perform its original function.

In this case, a visual inspection of the product should be made, paying particular attention to the switch positions on the panel, as well as the switch for the burner and the timer. If all the parameters are set correctly (the device is brought to the working position, the necessary cooking function is selected, and the delay mode is turned off), the device should be diagnosed for malfunctions

If all parameters are set correctly (the device is brought to the working position, the required cooking function is selected, and the delay mode is turned off), the device should be diagnosed for malfunctions.

Causes of non-working burners and ways to eliminate them.

Using unsuitable utensils .

Repair of washing machines Articles Electric stoves, basic malfunctions Electric stoves, main malfunctions Year by year, this miracle of technology is being improved, new models appear that are significantly superior to the old ones.

However, the basic mechanism and rules of operation they have in common, and hence the common mistakes that people make. It is these violations that most often become the causes of electrical breakdowns, and not the expiration date of the parts.

One of the most common malfunctions in electric stoves is the burnout of the electric heating element. The reason for the breakdown is often not the implementation of elementary rules for using the stove.

comprehend and it becomes clear what you are and how you should act, make and write! How organizationally correct, not stupid, in an engineering way, call your actions and the documents you draw up.

And realizing this (this organizational process), you will, explaining, strongly demand from responsible (and not responsible) workers in medicine to fulfill their (their) job duties, and not push some of them away, and at the same time also their own a responsibility, on the YOU and your organization.

For the sole purpose of fulfilling their official duties, improve your professional skills in its organizational part, and demand, explaining to them, the same from all medical workers of any official rank, up to the Minister of the Ministry of Health of the Russian Federation !!! And as an example of organizational and engineering insolvency cm.

In both cases, a large current flows through the contact groups, from which carbon deposits form on them. Operation of a heating element with several spirals

Suppose the heating element of an electric stove has two spirals: C1 and C2. For their switching, a three-position switch with three contacts can be used: K1, K2, K3.

When K3 is turned on, both coils are connected in series and will work at half their capacity. When K2 is turned on, the C1 coil will heat at full strength. The maximum heating will be obtained with the simultaneous closure of K1 and K2 - two spirals will be connected in parallel. All other possibilities are meaningless and must be ruled out by the design of the switch itself.

To fix such a switch, you need to disassemble it and get to the contacts to clean them with sandpaper or a thin flat file.

3 main disadvantages of IR heaters

- “The heater was installed, but it’s no use - it’s cold, as it was.”

- “I’m standing under the heater – it’s too hot and not comfortable. In the area of his work, everything is very hot."

- “When the device is working, it crackles, something in it taps when heated, it does not let you sleep.”

The company "Teplotema" does not stand aside - it hears the client and solves the problem. We study all reviews of infrared heating and the reasons why problems arise during their operation.The field of study of the operation of IR heaters is not limited to TM Bilyuks, we study similar equipment from all manufacturers, including foreign ones. Based on your feedback and wishes, we make adjustments to the design of devices, improve their practicality and functionality. Our ceiling heaters must be perfect - in economy, efficiency and safety.

Cons of infrared heating - how to fix the problem

Often, consumers do not bother to thoroughly study the rules for operating ceiling electric heaters, or they completely neglect the instructions. Today we have taken this issue upon ourselves and, at the request of the client, we perform a free calculation of the thermal and economic indicators of an object for heating. In addition, a team of our installers will perform the installation of an infrared heating system at almost cost. We guarantee you warm and reliable operation of the equipment (up to 25 years!).

The problem arises due to an incorrectly selected ceiling heater model, when its power does not match the parameters of the room. If it is not, then it is set either too low or too high. Each device has its own heat flow power, which determines the lower level of its installation above the floor level. You feel hot? — the device is too low. What if it's cold? This means that it is located above the floor above the norm, or its power is rather weak for this room.

It is important to take into account the fact of room insulation, as well as the concrete floor and walls, which require a lot of heat to warm up. And it can be given by a ceiling heater of the appropriate power

Of course, you will be cold if you deliberately install a low-power heater in an uninsulated room. In the model range of infrared heating, there are both very economical devices - low-power, but with very soft heat, designed for small insulated rooms. They are very comfortable and not hot. But there are also "monsters" - outdoor ceiling heaters or industrial heaters that can deal with frost and dampness in harsh conditions.

No less important - at what points and how are thermostats installed? If the thermostat is directly under the heater, it heats up quickly and turns off the appliance. Of course, in his "understanding" the desired microclimate has already been achieved

On the other hand, when it is located somewhere near the front door, or at the window, through which drafts and cold are blown, its “intelligence” works correctly - you need to heat and heat ... As a result, an excess of heat forms in the area of the heater, and you hot. Everything is simple - like everything ingenious.

In conclusion, for these reasons, you should not miss the fact that the TM Bilux heater is defective (rarely - but possible), or you are using equipment from another manufacturer that does not meet quality standards, and its product does not meet the passport data of the device.

Extraneous noise occurs due to deformation of the heater materials during heating or cooling. Moreover, this applies only to the outdoor series of heaters, in which the heaters are open and heated red-hot over 500 ° C. You can't get away from this. However, this series of devices is not used for home heating. Its purpose is the rapid heating of large and cold non-residential premises. It makes no sense for heaters of such high power to maintain a constant temperature all day, turning on and off: they work on demand - turned on for a certain time, then turned off. A little crackling or tapping will not create a problem or any discomfort.

In the household series of ceiling heaters, the heating elements are closed, their temperature is not higher than 400 ° C, and they work absolutely silently. For its equipment, TM Bilux uses only certified, very high quality materials that practically do not deform, never blacken, do not emit third-party odors.Heaters of this series should not knock, crack ... If there is such a problem, then you have equipment from an unscrupulous manufacturer who uses cheap materials in the design of the device.

Classification of oil coolers

Oil-filled electric heaters are classified as follows:

- Floor radiators. The most popular and widespread type of oil heaters. The device is equipped with special wheels for ease of movement. Often such devices are universal in terms of installation type, i.e., they allow the use of both floor and wall mounting.

- Wall radiators. With the help of brackets, which are equipped with such heaters, they are hung on the wall. Compared to floor structures, wall modifications are less powerful and have lower heat dissipation.

Plinth heaters. The latest modified development of the device with a wall-mounted arrangement. The device is placed at the bottom of the wall, which ensures good air circulation. It is used as a full source of heat, which is an alternative to central heating. Heaters with thermostat. In order to ensure uninterrupted operation of the device for a long time and reduce electricity consumption, electronic thermostats are built into the heaters that maintain the set temperature and exclude possible drops. Fan heaters. To speed up the heating of the air, the devices are equipped with built-in fans, which additionally redistribute the flow of air masses. The negative point inherent in these varieties is the noise during the operation of the fan.

Activities carried out as part of the service maintenance of climate equipment

- filter cleaning;

- front panel cleaning

- cleaning and antibacterial treatment of the fan;

- cleaning and antibacterial treatment of the evaporative heat exchanger;

- cleaning, treatment with antibacterial agents of the drainage system, checking the conductivity and functioning of the drainage system;

- checking electrical wiring.

- cleaning of the condenser heat exchanger;

- cleaning the module case;

- cleaning the ventilation mechanism;

- cleaning and checking the drainage system;

- checking electrical wiring.

- checking blower pressure and air suction force, evaporation temperature, airflow condensation and subcooling of the charged refrigerant;

- refueling of freon liquid (if necessary);

- checking the operation of the remote control.

An application for maintenance (in the list of documents - Appendix No. 1) is sent to fax +7 (495) 789-96-23 (ext. 9) or to klimat@30000.ru in a scanned form.

Departure of specialists for maintenance of climatic equipment is carried out within two days from the moment of processing the application by our specialists.

All activities within the framework of the maintenance of split systems and air conditioners are regulated and carried out in accordance with the Technological map for the maintenance of a split system (multisplit system) of air conditioning (in the documents - Appendix No. 2). The fulfillment of the tasks assigned to the specialists is confirmed by the signature of the client in the certificate of completion.

The warranty for the performed service work depends on the frequency of maintenance (6, 3 or 1 month).

Clogging of filters and air exchangers of modules with dust, fluff and other debris is not covered by the warranty case.

In case of a false call of specialists during the warranty period, an act of defect detection of equipment is drawn up (in the documents - Appendix No. 3).A false call is considered to be a call to specialists to repair devices whose performance has decreased due to clogging of air exchangers with household waste, violations of equipment operation rules and similar reasons.

All organizations face the need to retire old equipment. Computers, office equipment and other property must be disposed of according to the write-off act. Correct write-off requires an expert opinion on the condition of the equipment, which contains an assessment confirming the impossibility of further use. A specially created commission or an invited expert organization draws up an act of technical examination, on the basis of which it is possible to write off fixed assets from the balance sheet and dispose of them.

Property tax has to be paid for unused, but out of order or obsolete equipment. You can write off fixed assets gradually - through depreciation, but there is a shorter way - drawing up an equipment write-off act. It is recommended to write off material assets that:

- cannot be used because they have become unusable;

- do not exist according to the results of the inventory;

- obsolete;

- extremely worn out;

- damaged due to the impossibility or economic inexpediency of repair.

Every year, the head of the organization must issue an order appointing a commission to write off fixed assets. As a rule, the deputy director becomes the chairman of such a commission, and the chief accountant, economists and engineering and technical workers become members of the commission.

Oil for oil heater

The question of which oil is in the heater is rarely decided, because these devices are always hermetically sealed to prevent evaporation and leakage of the working substance. During operation, replacement is extremely rare.

If a depressurization has occurred, then adding oil will not be enough, first you need to repair the case and solder the leak. After the tightness is restored and if there is a technological hole for filling the liquid, it is possible to refuel or change the oil.

Various transformer, mineral automotive (transmission) and sometimes even waste oils can be poured into an oil heater

It is important to remember that it is impossible to mix oils of different origin in the radiator, because

an unpleasant reaction may occur (a precipitate will form, the composition will thicken, etc.). Topping up is allowed only a substance identical in composition. It is not recommended to do this on your own. It is better to carry out repair work in specialized service centers.

Rules for issuing an act

The act does not have a standard unified sample, therefore it is drawn up in free form or according to a template developed and approved by the company. It can be written both on a regular sheet of A4 format and on the letterhead of the organization, both in handwritten and printed form. The main thing is that it be certified by the signatures of all members of the special commission. It is necessary to draw up a document in at least two copies, depending on the number of interested parties. Each of the copies must be certified by original signatures.

The deed must contain

- information about the name of the equipment,

- his passport details

- specifications and other parameters.

The more complex the equipment, the more detailed it should be described, up to fixing the conditions of storage and operation.

Here you need to enter detailed data about the detected malfunction.

Sometimes photographs of the breakdown are attached to the act as an additional application, which must be approved by the head of the enterprise.

Two problems with thermostats

For wall-mounted models of cheap and middle class, the thermostat is located in the case. Sometimes the sound comes from it.Manufacturers of budget infrared heaters can use mechanical switches that will make clicks when the heating element is turned on and off. This is a rare occurrence, but it does occur.

Each heater has its own hysteresis. This is the temperature difference between turning the heater on and off.

Example

Let's say you set a temperature of +24 degrees on an infrared heater. In this case, the hysteresis of the thermostat is 3 degrees. The heater will work as follows:

When the room temperature warms up to +24 °C, the heater will turn off. The room will gradually cool down. When the sensor sends information to the thermostat that the temperature has dropped to +21 degrees, it will turn on again.

The difference between +21 and +24 °C is called hysteresis.

Not all thermostats can be set to the desired hysteresis. Some manufacturers make it too small or too big. Because of this, the heater may crack because:

- It turns on too often, which may cause the thermostat to click;

- Rarely turns on. The elements of the heater have time to cool down and their mutual displacement occurs, which causes clicks;

- It works for a long time, which causes vibration of the heating element spiral.

There is no optimal hysteresis. It all depends on how well the room warms up and how quickly it cools down. If you have the opportunity to set the temperature difference yourself - experiment. If not, call a specialist. Or install a thermostat with the ability to adjust the hysteresis.

Malfunctions of Nobo heaters

In Nobo heaters, as in any other devices, malfunctions may occur during operation. However, failures due to the fault of the manufacturer make up 0.01% and that is why the warranty period for these heaters is 10 years, and the service life is calculated for 30 years. Most cases of malfunction occur due to the fault of the buyers themselves, who violate the rules for the operation of convectors. Let's try to consider the most common violations in the operation of heaters and what should be done to avoid such violations.

2. The convector switches itself from the “economical” mode to the “comfortable” mode.

This phenomenon can be observed in non-programmable thermostats that can operate in two modes: “COMFORT” and “ECONOMIC”. In the event of a temporary power outage and its subsequent activation, the convector automatically switches to the "COMFORTABLE" mode, regardless of the mode in which the convector worked before the power outage. The same phenomenon may occur if the voltage in the network deviates from the prescribed voltage values of 230÷240±10%. I would like to note the peculiarity of the operation of electrical appliances in our country houses. Often (say, when a neighbor uses a welding machine) frequent and sudden power surges are observed. Such critical operating conditions are not provided by the convector manufacturer. The convector may not be able to cope with such sudden voltage drops and burn out.

Actions: connect the convector through a voltage stabilizer.

3. The convector often turns off due to overheating.

Switching off the convector due to overheating may occur if the convector is selected and installed incorrectly. The standard selection of a heater is calculated at the rate of 1000 W per 10 sq.m. If you install a convector of much lower power, the heater will not be able to heat the air to the set temperature, it will constantly work and, as a result, turn off due to overheating.

The same phenomenon can be observed if the convector is chosen correctly, but installed incorrectly. The temperature sensor of the Nobo heater is located at the bottom of the convector and measures the temperature of the air entering the convector.However, if you install a convector, where there is a constant flow of cold air, then the convector in its work will start from this temperature and try to heat the air to the set value. But a constant influx of cold air will not allow you to accurately track the temperature of the air in the room. The convector will constantly work also due to overheating.

Actions: ensure free inflow of incoming air to the bottom of the convector and free outflow of hot air from the top of the convector.

4. It is warm at one end of the room and cold at the other end of the room.

This phenomenon can be observed if the convector is chosen correctly, but the installation site is chosen incorrectly. For example, in a room of 20 sq. m. installed one convector 2000 watts.

Actions: Ideally, it is better to install 4 x 500 W convectors in places where there is more cold inflow (under windows, along walls that face the street). Of course, it is not always possible to install 4 convectors, then you have to find a compromise between the number of convectors and the quality of space heating.

In cases where the convector breaks down or does not work and this malfunction is not the fault of the consumer, you should contact our service center and the malfunction will be fixed under warranty and free of charge.

Oil cooler device

Different models of heaters may have a different number of heating elements, thermostats and switching devices for connection and connection. They also have forced airflow systems to enhance convection and increase heat transfer.

The heating elements are housed in an oil-filled, sealed housing with ribs, covered with a durable dielectric powder coating. Switches are attached to the heater from the outside. All connections of heating devices and external control elements are connected through a hermetic coupling.

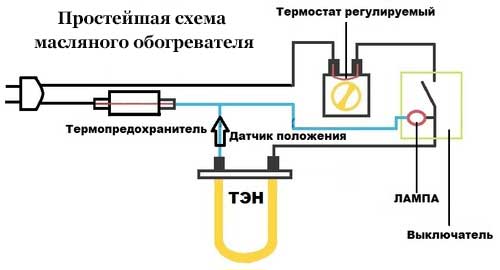

The oil heater circuit is designed as follows: a power cable with a plug is connected through switches and a thermal fuse to the heating elements. At the same time, the thermal fuse provides a break in the supply circuit in case of emergency overheating of the device. The latest models of oil heaters are also equipped with a position sensor that turns off the device in case of a fall or a critical deviation from the working condition.

Advantages and disadvantages

Oil-filled electric heating radiators have a number of positive qualities, including:

- Compactness. These batteries take up little space.

- Mobility. Most models, thanks to the wheels, can be easily moved from room to room.

- Safety. The metal case does not heat up above +60…+70°C, which eliminates the possibility of burns and injuries. All working elements heated to high temperatures are inside the casing.

- Silence. Oil batteries do not make noise during operation (except for models equipped with fans).

- They do not dry out the air in the room, do not burn out oxygen and do not emit unpleasant odors (compared to devices with open heating elements).

- Democratic price.

- Ease of operation. It is enough just to plug the cord into the outlet and follow the simple rules.

The disadvantages of such structures include the following qualities:

- Inertia. Mineral oil takes a long time to reach the operating temperature (due to its high heat capacity) and the room is heated slowly. But the liquid does not cool down immediately, gradually giving off the accumulated heat.

- Sufficiently large weight and dimensions, which is not always convenient. The disadvantage is compensated by the presence of wheels.