Oil evaporation technology

In furnaces of this type, it is not oil that burns, but its vapors. That is, mining is heated up before the start of combustion, it begins to evaporate, and already the vapors are ignited. This technology allows dirty, heavy, poorly burning fuel to be decomposed into lighter components, and then burn them. It is she who, with the right parameters, makes it possible to achieve almost smokeless and complete combustion of fuel, in which there are practically no emissions: everything burns out.

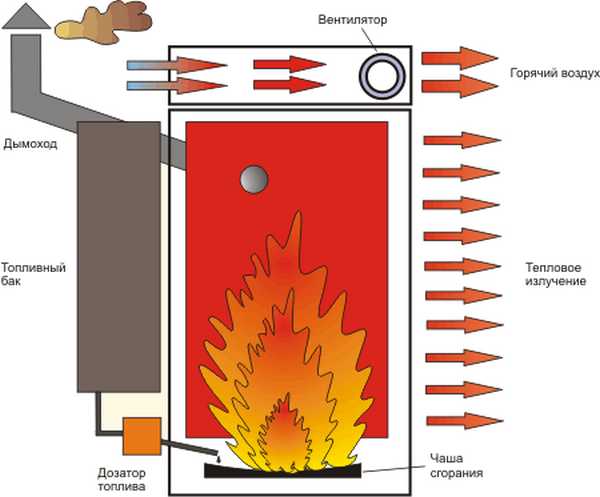

Do-it-yourself boiler for working out: the principle of a boiler for evaporating oils

The easiest and most effective way to implement this technology is to use a red-hot bowl into which mining is dripped.

When in contact with hot metal, the oil evaporates sharply, the vapors mix with the air supplied here, flare up and burn out. The amount of heat generated in this case is large. To achieve maximum efficiency and complete combustion, it is required that the burning mixture be in the combustion chamber for a long time. Therefore, at the mouth of the duct, it is necessary to install a fixed impeller, which will create the required turbulence in the combustion chamber.

Do-it-yourself steam boiler for working out can be implemented in this form

Despite the high efficiency and “omnivorousness”, this principle of operation is rarely implemented in factory boilers manufactured in the USA and Europe. On the other hand, Russian manufacturers produce mining boilers that work specifically on evaporation technology. The main stumbling block in the implementation of such boilers is the method of preheating the bowl. Those who make these boilers on their own do it simply: they throw a wick soaked in gasoline into the bowl, pour a little diesel fuel or the same gasoline, set it on fire, waiting until the bowl warms up to the required temperatures. After that, open the oil supply.

In Europe and the USA, such a solution is unacceptable: it is unsafe. But our manufacturers also use this method of ignition of their stoves.

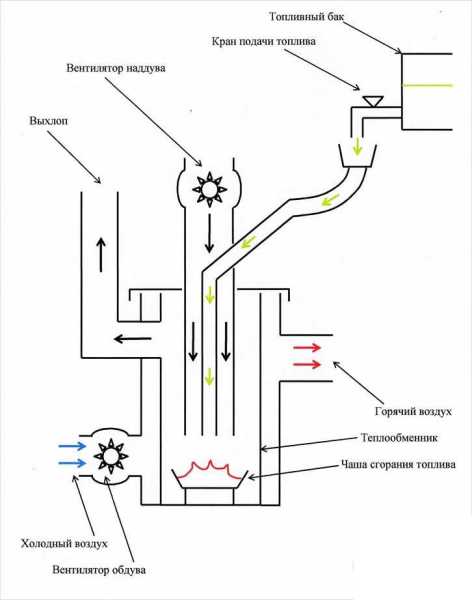

Another version of the plasma bowl oven

The video demonstrates one of the options for heating a garage with a working furnace. But in this embodiment, a non-drip fuel supply is implemented: it flows in a trickle and burns far from completely

It is for this reason that the author of the project paid such attention to the insulation and sealing of all removable parts: in order to minimize the ingress of smoke into the room and made a high chimney for better draft

Oil boiler

In principle, a liquid fuel boiler (or several twin boilers) can be used as a boiler station, but then it is more profitable to heat it with fuel oil, because with the same consumption of fuel oil and gas, the specific heat released from gaseous fuel is much less. True, there is one sin with such heating devices, which not only spoils the overall picture, but makes you think about the fundamental installation. We are now talking about ignition (beginning of operation), which is the basis of the boiler and the beginning of the heating season. It is no secret that any hydrocarbon is eventually a combustible material (some require appropriate processing), but, unlike gasoline, oil and diesel fuel start the combustion process at higher temperatures (this can be seen if you try to light a few drops of gasoline from a match and oil).

The design of the boiler for liquid fuel

That is, all other things being equal, heavier hydrocarbons have a higher ignition temperature, from which it can be concluded that the design of a liquid fuel boiler must have a serious igniter and heat-resistant heat exchanger elements.Diesel fuel, fuel oil and oil provide stable and long-term combustion, provided that fuel is systematically added to the combustion chamber.

The simplest device for a liquid fuel boiler

The easiest option for understanding and describing the properties of these types of boilers is a do-it-yourself stove with a dropper. A firebox standard for stoves has a door for kindling with ordinary wood, and at the top there is a steel dropper through which fuel enters directly into the combustion chamber. To ignite the unit, it is necessary to flood it, like a conventional stove, let it heat up, and then open the dropper to a minimum. Adjusting the dosing of liquid fuel automatically increases or decreases the combustion temperature, and the combustion force (intensity) is regulated by a blower (supply ventilation). The smaller the volume of incoming air, the weaker the combustion, the more conserved the fuel and the more stable the heating temperature.

Heating on liquid fuel can only be organized with an uninterrupted supply of fuel, therefore it is not recommended to extinguish boilers on liquid fuel for a short time (only for the summer period). Creating conditions for the correct supply of flammable liquid and timely replenishment of the stock in the tank creates another nuance - a characteristic smell.

Pros and cons

Among the qualitative and technical indicators, there are no unequivocal minuses or pluses, since some, at first glance, negative features may be for the sake of expanding the list of positive points. Everything has already been discussed in the article, but it will not be superfluous to recall and classify all the nuances.

So the pros:

- autonomy (in this case, we should talk about isolation from engineering systems and electricity);

- depending on what fuel can be used: if only one type is a minus, and if the boiler is represented by a combined system, this is a plus;

- stable combustion and maintaining an even temperature (subject to the same dosage, maintaining combustion, even with wind or precipitation, is not difficult).

As 100% cons, we note:

- heavy heating of the fuel to reach the ignition temperature;

- lack of pauses in the operation of the heater (unjustified fuel consumption);

- regulated minimum temperature in the system (each has its own and depends on the volume of the coolant, the size of the combustion chamber and the density of the hydraulic piping).

Do-it-yourself waste oil boiler (video)

https://youtube.com/watch?v=E22zPchFpzk

Oil powered device

Due to the special operation of the burner, the diesel boiler will not operate on fuel oil or waste oil. Additional burners for modernizing a diesel fuel boiler are very expensive, but it is not a fact that after changing the configuration of the unit with your own hands, it will work stably.

The oil fired boiler has the following advantages:

- incredibly high thermal conductivity;

- low rate of ash in the device;

- luminous flame, which contributes to the occurrence of radiative heat transfer in the furnace;

- can be used in both large and small boilers;

- extraction and storage of fuel oil;

- high price when buying "clean" fuel oil;

- high pour point + 25-30 o C.

The purchase of this kind of boiler is beneficial only if there are enough volumes of fuel in constant access. Otherwise, the unit will be expensive and will not pay for itself at all. Oil-fired boilers are predominantly used in places where this fuel is processed by one's own hands or created.

Liquid fuel boiler on diesel fuel

A widespread type of liquid fuel units is diesel fuel. They are low cost, high efficiency and easy to use. House heating units using liquid fuel - diesel fuel - do not require special permission for installation in a local heating network. They can be modified with your own hands: connected to the gas main.

The diesel heating unit has a design that includes:

- diesel burner;

- fuel filters;

- pump;

- a separate control panel for the automated system;

- safety sensors to maintain stable combustion and the required temperature of the coolant in the system.

- The fuel is mixed with air in an inflatable burner.

- Mixed with air, it passes into the combustion chamber thanks to a powerful fan, where it burns out.

- The coolant heats up, as do the walls of the chamber in which it is located.

- The gases formed during operation leave the device system through a special chimney provided by the design.

Due to the fact that a diesel fuel boiler is not much different from a gas boiler. and it is possible to reconfigure it yourself, since the key difference lies in the type of burner. But their modification with their own hands is possible only for diesel fuel boilers with a mounted burner. With the built-in such a trick will not work.

Do-it-yourself re-equipment of the firebox with the help of the parts included in the boiler package should take place only according to the proposed drawings and nothing else.

calculate the fuel consumption of the device and its heat output

This is easy to do, thanks to the formula: boiler power in kW / 10 = kg of fuel per 1 hour of operation. For a region with average climatic conditions, 3 tons of solarium will be needed to supply a building with an area of 300 m 2 with a coolant. On average, 0.1 l / h per 1 kW of device power. Consumption may vary depending on the needs of residents in temperature - if someone feels comfortable at a temperature of 22-24 ° C, then for others it will be optimal from 25 ° C. And the higher the temperature, the greater the fuel consumption.

Liquid fuel boilers overview of models and selection of the best

This series of models is produced by De Dietrich (France). Boilers are made of cast iron, have a power of 21 to 39 kW. They can be provided with one of three systems for adjusting the operation of the unit (the buyer can choose) - manual, remote, automatic adjustment. It is possible to convert to gas with the condition of replacing the burner. The model costs approximately 71,200 rubles.

Delta Pro 25/45/55

Manufacturer - Belgium (ACV). The purpose of these installations is domestic use, mainly not only for heating, but also for providing the residents of the house with hot water - a tank for heating water is connected to the heating circuit. The liquid is heated to +30 degrees in about 10 minutes. The boiler can be converted to use gas fuel. The cost is from 160,000 to 202,000 rubles.

Kiturami STS Oil

South Korean boilers are in great demand due to their low price (from 28,920 rubles). However, they are of excellent quality. They are made of stainless steel, lightweight and durable, as well as compact.

Bison 30NL/40NL/ 50NL

Producer - Slovakia (firm Protherm). This range of models combines several units that work perfectly with liquid fuel. They differ in power, which directly depends on the number of cast iron sections in the heat exchanger. A viewing window helps to monitor the operation of the equipment. The units also provide water heating. Interestingly, the manufacturer calls the boilers the names of animals. The equipment can be converted to use gas fuel - the burner is purchased separately. Cost: 46,100 - 74,600 rubles.

These Korean boilers serve at least 10 years, according to the manufacturer. Their power starts from 11 kW. The units are equipped with a turbocharged burner built inside. Due to this, it was possible to achieve noise reduction. Boilers of higher power (from 40 kW) are equipped with a burner with gear pumps. The boiler will cost from 38,580 to 49,850 rubles (depending on the specific modification).

The manufacturer of these boilers is Germany (Buderus). They work perfectly on liquid fuel, if necessary, they are easily converted to gas. Differ in reliability, efficiency, safety.Very economical - this was achieved through a unique control system that monitors weather conditions and is called Buderus Logamatic

And, which is also very important, the boilers of this company look very presentable. The average market value is about 125,580 rubles

Device and principle of operation

As mentioned above, liquid fuel heating boilers are structurally similar to two-way and three-way gas boilers. By virtue of their design, the products are produced in the floor version.

For reference. In boiler plants with a fire-tube heat exchanger, the combustion products can change direction several times, making several passes through the flame tubes and intensely transferring heat to the water jacket. According to the number of moves, the heat exchanger is assigned a characteristic - three-way or two-way.

The similarity lies in the design of the heat exchanger from the flame tubes enclosed in a water jacket. In the very center there is a chamber for burning fuel, only for a diesel unit it has a cylindrical shape. This is due to the design features of the burner device using liquid fuel. The main elements and details are shown in the figure.

installation of a Viessmann oil-fired boiler

A - outer heat-insulating shell; B - heat exchange surfaces of flame tubes; C - combustion chamber; D - electronic control unit; E - burner device.

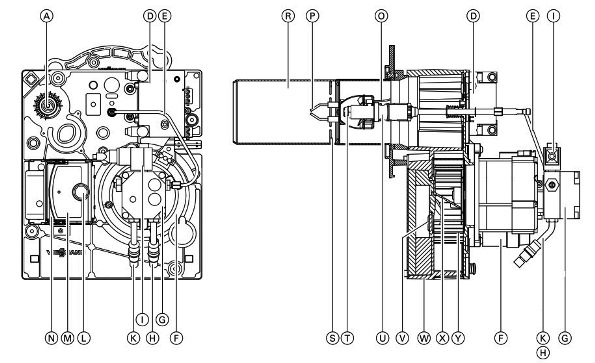

In the products of leading foreign manufacturers, the firebox is made of heat-resistant stainless steel, budget domestic heat generators can also be made of ordinary thick metal. The material of the heat exchanger is cast iron or steel; basalt fiber or dense polyurethane foam is used for thermal insulation. A burner that runs on liquid fuel and is of particular interest, its design with a breakdown of the elements is shown below.

Diesel burner drawing

A - air control throttle; D - block of the ignition system with a flame control sensor; E - fuel line; F - fan motor; G - pump; K, H - supply and return pipelines for fuel; I – electromagnetic valve; L - fault signal reset button; M - automatic heating control; N - console; O - ignition cable; P - electrodes of the ignition system; R - cylindrical working part; S - mixing device; T - nozzle; U - rod with fuel heater; V - air intake device; W - burner body; X - air channel; Y - fan impeller.

The working part is made in the form of a cylinder with many holes through which the flame passes. When the combustion of fuel occurs, the flame of the burner heats the cylindrical walls of the furnace, as shown in the photo.

Diesel burner operation

A special container is intended for fuel, it can be free-standing or suspended from the wall, a supply line is laid from it to the burner. Some burner devices have a return fuel line for pressure relief, then the installation of the boiler and its connection are provided by two pipes - supply and return, going into the fuel tank. Ignition is performed automatically at the command of the control unit.

How to make a liquid fuel boiler with your own hands

What will be needed in the process of work:

- welding machine;

- angle grinder (grinder);

- metal barrel with a volume of 200 l;

- trimming reinforcement (W 15 mm and length from 3 cm).

If there is no barrel of a suitable size, you can make it yourself, from sheet metal, for this you will need pipes with a diameter of at least 5 cm and a length of 80 - 100 cm. An all-metal circle with a thickness of 4 mm or more can be used as a bottom.

- Inside the barrel, it is necessary to weld three supports parallel to the ground: the first will be needed for the installation of the furnace itself, the second at the level of the blower door in the boiler, and the third 20 cm above the pipe.

- For the manufacture of grate (a cast-iron grate through which air penetrates under the fuel), it is necessary to make a metal circle with slots, the thicker it is, the better. The grate partition is located inside the boiler.

- In the lid of the boiler, which, like the grate, must be made of a thick metal circle, a hole is made for attaching the chimney pipe.

- In order to get a hole for the stove doors, you will need to make a slot in the bottom of the structure, the door should be slightly larger than the hole. Also, inside the box it is necessary to make a partition, it will separate the ash and furnace compartments.

8 Sime RONDO 3

The performance of a combi boiler that works not only on diesel fuel, but also on natural gas, can provide efficient heating of rooms up to 240 sq. meters. The heavy-duty cast iron sectional type heat exchanger is highly reliable and capable of many years of uninterrupted operation. Operation in low-temperature modes allows significant savings in energy consumption. In this case, no harm will be done to the liquid fuel unit.

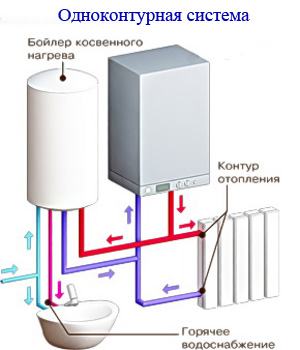

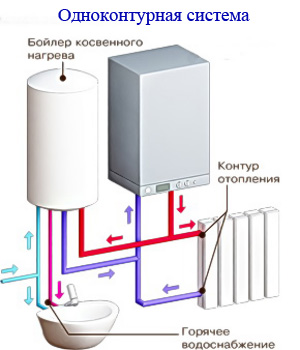

The processor unit controls the operating mode of heating, which is best connected to the network through a stabilizer. In addition, there is the possibility of integrating external control. This function is very convenient for the home - especially if the boiler is located in a non-residential area that does not have communication with the residential part of the building. The efficiency of the unit is 94.6%, which is a decent indicator for an atmospheric boiler. It can also be used to organize hot water supply - for this you just need to add an indirect heating boiler to the heating system.

Classification

Depending on the possibilities of heating water, diesel heating boilers are divided into

- single-circuit, which are not intended for heating water;

- double-circuit with heating element or storage boiler.

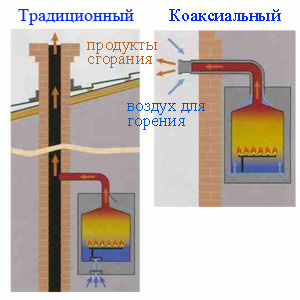

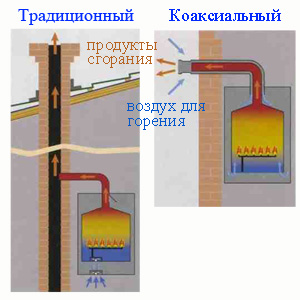

Diesel boilers can have natural draft when gases are removed through a chimney or forced draft.

Forced draft is provided by draft fans and requires the installation of a coaxial chimney (it is built on the “pipe in pipe” principle - combustion products are removed through the inner pipe, and combustion air through the outer one).

A feature of oil boilers is the presence of an oil heating system.

Almost all modern models have automatic control, a built-in thermostat, operation control sensors, forced removal of combustion products.

3 Buderus Logano G125 WS-25

The single-circuit boiler Buderus Logano G125 WS-25 with high efficiency (96%) has a number of innovations. German engineers managed to achieve high performance due to the coordinated interaction of the heating boiler, burner and control system. The device is characterized by silent operation, this is achieved by optimizing the mixing system. The boiler is simple and easy to operate, all functions are regulated by pressing or turning the corresponding keys. It can be connected to any chimney and soot is kept to a minimum, making periodic maintenance easy. The model is perfect for heating homes, shops, offices up to 230 sq. m.

The owners of cottages and retail facilities in the reviews flatter about the performance of the Buderus Logano G125 WS-25 boiler, its ease of operation and maintenance. The disadvantages of consumers include the high price of the device and spare parts.

How to store solar

Perhaps this is the very first question that confronts the owners of a diesel boiler. And it's true: the storage of liquid fuels is subject to special requirements to ensure your safety.

There are 2 types of storage tanks for diesel fuel:

- open-mounted - are plastic barrels made of polyethylene or PVC.Their kit must necessarily include a system for taking fuel from the tank, a sealed cover and a float to determine the level of liquid in the tank.

When can they be used? For fuel storage in small country houses, if the planned volume of diesel fuel does not exceed 1000 liters.

Tank for storage of large volume of fuel

- closed installation - most often made of galvanized iron, however, it has recently been possible to use chemically resistant plastic. They are installed in a pre-dug pit, which should be at a distance of at least 5 meters from the foundation of the house. In this case, the system must be equipped with a pump to supply fuel from the depth.

When can they be used? They are indispensable if you are going to store a large amount of diesel fuel (up to 20,000 liters).

Such systems must be equipped not only with level sensors, but also with fuel leakage sensors. Diesel fuel for filling the barrel is delivered by a special service for the sale of fuels and lubricants.