The device and principle of operation of Thermona boilers

The Czech company Thermona produces gas boilers in wall and floor installation methods, which are single-circuit and double-circuit. The principle of operation of Thermon units does not differ from the principle of operation of other gas boilers.

The boiler consists of a gas block, where the gas is ignited, a water block, in which the coolant is heated due to the energy released during the combustion of gas. The pump delivers heated water to the heating pipes.

The expansion tank is used to protect the device from excessive pressure. The exhaust carbon monoxide is discharged through the chimney system to the outside. All work of a copper is controlled by automatic equipment and protective sensors.

Wall units

The power of wall-mounted boilers ranges from 14 to 90 kW. They are made with the possibility of flowing and indirect heating of hot water supply in the tank.

Can work from the main and liquefied gas. Equipped with stepless automatic flame modulation, three-stage circulation pump with protection, protection devices against overheating, carbon monoxide leakage, freezing, automatic bypass. They have automatic ignition, which saves gas consumption.

They differ in the way the products of gas combustion are removed - with natural draft through the chimney (models where an open combustion chamber is installed) and through a coaxial chimney, when exhaust gas is removed through the inside of the pipe, and air enters through the outer part for the operation of the unit (turbo closed combustion chamber models) .

According to the method of operation, they are divided into convection and condenser. Classical condensing units such as Thermona 28 LXZ.A have a steel burner and a copper heat exchanger. Convection ones differ from condenser ones in the presence of an additional heat exchanger, an economizer installed on the exhaust gas exit path and using the heat of combustion products. Such models have a high efficiency of about 107%.

Floor boilers

Floor-standing boilers of Thermon differ in non-volatile, where the energy to maintain the operation of the security system is generated by an internal thermogenerator and volatile. The Therm R/B heat exchanger is made of cast iron sections with an improved design, which allows to increase the efficiency of the unit.

A reducer is installed in front of the gas burner, which smoothly regulates the fuel supply and the power of the unit. Type of ignition - electric ignition. Boilers operate with natural circulation of the coolant. Models of the Therm E/B series with connection to electricity are used only for heating. A series of Therm EZ / B devices work on heating the liquid, and on heating the room.

Basic error codes

During the operation of Thermona gas boilers, various malfunctions and malfunctions may occur, which are displayed on the screen in the form of error codes. Some can be eliminated by resetting the error, if the code reappears, intervention is required to resolve them. The main ones, and what needs to be done and checked, we will consider below.

Error e01 (e1) occurs when the ignition of the boiler fails.

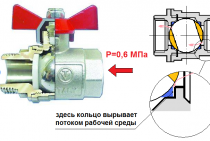

Error e02 (e2) indicates a low pressure in the heating circuit.

Check the following:

Error e05 appears when the hot water sensor malfunctions.

In such a case, you need to check:

Error e06 indicates that the boiler is overheating.

To fix it, check:

e08

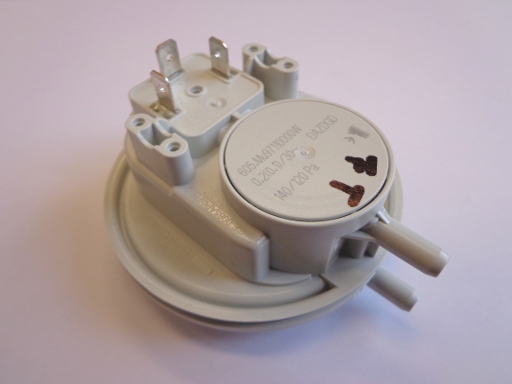

Error e08 (e8) appears in case of problems with smoke removal or a failure of the manostat in boilers in turbo boilers.

The reasons for its appearance:

e12

Error e12 means a small flow of water into the heating system. The causes and methods of elimination are similar to the description of error e02. Additionally, check the microswitch on the flow sensor by measuring its resistance and connecting the wires to the control board.