Freestanding firebox

A separate boiler room is intended for high power units - over 200 kW. But if you need to preserve the architectural appearance of the house, then it makes sense to build such a structure for a lower power boiler.

Modern polymer materials and technologies make it possible to lay underground communications for supplying heated coolant and hot water from the boiler room - a high degree of thermal protection will minimize the loss of thermal energy during the transportation of heated liquid.

A separate boiler room is being built from:

- fire-resistant materials (building blocks of various types, bricks);

- it is allowed to use metal sandwich panels with a non-combustible thermal insulator inside;

- non-combustible roofing material is used;

- reinforced concrete flooring is used for the floor.

Room requirements:

- ceiling height in a separate building should be from 2.5 m;

- when calculating the volume of the room, 0.2 m2 is added to the minimum value (15 m3) for each kilowatt of heat generator power;

- under the boiler weighing more than 200 kg, a foundation is mounted separate from the base of the building, the height of the podium above the floor level is up to 15 cm.

Standard requirements are put forward for doors, ventilation and chimney arrangement.

economy

- Which boiler provides the cheapest heating (see Boiler in the basement: do-it-yourself installation)?

Here is the rating of heating equipment for this parameter in 2017 prices:

| Thermal energy source | The price of a kilowatt-hour of heat, rubles |

| main gas | 0,7 |

| Dry firewood | 1,2-1,4 |

| Coal | 1,5-1,7 |

| Pellets | 1,6-1,8 |

| Diesel fuel | 3,4-4,0 |

| Electricity | 4,0-5,5 |

If your house is gasified, you are provided with cheap heat

However, there are a couple of solutions that can significantly reduce costs when using expensive electricity for heating needs.

The heat pump uses electricity not for direct heating, but for the operation of a compressor that circulates the coolant between two heat exchangers - an internal one that gives off heat to the heating system, and an external one located in the ground, under water or in the air. The highlight of the design of the heat pump is that it is able to take thermal energy from a relatively cold environment to heat a hotter one.

Monobloc air source heat pump

Not only that: the amount of heat transported to the house from a low-grade heat source is 3-6 times higher than the amount of electrical energy consumed to operate the compressor. This feature allows electric heating using heat pumps to successfully compete with solid fuel boilers.

You get most of the heat energy for free

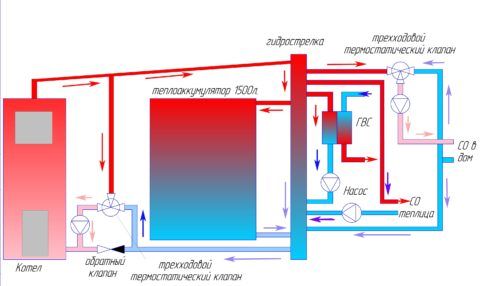

Another solution to reduce the cost of heating the basement with electricity is the use of a heat accumulator (a heat-insulated large-capacity water tank). Complete with a two-zone meter, it is able to reduce the cost of a kilowatt-hour of heat to 1.5-2 rubles.

Heat accumulator in the basement

How does this scheme work:

- At night, the electric boiler operates at rated power, maintaining heating and heating the water supply in the accumulator;

- Nightly electricity consumption is paid at a lower nightly rate;

Meter with separate accounting for day and night energy consumption

During the day, the boiler is turned off, and the water continues to circulate between the heat accumulator and the heating devices, gradually giving them heat.

Heating circuit with a heat accumulator

Sources

- https://ProPodval.ru/mikroklimat/uteplenie/mozhno-li-gazovyj-kotel-ustanovit-v-podvale-chastnogo-doma.html

- http://jsnip.ru/vodosnabzheniya/trebovaniya-k-gazovym-kotlam-v-chastnom-dome.html

- http://avtonomnoeteplo.ru/otopitelnye_kotly/384-mozhno-li-ustanovit-gazovyy-kotel-v-podvale.html

- https://ProfiTeplo.com/sistemy-otopleniya/110-kotelnaya-v-chastnom-dome.html

- http://bouw.ru/article/normativnie-trebovaniya-k-gazovoy-kotelynoy-v-dome

- https://v-teplo.ru/trebovaniya-k-kotelnoi.html

- http://obustroen.ru/inghenernye-sistemy/otoplenie/kotly/gazovaya-kotelnaya.html

- https://pogreb-podval.ru/planirovanie/kommunikacii/kotelnaya-v-cokolnom-etazhe-435

Features of installing gas equipment in the basement

Placing a gas boiler in the basement is convenient for people living in a private house, but this is not always allowed. The exceptions for a long time were liquefied hydrocarbon gas systems, which were used everywhere for a long time.

Boilers of such a system operate on fuel extracted from oil. As soon as natural gas became widespread and special equipment for residential buildings was produced for it, restrictions on installation in basements were completely removed.

Now the requirements of SNIP allow up to 4 gas units of any type located in the basement, the total power of which should not exceed 200 kW. The degree of security is so high that their location is possible even in the attic.

One of the main requirements before starting installation work on the installation of gas equipment is an approved boiler room project. This must be done before starting the system, since its operation is a factor of increased fire hazard, as a result of which it may be prohibited by the fire inspection. In this case, it comes even to the dismantling of the boiler room or the restructuring of the system.

Ventilation system of the boiler room

In order for the heater to function as efficiently as possible (and the principle of its operation, we remind you once again, is based on the combustion of gas and the subsequent release of heat), it is necessary that fresh air constantly enter the room, which is essential to remove fuel combustion products. In most cases, in order for the air exchange in the boiler room to reach the required level, normal natural ventilation is sufficient. Dilapidated doors and window frames, as well as a number of other places where there are gaps for one reason or another, provide an ample amount of fresh air. But if all this is not enough, since the room is sealed, then it is advisable to look at the possibility of equipping an additional ventilation system. And if this is not done, then the combustion products will remain inside the room, leaving behind traces in the form of soot and soot on all surfaces. Moreover, the unattractive appearance of the furnace is only the smallest problem that will befall you in the absence of proper ventilation.

1 Building codes and regulations governing the gasification of private houses

The main document regulating the gasification of a private house is SNiP “Gas supply of a country house. Requirements and rules for the installation of gas equipment. It will be useful to familiarize yourself with the documentation on fire safety, installation of ventilation pipelines, laying of water supply and sewer systems. There is a trip to the authorities, and the information will not be superfluous.

For gasification of a private house, it is necessary to obtain technological conditions

Gasification of a private house begins with obtaining technological conditions. This document is basic when connecting to a gas pipeline; to obtain it, you need to contact the gas supply service. The application indicates the planned gas consumption for your home.

The calculation is made on the basis of average statistics:

- For cooking on a gas stove, 0.5 cubic meters are consumed. m / day;

- Using an instantaneous water heater (gas column) -0.5 cubic meters. m / day;

- Heating is the main consumer of "blue" fuel. Its consumption depends on the power of the boiler. For central Russia it is 7-12 cubic meters. m / day.

The submitted application is considered by specialists of the local gas supply service. As a response to a written request, they prepare specifications or issue a justified refusal. The review process depends on the speed of the service, but on average varies from 1 to 4 weeks.

The technical conditions received in hand, this is the permission to gasify the house.Self-installation, without permits, is considered illegal and extremely dangerous to human life and health.

Recommended

Expansion tank requirements

The hot coolant exits the boiler into the distribution manifold and is pumped into the heating system by a circulation pump. As required by safety standards, an expansion tank must be installed in the system to compensate for water intake and an emergency pressure relief valve. A water supply device for the main heating circuit is also embedded in the system.

Recently, two-layer polypropylene pipes with an aluminum amplifier have been used to make the heating circuit. SNiP allows the use of plastic certified pipes for heating systems, subject to the requirements for the coolant: pressure not more than 3 bar and temperature not more than 105 ° C.

The operation of the gas boiler is provided by a system of gas supply, burners and automation that controls the process of burning natural gas. One or two electric fans supply air to the combustion chamber.

Often, two boilers are installed in gas boilers - the main one, designed for the design heating capacity, and an auxiliary one. The smaller one is in demand for hot water during the absence of heating.

3 Features of gas boilers that affect the boiler room at home

Paperwork is left behind, and you can proceed with the installation of the boiler. But keep in mind - the type of boiler affects the requirements for SNiPs for the boiler room at home.

There are single and double-circuit heating gas boilers. The first of them serve exclusively to maintain a comfortable temperature in the house, the second are integrated into the water supply system. That is, a double-circuit boiler not only heats, but also provides the house with hot water.

The gas boiler in the house depends on other characteristics. Ventilation is essential for the safe operation of hot water boilers. There are heaters with natural and artificial ventilation. It depends on what will be the boiler room in a private house.

Air enters boilers with natural ventilation from the rooms of the house, and combustion products are discharged into the general air purification system. Devices with artificial supply and exhaust circulation take air from the atmosphere outside the building, and the remains of the burnt fuel are removed to the street through the chimney.

The device with artificial ventilation can be placed indoors. As a rule, such boilers are used in houses and cottages with a solid area. For a small house, where every meter counts, this is not the best solution. The best option in this case is a boiler room separate from the house.

2 Design documentation for a gas boiler house

Project documentation is developed by design specialists, whose right to this activity is confirmed by the relevant papers. The project reflects the scheme of laying gas communications along the personal plot to the entrance to the boiler room. This point must be reflected in the sketch.

Project documentation for a gas boiler house should be handled by specialists

The prepared project must be submitted to the service that controls the gas supply at home. Other documents to be submitted along with the application:

- Technical passport of the gas heating boiler;

- Operating Instructions;

- Certificates of conformity of the boiler to SES standards and documentary evidence of its safety for people and the environment.

All these documents are drawn up by the boiler manufacturer and given to the buyer upon sale. Consideration of an application for gasification of a house can take up to three months. Depends on the complexity of the project. The minimum period is one week.

Based on the results of verification of the submitted documents, the commission issues a positive verdict or a justified refusal. In the latter case, the applicant is invited to eliminate the identified shortcomings and resubmit the documents.

Requirements for a basement room with a boiler room

Boiler rooms in the basement of a residential building are subject to certain requirements for arrangement, in accordance with which the following requirements must be met:

- The room must be more than two meters high. Optimal is 2.5m;

- The boiler room must be isolated from the living rooms of the house, in which the installation of gas equipment is strictly prohibited;

- The placement of one boiler must account for at least 4 square meters of the room, moreover, the system must be located at a distance of one meter from the wall of the building;

- Access to the boiler must be free from any side, so that it can be quickly turned off or repaired;

- The boiler room must have a window with an opening of at least a quarter of a square meter. The recommended size is 0.03 sq.m. per cubic meter of basement;

- The door to the basement should be comfortable and safe, with an opening width of at least 0.8 meters;

- The floor covering can be a cement screed, but not linoleum or laminate. All combustible materials are strictly prohibited. It is recommended to finish the floor with tiles or tiles made of refractory materials;

- All wall and ceiling surfaces must be treated with fire-resistant materials and sheathed with tiles or tiles. If there are things around the boiler room that are vulnerable to burning, they must be covered with special shields with insulation;

- At the entrance to the boiler room, ventilation vents must be made, as a rule, pierced at the bottom of the door;

- A boiler room with a gas unit requires the arrangement of a supply and exhaust air exchange system;

- Access to the premises is restricted to unauthorized persons, except for repair teams or maintenance personnel. Children and animals are strictly prohibited from entering the boiler room.

These requirements are dictated for the safety of people living in the house. In addition, this allows you to use the equipment in the most optimal mode. Failure to comply with these requirements leads to fires and accidents, since the small size of the room with a gas boiler is very favorable for the emergence of a fire source and its subsequent spread.

All restrictions on room volumes apply to boilers with an open combustion system. Almost all modern models are equipped with a sealed firebox, but if old equipment is in operation, then the dimensions of the room can be 7.5 cubic meters, 13.5 or 15 cubic meters for boilers with a capacity of 30.30-60 and 60-200 kW, respectively.

All modern models can be located on any volume of the basement, but in the case of location in the basement, it is necessary to equip a separate exit to the street. All outlets are immediately made of refractory materials.

After the building is put into operation, and the boiler room is not equipped, living spaces should not be allocated for these purposes. It is recommended to build a separate building, an extension to a residential building, but in this case it is necessary to provide for all the requirements for the arrangement of the boiler room.

Requirements and rules for installing a gas boiler house in a country house

Let's start with the fact that the requirements for the premises of a gas boiler room are distributed by type of premises. So, if the heat output of the boiler is ≤ 30 kW, then it can be installed directly in the house - in the kitchen, for example, in the basement or in the annex. With a heat generator power ≥ 30 kW, it will be necessary to allocate a separate room for it, equipped in accordance with all fire safety rules.

There are separate requirements for boilers installed in kitchens and the main points are listed below:

- If the kitchen is gasified, then its minimum area should not be less than 15 m2, while the ceiling height should not be less than 2.5 meters;

- The kitchen ventilation system or exhaust hood should provide hourly air exchange in the amount of 3-5 kitchen volumes.So, if the room has a volume of 15 m2 x 2.5 m = 37.5 m3, the minimum volume of air moved per hour should be 113 m3;

- Glazing to the kitchen should be such that the proportions of 0.3 m2: 1 m3 are observed, while the window (or windows) must have a window or a swivel frame. To ensure air flow from the street and between rooms, a grate or a gap of any shape with a cross section of ≥ 0.025 m2 is arranged in the lower part of the door leaf.

Additional requirements for a kitchen with gas heating installed in them in terms of fire safety are as follows:

- Under the front door to the kitchen, it is necessary to equip a narrow opening for air exchange with the rest of the rooms in the house;

- The distance from objects made of flammable materials to gas equipment must be at least 10 cm;

- If the load-bearing wall or interior partition is too close to gas appliances, then a metal or other sheet of non-combustible material is mounted between them.

Boiler room in the basement of a private house requirements, standards, features

Installing a gas boiler in the basement is an obvious solution, since such equipment cannot be located in residential premises, and it is too expensive to build a separate structure.

We will talk about the requirements for a boiler room in the basement of a private house put forward by state standards and building codes, as well as answer frequently asked questions.

In the photo - a boiler room in a private house in the basement.

Is it possible or not

A gas boiler room can be installed in the basement or basement of a residential private house.

Often the question is: "Is it possible to install a gas boiler in the basement?". The answer is unequivocal and categorical: it is possible.

The exception is systems that are supplied with liquefied petroleum gas (LPG) produced from oil.

The history of this issue dates back to the time when the location of boiler rooms in the basement and basement floors was really prohibited due to the widespread use of LPG.

However, with the transition to natural gas and closed-fired boilers, this ban was lifted, and now in the basement and basement, as well as on the attics and roofs of single-family houses, up to four heating or water-heating gas boilers with a total capacity of up to 200 kW can be located.

The heating boiler can even be placed in the attic.

Important! This permit applies only to those boiler houses that are built and equipped in accordance with the requirements of GOST, SNiP and other regulatory documents and norms. In general, given the specifics of the Russian bureaucracy, it is better to draft a future boiler house and approve it in all instances in advance

In general, taking into account the specifics of the Russian bureaucracy, it is better to draft a future boiler house and approve it in all instances in advance.

Interaction with officials is a whole art.

This will make it possible to demand truly exorbitant bribes, because it will be easier to give even a decent amount than to rebuild the boiler house or build it again.

On the other hand, if you bring a project for a future building, then there will be nothing to blackmail you with, the official can only make reasoned corrections and comments, after taking into account which he will have no choice but to approve your project.

Requirements for the premises

A gas boiler in the basement of a private house is a common occurrence.

In order to place a boiler room in a particular room, it must be brought into line with certain requirements.

Regardless of where exactly the room is located, it must meet the following parameters:

- The distance from the floor to the ceiling of the basement (the height of the room) should be at least 2 meters, the optimal height is from 2.5 meters;

- The room must be separate, it is strictly forbidden to place equipment in adjacent and combined with living rooms premises;

- The area of the boiler room is taken at the rate of 4 square meters per boiler, while the minimum distance from the front of the equipment to the opposite wall should not be less than one meter;

- The equipment must be freely accessible from all sides for normal and convenient maintenance and repair of all parts of the system;

- In the boiler room, windows to the street should be provided, the area of \u200b\u200bwhich is taken at the rate of 0.03 sq. meters per cubic meter of room volume, but not less than 0.25 sq. meters;

- The width of the doorway should not be less than 80 cm;

- The floor must be level and solid, made of non-combustible materials. It is best to make a cement-sand screed, which can then be covered with tiles or other waterproof and fireproof material;

- Wall and ceiling structures should be made of non-combustible materials, finishing - plaster or tile. Near the firebox, wall coverings that can catch fire or deteriorate under the influence of high temperatures should be covered with special shields made of non-combustible materials with a heat-insulating gasket;

- The entrance door must have a basement ventilation hole in the lower part or a gap between the leaf and the floor with an area of at least 0.02 sq. meters;

- The room must have supply and exhaust ventilation;

- It is better to limit access to the boiler room to the circle of persons who are directly involved in the maintenance or repair of equipment. Penetration into the boiler room of children and unauthorized persons is unacceptable.

Important! All these requirements are dictated by objective reasons and are aimed at maintaining your safety and normal operating conditions for heating equipment. https://www.youtube.com/embed/BV10ePz3DgQ

The price of neglecting these rules can be too high, up to the occurrence of emergencies, accidents and fires.

Norms of SNiP in the case of a separate furnace

A separate boiler room should be placed as practical as possible both in terms of fire safety, but also in terms of saving free space.

Important! Any device that runs on gas makes noise during operation, but if the room with it is located independently from the house, then there is no need to worry about this. For this reason, if the boiler room is located outside the house, but somewhere nearby on the site, then consider not only the basic requirements for a boiler room in a private house, but also a number of auxiliary rules

For this reason, if the boiler room is located outside the house, but somewhere nearby on the site, then consider not only the basic requirements for a boiler room in a private house, but also a number of auxiliary rules.

The foundation of this separate building must not come into contact with the foundation of the house itself.

The roof of the building, as well as the walls, must be made exclusively from refractory materials.

The composition of the concrete solution used in construction must necessarily contain sand.

The heating boiler needs a separate foundation

At the same time, it is important that because of this the device does not rise too much above the floor level - no more than 20 centimeters.

Moreover, where it is planned to install a heater, a sewer line should be laid so that, if necessary, the owner can always release the coolant from the system.

See also our guide on how to make a boiler piping with your own hands