Advantages and features of installing water ball valves

At the same time, a fake often has a dull sheen, fairly noticeable defects and even a matte finish. However, even if outwardly the crane looks decent, this does not mean that it is the best. Take an ordinary magnet and check the faucet. Often the ball is made of steel, which quickly rusts in a humid environment. The magnet will tell you exactly what material you are dealing with.

Maximum allowable pressure. The best ball valve is a valve with a high allowable pressure. For cold water, this figure is 10 kg / cm 2. for hot - from 20 kg / cm 2. However, experts always advise buying valves with a high allowable pressure. This will help to avoid problems that often occur with strong water hammer.

The principle of operation of the ball valve

Ball valves are designed to completely shut off the working flow and are not applicable for its regulation

.

Replacing a ball valve will not take many years if it is used for its intended purpose and according to the rules set out in the instructions.

The principle of operation of a ball-type valve is based on shutting off the working flow by means of a locking element, which is a ball with a through cylindrical hole.

During the rotation of the ball around its axis, which is perpendicular to the fixed body of the crane, there is an overlap or opening of access to the working flow.

Regarding the shape of the hole, it is not always round (rectangular, oval, trapezoidal). The size (diameter) of the opening of the locking element also varies depending on the application of the valve and the pipeline network.

The locking element of a ball-type valve, depending on the purpose and dimensions of the valves, can be sealed mainly in two ways.

Namely:

- ball on supports - for large diameter cranes;

- floating ball - for small cranes.

Sometimes valves with additional sealing rings are also applicable.

Closing and opening of ball valves is performed by turning the handle by 90°.

Ball valve classification

According to the method of fastening, ball valves are divided as follows:

Socket ball valve - most often used for equipping gas, plumbing and heating systems of public and residential buildings.

They are small, practical and convenient. Coupling ball valves should be used for mounting in pipes with a diametrical section not exceeding 45 mm. For pipes with large dimensions, it is better to use flanged ball valves.

Flanged ball valve - applicable in pipes with a diameter of more than 45 mm. The use of seals during the installation of gaskets ensures high strength and tightness of the connection between the pipe and the ball valve.

Flanged ball valves have high strength and are adapted to heavy loads. They, in turn, are divided into collapsible, consisting of 2 parts, and non-collapsible - with a cast body. Flanged ball valves are excellent for those pipelines whose working medium is gas or oil.

- Ball valve is widely used in food, chemical and other industries. Ball valves of this type are easy to use due to the possibility of multiple dismantling.

- Welded ball valve - unlike other types of ball valves, it is installed in closed places that do not provide for the dismantling of the valve.

A welded ball valve is installed by welding, so the installation of ball valves of this type should be carried out exclusively by specialists. Most often, a welded ball valve is used in construction.

Combined ball valve - a valve, the design of which involves several methods of its attachment to pipes.

Classification of ball valves according to the number of branch pipes:

- globe valves;

- angle ball valves;

- three - and multi-way ball valves.

The latter are used to mix and redirect work environments.

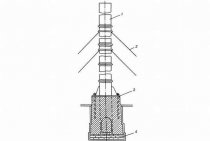

Separately, it is worth highlighting the ball valve for underground installation.

The difference between this type of valve is that it has a high valve axis, which allows the use of a ball valve in underground pipelines. In this case, the axis with the handle of the crane protrudes above the ground surface and makes it possible to shut off and turn on the flow in the underground pipeline.