Advantages and disadvantages

There are several most significant advantages of using rotary pumps:

- more uniform, if we compare rotary pumps with reciprocating type devices, the supply of liquid to the pipeline system (meanwhile, due to the design features of rotary equipment, it will not be possible to ensure a completely uniform supply);

- reversibility, that is, the possibility of using such devices both as a pump and as a hydraulic motor;

- lack of valves, which helps to reduce power losses and, accordingly, increase efficiency;

- high performance due to operation at significantly higher speeds compared to piston-type devices.

The efficiency of the pumping process with a lobe rotary pump is ensured by verified tolerances between the casing and the rotaries

If we talk about the disadvantages that a rotary pump has, then the most significant of them include the following.

- High demands are placed on the medium pumped by such pumps, since it should not interfere with the tight fit of the moving working elements to the inner walls of the casing. In particular, the fluid pumped by rotary pumps must have minimal chemical aggressiveness and not contain abrasive inclusions.

- The rotary pump has a more complex design compared to the reciprocating type, which affects both its reliability and the cost of production and maintenance.

Device principle

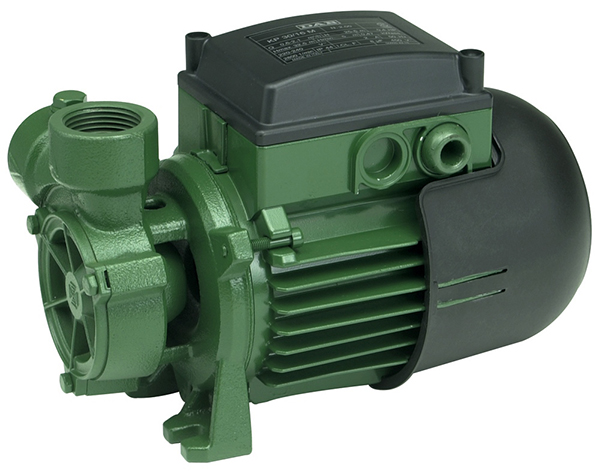

The surface self-priming pump is used as a water pressure generator for country houses where there is no centralized water supply. The equipment is used to lift liquid from a source (well, open reservoir or well) and transport it further through a pipeline.

Such a device and principle of operation does not lead to the appearance of pressure surges and strong noise. Specialists install the machine on the ground floor or basement of a country or country house, and combine it with a water supply source using metal pipes or plastic hoses.

It features a durable and reliable body, resistance to environmental factors and performance. And its main drawback is its suitability only for raising water from a deepening up to 10 meters. If you need to pump water from other sources, then it is better to use an injection pump or a screw pump, and the use of a self-priming one should be abandoned.

The water pump device is as follows. The main elements are the engine, combined with the body by means of a coupling, as well as the impeller, which is a device with blades for an intensive flow of water. The pumping mechanism is set in motion by the operation of the motor shaft. The design of the pump includes other elements - water hoses, fittings, an ejector.

The principle of operation of the vacuum pump determines:

- Ease of installation, maintenance, repair of equipment;

- High productivity, speed of equipment;

- Low noise/vibration level during operation;

- Durability, reliability of the case.

In addition, this type of pumping equipment can operate autonomously without consuming electrical energy. These factors determine its demand among the owners of summer cottages, country houses, who use them to raise drinking water, fill pools, and water the garden.

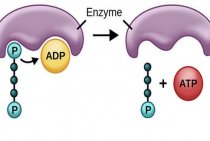

The principle of operation is to rotate the motor, which leads to the movement of the impeller. The wheel enters the body through a special hole, protected from accidental leaks by a special seal.At the end of the shaft (wheel) is a mechanism for pumping fluid. When rotating, the disk with blades creates a vacuum in the end area of the equipment.

This is how water moves during pump operation.

This leads to the generation of a pressure force in the upper zone of the housing and the rise of water from a well or well. Two openings are equipped in the body: opposite the resolution area there is an inlet for liquid, and an outlet in the zone of increased pressure. The pump device includes an ejector. It is installed under water or on the end side. The task of the ejector is to increase the volume of the intake.

The described principle of operation is typical for different types of pumping equipment, while their performance and other characteristics differ.

Application area

The devices of this type are primarily used for pumping various liquids and emulsions. At the same time, they can be used in the presence of a large amount of impurities of a large fraction, since a grinder is included in the design.

Scope of vortex centrifugal pumps:

- Firefighting. The design is reliable and can work for a long period.

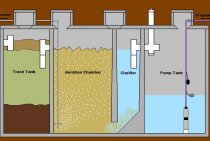

- Water purification systems. As previously noted, the pump can operate at a high impurity concentration.

- Water supply from the well to the house.

- Irrigation systems. The simplicity of the design determines its small overall dimensions and relatively low cost. Therefore, if necessary, you can install it to create pressure in the system.

Based on the principle of operation of a centrifugal vortex pump, other equipment is also created that is used for installation in a ventilation or gas supply system.