Maintenance of the boiler technical inspection and cleaning

For cleaning and maintenance, follow the manufacturer's instructions. This will help to avoid many troubles later.

In the event that the product passport says that those. maintenance should be carried out by a service center employee, it is better to follow this. Otherwise, self-tampering will affect the warranty service of the device. Self-inspection and maintenance of the drive consists of the following steps:

- The device is disconnected from the water supply and electricity supply systems

- Water tank completely drains

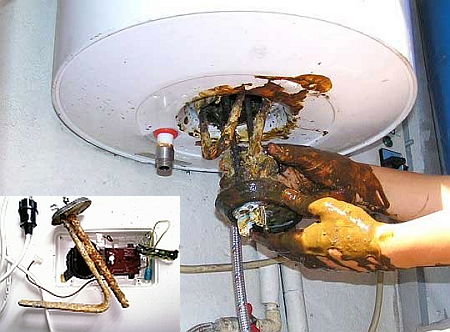

- Having unscrewed the fastening bolts, the case opens and the heating element is removed

- The inner surface of the tank and the heating element are cleaned of accumulated scale and dirt

- The protective gasket is being replaced. If there is a magnesium anode, it is replaced with a new one. The magnesium anode serves to prevent the occurrence of electrical corrosion of the tank and, therefore, increases its service life. Also, electrical corrosion can be caused by the lack of grounding of the device.

- The final step will be the reverse assembly of the water heater

Verification technology

Any repair begins with checking the heating element. Only then can a conclusion be made about the repair or replacement of the unit. Unfortunately, it is impossible to do this without disassembling titanium, so you will have to stock up on a screwdriver, ohmmeter, multimeter or control light.

The verification algorithm is as follows:

- You need to calculate the resistance of the device. It is done according to the formula R \u003d U2 / P. U - voltage, it is equal to 220 watts. P is the nominal power of the heating element. It is indicated in the technical documentation of the water heater.

- Remove the heater from the water heater. The water heater must be disconnected from the mains. After that, we disassemble the case if the element is installed inside and disconnect the wires. For some models, you can get to the unit being checked without disassembling the entire water heater. It is enough to remove the protective cover, disconnect the wires and remove the desired node. In order not to be mistaken, it is recommended to first study the instructions, there is a detailed description of the operation and maintenance. Some companies provide easy access to the insides, so you should not act at random, as the equipment can simply be damaged.

- We examine the heating element for damage, swelling, cracks. It must first be descaled.

- Next, you need to use a multimeter. We configure it to measure resistance, the range of values is up to 200 ohms.

- A check by the tester may show that the heating element is working, in which case the value will be equal to what was calculated by the formula. If zero and one appear, then this indicates that the heating element is faulty and needs to be changed.

The second important operability test procedure is breakdown testing. Here you can not do without a multimeter. In this case, it is required to turn on the buzzer. One probe is connected to the output, the second to the heater body. If the buzzer beeps, that is, a breakdown, then it's time to change the heating element.

The last important step is to check the insulation. This will require a megaohmmeter. It is set to 500 V. The probes are connected to the device body and the heater body. Normative resistance - 0.5 Ohm.

There is another way to check the heating element. It allows you to make a call without a tester, which is useful if the latter is not available. To do this, you need to use a control lamp. It can be made from improvised means. You will need a 220 W incandescent lamp, a cartridge, two single-core copper wires, probes. The scheme is simple: wires are connected to the cartridge, a light bulb is screwed into it.It is recommended to screw the probes to the ends of the wires. In this case, using a homemade tester is safe and convenient. The use of a test lamp implies that it is connected between the power supply and the device under test. If the light comes on, the node is working, otherwise it is not. The heater is checked by analogy - one is supplied with a zero value from the network, and the second phase with a pre-connected light bulb.

Stay up to date with the news

Boiler Repair

There are some of the most common problems that occur during the use of a water heater. Some of them can be fixed on their own. To eliminate others, you can not do without the help of a professional:

Damage to the integrity of the inner tank or outer shell

Such a malfunction may occur during inaccurate installation or careless use of the device. For example, a chip or crack can occur if you accidentally hit the boiler or drop a heavy object on it.

As a result of such a breakdown, the destruction of the heat-insulating material and the deterioration of the heat-insulating properties of the device will begin. It is also possible to actively develop corrosion. It is almost impossible to fix such a malfunction on your own. You will either need to contact a specialist or buy a new drive.

Gasket replacement

In the event that a leak has formed at the location of the protective gasket, you just need to replace it by conducting an independent maintenance. instrument maintenance.

Breakdown of the heating element

One of the most common malfunctions is the breakdown of the heating element.

Before starting to replace the heating element, you need to make sure that electricity is supplied to the drive. This can be done with a tester:

- The scale of the measuring device is set within 220-250 V

- We fix the voltage at the terminals of the tester connected to the mains

- Lack of voltage means boiler failure

- In the event that voltage is present, the test must be continued.

- The boiler must be disconnected from the network

- Then we disconnect the thermostat from the heater and remove the insulation from the contacts of the heater

- Using a measuring device, we take readings on open contacts

- The presence of voltage indicates the health of the heating element and vice versa

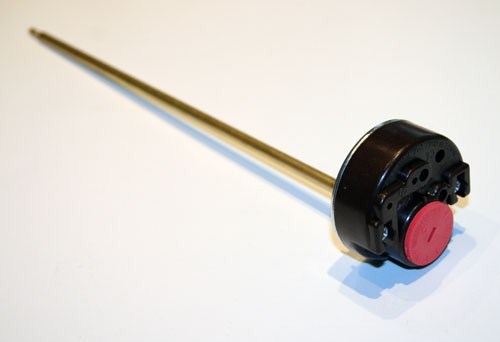

It is possible that the heating element is working, but the water does not heat up. Could be the thermostat is the cause.

- The tester should be set to maximum. We check the voltage at the input and output of the device

- If there is no indication, the part needs to be replaced.

(the presence of a positive reaction also does not give one hundred percent confidence in the serviceability of the device. It is necessary to continue measurements) - We set the measuring device to a minimum and carry out a check on the thermostat contacts for a short time

- We try to warm up the temperature sensor with matches or a lighter and monitor the thermal relay. In the event that heating caused the thermal switch to open, the device is in good order. Otherwise, it will need to be replaced.

Other boiler malfunctions

In cases where the heating element and the thermostat are working properly, but the water is not heated, the possible reason lies in the boiler settings. If this does not help, the control board may be faulty. In this situation, you must contact the service center.

If a breakdown of one or another part is detected, it is necessary to replace it with exactly the same one, corresponding to all its characteristics (not only in appearance). The disassembly of the drive for maintenance should be done very carefully and gradually. In the event that the flasks of the device are broken, it will most likely be necessary to completely change the thermostat.

In situations where you are not confident in your ability to check or replace a particular part, it is better to contact a specialized service so that there is no need to purchase a new drive.

How does a boiler variety of devices work

Currently, there are two types of water heaters:

- The design of accumulative models provides for a large water tank in which a tubular heating element (TEN) is located. Water enters this tank, heats up to a certain temperature and is stored there. The constancy of the water temperature inside the tank is controlled by a temperature sensor, which is connected to a thermostat. To reduce heat loss, the tank body is covered with insulation.

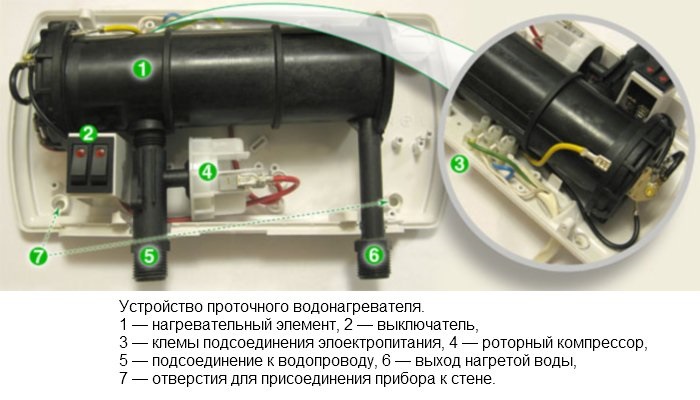

- In the design of flow models there is no tank for storing liquid, but there is also a heating element. Water heating occurs during its passage through the body of the device and the heating element. Due to this difference from storage models, flow devices have much more power, and, accordingly, increased power consumption. But at the same time they are more compact and easier to install.

A thermostat is used to automate the operation of water heaters. Due to the incoming information from the temperature sensor about the water temperature, it turns on or off the heating element. Thanks to this automatic design, energy is saved and emergency overheating of the water in the tank is prevented. Usually, the heating element is turned on when hot water is taken from the storage tank and replaced with cold water from the central water supply system.

The malfunctions that occur in storage and flow models are similar and are eliminated in similar ways.

Causes of boiler failures

To understand why heaters fail, you need to understand the principle of their operation and the purpose of the main elements. Regardless of what type of boiler you have - storage or flow, their design is similar. Only the brand, design and capacity of the tank differ.

The device of the heater tank is quite simple. It consists of two parts: internal and external. Between them is laid a layer of thermal insulation - polyurethane foam. The body includes two branch pipes: one with a divider at the end is used for pumping cold water, the other for hot water.

The presence of a thermostat allows you to set the desired heating temperature.

Breakdowns do not just happen, there are reasons for this:

- Power surges in the network.

- Prolonged neglect of service.

- Incorrect installation or connection of the device.

- The appearance of scale and corrosion on parts.

- Late repair.

To find out the cause and pinpoint the exact location of the problem, diagnostics of parts are carried out.

Possible malfunctions

The heating element is the most vulnerable element in the boiler. The reason is that it is the most exploited element, and in addition, it is exposed to scale. To prolong the service life, it is recommended to periodically clean it. This can be done without completely disassembling the case using special tools. But I recommend carrying out a full set of procedures for cleaning not only the heater, but also the tank itself from scale and dirt.

If the node is broken, then it will have to be changed, but first check what exactly is out of order. There are several types of faults:

- The filament inside the heating element burned out.

- The glow wire on the heater body is burned out. This may result in electric shock if the water heater is not equipped with an RCD. Otherwise, the protective mechanism will constantly turn off the equipment.

- The appearance of scale.

TEN for a boiler types of tubular electric heaters

Two types of tubular electric heaters are used in water heaters:

- The dry-type heating element is located in a special flask and does not have direct contact with water. In the event of a malfunction of the heater, you just need to get it out of the flask and install a new one. In most cases, dry-type heating elements have a lower performance than wet-type heating elements. As a result, the boiler usually contains 2 such elements.Due to their characteristics, "dry" elements often fail. Scale in dry type heating elements is deposited on the flask.

- The wet type heating element has direct contact with the surrounding water. In the event of a breakdown, you must first completely empty the water tank. "Wet" models are considered more durable and therefore are very popular. The scale formed during the operation of the device settles directly on the surface of the heating element.

Boiler malfunctions are the most vulnerable parts of the drive

After purchasing the device, before installing it, you should carefully read the technical documentation. It will reflect the design of the device, the location of its individual parts, instructions for proper installation and operation.

In order to correctly respond to the problem and eliminate it, it is necessary to find the place of the leak and determine the cause.

Possible malfunctions may be related to the following:

- Worn protective gasket in the case

- The malfunction is caused by the operation of the heating element. Its replacement is required.

- The thermostat, temperature sensor is out of order. High quality boilers usually have several redundant devices that control each other's work.

- The leak occurred in the area of connecting pipes for cold water supply and hot water outlet. Most likely, the problem arose at the installation stage, due to poor sealing of the joints.

Often, a safety valve is connected to the drive system to protect the drive. Thanks to this element, the number of breakdowns of the device is significantly reduced.

Causes of malfunction and repair of water heaters

Hot water pressure problems:

- The required power for instantaneous electric water heaters is 8-10 kW. Only with such power will the pressure of hot water be strong enough. Otherwise, only a thin stream will be supplied.

- Due to the design features of an instantaneous gas water heater, there are several reasons for a weak hot water pressure. With the formation of scale, the heat exchanger of the gas unit is clogged. A blockage in a waterworks or gas column filter leads to an automatic shutdown of the column if the pressure drops below an acceptable level.

- There are reasons for storage electric water heaters. First you need to check the pressure of the water supply at the inlet to the storage water heater. At normal pressure, the inlet pressure is checked. If the parameters correspond to the norms, the nozzles should be checked for blockage. The meshes on the mixers or the filter at the inlet are also checked for clogging with scale.

It must be remembered that it is impossible to violate the rules for operating the water heater.

Arbitrary supply of either cold or hot water:

- For instantaneous water heaters, the main reason is the incoming water pressure. Both electric and gas instantaneous water heaters heat the water that is in the heating circuit. With a large pressure of water, the outlet water temperature begins to fall, and with a decrease in pressure, it increases. In modern columns, there is an automatic decrease in the flame, but it will not be possible to completely avoid discomfort during a change in water temperature. The solution to this problem is to install a constant water pressure.

- For a storage water heater, the gasket in the mixer, made of rubber, may be the cause. When the water heating reaches 60-90°, the gasket also heats up, which expands and covers the narrow gap. The tap with hot water is unscrewed, and boiling water begins to pour. To fix this problem with your own hands, you should replace it with a faucet with a ceramic gasket or cartridge. Also, the cause may be a break or corrosion of the hot water outlet pipe.

Repair of a malfunction in the form of a leak from the check valve:

- checking the check valve (connecting a known-good valve);

- checking the water pressure in the system (installing a pressure gauge at the water heater inlet);

- installation of an extended tank.

Malfunctions of the RCD of the water heater in the form of frequent operation of the device:

- the device is faulty;

- incorrect grounding.

As a rule, the RCD is not intended for repair, so a replacement must be made.

Malfunctions in the form of a leak in the water heater tank:

- If the leak occurs from the place of the body, then the reason is the depressurization of the internal tank.

- If the leak occurs from under the plastic cover, then there can be two reasons.

- The result of incorrect factory alignment or cleaning, or defective rubber gasket flange.

- Leaking from other openings or at the seams. In this case, repairing the water heater is useless.

Before checking the water heater for leakage, it is necessary to de-energize it and remove the bottom cover.

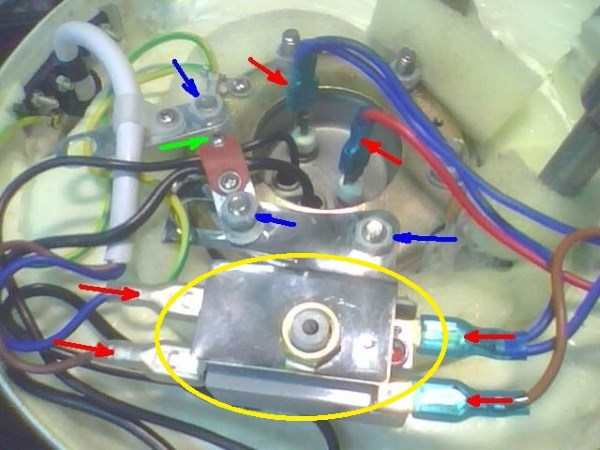

Scheme of the device of the water heater.

Malfunctions in the form of a small amount of hot water in the water heater:

In the case of an electric storage water heater, the main reason is incorrect connection. A significant disadvantage of this type of water heater is a certain amount of heated water, so you should make sure how much water is heated by the water heater.

Malfunctions in the form of lack of water heating:

- poor electrical connection of the thermostat with the heating element (it is necessary to check the connection of the thermostat with the terminals of the heating element);

- during switching on, the protection in the thermal relay starts to work (restart the circuit breaker);

- malfunction in the electrical circuit (check all components of the circuit).

How to repair a boiler with your own hands

Consider the main malfunctions and ways to eliminate them.

Leak in the heater

The most common problem with electric boilers is considered to be a leak. Occurs due to corrosion of the tank, when individual elements fail. Most often it is:

- Lack of grounding, which leads to electrical corrosion.

- Natural wear.

- Breakage of the safety valve.

What to do if the tank is leaking? Do not weld a leak on your own: this can lead to irreparable consequences!

Why You Shouldn't Repair Your Tank:

- The outer and inner parts are inseparable.

- In modern technology, glass enamel is used, which is easily damaged and cannot be repaired.

It happens that a leak occurs from under the flange that secures the heater. Then you need to drain all the water, remove the gasket and assess its condition. If it is damaged or worn, replace it. In order not to miscalculate with a new gasket, take the old one to the store.

No water heating

If cold water flows instead of hot water, the heater is broken. In addition to the lack of hot water, the RCD can be knocked out when the boiler is connected to the network. Problems with heating elements arise due to corrosion and scale.

How to understand that the scale completely covered the heating element:

- As it precipitates, a rumble can be heard during water intake.

- There is a smell of sulfur.

To make sure that the heater is broken and does not work, diagnostics will help:

- Drain the water from the tank.

- Open the heater cover.

- Measure the voltage at the terminals of the heating element using a tester (220-250 V).

- If everything is in order, set the multimeter to resistance measurement mode.

- Disconnect the heater from the mains.

- Disconnect the heater contacts.

- Attach the probes of the multimeter to them.

- When broken, the indicators will tend to infinity.

- If the part is operational, 0.68-0.37 ohms will be displayed on the screen.

Additionally, make sure that there is no current leakage to the case:

- Attach one probe to the copper pipe, the other to the heating element contact.

- If there is no leak, the display will show 1.

- If there is, the tester will give values with a minus sign or, conversely, too large.

Heater cannot be repaired, needs to be replaced

It is important to choose the right part for your model, so it is better to write down the part number or take it to the store

The water temperature is above normal

If too hot water is supplied, the problem is in the thermostat or thermostat. An additional sign of a breakdown is the lack of heating when the thermostat does not turn on the heating element. To perform diagnostics and repairs, the thermostat must be dismantled.

Troubleshooting:

- Disconnect the boiler from the network.

- Drain all water.

- Remove the tank from the wall.

- Remove the cover (for vertical models, the cover is located at the bottom, for horizontal models - on the left, for Termex models, the panel screw is in the middle).

- The thermostat is marked in yellow in the picture. Disconnect its contacts and remove from the case.

Now you can check the part for serviceability. The easiest way:

Press the safety button as shown in the photo:

- Heat the copper tip with a lighter.

- If OK, the button will be disabled.

Diagnostics with a multimeter is carried out as follows:

- Set the tester knob to the maximum value.

- Measure the resistance across the contacts.

- If the multimeter does not respond, the part cannot be repaired, it is better to replace it immediately.

The boiler does not turn on for a long time, often turns off

This also indicates a problem with the heater. Due to the scale, the water can heat up for a very long time, the consumption of electricity increases, as the heat removal is disturbed. To avoid breakage, change the magnesium anode in time, which purifies water from impurities.

There are such problems:

- During operation of the appliance, the surrounding equipment also heats up. This happens when the plug is designed for more power consumption than the socket, or the contact between them is broken. It is best to call an electrician to check and replace.

- Weak water pressure. It is necessary to check whether cold water is pumped normally. Inspect the mixer, perhaps the reason is in it. If everything is in order, inspect the relief valve. Clean it from dirt and scale.

- The boiler does not turn on at all. After the repair, the device did not work? You need to check the electronics and the main board. This work is best left to a specialist.

Now you are aware of the main problems of boilers. Carry out routine inspections, install water filters, clean the heater in a timely manner, then problems will not affect you.