How is the drain tank

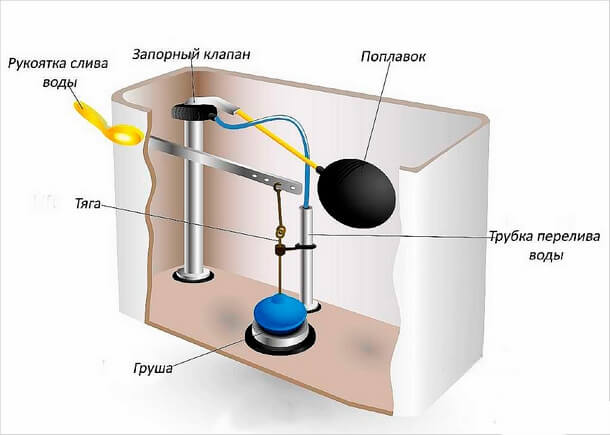

Regardless of what design the tank is installed - modern or Soviet era, it contains certain components that differ in appearance, but perform similar tasks: filling with water and then draining.

Filling

The mechanism ensures the supply of liquid into the accumulator, this process is completed when a certain level is reached. Nodes that form the system:

- float element;

- stop valve.

The buoy is located on a plastic (or metal) lever; it changes its position depending on the volume of liquid in the tank: it lowers during draining and rises as it is filled. At the minimum level, the float activates the supply circuit, at the maximum it blocks the water flow.

Drain

This regulator is used to drain fluid into the toilet bowl. Its constituent parts:

- drain siphon;

- drain lever;

- overflow tube.

The siphon device blocks the drain opening and, if the button is not pressed, blocks the arbitrary loss of fluid. The lever scheme can be presented in the form of a pneumatic chamber, a rod or a classic lever. It is designed to drain water when pressing the button element with your hand. The overflow tube is provided with a number of marks and is located under the float. It blocks further filling of the tank when the volume reaches a certain level.

The subtleties of the button

Similar descent options are implemented in modern models of tanks. They can be presented in the form of one (using all the collected water) or two keys.

If a double regulator is built in, this feature determines the amount of liquid flowing down: pressing a larger element completely empties the tank, using a small button resets half the volume.

In some products, a combined scheme works, when the water pressure going into the toilet bowl depends on the force of pressing the trigger. This model will be the most economical, because it allows you to use the volume of the tank that is needed.

How to adjust the tank

After installation of equipment, situations often arise that require additional configuration. Consider the procedure:

Make sure that the moving elements of the valves are at a distance from each other. In no case should the fittings come into contact with the walls of the tank

This is very important for normal functioning.

The flow of liquid into the tank should stop when 150 mm remains between its level and the edge of the overflow sensor, in case of a discrepancy, it will be necessary to adjust the float. We make sure that it does not have distortions, when they are detected, we correct the situation with the help of a rocker arm (located at the top of the device), tilt or bend it.

The overflow tube can be adjusted by first loosening the lock and disconnecting the rod

The last action is not always required: there are designs where it is enough to unscrew the nut. By moving the part lower or higher along the marks, we respectively reduce or increase the volume collected in the tank.

Some models contain a special strip indicating the optimal value.

This value will provide the best flushing of contaminants.

Attention! You can find options when the overflow element is located on the inlet fitting. In this case, its configuration scheme does not change.

The filling tube may have an extra length, as a result - water is sprayed during the recruitment process

To solve the problem, it is enough to trim the unnecessary part.

There are shortcomings that manifest themselves only after prolonged use.

In modern devices, liquid is drawn through the bottom eyeliner.A common malfunction here is a clogged filter through which pressure is supplied. The component is located under the inlet valve displacer. The accumulation of debris in this area leads to two problems: sound effects during operation and slow filling of the tank.

The defect can be eliminated by washing the filter. To do this, turn off the water valve, empty the tank and unscrew the water supply hose. The filter element located inside the filling valve is removed and cleaned. We assemble in the reverse order.

Rust and various deposits on the walls of the container can affect gaskets and assemblies. This source of problems contributes to structural failure or leads to gaps between seals and parts. A leaky connection, in turn, causes a leak. To prevent such episodes, it is necessary to regularly clean the inside of the tank.

The scheme of the tank only at first glance seems complicated. In fact, this device is designed so that the owner can easily disassemble and assemble the stuffing. Knowing these nuances, you can change any part with your own hands or, if necessary, replace the entire kit without resorting to the help of a plumber. This will save you time and money.