What is a dry running pump

Wherever the pump pumps water, sometimes a situation arises that the water is over - with a small flow rate of a well or well, you can simply pump out all the water. If water is pumped from a centralized water supply, its supply can simply be stopped. The operation of the pump in the absence of water is called dry running. Sometimes the term "idling" is used, although this is not entirely correct.

In order for the water supply at home to work normally, you need not only a pump, but also a dry water protection system, automatic on-off

What's wrong with dry running, besides wasting electricity? If the pump runs without water, it will overheat and burn out - the pumped water is used to cool it. No water, no cooling. The engine will overheat and burn out. Therefore, protection against the dry running of the pump is one of the components of automation that will have to be purchased. There are, however, models with built-in protection, but they are expensive. Cheaper to buy automation.

Water level sensors

These sensors are installed in a well, borehole, tank. It is advisable to use them with submersible pumps, although they are compatible with surface pumps. There are two types of sensors - float and electronic.

float

There are two types of water level sensors - for filling the tank (protection against overflows) and for emptying - just protection against dry running. The second option is ours, the first one is needed when filling the pool. There are also models that can work this way and that, and the principle of operation depends on the connection scheme (included in the instructions).

The principle of operation of the float switch

The principle of operation when used to protect against dry running is simple: as long as there is water, the float sensor is pulled up, the pump can work as soon as the water level has dropped so much that the sensor has dropped, the contactor opens the pump power circuit, it cannot turn on until until the water level rises. To protect the pump from idling, the float cable is connected to a break in the phase wire.

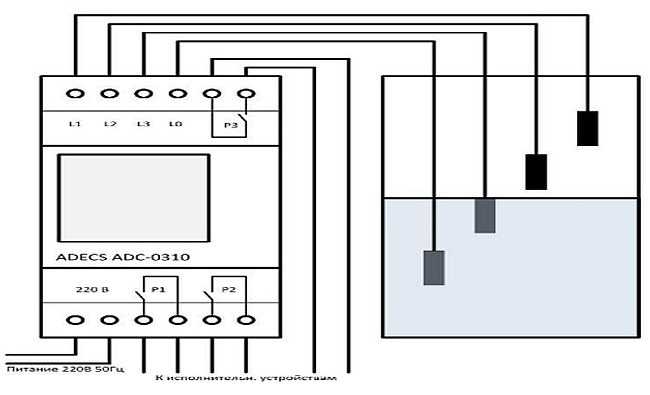

Level control relay

These devices can be used not only to control the minimum water level and dry running in a well, well or storage tank. They can also control overflow (overflow), which is often necessary when there is a storage tank in the system, from which water is then pumped into the house or when organizing pool water supply.

Electrodes are lowered into the water. Their number depends on the parameters they track. If you only need to monitor the presence of a sufficient amount of water, two sensors are enough. One - falls to the level of the minimum possible level, the second - the base - is located a little lower. The work uses the electrical conductivity of water: while both sensors are immersed in water, small currents flow between them. This means that there is enough water in the well / well / container. If there is no current, it means that the water has dropped below the minimum level sensor. This command opens the power supply circuit of the pump and it stops working.

The same device can control different levels, including the minimum

These are the main ways in which protection against dry running of the pump is organized in the water supply systems of a private house. There are also frequency converters, but they are expensive, so it is advisable to use them in large systems with powerful pumps. There they quickly pay off due to energy savings.

Water pressure switch for pump

The automation system of the water supply system is responsible for ensuring that water from the tap flows under pressure.

Principle of operation

The system consists of the following components: pump, hydraulic accumulator and pressure switch. The borehole pump pumps water through the pipeline to the accumulator.

A hydraulic accumulator for water supply systems is a tank inside which there is a pear-shaped membrane. Water on one side and compressed air on the other. As the membrane expands, it compresses the air.

You open the tap, the water flows under pressure, and the pressure in the system decreases - as soon as the pressure drops below the critical one, which is set by the adjustments, the relay turns on the pump, and it pumps water into the tank again.

Thus, the pressure switch is designed to control an electric pump. This increases the life of the pump.

The design of the water pressure switch

This is a block inside which there are springs regulated by special nuts. The water pressure in the water supply system is transmitted using a membrane or bellows. These transmitters either overpower the spring (at maximum pressure setting) or weaken the spring (at minimum pressure).

The springs close or open the electrical contacts inside the relay. When the minimum set pressure value is reached (usually less than 1 bar), the relay contacts are closed and electric current flows to the pump that the relay controls. Water flows from the well into the tank.

As soon as the pressure reaches the set maximum, the spring opens the contact, the electrical circuit of the pump breaks, and it stops pumping water.

The standard relay can be adjusted from 1 to 8 bar.

When choosing a manufacturer, pay attention to the setting range, the working environment (after all, the relay can be used not only for water), additional functions (in addition to starting the pump by pressure, some relays start it along the flow, as well as protect him from "dry run"). Naturally, the more functions such a relay has, the more expensive it will cost.

The operating pressure range also affects the price.

Pressure switch Gileks, Danfoss, Italtecnica

So, a Danfoss (Denmark) pressure switch with a range of 0.2 - 8 bar will cost about 3,000 rubles. Pressure switch Grundfos (Germany) with similar settings will cost 4.5 thousand rubles. The pressure switch of the Italian company Italtecnica with standard values costs 500 rubles. The relay of the Russian company "Dzhileks" similar to Italian products is cheaper by 200 rubles.

Thus, the domestic manufacturer is cheaper, and in terms of its characteristics it is in no way inferior to Western counterparts. But, it is desirable that all pumping equipment be produced by one manufacturer, that is, if you have a Grundfos downhole pump, then it is better to use a pressure switch in accordance with the recommendations of this manufacturer.

Overview of basic concepts

The relay of the pumping apparatus in automatic mode turns on and off the device that supplies pressure to the accumulator.

In such a situation, use the following indicators:

- switching pressure, which is equal to 1.5 bar. In this case, the relay contacts are closed, the device is turned on and the hydraulic tank is filled with water;

- shutdown pressure, which is 3 bar. In such a case, the relay contacts open and the pumping apparatus is turned off;

- differential pressure is considered the difference between the previous 2 indicators;

- limiting shutdown pressure, which is equal to 5 bar. In such a situation, experts turn off the pumping device.

New device out of the box

A hydraulic accumulator with a pressure switch is considered a tank with a rubber container - a “pear”. The adjustment of the accumulator consists in the fact that a lot of air is launched into this “pear” through the nipple from the car. In such a situation, they increase in the "pear" and push the water out of the accumulator tank into the water supply.

Also, to ensure the normal functioning of the water supply, automation is used for water supply pumps without a hydraulic accumulator. Such automation for the pump adjusts the operation of the pumping apparatus in such a way that it starts to work not in manual, but in automatic mode - without the use of "pears" and other human presence.

Checking the pressure in the accumulator

When setting up the pump relay, first determine the air pressure in the empty tank of the accumulator, which should be equal to 1.5 atm. However, during transportation or long-term storage of the pump, a small air leak occurs in the hydraulic tank, which subsequently reduces the water pressure in the tank.

When measuring pressure in the pumping apparatus, an automobile or electronic pressure gauge is used.

In order to determine the pressure of the accumulator in the pumping apparatus, it is necessary to unscrew the cap under which the nipple is installed, attach a pressure gauge to it and record the value obtained. If this parameter turned out to be small, then a large amount of water can be poured into it.

To ensure a powerful water pressure, the air pressure must be at least 1 atm. In such a situation, it is possible to provide for the domestic needs of small houses.

With a high water pressure, the pumping device turns on more often, as a result of which the life of the pump is reduced. At the same time, the pressure of water in the water supply in the country remains the same as in the city. In such a situation, you can take a bath with a hydromassage.

With a low water pressure, the wear of the pumping apparatus becomes less, however, in this case, the owner of the apartment of the apartment can only take a regular hot water bath, and not a jacuzzi.

Water flow control devices

In any situation that causes the pump to run dry, there is insufficient or no water flow. There are devices that monitor this situation - relays and water flow controllers. Relays or flow sensors are electromechanical devices, controllers are electronic.

Relay (sensors) of the flow

There are two types of flow sensors - petal and turbine. Flap has a flexible plate that is in the pipeline. In the absence of water flow, the plate deviates from the normal state, contacts are activated that turn off the power to the pump.

Turbine flow sensors are somewhat more complicated. The basis of the device is a small turbine with an electromagnet in the rotor. In the presence of a flow of water or gas, the turbine rotates, an electromagnetic field is created, which is converted into electromagnetic pulses read by the sensor. This sensor, depending on the number of pulses, turns on / off the power to the pump.

flow controllers

Basically, these are devices that combine two functions: protection against dry running and a water pressure switch. Some models, in addition to these features, may have a built-in pressure gauge and check valve. These devices are also called electronic pressure switches. These devices cannot be called cheap, but they provide high-quality protection, serving several parameters at once, providing the pressure required in the system, turning off the equipment when there is insufficient water flow.

| Name | Functions | Parameters of operation of protection against dry running | Connecting dimensions | Manufacturer country | Price |

|---|---|---|---|---|---|

| BRIO 2000M Italtecnica | Pressure switch + flow sensor | 7-15 sec | 1″ (25mm) | Italy | 45$ |

| AQUAROBOT TURBIPRESS | Pressure switch + flow switch | 0.5 l/min | 1″ (25 mm) | 75$ | |

| AL-KO | Pressure switch + check valve + dry running protection | 45 sec | 1″ (25mm) | Germany | 68$ |

| Dzhileks automation unit | Pressure switch + idle protection + pressure gauge | 1″ (25mm) | Russia | 38$ | |

| Aquario automation unit | Pressure switch + idle protection + pressure gauge + check valve | 1″ (25mm) | Italy | 50$ |

In the case of using an automation unit, a hydraulic accumulator is an extra device. The system works perfectly on the appearance of a flow - the opening of a tap, the operation of household appliances, etc. But this is if the headroom is small. If the gap is large, both a GA and a pressure switch are needed. The fact is that the pump shutdown limit in the automation unit is not adjustable. The pump will only turn off when it reaches maximum pressure. If it is taken with a large headroom, it can create excess pressure (optimal - no more than 3-4 atm, anything higher leads to premature wear of the system). Therefore, after the automation unit, they put a pressure switch and a hydraulic accumulator. This scheme makes it possible to regulate the pressure at which the pump is turned off.

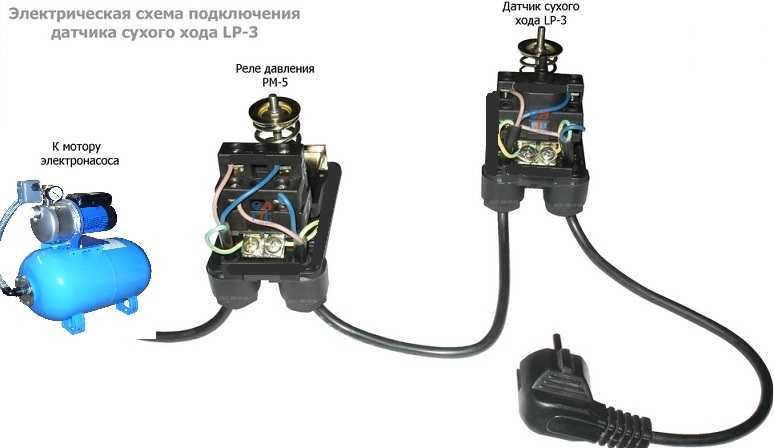

Dry run protection relay

A simple electromechanical device controls the presence of pressure in the system. As soon as the pressure drops below the threshold, the power circuit breaks, the pump stops working.

The relay consists of a membrane that reacts to pressure and a contact group that is normally open. When the pressure drops, the membrane presses on the contacts, they close, turning off the power.

This is what dry running protection looks like.

When is it effective?

The pressure to which the device responds is from 0.1 atm to 0.6 atm (depending on factory settings). This situation is possible when there is little or no water at all, the filter is clogged, the self-priming part is too high. In any case, this is a dry running condition and the pump must be turned off, which is what happens.

Wiring diagram for a dry-running relay in a system with a hydraulic accumulator

An idle protection relay is installed on the surface, although there are models in a sealed housing. It works normally in an irrigation scheme or any system without a hydraulic accumulator. Works more effectively with surface pumps when a check valve is installed downstream of the pump.

When it does not guarantee shutdown in the absence of water

You can put it in a system with GA, but you will not get 100% protection against dry running of the pump. It's all about the features of the structure and operation of such a system. They put a protective relay in front of the water pressure switch and the accumulator. In this case, there is usually a check valve between the pump and the protection, that is, the membrane is under pressure created by the accumulator. This is the usual pattern. But with this method of switching on, a situation is possible when a running pump, in the absence of water, does not turn off and burns out.

More detailed connection diagram of the pressure switch in the water supply circuit with a deep pump

For example, a dry run situation has been created: the pump has turned on, there is no water in the well / well / tank, there is some water in the accumulator. Since the lower pressure threshold is usually set on the order of 1.4-1.6 atm, the protective relay membrane will not work. After all, there is pressure in the system. In this position, the membrane is pressed out, the pump will run dry.

It will stop either when it burns out or when most of the water supply is used up from the accumulator. Only then will the pressure drop to critical and the relay will be able to work. If such a situation arose during the active use of water, nothing terrible will happen in principle - a few tens of liters will run out quickly and everything will be fine. But if it happened at night, they let the water out of the tank, washed their hands and went to bed. The pump has turned on, there is no signal to turn off. By the morning, when the analysis of water begins, it will be inoperative. That is why in systems with hydraulic accumulators or pumping stations it is better to use other devices to protect against the dry running of the water pump.

Overview of basic concepts and principle of operation

With the help of a water pressure switch for the pump, the on and off of the device that supplies water to the hydraulic tank is automatically controlled. In this case, experts use a number of concepts, such as:

Switch-on pressure or lower pressure (Pvkl), at which the contacts of the pressure switch for the submersible or well pump close, the device turns on and water begins to flow into the tank. The manufacturer's default setting is 1.5 bar.

Cut-off pressure or lower pressure (Poff), at which the relay contacts open and the pump turns off. The manufacturer's standard settings are 2.5-3 bar.

Pressure drop (ΔP) - the difference between the previous two indicators.

The maximum allowable shutdown pressure at which the pumping station can be shut down. The manufacturer's default setting is 5 bar.

The accumulator is a tank in which an additional rubber container, called a "pear", is built in.A certain amount of air is pumped into this “pear” through the most common automobile nipple. The higher the pressure in the "pear", the more it presses on the water accumulated in the tank, pushing it into the plumbing system. This ensures that the water pressure is sufficient for comfortable use.

Membrane accumulators are arranged somewhat differently, but their principle of operation is approximately the same. The tank is divided into two parts by a special membrane, on one side of which there is water, on the other - air, which presses on the water, etc.