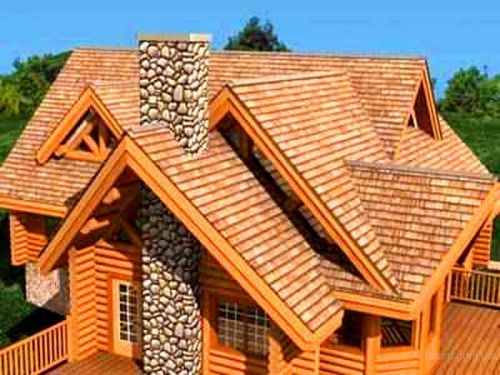

Common types of roofs of wooden houses

It should be noted that it is rare to find a house made of wood with a shed roof. Such a roof of a wooden house is not very practical, and given that the shape of a shed roof is not very beautiful, then other, more interesting options are often chosen.

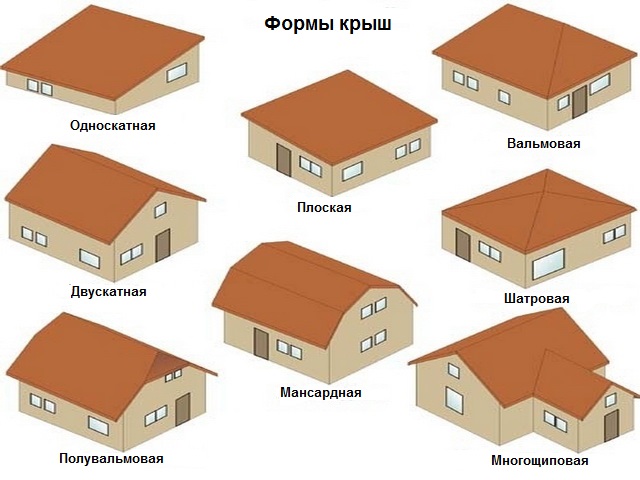

The existing types of roofing for a private house are so diverse that choosing the one on which wood roofing material will look good is a rather difficult task. However, regardless of the type of roofs, a wooden coating will always look original, original and unique. Conventionally, all types of roofs of wooden houses can be divided into the following categories:

- Hip roof (which has not one slope, but several);

- Mansard - otherwise they are also called broken roofs;

- Gable - one of the most traditional forms of roofs;

- Multi-gabled - roofs with a large number of gables;

- Hipped roofs are another type of hip roofs, which have equal, identical in shape, slopes;

- Semi-hip (there are both gable and four-slope).

If the roof projects of wooden houses were originally conceived in such a way that there was a wooden roof with slopes, then this can bring additional amenities, such as:

- Excellent runoff of water from the roof;

- Good properties for thermal insulation of floors;

- Removal of snow cover from the roof under own load;

- Possibility of using cheaper materials.

And this is not all the benefits listed, but only some of them.

How can roofs differ?

Log cabins, as a rule, have pitched roofs of various shapes. The most typical and simplest for private houses is a gable (or gable). That is what we will talk about in this article.

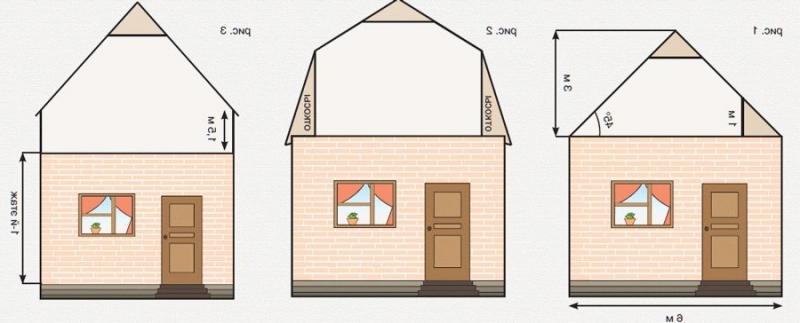

Also in low-rise construction, attics are popular, and, accordingly, attic forms of roofs. However, for the attic it is not necessary to build a roof with a broken configuration. You can make the so-called "semi-attic" if you raise the walls by about 1/3 or half the floor and put a regular gable roof. You can even get by with a regular gabled (triangular) roof if it's wide and high enough.

In principle, you can cover the crate with slate, and you're done. And insulate the ceiling already - the ceiling between the attic and the residential floor. This is, of course, the simplest and most brutal option. With a roof, even a non-warm one, many people prefer to tinker more thoroughly - especially now, when so many materials have appeared, and according to the assurances of their manufacturers, one cannot take a step without all sorts of steam, hydro and other insulations and heaters. But the key idea is that it is much easier to constructively insulate the attic floor (ceiling) than the roof itself. Especially if we are talking about a log house with chopped gables, and then it will be clear why.

On the other hand, you can make an insulated roof - for the attic, or in order not to make a separate ceiling (for example, in a bathhouse - in a rest room).

- According to the design of the bearing elements:

- Many people know that the main load-bearing elements of the roof are the rafters. But there is also…

- roof on slopes

The rafters can be rigidly connected to the frame of the house, or they can be sliding ("floating") - an independent truss structure. Hard ones are traditionally divided into:

- hanging - exert bursting pressure on the walls when transferring the weight of the roof to the building; permissible with a width between supports (external walls) up to 6 - 6.5 meters;

- layered - interconnected by a puff - a beam - at the lower ends, and thus exert vertical pressure; are obligatory at a step between supports from 7 meters.

In its pure form, hanging rafters are rare, they are often reinforced with crossbars, additional posts, jibs and other structural elements. All together, the construction of a pair of rafters with other elements is called a truss. In addition to hanging and layered structures that are assembled on site, there are roof trusses that are assembled at the factory and delivered ready-made.

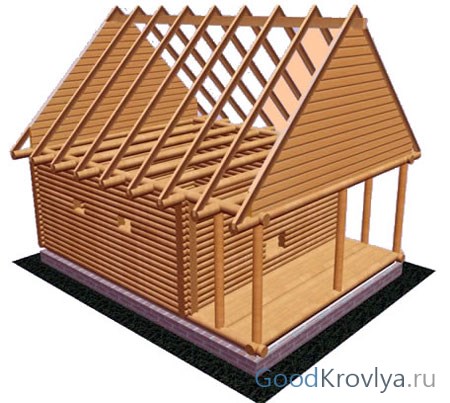

Roof design

The construction of the roof roof begins with the calculations of the truss system and roofing materials. The rafter system consists of timber and boards. The configuration of the structure depends on the type of roof chosen, it can be single-pitched, two- or four-pitched, with straight or broken slopes.

When calculating the power of the rafter system and the installation step of the rafter legs, it is important to take into account the load on the roof, which is summed from the individual loads:

- own weight of the roof frame;

- the weight of the elements of the roofing cake;

- snow load characteristic of the region;

- wind load;

- the approximate weight of people repairing or servicing the roof;

- safety margin in case of cataclysms (hurricane wind, increased rainfall).

Snow and wind load depend on the climatic features of the region (which requires the introduction of correction factors in the calculations), as well as on the angle of inclination of the roof slopes.

When calculating the material for the roof, it is important to take into account the working dimensions of sheet roofing materials, since they overlap. To minimize insulation waste and simplify its installation, it is recommended to choose the rafter spacing taking into account the appropriate width of the thermal insulation material.

The calculation of the construction of the roof can be carried out independently, using the appropriate tables from the reference literature, or by resorting to a specialized calculator, of which there are plenty on the Internet. It is recommended to entrust the calculation of complex roofs to a professional architect.

When calculating the cost of building a roof, the amount of each of the main materials is multiplied by its cost and 10% is added to the resulting value. We must not forget about consumables - fasteners, sealants, etc. The total cost also includes the transportation of materials.

Timber preparation

The construction of the roof of the house is carried out on the basis of a detailed project, which indicates the length and cross section of all structural elements, as well as the principles for the implementation of attachment points.

For mounting the frame, it is important to use well-dried (moisture content up to 15%) high quality lumber - without chips, cracks and other defects. This guarantees the necessary reliability of the truss system, and also eliminates the deformation of its elements during operation.

The roof frame is mainly built from coniferous wood, as this material is durable, resistant to decay, and durable.

To increase fire resistance and protect the wooden frame elements from damage by microorganisms, they are treated with special refractory and antifungal agents before installation.. The fire-retardant composition is applied in two layers, while the second layer can be applied only after the first is completely absorbed and dried. The installation of the wooden parts of the frame is started after they are completely dry.

In the rafter system, elements made of rolled metal can also be involved - corners, channel bars. But metal structures are rarely used for self-construction of the roof, since their installation requires the use of welding equipment.

Rafter system for a wooden house

Rafters are the first step in shaping the relief of a pitched roof. Among all types, when building wooden roofs, one of three options is used:

- Wooden farms;

- Hanging rafters;

- Overhead rafters.

Wooden trusses are a very rare solution in individual construction. It is rational to use such structures for the reconstruction of old buildings, as well as in the construction of industrial facilities. The main characteristic of wooden trusses is their ability to cover large spans up to 20 meters long and the use of unchanged wooden structures.

Hanging rafters are wooden roof structures when there is no central load-bearing wall in the house. They are mainly used for buildings whose width is less than 8 meters. In addition, hanging rafters are used in complex architectural solutions, for example, in the construction of the roof of a Chinese-style house.

Laminated rafters - the most common scheme for the construction of a wooden pitched roof. They got their name due to the design feature, when the lower end of the rafter leg is located on the Mauerlat, and the upper one rests on the rack. The pitch used can vary from 60 to 200 cm. Timber or composite boards are used as the material. The ideal solution for houses with a width of 7 meters, the design of which implies the presence of at least one load-bearing wall.

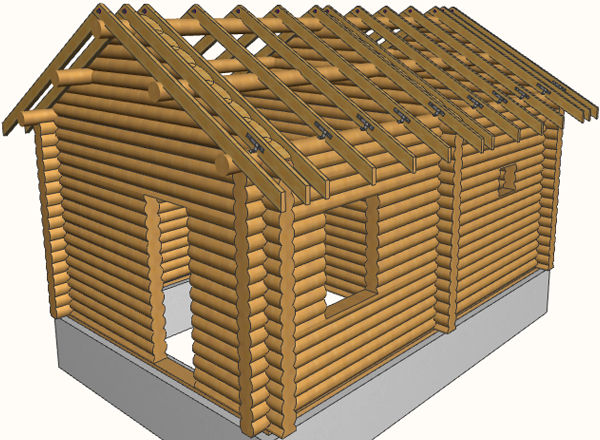

Anti-shrink roof construction for chopped gables

There are two fundamental solutions:

- roof on slabs - similar in technology to the traditional nailless roof structures of traditional Slavic log cabins;

- installation of sliding rafters.

There is also a slab-rafter system, but these are the same sliding rafters, only with the addition of side rafters.

In fact, this is butter, because in the first version, the supporting beams are located horizontally, and in the second, vertically. Both structures are strong enough to withstand the heaviest, for example, tiled roofing. Duplicate them - it makes no sense.

Another thing is that in addition to holding the roof, they also firmly connect the gables. And when rafters are added to such a structure, they do it in two cases:

- to fill the crate on the vertical rafters;

- to make a thick cake of a warm roof for the attic.

It is likely that engineering solutions for arranging a warm roof on a slab basis are quite possible, but they have not yet been developed, since so far developers have enough rafters. Therefore, if you are planning to build an attic, you cannot avoid installing rafters if you do not want to experiment.

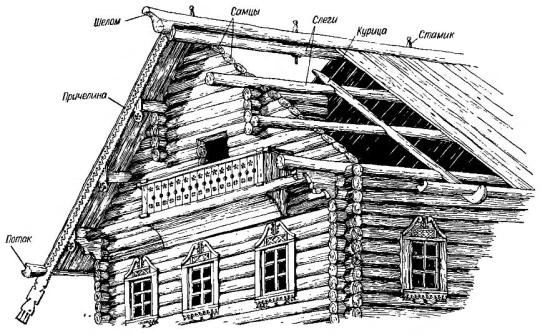

Roof without a single nail

Chickens cut into several side sleds. The chickens themselves were cut down from spruce trunks, the hook was obtained from the root system. On the hens, a stream was kept - a hollowed out log, against which the boardwalk rested - the roof boarding. The upper part of the hedge was freely laid on the ridge beam in such a way that during shrinkage the upper ends of the gorges could freely converge. To do this, leave a place when laying. The ridge beam (knes) was hewn on both sides so that the gorges fit snugly.

If you leave 10 cm to lift the gorges along the knes, then this is more than enough, because when shrinking, the chicken will also fall, and hence the gorges lying on the slopes. From above, the gorges were pressed down to the ridge beam with a frost - a heavy hollowed-out log. Thus, the gorges were fixed both at the top of the roof and on the plumb lines.

Of course, now no one forces meticulously following the ancient technology, where appropriate, you can use nails, self-tapping screws, etc. The main thing is to grasp the principle. And what is he?

Here's what:

In the same way, today you can fasten a continuous crate on a flat roof. If there is no desire to mess with chickens (although this is no more difficult than with a rafter system), then you can rest the boards against a hollow hollowed out in the upper crown.And you can vice versa - fasten the boards on the ridge beam, so that they then sink into the hollow in the upper crown. It is in this way that they act when constructing a warm roof according to the “Norwegian” technology, which I will briefly discuss below.

Roof construction of a private house crate

Having finished installing the rafters, you can fill the crate. For its arrangement, you will need boards (2.5 cm thick) or bars. The crate can be either solid or have gaps. But before building the roof. waterproofing should be laid along the rafters. When creating a living room in the attic, it is best to insulate the roof in advance. Insulation is placed in the space between the rafters. The material can be mineral wool or polystyrene.

To create a residential "warm" room in the attic, lay the insulation in a double layer. The thickness of one layer should not be less than 50 mm. The insulation layer contributes to the absorption of noise from outside the room. A vapor barrier membrane is laid on the insulation. It protects the material from the formation of condensation on it. In order not to spend money on repairing the roof of a private house once again, follow all the instructions and recommendations. Try to properly lay the layers of the roofing cake.

Roof shapes

Pitched roof roofs come in a variety of shapes. It is worth highlighting here:

- lean-to;

- gable;

- four-slope (tent and hip);

- broken lines.

The most common are gable and four-slope hip roofs.

The most common are gable and four-slope hip roofs.

The most common option is a gable or four-slope hip roof. The first requires the device of gables. Broken lines are relevant in the construction of the attic. First, the rafters go at a steep angle, and then at a smaller one. This technology allows you to raise the ceiling of the attic. We also recommend reading about the truss system of a semi-hipped roof.

Roof truss system design

The design of the truss system of the house must be checked for strength by specialists. When calculating the strength, take into account, in addition to loads. the slope angle of the slopes and the shape of the roof, as well as the type of truss system and the safety factor.

The rafter system consists of many elements. Each element is acted upon by forces of different magnitude and direction. On the truss system as a whole and on its individual parts, loads are directed vertically, horizontally and tending to rotate the part.

When designing a truss system, they take into account whether there will be an attic or an attic on the roof, the presence of windows in the roof or gables, the conditions for supporting the rafters on the walls, the shape of the house plan and other factors. It is better and more correct to build the roof of a house according to a project completed by a specialist designer

The construction of simple types of roofs can be entrusted to an experienced specialist who does not have the qualifications of a designer

It is better and more correct to build the roof of a house according to a project completed by a specialist designer. The construction of simple types of roofs can be entrusted to an experienced specialist who does not have the qualifications of a designer.

The roof truss system of a private house must meet the following requirements:

- The truss system must be strong and tough - change in the shape or size of the roof under the action of loads should not exceed the allowable values.

- The roof must be light. in order to load the walls and foundation of the house with their weight less.

- truss system must not submit a dispute (force in the horizontal plane) on the walls of the house.

- The truss system must be durable. Replacing or repairing the truss system is an expensive pleasure.

To fulfill the first two requirements, the truss system is made of separate linear elements assembled into a triangular structure. A separate flat triangle of the truss system, from two rafters and related parts, called a truss frame or truss.

Rafter frames or trusses mounted on walls parallel to each other at a certain distance and form a roof truss system .

It is impossible to make changes to the truss system designed by a specialist at will. The addition or exclusion of any detail will lead to a redistribution of loads to other nodes of the system. Even changing the number of nails to connect parts, can lead to destruction of the house. For example, an increase in the number of nails used to nail the rafters can lead to unacceptable thrust on the walls. Read about it below.

Try to make the rafter system symmetrical. The symmetrical arrangement of the rafter legs, racks, struts, will allow you to evenly distribute the load on the roof slopes, which will increase the stability of the roof and walls of the house.

To remove moisture from the wooden parts of the roof and condensate, attic space should be ventilated with the help of vents. In mansard roofs, ventilated gaps are arranged for this.

To protect against moisture, Mauerlat and other wooden parts of the truss system separated from the masonry walls with waterproofing. If this is not done, then the tree will quickly rot.

The rafter system for a private house is made of wood. Sometimes, for example, in frame houses with a metal frame, metal profiles are also used to make the truss system.

What kind of roof should be put on a log house

For the roof of a log house with chopped gables, only the option with sliding rafters is suitable.

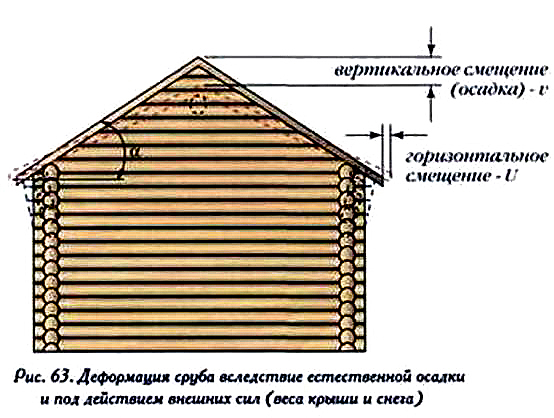

All this is due to significant shrinkage of the log house. Now we are talking about gable roofs. It's simple: if some part of the log house is higher than the other, then the geometry between these parts will change after shrinkage. Each log loses in the process of shrinkage up to 15% of the volume in diameter, but this is by a fairly large account. For rounded logs, the standard is 6-8%.

The chopped pediment is like this:

The logs in the gable (pediment) part are called "males".

If the log house is a flat box, then all its walls will settle in the same way. But if some parts (pediments) are higher than others (longitudinal walls), then the difference in height between them will change, and if you build a roof on rigidly fixed rafters, then it will literally be torn off the log house, the males can fall out ... In general, this is fraught with a serious emergency situation.

Here is how the chopped pediment shrinks:

For which log cabins are rigid truss structures suitable? For the pincerless! When the roof is placed on a flat frame box - for example, a hip roof. Or you can make a frame gable (with clogged boards, a blockhouse, etc.) ... But this will no longer be a log house in its purest form.

A full-fledged log house with a gable roof can only be with a chopped pediment. Why? Because the pediment is also a part of the house, and a considerable one at that. If you make it a frame, it turns out that half the house is a frame assembly. Maybe this is practical - because it is easier - but in this case, it is practical to build the whole house using frame technology. Log cabins are erected for the sake of their special merits, and if you do it, then do it properly and without half-measures.

How to build a house roof correctly basic steps

Before you begin to study the material on how to build a roof at home with your own hands, it is important to become better acquainted with the design features of each type of roof. So, the basic requirements for the roof structure are as follows:

- high mechanical strength, which can withstand not only the weight of the roof, but also large wind loads combined with the pressure of a mass of wet snow;

- low weight of the roof, which contributes to the absence of pressure on the bearing walls and the foundation of buildings and structures.

Depending on the design, the following types of roofing are distinguished :

- flat;

- pitched (with and without an attic).

If everything is more or less clear with a flat roof, then with a pitched roof the situation should be clarified. First of all, arranging a roof with an attic space has many advantages. :

it becomes possible to get an additional utility room where you can organize the storage of things;

over time, you will be able to convert the attic into a living space (the so-called attic);

the level of general ventilation of the building increases significantly during the construction of attics;

the attic is an additional layer of thermal insulation between living quarters and the environment, therefore, during its construction, special attention is paid to the insulation of this room.

Wooden roof repair

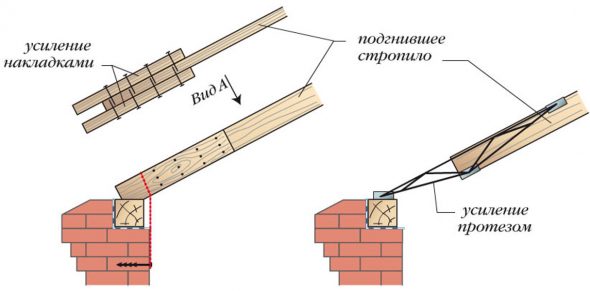

Problems with wood flooring usually occur in places where there has been stagnant water or the elements do not fit snugly together. It is not recommended to make inserts or patches, it is best to completely change the failed wooden elements, laying new ones in their place. If the rafter is damaged by rot, the same one is prepared, with the appropriate dimensions and tie-ins, after which it is installed at the place of damage to the part.

If the rafters were damaged, then the entire roof may sag. In this case, it is necessary to support it with racks and hold it with jacks, then install the struts under the rafters and fix them with brackets. If the rafter leg has just begun to rot, it can be strengthened by installing pads that are fixed on both sides of the rafter with bolts. The overlay should be at least twice the length of the rotted area.

You can strengthen the rafters by installing pads that are fixed on both sides with bolts.

To avoid the need for repairs, it is necessary to periodically inspect both the roofing material and the truss system. If a dull sound is heard during the tapping of the beams, this indicates internal damage, it is better to replace such an element immediately.

Roof insulation materials

It is very important to choose a high-quality and reliable material for the thermal insulation of the roof of a house from a bar. There are a number of parameters that must be met by roof insulation

Material requirements

The main indicators of a high-quality heat insulator:

- environmental friendliness and safety for humans.

- low thermal conductivity (no more than 0.04 W / m ° C);

- light weight so as not to create additional load on the load-bearing structural elements;

- keeps its shape well;

- high vapor permeability;

- soundproofing properties;

- density not lower than 15 kg/m3.

What insulation can be used for the roof

Types of roof insulation

It should be said that among the huge number of modern heaters, there are not so many materials that meet the criteria listed above.

To insulate the roof, you can use:

- mineral wool;

- ecowool;

- expanded clay;

- expanded polystyrene;

- polyurethane foam.

Features of each material

To determine which insulation is better, let's dwell on each in more detail:

Mineral wool is considered to be the best material for thermal insulation of a wooden house.

With a small weight, it has a high density, which is very important when insulating a roof structure. Mineral wool is not combustible and does not absorb moisture, these indicators are especially valuable when used in wooden buildings.

Resistance to high temperatures allows it to be used for warming the roof of the bath. The material is of natural origin, rodents do not like it, insects do not start in it.

Ecowool. It is made on the basis of cellulose, has light weight and affordable price. It is a good heat and sound insulator. But the material has increased flammability, to prevent ignition, fire retardants are added to the composition, which prevent the spread of flame.It is undesirable to use in very damp rooms.

Expanded clay. Loose insulation, consisting of hollow granules. Due to its porous structure, it has high thermal insulation properties. For efficient heat transfer, a thick layer of material is needed, which increases the load on the supporting structures.

Styrofoam. It is presented in the form of plates, which are light weight, high strength, have good heat-insulating abilities. The material is combustible, therefore, when insulating a log house, it is necessary to choose plates with a combustibility index of G1.

Polyurethane foam. Similar to the previous material, it is a small, durable plate that is easy to install and lasts a long time. Sprayable insulation is also on sale, but its installation requires professional equipment.

General roof arrangement

In all variants of wooden roofs, there is a base on which wooden inclined structures are mounted, holding the planes of the slopes directly. Such a base is called a Mauerlat and is attached around the perimeter of the structure.

It is created from the upper crowns of a log house or the last row of beams. Mauerlat, to give it greater strength and reliability, may have transverse overlaps or screeds.

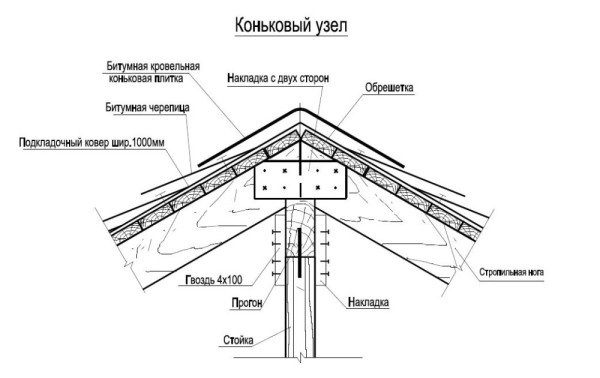

Rafters are fixed on the base, which are prefabricated trusses in the form of a triangle, including:

- rafter leg (inclined beam);

- a transverse beam to which a vertical support (headstock) is attached;

- headstocks on which the junction of inclined beams rests.

Boards are laid on the rafters to support a layer of waterproofing material (roofing, film) and directly to the roofing itself - slate, tiles, ondulin.

The design of truss trusses may not be based on stocks, but be reinforced with crossbars, blocks that connect the rafters horizontally and are usually attached, like the upper and lower chords, at a short distance from the top and base.

Headstocks, in turn, are reinforced with struts to increase the bearing capacity. The strut is a bar, with one end resting on the place where the headstock is fixed, and with the other end on the rafter leg not far from its top.

The wooden roof has the following designs:

- lean-to;

- gable;

- four-slope or tent;

- hip or semi-hip;

- complex or attic.

- Single sided option.

Shed wooden roofing is done mainly at outbuildings, garages, sheds. Roof trusses in this design have the shape of a right triangle.

The vertical side is simply sheathed tightly with boards. Rafter legs protrude beyond the perimeter of the building on both sides, forming cornices.

Shed roofs have rafters reinforced with crossbars without transverse beams. The ceiling in buildings with such a roof is not created, and the trusses form a hanging structure.

Such a roof, as a rule, has a rafter system in the form of isosceles triangles. The junction of two roofing planes forms a ridge. Attic entrances are arranged from the side of the vertical sides.

Due to the simplicity of design and installation, this type is most common in the construction of country and garden houses. Inside the structure itself, an attic space is formed, which is used as a dry pantry or, with additional finishing, as a living space.

The rafter system of such a roof converges at one point, and all rafters are supported - one rod, called the uterus. As a result, a roof is formed, which has four inclined planes of a triangular shape, converging at one point in the form of a tent or pyramid. In this design, there is no skate.

It is used in the construction of one-story buildings of the correct quadrangular or polygonal shape.The angle of inclination of the planes is selected depending on the amount of precipitation and the strength of the winds prevailing in the region where the construction is being carried out. When creating such a roof, elongated cornices are possible, which prevent weather precipitation from entering the walls.

These structures are a combination of two and four-slope systems. The frontal parts of them have the shape of a trapezoid. Triangular planes adjacent to the ridge connection of two more slopes are called hips.

These designs are used to create the second floors in the house, attics and roofs of complex shape with attic ledges, balconies and other non-standard buildings that correspond to the chosen style and design of the house. The design features of such roofs include valleys, various spacers and ribs that enhance rigidity and reliability.