Which side to put

You can lay the foil backing yourself. The process is distinguished by its simplicity and speed. It consists of two stages - preparation and direct installation.

Training

Before laying laminate boards, you need to properly prepare the floor surface. It is from the quality of the preparatory work that the durability of the flooring will depend.

Preparation includes the following:

-

The floor surface must be level, firm and dry.

The first step is to dismantle the old coating and assess the condition of the existing screed. If there are many cracks and chips on it, it crumbles and exfoliates, then it needs to be dismantled and a new one created. If the defects are minor, then the existing chips and cracks should be eliminated with putty, and the surface should be leveled. - When choosing the material used to level the surface, it is necessary to take into account the depth of the irregularities

. Measure the floor with a building level and calculate the difference between the highest and lowest points. If the value obtained is greater than 3 cm, then it is advisable to perform a traditional cement-sand screed. If the depth of unevenness does not exceed 1 cm, then you will have to use a self-leveling mixture. -

Before installing the laminate, the screed must be completely dry.

. You will have to wait about 14 days. To check the readiness of the surface, you must use a simple method: install a glass jar with the neck pointing down. Wait a day and inspect the glass. If moisture has settled on it, then you still need to wait, since the screed has not dried. - If the installation is carried out on a wooden base, then the condition of the surface will have to be assessed in order to detect the presence of bumps, cracks and instability.

. If the condition of the floor is unsatisfactory, then the boards will need to be redone. Minor irregularities can be eliminated by applying the installation of fiberboard sheets. -

The preparatory activities end with a thorough cleaning of debris and dust.

. A vacuum cleaner will help to cope with this work.

On the video - preparing the substrate for the laminate with foil:

As for the shortcomings, it is only one. This is a high price, because of which not everyone can buy such a high-quality laminate lining.

Installation

It is necessary to lay the foil product in the direction in which the laminate will be installed. Lay the lining so that the reflector is on top. On the strip, which is concentrated along the wall, leave an allowance. It will be several centimeters.

Installation of all strips is carried out end-to-end, and fastened with foil tape. It must be glued very carefully so that there are no creasing edges of the material and cracks.

The flooring of the material is carried out in a volume that will be enough for laying 2-3 rows of laminate boards. After that, mount the floor covering and lay the next strip of lining. The allowances that are near the wall, after installing the laminate boards, disguise them under the skirting boards.

On the video how to lay a substrate with foil:

In order for the installation process to be carried out as accurately and efficiently as possible, it is necessary to adhere to the following recommendations:

- You can not choose a substrate of great thickness or lay it in 2 layers. To hide the strong unevenness of the floor, it is better to carry out the preparatory work to level the surface as evenly as possible, and lay thin insulation on the dried layer.

- When laying the lining, it is necessary to ensure that there are no coincidences of its seams with the joints of the floor covering.

- The installation of the roll substrate should be carried out with an overlap on the walls. Further strips are laid without overlap, fixing with masking tape.

- Sheet insulating material is laid in a checkerboard pattern, and then fixed with adhesive tape.

You may also be interested in knowing about

A hidden underfloor heating system is an excellent option, both for creating additional comfort in the room and for full-fledged heating of the house. If we consider in section the structure of the classic version of such heating, we can see at least four separate layers. Each of them has its own purpose, and the exclusion of any of them will negatively affect the efficiency of the entire heating unit. One of these structural elements is a foil substrate under a warm floor. And what is its purpose, we will tell you in this article.

Floor preparation

Before starting installation, the base must be prepared and leveled. Laminate makes high demands on the quality of the surface of the subfloor, because the condition of the laminated coating and its service life depend on it:

- The surface of the subfloor must be very carefully leveled, dry and clean. First, the condition of the existing screed is critically assessed, if it already exists. In the presence of cracks and damage, they are eliminated.

- If there are irregularities and significant differences in height (more than 2-3 mm), the surface can be leveled using a self-leveling floor, or by laying plywood sheets.

- Before laying laminated panels, the screed or self-leveling floor must be completely dry. The moisture content of the subfloor can be easily checked with a plastic film attached to the base with tape or with a small glass jar placed upside down on the floor. If even a slight condensate appears the next day, it is worth waiting with the installation.

- With a plank base, it is also required to pre-prepare it. With a fragile, shaky foundation, either a complete re-laying of the floor is made, or defects are eliminated, a partial replacement of boards or a log is made. Roughness and differences are removed by grinding or plywood sheets are laid.

- Clean the floor of all dirt using a vacuum cleaner.

Compatibility of substrates and heating systems

For each model in the heat supply, appropriate heaters are made. If they are not used correctly, you can come to additional costs or not get the desired heating of the room.

Therefore, before you buy them, you need to pay attention to the following indicators:

- Underfloor heating foil underfloor, designed for film infrared coatings. This is a new insulating combined product. The sides of this substrate are equipped with a foil layer with an aluminum interlayer or a metallized polypropylene film. Due to this, the product is able to maintain and reflect the required temperature in the room.

- For a water heating system, foil insulation should consist of classic heat insulators, such as penofol, isolon, polyethylene foam and other similar materials. The second is a reflective coating consisting of a polypropylene metal film or aluminum foil.

- The underlay for a warm electric floor is made of foamed polymers with a laminated coating. This substrate does not conduct current, does not interact with alkaline solutions and retains its properties throughout the entire operation. The thickness of this material is no more than 5 millimeters, which allows it to be used in rooms with low ceilings.

Having decided what kind of underlying material is needed when installing the heating system, it will be possible to proceed with the installation process itself.

Substrate laying

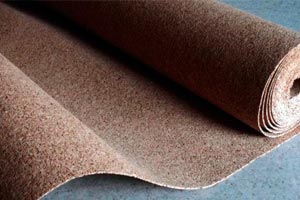

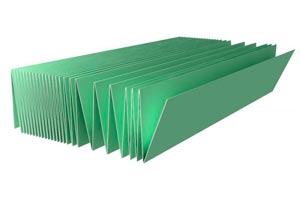

The method of laying the substrate depends on its form of release. Basically, there are three types of sheet formation: roll, accordion and layers.

The width of the roll is most often 1.2 m, length - from 10 meters. The rolling of the roll is carried out in a direction perpendicular to the forthcoming laying of the laminate boards.

This is done so that during the operation of the floor, the seams of the substrate do not part.

The installation process itself will look like this:

- The rough base is carefully cleaned of dirt, which can create additional irregularities, and a polyethylene film is laid out on it as a moisture-proof layer - at will or on the recommendation of the laminate manufacturer.

- Further, starting from any wall, the roll of the substrate is rolled out. Its edges must necessarily go to opposite walls at least a few centimeters, then the excess can be cut off.

- Then, close to the first strip, the second is rolled out. You can fasten them together with both simple adhesive tape and aluminum tape. The main thing is that the seam is strong and reliable. Thus, the entire necessary floor surface is covered.

Sheets

The process of laying them begins in exactly the same way as the roll substrate, that is, with cleaning the floor and moisture protection flooring.

There are only two rules:

- The perpendicularity of the long side of the backing to the intended direction of the laminate.

- Laying adjacent rows of platinum in a checkerboard pattern.

The plates are also fastened with adhesive tape or special adhesive tape.

This is a symbiosis of the compactness of the plates already fastened together along the long side and the convenience of roll rolling.

This form of the substrate is much less common than the previous two, although it combines the convenience of each of them.

It is easier to transport than, for example, rolled, and faster to stack than sheet.

Laying it is the same as rolling out a roll substrate.

Laying the flooring, getting started

Like all repairs, laying a laminate begins with surface preparation, without this process it is problematic to achieve a good result. However, first we will prepare the entire tool.

Required tool

-

Jigsaw and hacksaw

. It is better to work with a power tool, and the speed increases, and the quality of work does not suffer. -

Hammer and mallet.

Work with a rubberized mallet that can hardly damage the laminate. - Roulette and level.

-

Stationery or shoe knife.

A polystyrene laminate substrate is easily cut by both, so there is no fundamental difference in how to work.

In addition to the need to purchase the right amount of material, the calculation is something like this: one pack (5-10 boards) is enough for 2-3 square meters. m., but make an error that you do the work yourself, without the help of specialists, so it may not be so smooth.

As for the substrate, it must be purchased in the right amount, without a stock. It's still not wooden boards, the film is harder to screw up.

Surface preparation

What you need to mount the screed:

- Dry mix.

- A container for diluting the solution.

- Drill with a mixing nozzle, or a construction mixer.

- The rule, or something perfectly even and long.

- Guide beacons.

- Trowel and grater.

- Clean the floor from various fragments: dirt, dust, concrete chips, wood shavings.

- All cracks are carefully puttied and walk with a floor primer.

- Mark the clean floor level on the wall, the top point of the laminate: you can navigate along the bottom edge of the door, or according to the previous flooring.

- Using a level (building or laser), draw a line around the perimeter of the room.

When the whole room is ready, it is necessary to wait a few more hours, or even days, for the final hardening of the screed.

Remember, the screed is very important for the quality laying of the laminate, so the end result of the repair depends on the work done.

Substrate laying

It is up to you to decide which substrate to put under the laminate, but we will tell you how to do it.

If you purchased a rolled canvas, start from the outermost wall and cut into strips with a small margin.

All joints between the canvases are sealed with permeable tapes. For a budget option, you can use adhesive tape.

Laying laminate

So we got to the most basic - laying the flooring. The process is not too difficult and does not take much time, the main thing is to understand how it is done and everything will go like clockwork.

In order to make it more clear, it consists in connecting the laminate boards to each other, most often a rubber mallet is used.

Having chosen one wall from which to start work (perpendicular to the window), you should take several boards and put them side by side: this way you will understand how the drawing will look. In some cases, it is very important, so a preliminary inspection will not hurt.

- After finishing one row, cut the last plank to size with a jigsaw. Try to cut tightly, the maximum should be 5-10 mm.

- The next row starts with a sawn-off board, this is necessary to create a checkerboard effect when the joints of the laminate do not intersect and do not converge.

The right angle guarantees a good result

- Try not to rush, carefully punch all the joints, so that in a week you won’t have to start repairing a new floor covering.

- After the laminate has been laid, it should not create a large resonance in the ambient temperature, it is necessary to carefully commission the wooden materials.

Installation of a water system with the participation of a substrate

The water heating system has a high device threshold. Therefore, in order to minimize the height of the room, it is necessary to use a material with a minimum thickness. The installation process takes place as follows:

- A layer of waterproofing is laid on the prepared surface.

- A substrate is laid on this layer end-to-end in such a way that the reflective side looks up.

- The seams between the pieces of materials are glued with metallized tape.

- Next, the heating system is installed.

- Pipes are filled with screed.

After the screed dries, proceed to the installation of the floor covering.