Ceramic sewer pipes

The characteristics of ceramic pipes make it possible to use them in particularly unfavorable conditions. It is advisable to use ceramic pipes for sewerage at a high level of groundwater, which are characterized by high aggressiveness. The only possible option under such conditions is their resistance to corrosion.

Immunity to chemical influences makes it possible to use ceramic pipes for industrial sewerage, where effluents are characterized by a high content of chemically active elements. These products are resistant to static loads.

The thickness of the walls allows laying in places with traffic. The diameter of ceramic pipes allows their use for the construction of sewer systems with a high intensity of drainage.

Ceramic pipes

Disadvantages of ceramic pipes:

The standard length of pipes is insignificant, which increases the complexity of their installation and reduces its speed.

Considerable weight complicates transportation and installation.

Ceramic pipes are very fragile - they can be easily damaged by careless impact. Delivery and stacking must be done with great care.

Ceramics, unlike plastic pipes, does not tolerate freezing - products burst

In this regard, during installation, it is necessary to observe certain depths of laying, or to carry out all the required measures for thermal insulation.

The difficulty of cutting to the required size, as the pipes are fragile.

Types of plastic used for sewer pipes

So, consider such a product as a sewer pipe: plastic, or rather its type, is of great importance, and not all of it is equally good for this application. For the production of sewer pipes, several polymeric materials are used, which have either universal or specific uses.

Polypropylene

When they talk about the abundance of advantages that plastic sewer pipes have, for the most part they mean exactly polypropylene. This material really has a whole bunch of advantages:

- Long service life. Experts predict that it will serve for at least 50 years, and they emphasize that this is a minimum, and subject to all operating conditions, it will last 100 years.

- Low thermal conductivity. This property prevents the formation of condensate and eliminates the need for insulation almost throughout the entire system.

- Resistant to all types of corrosion. Polypropylene does not react with aggressive chemicals, which not only prolongs the life of the pipeline, but also eliminates the possibility of clogging, since the inner surface of the pipe always remains smooth and does not retain contamination.

- Resistant to temperature extremes. Under the influence of both low and high temperatures, the material does not lose its strength, durability and does not change the linear parameters. This property makes it possible to install pipes made of polypropylene both on the inside and on the outside of the sewer.

PVC

This material also has strength and durability, and its cost is lower than the price of polypropylene products, but there are a number of disadvantages that, under certain conditions, can be considered significant and make this material not the best option for use. These include fragility at sub-zero temperatures, low fire resistance, as well as the release of toxic substances during combustion.

Polyethylene

High pressure polyethylene used for the production of sewer pipes also has the advantages of high resistance to chemicals, durability and low thermal conductivity, however, it is not able to withstand such high temperatures as polypropylene, and does not sufficiently resist mechanical damage and UV radiation.

In general, all polymer pipes are lightweight, easy to install and have a high degree of resistance to various chemicals.

metal pipes

These are ferrous metal products, which are the best from an economic point of view:

- they are high strength;

- can be operated in a wide temperature range;

- easy to process.

But all these advantages are negated by their susceptibility to corrosion and a significant mass. At the moment, metal types of pipes for sewerage in everyday life are practically not used. They are used only in industry for the removal of waste chemical liquids.

Cast iron pipes

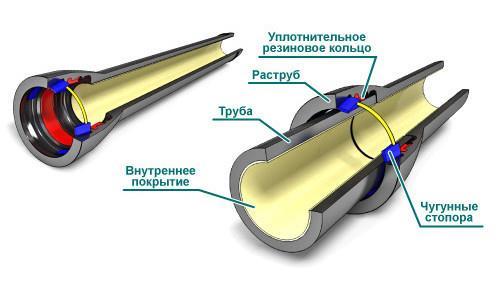

Modern cast iron pipe

Cast iron is more expensive than steel sewer pipes due to its significantly greater mass, but it is less susceptible to corrosion. Cast iron products are sometimes used in everyday life for sewer risers and external outlets to the collector.

In addition to the advantages and disadvantages inherent in all ferrous metal products, cast iron sewer pipes:

- They have a rough surface, which contributes to the accumulation of dirt, which leads to a noticeable decrease in the permeability of the drain.

- Inconvenient during installation - special materials and certain experience of workers are required to ensure the tightness of the joints.

The modern version of cast iron is ductile iron pipes for sewerage, obtained by modifying simple cast iron with magnesium. As a result, the material became more durable and ductile, eliminating the risk of cracks and their propagation.

VChShG pipes combine:

- Mechanical characteristics of steel: impact resistance, tensile strength, ductility, high relative elongation.

- Corrosion resistance of cast iron.

Kinds

To understand which pipes to use in the sewer is better, you need to consider what the construction market offers consumers. They are made from the following materials:

- asbestos cement;

- ceramics;

- metal;

- polymers.

Advantages and disadvantages of asbestos cement

The advantages of a mixture of asbestos fiber and cement include the following:

- service life up to 100 years;

- immunity to aggressive environmental influences and the type of liquid;

- lightness of the material;

- ease of installation;

- no blockages.

Asbestos cement is not without drawbacks. It is quite fragile, so it should be protected from mechanical stress. Such sewer pipes are good to use in an apartment.

Advantages and disadvantages of ceramics

Ceramic pipelines were laid in antiquity. But even now they are in demand due to their high performance. These include:

- immunity to chemical and temperature effects;

- no blockages;

- ease of installation and replacement.

A ceramic sewer pipe can pass any type of liquid. It cannot be damaged by chemicals. The smooth inner surface eliminates the formation of mechanical and biological blockages.

Ceramics have one drawback - fragility, which complicates the task of transportation and installation.

Advantages and disadvantages of metal

Among metal products, pipes made of steel and cast iron are the most popular.

Steel has the following advantages:

- strength;

- ease of processing and installation;

- ability to withstand high temperatures.

However, it is not recommended to use it for laying water pipes due to its impressive weight and susceptibility to corrosion.

Cast iron has the same advantages as steel. It is not subject to corrosion and is able to withstand significant loads. However, cast iron is very heavy, and many consumers note its fragility. The inner surface of cast iron products is rough, which contributes to the formation of blockages.

Advantages and disadvantages of polymers

Now consumers rarely have to think about which pipe to choose for sewage. Most often, preference is given not to heavy metal, but to light polymeric materials (plastic). They are used for laying internal and external pipelines due to their high strength characteristics.

You have to choose from three polymers:

- PVC (polyvinyl chloride);

- PVC np (unplasticized polyvinyl chloride);

- PP (polypropylene);

- (PET) polyethylene.

Plastic products have the following advantages:

- have high strength;

- UV resistant;

- do not deform under temperature changes.

Polyvinyl chloride is used in gravity sewer lines. Exposure to low temperatures leads to a loss of elasticity, making it brittle. High temperatures cause deformation. Polyvinyl chloride is destroyed by chemicals.

The service life of polypropylene is up to 100 years. It is strong, light, elastic and withstands high temperatures without being deformed. However, it is not recommended to use it for laying outdoor plumbing.

For the installation of external sewerage, it is recommended to choose materials from polyethylene. They are durable, polished inner surface eliminates the formation of blockages. The only drawback is the sensitivity to ultraviolet radiation. Therefore, they are used under the condition of absence of exposure to the sun.

Related video: Pipes for external and internal sewerage

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Selection of the section and dimensions of the pipeline

Wiring diagram of the internal sewerage

The main points of the selection of pipes for sewerage:

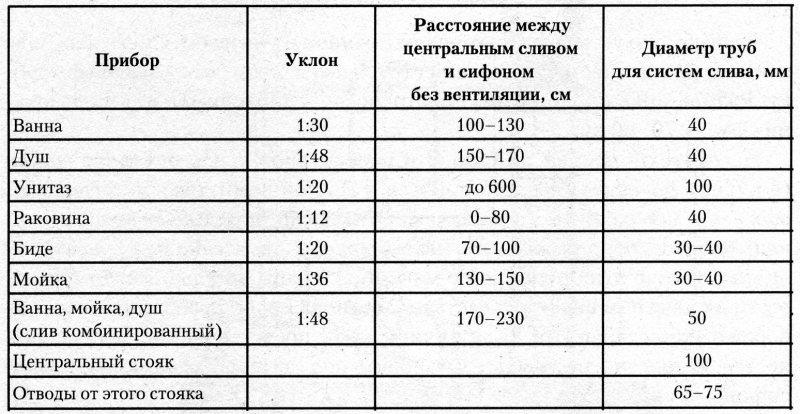

- Traditionally, the diameter of the pipes of a system that provides normal flow is 100 mm.

- In buildings of individual construction, intended for the permanent residence of a large number of people, the diameters of the pipes are set by the designer.

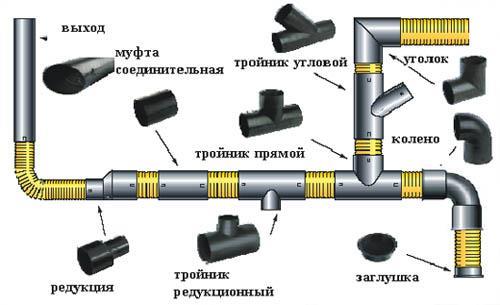

- Types of sewer pipes and connections depend on the specific operating conditions of the system. The pipeline layout can be carried out from pipes with a diameter of 50 mm, in geometrically complex sections - from corrugated pipes connected to PVC channels. Their connection is carried out by means of special sockets. For products that do not have sockets, rubber, less often polymeric couplings are used.

- Usually the sewer pipeline consists of products of round section. But on sections with a high load, which can be created by intensive movement or the weight of the soil, it is permissible to use products with an elliptical section. In cases where the deepening of the sewerage is insignificant (0.5-1 m), channels with a semicircular, trapezoidal or rectangular section provide good throughput.

- Pipes for sewerage are selected depending on the purpose of the site:

- from the riser to the plumbing equipment - diameter 50-100 mm;

- for risers - diameter 100-110 mm;

- in the basement or basement, in the case of a complex system with a large number of connections - a diameter of 110-150 mm;

- outdoor pipes that convey wastewater to a cesspool, septic tank or centralized sewer network must have a diameter not less than the diameter of the last pipe from the building.

Thermal insulation of external sewerage

In case of insufficient penetration of the wrist section, the equipment located in the freezing zone must be insulated to prevent pipe breaks in winter. Due to the stability of temperatures at depth, insulation of the network located below the freezing level is rarely done. But it is advisable to do the thermal insulation of pipelines in any case to completely prevent the likelihood of emergencies and subsequent repair work.

The flawless operation and duration of the operation of sewer communications depends on the proper selection of pipes. Information about the advantages and disadvantages that various types of sewer pipes have makes it possible to make the right choice for those who want to repair or equip individual houses with sewage.

Installation of plastic sewer pipes

For the device of the system, plastic sewer pipes of different diameters are used, which is selected depending on the load in this area. So, for example, a pipe with a diameter of 50 mm is used inside buildings, as a rule, when distributing wastewater, a diameter of 110 mm is more suitable for transporting waste from toilets, and a pipe with a diameter of 300 mm is used in the construction of sewers in apartment buildings or industrial facilities, that is, there where it will bear the greatest load.

Required diameters of plastic sewer pipes

Design work and diagramming

The initial stage of sewerage construction is the preparation of a project, according to which sewer plastic fittings and pipes are purchased in the required quantity, observing all the required dimensions

You can draw up a project based on an existing system; before dismantling it, you need to carefully examine it, noting all the features and paying special attention to the shortcomings so as not to repeat them in a new structure

If possible, you should save the entire route of laying pipes, this is done in order to avoid making new holes in walls and ceilings. If the old scheme is preserved, it will also be easier to select the diameter and measure the pipes.

The diagram shows the locations of the riser, sewer units and other key places.

Measuring the length of the pipe on the ground

Pipe laying

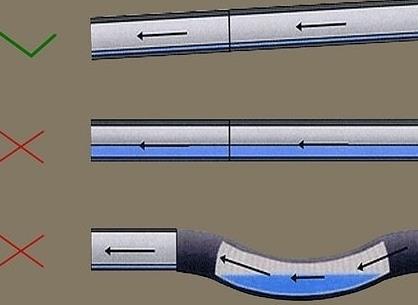

The laying of sewerage from plastic pipes begins from its highest point. As you lay, you should not forget about the need for a slope and observe its value.

This is especially important if the sewer is a non-pressure type and the water flows down into the riser by gravity.

It facilitates the task of using the level, with its help it is easiest to control and observe the angle of inclination. It is also necessary to ensure the minimum distance between the fasteners, since if it is exceeded, the plastic pipe may bend under its own weight.

Proper location of sewer plastic pipes

Pipe connection

Before proceeding with the installation of the system, you should consider how the sewer plastic pipes will be connected. There are two options for docking and sealing: using glue or welding.

- Adhesive connection. Before applying the adhesive, cut the pipes to the desired length, remove burrs with sandpaper and degrease both the surface of the pipe itself and the fittings that will be used for connection. The glue is applied in a thicker layer on the pipe, thin - on the connecting elements. When inserting the pipe into the fitting, it is recommended to turn it slightly to distribute the adhesive more evenly.

- Connection by welding.Before connecting sewer plastic pipes in this way, their surface is thoroughly cleaned of contaminants, the palnik is heated to the required temperature level and the fittings are prepared. Before soldering, both pipes and fittings also need to be degreased; after this procedure, they are put on the nozzles of the soldering iron, where, after heating for the required time, the fitting is inserted into the pipe. The quality of the resulting connection is checked: it should not have burrs and excess plastic.

Pipe welding

Upon completion of the installation of pipes, gaps between pipes and walls or ceilings should be sealed. As a rule, mounting foam is used for this.

The process of installing sewer pipes does not require high qualifications, but if there is even the slightest doubt about whether it will be possible to do all the work efficiently, you should turn to professionals.

Plastic pipes are by far the best material for sewerage, their installation and connections are not highly laborious and complex, but certain rules and requirements must be observed.