Choosing a chimney for a gas boiler

Any wall-mounted gas boiler needs a chimney. Depending on the model, this can be either a traditional chimney or a small horizontal chimney that can be led outside right through the wall of the house.

In double-circuit boilers with an open combustion chamber, the combustion process occurs with the help of air from the room in which the heater is installed. Typically, such models are installed in specially equipped boiler rooms. To remove combustion products, they are connected to traditional chimneys for gas boilers made of ceramic or stainless steel.

Wall-mounted boilers with a closed combustion chamber (turbocharged) use outside air in their work. It is fed into the device through one of the channels of the coaxial chimney. The second channel is used to vent flue gases into the atmosphere. The coaxial chimney is very easy to install and you can connect a gas boiler to it with your own hands.

What is a bellows liner and what are its advantages

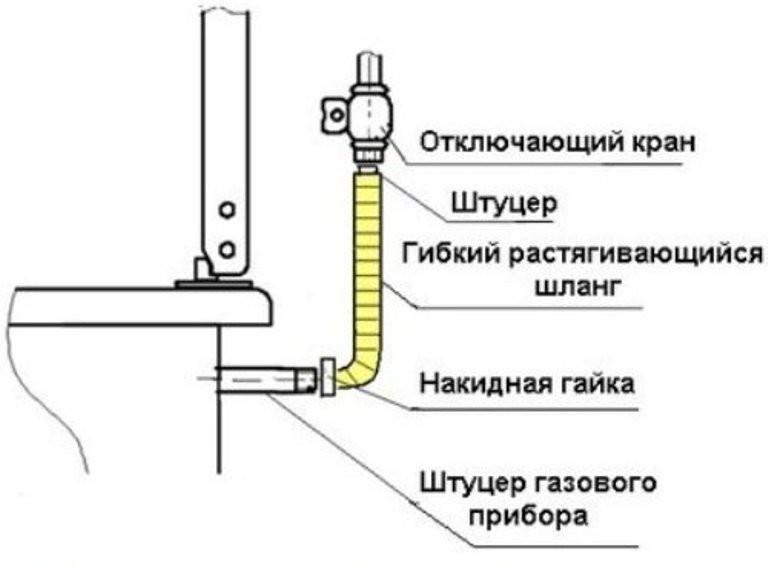

The bellows gas hose is a corrugated pipe made of stainless steel. Special fittings are installed at the ends of the hose for the construction of a strong and safe connection. Fastening of the eyeliner to pipes and equipment is carried out using union nuts made of the same material. To increase the level of tightness, metal or plastic sealing rings are installed at the junction.

As a rule, sealing gaskets are included in the flexible piping kit.

Eyeliner kit

The advantages of a bellows hose over other types of flexible pipes designed to connect gas equipment are:

- strength and rigidity. At the request of manufacturers, the period of use of the bellows is up to 25 years;

- the ability to work correctly at different temperatures;

- exposure to direct sunlight;

- the ability to withstand high pressure;

- the possibility of stretching, and with an increase in length up to 50%, the strength of the eyeliner does not decrease.

The disadvantages include the cost of equipment, which is 2-3 times higher than the price of rubber analogues.

Gas connection installation

The installation of the bellows gas hose is subject to the following rules:

- it is unacceptable to hide the eyeliner in the wall, since any leak that is not detected as soon as possible can lead to emergencies, damage to property and death of people;

- do not install a hose with a large number of kinks;

- the ingress of condensate on the equipment will help to reduce the life of the eyeliner.

Mounting scheme:

- choice of installation location in accordance with the recommendations given above;

The optimal scheme for connecting a gas stove

- shutdown of the gas supply to the premises. To make a temporary shutdown, you can use the tap installed in the apartment, and in its absence, you need to contact the management company;

Individual tap for shutting off gas

- dismantle the old eyeliner (if any);

- if there is no supply and tap, then before connecting the equipment on the pipe, it is necessary to cut the thread and install a tap that allows you to shut off the gas supply directly in the living room. For example, to troubleshoot equipment;

- dielectric installation;

- a flexible hose is attached to the faucet. As a rule, in this situation, the “nut” connection method is used;

When connecting the eyeliner, special attention is paid to the installation of the sealing gasket. A connection without a gasket will not be completely sealed.

To increase the tightness, you can additionally use FUM tape or other similar material.

- connection of the piping to gas equipment using an o-ring. All nuts and fittings must be fixed with an open-end (wrench) wrench without any extra effort. Even slight overtightening can lead to damage to the seal and rapid depressurization;

Connecting the plumbing to the equipment

- examination. To detect a leak, you can use a soap solution and an ordinary brush (sponge). If soap bubbles appear on the surface when applying the solution, then the connection is not tight.

Soap leak detection

How to connect a gas stove yourself, look at the video.

If it is not possible to carry out the work on the installation of equipment on your own, it is recommended to contact the specialists of the gas service. Replacing the eyeliner will cost approximately 300 - 500 rubles.

Types of gas valves

In old buildings, two types of cranes were usually installed on vacation:

- petal;

- suberic.

What is the difference between the designs of these products can be seen in the figure.

When a plate is changed or a valve fails, it is best to install a new ball valve.

This device is much better, but more expensive. Installing an Italian faucet will cost $10. You can also install a cheaper domestic crane, costing $ 5. They are no worse than their foreign analogues, but sometimes they have defects. Therefore, do not forget to take a receipt with you when buying so that you can exchange a defective product for a good one.

Varieties of gas flexible hoses

The current market offers a fairly extensive list of gas hoses. In addition to the material, you will also need to choose a manufacturer. And in this case it is better not to save. A thing is bought once and for a long time. Having saved 500 rubles, you can later spend a lot on health and repairs if the pipe starts to let gas through. So let's start with the varieties.

rubber-fabric

It has a lot of advantages that allow it to be used in a gas system:

- easy installation;

- good flexibility;

- low cost;

- various sizes;

- excellent electrical insulation.

The disadvantage of such rubber parts is poor rigidity. Today, the industry produces hoses from a special material of high elasticity. Therefore, their service life can reach 10 years.

The cost of such hoses usually does not exceed $ 7.

Bellows metal

Professional gasmen consider it the most suitable for gas systems. The service life of such hoses can be more than 25 years. It connects to the gas stove without any difficulties. Bellows systems can be connected to boilers and columns, and they are completely safe.

If you have a gas stove in your kitchen equipped with an electric ignition to connect a bellows device, a special insulating connection is created between it and the faucet.

This type of hose is free to bend and can withstand high pressures up to 6 atmospheres. It withstands a significant temperature difference ranging from -50 degrees and ending with heating up to 200 degrees. The main disadvantage of bellows hose is its cost. It is many times higher than similar gas connections.

The advantages of such bellows metal systems include:

- made of stainless steel;

- corresponds to GOST;

- meets all technical requirements;

- protected from any mechanical influences by a special polymer coating;

- able to withstand any mechanical impact;

- warranty period exceeds 30 years;

- withstands a voltage of 1500 volts.

Oxygen

It can also be connected to gas stoves, but you need to take into account a few very important points:

- The inner diameter must exceed 16 millimeters;

- The surface in contact with oxygen must be well cleaned of oil. Otherwise, the hose will overheat and damage the material.

The advantages of oxygen hoses include the following characteristics:

- withstand high pressure. It can reach 20 atmospheres;

- very easy installation;

- low cost;

- rich assortment;

- does not conduct electricity.

What to do if the diameter of the gas pipeline does not match the boiler nozzle

Sometimes the inlet on the boiler with the diameter of the gas pipeline may not match. For example, the gas pipe of the Navien floor boiler is made under 1/2 ″, and the gas pipeline pipe is 3/4 ″. Is it possible to connect the device using DU-15 1/2″ bellows connection instead of 3/4″? Such a transition is acceptable, since it is local and does not offer significant resistance.

A modern private house, and even more so an apartment in an apartment building, cannot be imagined without gas equipment. It can be a stove, and a heating boiler, and a heating boiler, and other household appliances.

Gas is supplied to a house or apartment through a system of pipelines, and from it to each individual consumer by means of a flexible connection. Flexible gas piping can be made in several versions at once.

It's a must-know valuable advice

Before purchasing a flexible hose, it is necessary to check the size of the thread at the outlet of the plate, its classification and whether it belongs to a straight or angled type. If the outlet is of a direct type (directed towards the wall), it is necessary to purchase a sleeve with a square at the end.

The gas hose must not be painted - this will accelerate its cracking. A more attractive look can be created by pasting with special paper or oilcloth.

And it is also strictly forbidden to tightly sew up gas communications with false plasterboard panels and other structures - this will make it difficult to carry out service work with individual elements.

For camouflage of the gas supply system, a collapsible box is used, which, if necessary, is easily dismantled. In this case, all structural elements of the gas system will have constant access.

It is forbidden to use extra connections. Independent complication of the gas structure, according to the technical regulations, may result in a fine or disconnection from the gas supply

If a master was called to connect the gas stove, it is necessary to check the correctness of the work: the extra drive from the faucet on the descent must be unscrewed, the flexible hose is directly connected exclusively to the faucet located on the branch pipe, and its other end - only with the gas stove outlet.

You can also use an adapter. Any additional settings are prohibited.

Instructions for self-connection

Payment for the services of a gasman for installation work is not too high, but many home craftsmen prefer to do everything on their own. This is a feasible occupation that requires the purchase of components and theoretical knowledge.

And to connect, you will need to prepare the following tools and buy materials:

- keys: gas No. 1, adjustable 22-24;

- a screwdriver to tighten the clamp, if required;

- seals (thread loctite 55, linen, FUM - tape);

- gasket ½;

- gas sleeve;

- ball valve 1/2';

- brush and soap solution, which will be required to control the progress of work.

A rag and a plastic stopper will also come in handy. The rag will be used as a temporary cover against a gas leak. The narrowed edge of the plug must be adjusted to the opening of the supply pipe. If during the extraction process, a homemade part gets stuck, it can be easily removed with a corkscrew.

Step #1: Dismantling the old stove

Closing the crane on the descent is a top priority to ensure the safety of the work performed. Next, you need to unscrew the lock nut located on the outlet and remove the coupling. If the coupling and locknut of the old plate were previously painted, this will greatly complicate the process of their dismantling.

Sometimes this procedure cannot be performed, then you will need to cut the eyeliner with a grinder.

The dismantling of the gas stove is carried out after disconnecting from the pipe-conductor of the gas main. Difficulties encountered with unscrewing the locknut on a metal pipe are solved by trimming the liner

In the process of unscrewing the drive located in the lowering tap, it is necessary to hold the tap itself with a key. It will not have to be removed if the crane is not planned to be replaced. When it is planned to postpone the installation of the plate, an additional plug is installed on the descent.

Step #2: Performing a Faucet Replacement

There are situations when the wall is located very close to the crane and there is no way to dismantle it. In this case, it is necessary to bend the fastening and install a wedge between the wall and the pipeline. However, this is done in such a way that it is possible to continue to do the work.

It is necessary to prepare a piece of rags sufficient to completely cover the pipe after dismantling the old faucet. The next will be its tearing without full untwisting. And you will also need to prepare the selected type of sealant. Do not forget to thoroughly ventilate the room during work to eliminate gas vapors.

After unscrewing the faucet, the outlet from the pipe is tightly fixed with a finger, and then with a wet rag. The main actions are aimed at the maximum elimination of gas exit from the pipe. In this case, the thread on the branch should not be closed, since it will be covered with the selected sealant.

Before winding the sealant, the thread on the descent must be thoroughly cleaned. Further, its winding is carried out directly. This process ensures a secure and airtight fixation of the new faucet, which is then tightly twisted. The last step is to install the previously removed handle on the faucet.

With the help of soap foam, the tightness of the connection of the faucet and the gas pipe is checked. If the work has been carried out correctly, the installation of the gas hose can be continued.

If the gas equipment is connected to the main for the first time, it will be necessary to call the gas master. In his presence, a control check of the equipment for gas leakage with the valve open is carried out. In the event that the gas service employee did not find any violations, he must enter the established stove brand in the register.

Step #3: Connecting the Flexible Hose to the Stove

Using a sealant, the outer thread of the hose fitting is wrapped around. After that, it must be screwed into the faucet on the branch pipe. The connection of the flexible hose to the manifold is carried out at the finishing stage.

Next, the stage of test opening the faucet on the descent for gas leakage is mandatory. Using soap foam, the docking points are processed with a brush. If foaming occurs when the gas valve is opened, the work must be redone.

It is necessary to check the thread located on the plate manifold. Quite often it is 3/8′. In this case, you will need to install a 1/2 ′ adapter, with a seal

When work on replacing a gas hose is carried out in a private house where bottled gas is used, an additional replacement of the nozzle with a smaller diameter will be required. If this is not done, the burners will release too much soot, which likes to settle on furniture and utensils in the kitchen.

How to choose an eyeliner

When choosing a bellows-type liner for any gas equipment, you must consider:

- hose type;

- technical parameters of the eyeliner;

- equipment manufacturer.

Varieties of bellows liners

To connect the gas are used:

- metal bellows hoses;

- metal hoses with PVC coating.

Varieties of gas hoses

There are no fundamental differences between the types according to technical data. Hoses with polymer protection are more tight and have a longer service life (up to 30 years).

Selection of technical parameters

A flexible gas pipe is selected depending on the following parameters:

- working temperature. Most bellows gas hoses are capable of operating at temperatures from -55°C to +250°C;

- pressure inside the pipeline. Bellows flexible hoses are able to withstand internal pressure up to 6 atmospheres, which allows you to choose a device for connecting any type of gas equipment;

According to the current regulatory documents in gas supply networks, the pressure cannot be more than 0.03 atmospheres.

- hose length;

- connection method. Hoses can be equipped with union-nut or nut-nut pairs. The fitting is equipped with an external thread, and the nut with an internal thread. As a rule, with the help of a fitting, the connection to the gas equipment is connected, and with the help of a nut, to the gas supply pipes.

Ways to connect a gas supply

thread size. Hose is available with 15 mm (1/2 in.), 20 mm (3/4 in.), 25 mm (1 in.), 32 mm (1 1/4 in.) threads. If the size of the thread on the inlet does not correspond to the same parameter on the connected equipment, then an additional adapter will have to be installed, which helps to reduce the level of tightness of the gas supply system.

Popular manufacturers

In order for the gas supply to serve for a long period, it is important to choose the right manufacturer of equipment that guarantees the quality of the products. The most popular are: Italian company EMIFLEXp.a

The manufacturer's products are certified by Rostest and approved by Gostekhnadzor. Gas hoses can be used to transport liquefied and natural gas, provided the temperature is in the range -

Italian company EMIFLEXp.a. The manufacturer's products are certified by Rostest and approved by Gostekhnadzor. Gas hoses can be used to transport liquefied and natural gas, provided the temperature is in the range -

°С – +100°С and pressure up to 7 atmospheres;

The Chinese company Tuboflex also specializes in the production of high-quality eyeliners, which are less expensive than their Italian counterparts. Hoses are certified;

Hose from EMIFLEX

- G-BEKA (Turkey). Gas connections are notable for their low cost, large margin of safety and the ability to use them at any temperature up to +250°C. Working pressure - up to 6 atmospheres;

- OSCAR-M (China). Inexpensive products with decent quality, which can be used for domestic purposes.

Tying a gas boiler in the heating system

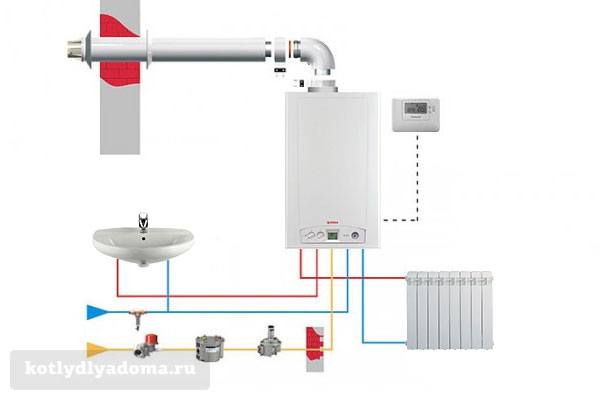

After the installation of the wall-mounted gas boiler is completed and the heater is placed on the wall, the first step is to connect it to the heating system. Depending on which model is installed single-circuit or double-circuit, there are various strapping schemes. We will consider the connection process using the example of a wall-mounted double-circuit gas boiler.

As you know, a double-circuit boiler, in addition to heating, is capable of producing hot water for household needs. Structurally, this is realized by installing one bithermic or two separate heat exchangers. A double-circuit boiler does not produce very much hot water, but it is enough for 1-2 distribution points (for example, a kitchen faucet and a shower).

A modern hinged gas boiler is very compact and already contains within itself the main elements necessary for the operation of a forced circulation heating system, such as: a circulation pump, an expansion tank, a safety group. In the heating systems of small private country houses, this is more than enough, but if necessary, you can install an additional expansion tank or another pump.

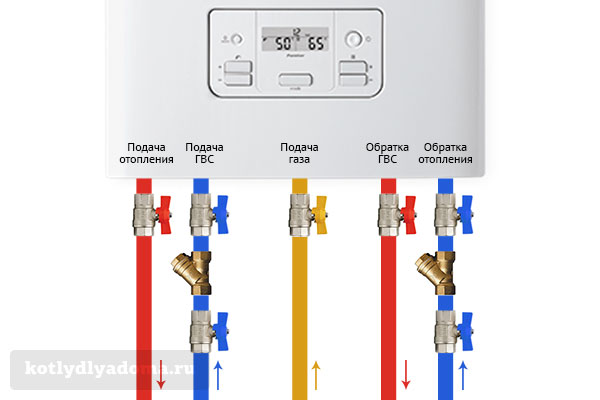

At the bottom of any mounted double-circuit boiler there are 5 nozzles. They are connected to: supply and return lines of the heating system, supply and return of hot water supply, main gas.The gas inlet is usually centrally located and colored yellow. All other lines can be arranged in any order, depending on the model of the gas boiler. Therefore, before starting the strapping, it is required to clarify the purpose of each of them in the instruction manual.

The piping of the wall-mounted gas boiler is carried out with polypropylene or metal pipes. The cross section of heating pipes is usually larger than DHW pipes 3/4 and 1/2 inches, respectively. The heating system is connected to the boiler through the American nuts. Ball valves are installed on each line, for the convenience of dismantling the gas boiler without draining the coolant and for isolating the boiler from the heating system, if necessary. To ensure tightness, all connections must be made using plumbing FUM tape or linen.

Coarse filters must be installed in the heating return line and in the DHW supply line. For the convenience of their washing and cleaning, they are also cut off with shutoff valves. Often, in order to increase the service life of the secondary heat exchanger of a double-circuit boiler, a magnetic fine filter is additionally installed at the DHW supply.

How to choose the right gas hose

It is necessary to purchase such devices only in special stores that have certificates for each product.

The gas hose braid should have a yellow mark. It is placed only on the gas hose, a blue-red line is placed on the water supply.

All hoses are available in different sizes to suit a wide range of applications. The most common range is one to two meters. Usually a fastening thread is made with dimensions - 1/2 ″ - 3/4 ″.

End faces can be supplied with two nuts. The so-called nut-nut, sometimes a nut with a fitting. This hose was called the "nut-fitting". A nut with an internal thread is called a mother, a fitting with an external thread is called a father.

Connecting a gas bottle to a stove How to connect a gas bottle to a stove

Not everyone will afford the construction of a country mansion with all amenities. Some part of the population is content with small plots with wooden houses, where they come for the weekend. It makes no sense to pull a gas pipe to the house, and it’s expensive, but connecting a gas cylinder to the stove will be most welcome. And it is inexpensive, and you can do it yourself.

Do you know what needs to be done to properly connect the cylinder to the stove? If not, then after reading this article to the end, it will not be difficult for you to connect yourself.

What you need to connect

- Gas stove. It must not be quite old. Be sure to check the integrity of the connections and burners.

- Gas reducer (30 mbar). Experts consider the most reliable gearboxes with threaded connections and brass nuts.

- Gas hose. It should be 1.5 meters longer. For example, if there are 5 meters from the installation site of the stove to the cylinder, then you will need 6.5 m, this is necessary so that the hose is not connected in a taut state, so it can crack faster.

- Fittings and collars for connections. This will be needed if you decide to use an old stove; with new models, such adapters are already provided in the kit.

- The tool must be copper-plated or brass-plated. Safety rules provide for working with gas connections only with such keys; they do not give a spark in case of accidental breakdowns.

- Linen or fum tape is needed as an additional sealing material.

- Soap solution.

A hose for connection must be used a special gas. When buying in a store, explain this to the seller.In no case should you use the old hose that was in your basement, even if it looks good, it may have internal cracks and the consequences will be disastrous.

Work procedure

We will proceed from the fact that the stove in the kitchen is already installed. The gas cylinder must be placed in another room or at least 5 meters away from the stove. The place for the cylinder must be clean and prepared. Build a special mount from wooden slats.

Plate connection

First you need to connect the hose to the stove. This is a completely safe job. We wind it onto the hose of the stove, tighten it with a clamp and, having screwed the fum-tape onto the inlet fitting of the stove, wrap it up to the stop.

Cylinder connection

First you need to install a reducer on the cylinder. It is screwed onto a special adapter with the accompanying winding of the fum tape.

The entire connection process must take place with a thorough inspection of each detail:

- There must be no contamination on the reducer and the cylinder, especially at the place of the threaded connections.

- The hose deserves special attention. In addition to the appropriate length, it should be free of cracks and constrictions, and should not be twisted. It is also better to replace it after the expiration date.

- The clamps should not be rusty during operation, this can lead to their rupture. When corrosion occurs, it is better to immediately replace them or purchase specialized ones with anti-corrosion treatment.

Check after connection

When you have finished all the work, you need to check the integrity of the connections

Carefully open the gas cylinder valve. You will hear a characteristic hiss

This means that the gearbox is working properly, and gas has begun to flow into the stove.

Then you need to dilute a little soap with water, it is advisable to add more soap so that the foam is thick. With a soft sponge, foam and apply to each connection, if small bubbles appear, this indicates that the connection is not reliable and needs to be tightened.

If there are no shortcomings, then you did everything right and you can turn on the stove and cook.

Note!

The propane-butane mixture is heavier than oxygen and, according to the laws of physics, it is able to accumulate in closed unventilated spaces. Therefore, experts do not recommend installing a gas cylinder in an underground room.

It will be enough to place it in the next room.

The main safety rules are spelled out in SNiP 42-01-2002. And if you have done such work, then your knowledge will help readers to properly connect the equipment.

If you are concerned about your own safety and the safety of your home, choose the right gas cylinder. And this story will help you with this.