Application features

Thermal insulation by spraying polyurethane foam needs protection from the harmful rays of the sun. That is, an opaque finish must be performed on top of the applied layer. It is also undesirable to use combustible polyurethane foam for the insulation of wooden buildings. Despite the presence of flame retardants in the mixture, manufacturers failed to achieve absolute fire safety.

Another disadvantage of PPU is the toxic substances released from the foam during the polymerization process. So during work it is necessary to use a good respirator and generally take care of your own safety. Well, the cost of insulation with polyurethane foam is very high, for 1 sq. m, it ranges from 550-680 rubles with a layer of 5 cm. But PPU has a low thermal conductivity of about 0.019-0.028 W / m∙K and, with proper spraying, can last at least 20-30 years. You can read more about working with such material in this article on PPU.

The main stages of application

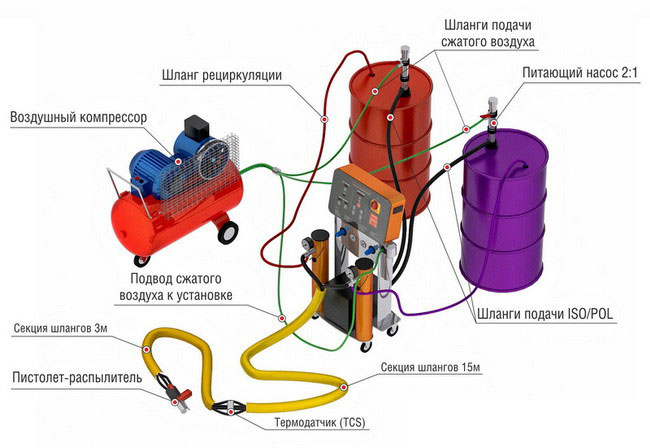

If you independently perform insulation by spraying polyurethane foam, you will need special equipment with a compressor and an air gun for work. Ideally, this should be an automated foam generator that controls all mixing and mixing parameters.

After that, you will need to order from the manufacturer a two-component composition for the preparation of polyurethane foam insulation. For further work, follow the instructions:

1. Mix the first ingredient with a construction mixer to evenly distribute blowing agents, regulators, flame retardants and polyesters.

2. In a separate container, prepare a hardener - the second component of thermal insulation. If a precipitate appears in it, it is heated to +70 ° C, re-stirred and filtered.

3. The combination of the two ingredients must be carried out in an absolutely dry room, where foreign objects or substances cannot enter the mixture.

4. The finished thermal insulation is fed by a compressor into a special sleeve and applied from a gun to the surface to be treated under pressure.

Usually the proportions of two-component mixtures are maintained at the level of 1: 1, but the dosage should be checked with the manufacturer. The process of spraying insulation, judging by the reviews, does not require any skills or complex preparation. It is only necessary to clean the base from dust and flaking pieces before warming, and also dry it thoroughly. Immediately after that, polyurethane foam is applied in a layer of 10-15 mm. A second pass is performed on an already frozen base.

Ecowool

This insulation is completely different from polyurethane foam, since it consists of natural components (cellulose), and costs 40 percent less. True, its thermal conductivity is also higher - 0.032-0.041 W / m∙K. In our review, we will consider ecowool, which provides for wet-glue spraying. This is the most expensive, but also the most effective method of its application. Lucky people living in areas where there are manufacturers of thermal insulation from paper raw materials can count on the minimum price. To apply dry ecowool and the adhesive component, it is enough to dilute it with water in the correct proportion and spray it with a continuous layer over the surface using an air gun. According to reviews, you can do without glue, but it is more reliable with it.

The density of ecowool is approximately 52-65 kg / m3, which guarantees its normal operation as a heater. But unlike PPU, it does not have the proper moisture resistance, therefore, it requires additional protection. However, with slight moisture (up to 14%), ecowool does not lose its properties - it "acts" like wood, giving off excess moisture, and not accumulating them.A really serious drawback is the flowability and shrinkage of the insulation - every year, cellulose thermal insulation loses up to 1.2% of its original volume. For 5-10 years of service, ecowool will sag by 6-12%, so manufacturers and craftsmen in their reviews recommend making the layer thicker.

When to use spray-on insulation:

1. Since spraying allows you to create a continuous layer, it is ideal for processing irregular surfaces with ledges, cells of non-rectangular shape and irregularities.

2. This type of coating is indispensable for thermal insulation of any building structures with a large number of metal elements. PPU spraying provides them with reliable protection against moisture penetration and subsequent corrosion.

3. For insulation of pipes and containers for various purposes.

Popular manufacturers of spray foam

Among the most famous brands it should be noted:

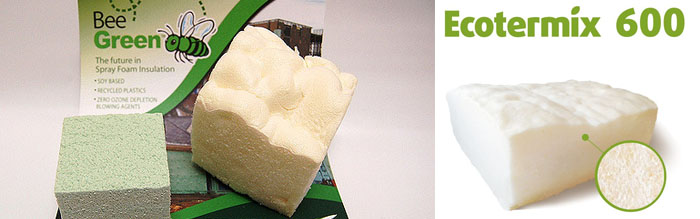

1. Ecothermix. The main advantage is that it does not contain harmful chemicals. Sprayed polyurethane foam thermal insulation Ecotermix contains vegetable oils that foam on a water basis. There are different types:

- Ecothermix 300 - is a closed cell, used for outdoor work.

- Ecotermix 600 - designed for internal processing.

Reviews of sprayed thermal insulation Ecothermix indicate economical consumption. After application, a comfortable temperature is established in the house, which is maintained throughout the year.

2. Polynor is produced in cylinders, which allows you to correctly calculate the required amount of PPU. Sprayed polyurethane foam insulation Polynor is easy to use, no additional equipment is required for its application. Ease of use affects the cost, the price of Polynor per cylinder is on average 400 rubles.

3. Heatlok Soy can be used for indoor and outdoor applications. The composition includes natural ingredients: soy and vegetable oils. It is a monolithic mass that envelops the base, adheres well to it and prevents the formation of corrosion.

How to apply with your own hands?

Before proceeding to insulate the surface with sprayed polyurethane foam, you need to prepare it. It must be dry, clean and even. The optimum temperature for the base to be treated is between 13 and 15°C. To carry out the work, cylinders are needed, in which components are placed in liquid form. With the help of a pump, substances are taken in to form foam. Then the mixture of 2 components enters the spray gun.

Sprayed thermal insulation is a relatively new method of thermal insulation of building structures. It consists in applying liquid formulations, which, when solidified, turn into a continuous coating with low thermal conductivity. Such a "fur coat" fills all the cracks and seams, so the insulation is as effective as possible.

The most popular material for thermal insulation of structures by the method of seamless application is sprayed polyurethane foam. For large-scale work, a two-component composition is usually used. After mixing, it is fed to the surface to be treated and there it increases in volume due to the action of blowing agents.

Produced in a very wide range. The most popular types:

Heatlock Soy.

A universal two-component composition with a density of 45-50 kg / m3 with increased adhesion, which makes it possible to glue the walls of cracks and unreliable seams during the spraying process.

Ecothermix-300.

Designed for external application, it has a closed cell structure and high density (35-40 kg/m3).

Ecothermix-600.

It is used for interior work, because it has open pores and higher moisture permeability. A distinctive feature is the minimum specific gravity (9-12 kg/m3).

Foam Kit.

A large range of polymer thermal insulation with different characteristics and structure.Closed-cell spraying has an average density of 28-30 kg / m3, open - only 8-10 or 16-20 kg / m3.

The manufacturer offers not only polymer compositions, but also all the equipment necessary for work at a reasonable price. The scope of two-component insulation is very wide, since PPU shows excellent adhesion to most materials and holds well even on vertical planes.

Separately, it is worth considering products from Polynor - a one-component composition available to most buyers. Polynor spray insulation is chosen for internal insulation of small areas. It has a density of 18-28 kg / m3, is easy to use, and the best part is that Polynor comes in 0.9 l cans (enough for a 3-cm layer on a surface of 1.5 m2).

Developers' opinions

Oleg, Krasnoyarsk.

“I heard a lot about thermal insulation using spraying, but I had never come across it before. And then I decided to add a loggia to my living space, and I urgently needed to insulate it with something. After studying the reviews and characteristics, I realized that I needed not soft foam, but a hard polymer layer - so that it almost did not squeeze through. I settled on Ecothermix, but took insulation intended for outdoor spraying.

Egor, Nizhny Novgorod.

“I don't see much point in sprayed PU foam insulation until it actually becomes more cost effective. Where to apply the polymer? It adheres well to even brickwork and polystyrene, pour polyurethane onto wood - then what is the point of building a “clean house”? You can try ecowool, but again, its shortcomings are not compensated by financial benefits. Such thermal insulation is good only in the case of non-standard surfaces.

Alexey, St. Petersburg.

“We were forced to use polyurethane foam spraying, because two walls in our private house were constantly damp. It's good that the fungus did not reach. They removed all the trim from the facade, stuffed the slats and foamed everything between them with polyurethane. For the second year now, there has been no dampness in the house, and the wallpaper does not fall on the head.

Vera, Moscow.

Summary: pros and cons

The prices for PPU thermal insulation are indeed one of the highest, plus you will have to pay specialists with equipment to carry out the work. However, there is another problem - the craftsmen may refuse to come to a small object, so you will need to look for an alternative way of warming or try to do it manually.

However, these shortcomings balance the advantages of the technology of spraying heaters:

- High adhesion with any building materials.

- Penetration of thermal insulation into all cracks and gaps of structures, regardless of the complexity of their shape.

- Creating a seamless "shell".

- Excellent sound absorption performance.

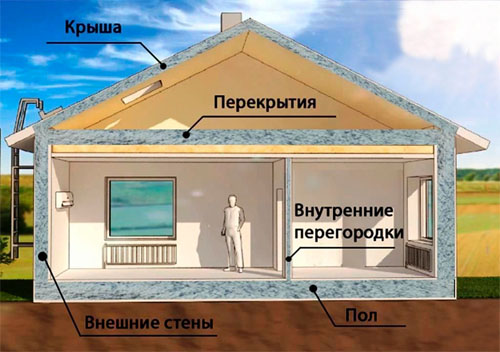

Where to use spray insulation

- Roof and attic structures

- Floor insulation

- Insulation of wall surfaces

Objects can be classified as follows:

- industrial buildings

- Outbuildings

- Refrigeration equipment

- Pipeline communications

- Technological tanks

As for the type of materials on which it is possible to conduct insulation, there are no restrictions in this regard.

To date, manufacturers of heaters offer a huge selection of materials.But ? The choice of material should be made based on the configuration of the wall, its heat capacity and thickness.

Do-it-yourself sprayed insulation

In any case, for self-insulation with polyurethane foam, you will need a balloon installation and the components necessary for this procedure, namely:

- Polyol to be mixed in a container with freon

- Isocyanate, also combined with freon 134

Both cylinders must be inflated until the pressure in them reaches at least 8 atmospheres.

Sprayed insulation in cylinders

The sprayed insulation in cylinders is more practical, as it has a professionally performed factory preparation, including the optimal pressure regime.

The price of sprayed insulation

In the long term, the cost of thermal insulation with sprayed insulation pays off by reducing energy costs.

Sprayed polyurethane insulation Polynor

Thus, this type of thermal insulators is a priority in the choice of material for a number of technological indicators and for reasons of practical and budgetary value.

Video about sprayed insulation

The process of insulating the roof of a house with sprayed insulation.

Video about Polynor sprayed polyurethane insulation. Instructions for working with this material.

Advantages of sprayed insulation

For this purpose, a high-pressure balloon installation is used, through which two structural components are sprayed, which, when combined, form a polyurethane foam.

The similarity of such a material, probably, was seen by many, using mounting foam to insulate window openings. Sprayed insulation for walls looks similar.

The sprayed insulation has a fairly light weight and can be applied with a layer of any thickness to a surface of any material without consequences.

At the same time, sprayed heaters are also known for their technological parameters that ensure the practicality of use:

- The highest thermal conductivity index is noted for these materials, and is about 0.020-0.028 W / mS. In more modern heaters, this figure is even lower - 0.017 W / mS

-

Excellent sound insulation performance.

This category of insulators successfully neutralizes even impact noise, providing silence in the room when building tools are working. - The vapor permeability of the sprayed heat insulators allows absorbing moisture without creating comfortable conditions for the formation of condensate

- The use of this material allows you to insulate even hard-to-reach places due to its consistency.

- The adhesion parameters inherent in this thermal insulation material make it possible to insulate surfaces made of any materials.

- The deadline for performing work with this insulation can also be called a record - for insulation of 100-120 square meters, 8-9 hours are enough with a low labor intensity of the process

- This is one of the few heaters, the device of which does not require equipping hydro - and vapor barrier

- In the characteristics of the sprayed type insulation, resistance to manifestations of biological and chemical origin is also noted.

You wonder - Another plus of the sprayed insulation is that it does not arouse interest among rodents, which have become a real problem when insulating with some other categories of heaters.