Mechanical cleaning of the heat exchanger

As an element of a gas boiler, the heat exchanger occupies a large space inside the unit. It is located above the combustion chamber, and it is not easy to get close to it.

Before it's done gas heat exchanger flushing boiler, this element is removed:

- first remove the outer part of the case. Before this, disconnect the gas supply and electrical power, if present in the device;

- the heat exchanger is disconnected from the pipes of the heating structure;

- remove the fasteners of this element.

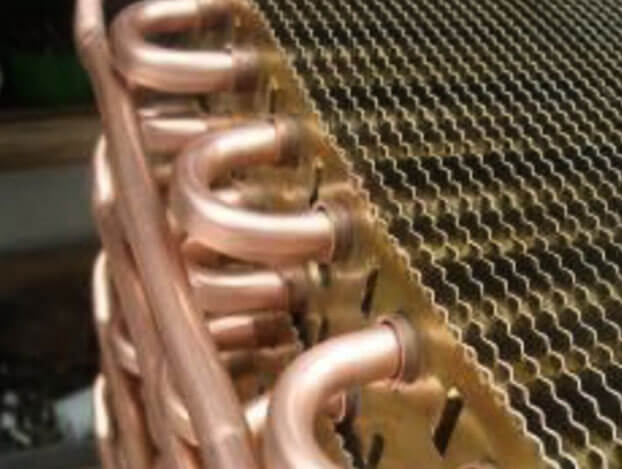

Inside the pipes, when the descaling of the heat exchanger has not yet been done, you can see that its cavities are clogged with deposits. Most of them consist of salts of various metals, usually sodium and calcium. Cleaning is carried out using metal tools such as pins, scrapers, etc.

This must be done carefully so as not to damage the wall of the heat exchanger.

The device is soaked in a container, it is possible in a bath, and a weak acid solution is poured there, for example, hydrochloric acid. After the deposits soften, they are removed. At the end of the procedure, it is necessary to rinse the internal cavities with water under low pressure. To do this, you can use a hose connected to the water supply by attaching it to the pipe.

Then you should wait until clean water comes out. For greater effect, use a mallet, tapping it on the heat exchanger during the flushing process.

Practical application of the booster

The first signs that the boiler heat exchanger needs to be flushed are clicking, energy overruns, and low water temperatures. Heating systems can experience pressure drops. All these signs indicate that a lot of salts and scale were deposited on the walls, which led to a decrease in the nominal passage and heat transfer.

Heat exchanger before and after cleaning.

If you are using a factory booster with a heating element, then you need:

- cut off the boiler from the circuit and drain the water from it;

- wind the hoses from the booster onto the heater;

- pour acid and turn on the unit.

If you made a booster with your own hands, then there is most likely no heating element in it. In this case, you can speed up the flushing process by turning on the boiler at a third of its power. With the expectation that the acid will heat up by 45-50 degrees. Only first you need to fill the heat exchanger with an active substance so that it does not burn out, and only then start the heater.

In order for the system to be reliable, it is necessary to correctly calculate the thickness of the pipes for heating. Conditional passage and walls matter.

Features of the selection of pipes for air heating are described here.

If it is planned to flush the entire circuit, then the supply and output of the reagent can be organized through heating radiators. At the end of modern batteries there are plugs that can be unscrewed and installed in their place. During cleaning, the acid foams strongly, so a special substance is added to it, which smoothes this process.

Booster is a device for chemical cleaning of heat exchangers and heating systems due to acid circulation. Making a booster with your own hands makes sense only when you have a free pump (submersible or circulating). If you need to buy a pump, then the meaning of self-production is lost. A cheap washing machine costs only 600 rubles.

Interesting on the topic:

- Scheme of steam heating of a private house

- Which stove to choose for heating the house: brick.

- Installation options for heating a wooden house

- How to heat a house efficiently and profitably?

Flushing technology

There are several cleaning methods that can be divided into:

Collapsible technology is necessary in case of severe pollution or if it is necessary to replace any components of the system. During work, the heat exchanger must be disassembled, and then each component is subjected to mechanical, hydrodynamic or chemical washing.

Since collapsible cleaning requires certain resources, a method is most often used that does not require the mandatory dismantling of the system. This is a chemical washing technology. If it is carried out regularly, it will help to preserve the properties and characteristics of the device for the entire service life.

Pumps for flushing the heating system

Pumps for flushing heat supply are a type of flushing units that are designed to remove scale, lime and other deposits that form in pipelines. The units have a flow reversal function, due to which they provide effective cleaning of the system without the possibility of formation of stagnant zones. Elements of pumping equipment are made of materials that are resistant to acid environments.

Heating: hydropneumatic flushing of the central heating system

With this equipment, as a pump for flushing the heating system, very stubborn deposits can be removed. Carrying out preventive procedures makes it possible to achieve the following effects:

- The resource of operation of the components of the highway becomes longer;

- The efficiency of the system (heat transfer) increases;

- Costs are reduced by reducing the consumption of the heat carrier.

The scope of use of pumps is quite extensive - from cleaning household heating networks of private country houses to servicing high-rise buildings and large-scale industrial complexes. The dimensions, power and other characteristics of the operation of the units differ, depending on their purpose.

One of the main criteria for a station for flushing heat supply is power. The larger the heating system, the higher the installation capacity should be. Another significant parameter is the capacity of the tank. Pumps can be equipped with tanks with a capacity of 10, 20 or 30 liters.

Another advantage will be the presence of a reverse toggle switch. This function will make it possible to adjust the water flow, direct it in the required direction. In a set with a pump, in most cases, hoses are supplied that are intended for connecting the unit to the system. All parts of the equipment are made of materials that can come into contact with the washing solution.

Do you want to purchase reliable equipment for flushing heating lines? The TeploProfi company can offer you high-performance pumps suitable for servicing systems of various sizes.

Heating ‘target=”_blank”>’)

Booster

Boosters are devices for chemical washing of heat exchangers in boilers and columns, any radiators and for cleaning the heating system. The operation is carried out without the need to disassemble the system. The installation consists of three parts:

There are systems without TENs. However, they are of low efficiency. Let's see how to make a booster for flushing heat exchangers. The first thing you need is a tank. A plastic canister with a volume of 10 liters or more can act as a container. You will also need ½ or ¾ inch hoses and a pump.

Make a booster based on the type of pump. This may be a submersible element or a separate pump. In the case of a submersible, no holes are needed in the tank. A hose is attached to the pump, which is connected to a heat exchanger. The second is taken to the tank. The main thing is that the pump can withstand the effects of acid - there are a number of chemically resistant devices.

The disadvantage of such devices is the absence in the design of the heating element. Do-it-yourself flushing of the heat exchanger using a cold reagent will take much longer. It also means higher electricity costs.

There was such a need not yesterday. Of course, there are specialists who do this (they charge a decent amount for this).To flush the boiler, the heat exchanger is dismantled and, after flushing, installed in place (it is not known whose). If this is not done, then the consumption of gas (electricity) increases and, ultimately, the passage of the exchange fluid stops.

But neither the gods mold the pots. Having rummaged through my "bins" I collected the necessary set of used components (so as not to buy). The task is to create a flow of flushing liquid through the heat exchanger (without removing it from the installation), heat the flushing liquid, control the heating temperature (in the machine). Everything is very simply done, the details can be reported separately.

Here is a view of the insides of a gas boiler (wall-mounted), (there are no step-by-step photos of manufacturing) for me not to show off.

Connecting the flushing hose to the unit. The end face of the washing unit is visible in the mirror.

Good day, gentlemen of the forum users. I have been visiting this forum for a long time, but I just got registered now. Actually the question: We are engaged in plumbing, boilers and columns. Until recently, heat exchangers were given for washing to our partners, and it is profitable for them, and our responsibility is lower (although there is less money.). in our market it is represented only by boosters AQuamax 10, 20, 40. I called the company and asked how it is, they say no one has returned it yet (of course). There are no reviews anywhere. heat exchangers of boilers up to 36 kW (10 liters would be enough). What kind of pump is there, well, obviously not peristaltic (as it would be logical)? Is it necessary to clean the insides after washing? Does the reagent eat the insides? to the appropriate branch, or share how to implement the idea without involving a bourgeois unit, I will be very grateful (within reason). this design.

Help, you are my only hope.

Thank you in advance for your answers. Regards, Alexander.