Navien Delux Coaxial device

The word Coaxial in the name of the boiler means the use of coaxial chimneys (pipe in pipe). Such a system is convenient in that only one pipe is used to supply air to the combustion chamber and exhaust gases, which can be taken out of the room to the street in the shortest possible way. In general, the boiler does not fundamentally differ from products of other brands. You can note the convenient location of the expansion tank and the non-standard location of the fan - it is located below the burner.

It is noteworthy that Navien boilers do not have a built-in control panel. All adjustments are carried out using a separate control panel. Also, the remote control is equipped with a temperature sensor and displays various information about the state of operation of the equipment and will report a malfunction with an error code. A feature of Navien is also the presence of an air pressure sensor, which not only performs the function of checking thrust, but also sends data to the control unit for portion control and determines the presence of reverse thrust. If there is excess pressure in the chimney, for example due to wind blowing, the gas supply to the burner will be cut off and the boiler will stop.

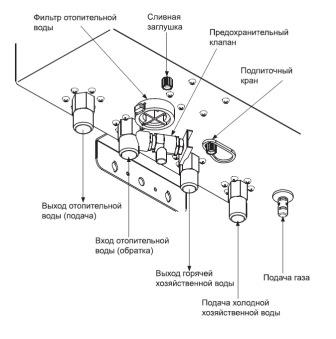

In the lower part of the boiler there are inlets and outlets of the heating and hot water circuits, a make-up valve, a drain plug, a cleaning filter and an overpressure relief valve.

Navien boiler error 10

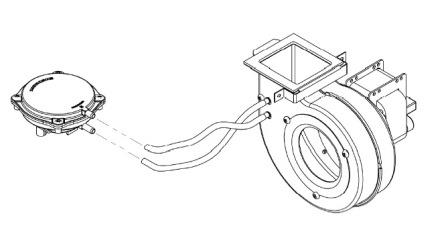

This error is related to the smoke exhaust system of the gas boiler. The products of combustion must be removed; for this, a fan is provided in the boilers. To control the operation of the fan and determine the presence of an acceptable draft for the operation of the boiler, a differential relay is used, which is connected to the turbine with two plastic tubes. When the fan is running, a vacuum is created, the relay closes, and the boiler functions normally.

Causes errors 10 may be a clogged chimney, back draft or incorrect connection of the air pressure control sensor to the fan. For the latter case, it is necessary to check that the yellow tube is connected to the bottom of the fan, and the transparent tube to the top, and the tubes themselves are not damaged, deformed or condensed inside.

Increased resistance in the chimney can occur due to direct gusts of wind or clogging of the chimney (bird nest or cobwebs, frost in winter). That's right, the place for the chimney to take into account the direction of the winds of a particular region at the design stage and the chimney should not be led to the leeward side of the house.

We stopped at the most common failures in the operation of Navien boilers, but in fact there are significantly more error codes. Ways to check and troubleshoot is the topic of a separate article. For convenience, here is a summary table of codes with a brief description:

| Fault number | Brief description of the problem |

|---|---|

| 02 | Low water pressure in the heating system or breakdown of the flow sensor |

| 03 | No signal from ionization electrode |

| 04 | Incorrect signal from the flame sensor or short circuit. Make sure that the ionization electrode is not in contact with the boiler or burner body, diagnose the control board. |

| 05 | Damage to the heating temperature sensor. Measure the electrical resistance of the sensor and compliance with the temperature table, make sure that the connection between the sensor and the control board is reliable. |

| 06 | Short circuit of the heating water temperature sensor circuit. Ring or replace the sensor. |

| 07 | Damage to the DHW temperature sensor. Check the dependence of resistance on temperature on the sensor, make sure that the sensor is connected to the control unit. |

| 08 | Short circuit of the DHW temperature sensor.Ring or replace the sensor. |

| 09 | Fan failure. Measure the resistance of the fan winding (reference value approx. 23 ohms). Make sure that there is 220 V voltage at the fan terminals. There may be a malfunction of the control board circuit (Navien board diagnostics is required) |

| 10 | Malfunction of the combustion products removal system |

| 13 | Short circuit of the CO flow sensor. Sticking of the sensor, or malfunction of the control unit. |

| 15 | Control board internal error (diagnosis and repair required) |

| 16 | Boiler overheating. Signal from the emergency thermostat. The causes of overheating may be insufficient circulation of the coolant (see error 02), clogging of the heat exchanger or a malfunction of the thermostat itself. Operation occurs at 98 degrees, shutdown of the accident when it cools down to 83 degrees. |

| 27 | Open or short circuit in the air pressure sensor circuit |

Differences between Navien Ace and Navien Delux

Navien Delux is a modified model that replaced Navien Ace. Navien Delux Coaxial is a series of boilers with two heat exchangers with a power of 10 to 30 kW with a closed combustion chamber and forced smoke extraction using a turbine. The manufacturer notes the following features of Navien Delux:

-

Frost protection system. Unlike boilers from other manufacturers, in addition to automatically turning on the burner when the temperature drops below 6 degrees, at temperatures below 10 degrees the boiler ensures continuous movement of the coolant by activating the circulation pump.

-

Variable speed fan. In Navien Delux boilers, a turbine is installed with an adjustable speed of rotation of the blades, depending on the readings of a special air pressure sensor. Thus, the optimal ratio of the gas-air mixture is ensured and the productivity of the boiler is increased.

-

The heat exchanger is made of stainless steel. Due to the use of a variable speed fan and increased combustion efficiency, it became possible to replace the copper heat exchanger with a stainless steel heat exchanger, which certainly has a significantly longer service life.

-

Also noted is the protection of boilers from the influence of mains voltage fluctuations by a special protective chip and the ability to operate at low (up to 4 mbar) pressure of main gas and water. In other words, the manufacturer tried to make a product that is maximally adapted to the worst operating conditions.

Navien boiler error 03

In gas boilers, the presence of a flame on the burner is checked by a special sensor - an ionization electrode. The logic of the unit is to continuously check for the presence of a flame after opening the gas valve. Symptoms of the appearance of error 03 on Navien boilers can be divided into two groups:

-

unsuccessful ignition attempts (flame does not appear)

-

ignition occurs, but the flame goes out

In the case when ignition does not occur, you need to check:

-

gas pressure at the inlet and outlet of the gas valve (can only be carried out by a qualified specialist using special equipment - a differential pressure gauge)

-

the condition of the ignition electrodes (gap compliance with the manufacturer's standard, contamination of the electrodes). The norm of the distance between the electrodes is 3.5-4.5 mm.

-

the integrity of the insulation of the electrode power wire (visually, you can make sure that the spark breakdown occurs precisely on the body of the gas burner, and not anywhere else)

-

correct setting of the boiler power on the DIP switch (valid if there is a problem during the first start-up of the boiler or after replacing the electronic board)

-

presence of voltage on the ignition transformer

Error 03 on the Navien boiler it will also appear in case of unstable combustion (intermittent flame) or if the control unit cannot determine the presence of a flame.In this case, it is necessary to make sure that the connection of the ionization electrode to the control board is reliable, check the boiler grounding and the absence of contamination on the electrode. Instability of combustion can be caused by an increase in the fan speed, so you need to make sure that the yellow hose from the turbine to the APS sensor is securely connected and not damaged.

If during the checks it was not possible to normalize the operation of the boiler, it is likely that the boiler board will need to be diagnosed, repaired or replaced. We recommend watching a video in which one of the users imitates error 03 on a Navien boiler:

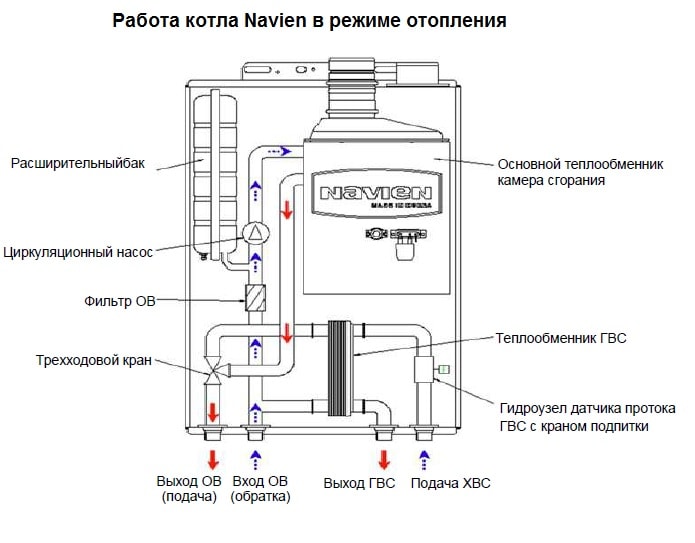

The principle of operation of the Navien boiler

The principles of operation of modern gas boilers are almost the same for all manufacturers, the differences are only in the configuration of the equipment and the internal arrangement of the actuators. The scheme of water movement in the boiler is shown in the figures. The Navien boiler works either to maintain the desired temperature in the CO, when the heated water from the first heat exchanger is pumped by the circulation pump in a large circle, or in the DHW preparation mode. The DHW mode is a priority, which means that if it is necessary to heat the water, a special three-way valve switches the circulation to the DHW plate heat exchanger, while the coolant flow through the heating circuit is blocked. The signal to switch the boiler to the DHW preparation mode comes from a flow sensor located on the hydraulic unit with a make-up tap.