Electrical repair

The electrical part of the pump includes the following components:

- inductor;

- starting capacitor;

- connecting wires;

- control terminal.

If the stator winding breaks, the pump becomes unrepairable, all other components can be repaired or replaced. To analyze the condition of electrical parts, you need an ohmmeter.

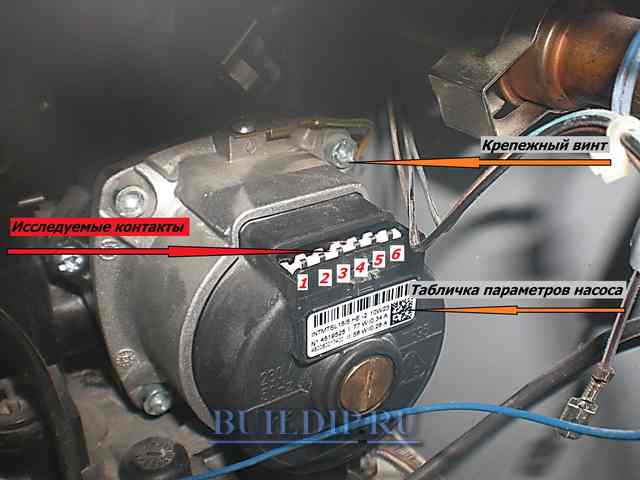

Photo of the circulation pump Wilo MTSL 15/5 HE - 2.

The main symptoms of a malfunction

If the boiler displays an error code corresponding to a violation of water circulation, and it is not reset, the problem may be hidden in the electronic part of the device.

Circulation pump with cover removed.

To troubleshoot, you need to:

- Turn off the heating mode in the boiler, and after stopping all units, turn it off (soft stop).

- Open the front panel of the case.

- If the pump is covered with a large layer of dust, clean its surface.

- Using the information on the diagram, remove the control terminals, dismantle the terminal with the capacitor.

- Visually examine the condition of the pump contacts and terminals; they must be free of oxides, burnouts and mechanical damage.

- Using a tester in the diode test mode, determine the integrity of the connecting wires that go from the control board to the pump.

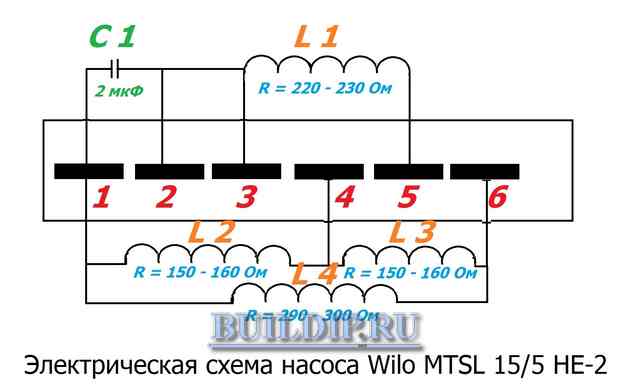

- Determine the resistance of the inductors with an ohmmeter. On a working device, the readings of the device on the contacts will correspond to the following values:

- No. 1, 4 - 150 - 160 Ohm;

- No. 1, 6 - 290 - 300 Ohm;

- No. 2, 3 - 0 (contacts are connected together);

- No. 3, 5 - 220 -230 Ohm;

- No. 4, 6 - 150 - 160 Ohm.

- The device will be considered faulty if the ohmmeter reading on any of the above pairs of stamps is 1 (winding wire break) or 0 (short circuit, except for contacts 2,3).

- Check the condition of the starting capacitor. To do this, set the tester's regulator to the capacitance test mode of 20 microfarads. Connect the probes of the device to the terminals of the capacitor and determine its capacitance. It must match the nominal ± 10%. Loss of capacity leads to a decrease in pump performance, it will emit an uncharacteristic buzz for it.

Electrical diagram of the pump Wilo MTSL 15/5 HE - 2.

Measurement of the resistance of the windings of the circulation pump.

Design features

Products from German manufacturers can work for a very long time without maintenance. And all because in its manufacture durable and reliable materials are used. So, for example, the body of the product is made of durable gray cast iron. Inside it is a stainless steel shaft. It is mounted with bearings made of graphite. The fluid feed rate has a three-stage adjustment. In this case, the maximum possible temperature parameters of the coolant can reach +110 degrees Celsius. In industrial models, this ceiling may increase.

Note! The described pump is also designed for very high operating pressures. Standard products used in everyday life are able to withstand a pressure of 10 bar

Industrial samples in a special design withstand a pressure of 16 bar.

2 Wilo pump repair tips

Repair of the pump is carried out only after disconnecting the power cable and drainage of the site. It should be said that pumps with a wet rotor are equipped with modules depending on the required power and size. Restoring the health of these devices is facilitated - the faulty module is replaced with a new one.

2.2 The shaft does not rotate when the pump is on and characteristic sounds

The reasons are: oxidation of the shaft after a long period of inactivity or the ingress of a foreign object into the impeller. In the first case, you need to repair the pump by following these steps: drain the water, unscrew the screws that tighten the motor and housing.Remove the motor with rotor and impeller. Turn the last knot by hand. Low power products require a screwdriver to unlock the shaft. For her, there is a special notch at the end of the shaft.

Testing the electrical box of the circulation pump

2.5 The pump vibrates, accompanied by noise

The reason lies in the wear of the bearings that ensure the rotation of the impeller. Worn parts must be replaced. Since the bearings are pressed into place with a puller, you will need a wooden mallet. Drive new bearings into the seat with precise, but gentle blows. The reason for vibration and loud noise may be low pressure in the system. Elimination implies its increase at the inlet, do not forget that the liquid level in the coolant also needs to be increased.

Double-rotor circulation pump Vilo

2.6 Low water pressure in the system

This problem occurs when the phases are incorrectly connected in three-phase pumps or the percentage of fluid viscosity is increased. For the first reason, it is enough to connect the equipment according to the instructions. In the second case, the repair comes down to cleaning the pipe filter, checking the good condition of the pipeline connected to the pump, and adjusting the installation parameters in accordance with the equipment rating data.

- Content:

- The device and principle of operation of pumps brand Wilo

- Heating pump Wilo Star

- Heating pumps Wilo Top

- Heating pumps Wilo Stratos

- Wilo Yonos heating pumps

How to choose a Wilo pump for a heating system

How to recognize the original Wilo pump

How to calculate which Wilo pump you need

How to properly install a Wilo pump in a heating system

Which pump is better to choose - Wilo or DAB

The principle of operation of the circulation pump Wilo MTSL 155 HE 2

The main part of the pump is an electric motor, consisting of a stator with several inductors for adjusting the rotation speed, and a rotor that is integrated on a shaft with bearings.

When power is applied to one of the stator windings, an electric field is created that drives the rotor with the turbine. Turbine blades take liquid from the suction pipe and move it along the outlet pipe. In this way, the coolant is circulated throughout the heating circuit.

Let's consider the main reasons leading to the failure of the Wilo MTSL 15/5 HE - 2 pump.

Unstable voltage in the network

With reduced power, the pump motor slows down to a complete stop. At increased voltage, the inductors heat up, which can cause an interturn short circuit or burnout of the winding wire.

Contamination of pump mechanisms

At a liquid temperature of more than 60 ᵒС, scale may form on the turbine and shaft, which will slow down the rotation of the motor armature. The causes of pump jamming can also be increased oxidation of the driving mechanisms or the ingress of foreign objects.

Poor quality material

If the pump uses parts made from low-quality materials, its resource is sharply reduced. For example, the shaft begins to jam due to the formation of a layer of rust on the surface of the bearings, because they are made of bronze, which includes iron. Such symptoms are typical for a non-original model.

Incorrect use of the device

Water through a working pump must constantly circulate at a certain speed.If the movement of the coolant is disturbed (the valve of the return or supply line is closed, the system filter is clogged, etc.), the bearings and inductors will overheat in the device - this will lead to jamming of the rotor, breakage or short circuit of the stator winding.

The Wilo MTSL 15/5 HE - 2 circulation pump cannot be used when there is no water in the pipeline. But since Ariston double-circuit automatic units are equipped with liquid pressure sensors, the boiler will not turn on if there is no water in the system or its pressure is low.

1 Design and technical features

Vilo pumps significantly increase the efficiency of the heating system and the heat transfer of the coolant. Their use makes it possible to use pipes with a smaller cross section when assembling the line, which will reduce fuel costs, reduce carbon dioxide emissions, and make it possible to achieve savings without losing the quality of operation. This is achieved through a properly thought out and developed design, designed for continuous operation.

Checking the water jacket of the rotor

The Wilo pump consumes no more than 250 W per day, the operation is silent, since there is no fan and similar technical elements that produce noise. There are two types of circulating equipment on sale - with a dry and wet rotor. The latter are used in the installation of heating systems, as a rule, inside small buildings. The difference also lies in the power and volume of the pumped medium. The weakest model is able to make the heating system more efficient on an area of 200 sq.m.

Powerful is designed for heating buildings, the area of which reaches 1000 sq.m. Both the one and the other unit has the most simplified design and small dimensions. The technical characteristics regarding the head height make it possible to raise water from 8 meters at a flow rate of 5 m3/h.

Distinctive features are the strength and corrosion resistance of the Wilo pump material. For example, the body is cast iron, the shaft located inside it is stainless steel. Its fastening is possible thanks to graphite bearings. The water flow rate is equipped with a three-stage adjustment.

1.1 Operating requirements and prevention

In order to avoid premature repair of Wilo pumps, the manufacturer urges to adhere to the following:

- Do not allow the appliance to idle when there is no water in the system. Dry running destroys the insulation, disturbs the cooling of the electric motor and disables all equipment.

- The operating mode is set strictly in accordance with the maximum-minimum capabilities of a particular model.

- When the pump is switched on, the flow of the coolant must not be blocked.

Dismantling the circulation pump

Subject to these rules, the pump will be characterized by maintaining a stable pressure, and the sound emitted during operation will be uniform and quiet. Most pumps do not need to be repaired for 5 years from the moment they are put into operation. It is required only when the main components are completely worn out or force majeure circumstances that caused the device to fail.

Prevention is another type of periodic measures, the implementation of which insures the pump and its elements against premature breakdowns. At the same time, simple maintenance is carried out with his own hands, without the intervention of a specialist. To do this, visual inspection of the external and internal parts of the unit should be carried out at least 3-4 times annually and cleaned if necessary.

Practice shows that cleaning becomes mandatory after 2-3 years of operation. The quality of the coolant, the general conditions under which the heating system operates affects the conduct of cleaning procedures.

For prevention, it is necessary to prepare a Phillips and flat screwdriver, a spanner wrench, and a cleaning brush.Inspection requires disassembly, during which you will find the main components of the hydraulic structure: housing, impeller, motor shaft, rotor, terminal box, propeller and the motor itself

Pay attention to such nuances:

- grounding performance;

- absence of leaks at the joints;

- pressure value in accordance with technical standards;

- lack of vibration and extraneous sounds (knocking, clanging);

- hull condition. It must be clean and dry;

- the pump should not get very hot;

- the amount of grease on bearings, flanges and driving units must be sufficient;

Also make sure that the terminal box cables are free of moisture and securely fastened, gaskets provide a seal, and connections to the mains are strong. Before dismantling the device, water is drained from the system, the area of \u200b\u200bits receipt is blocked, after which the pump is removed.

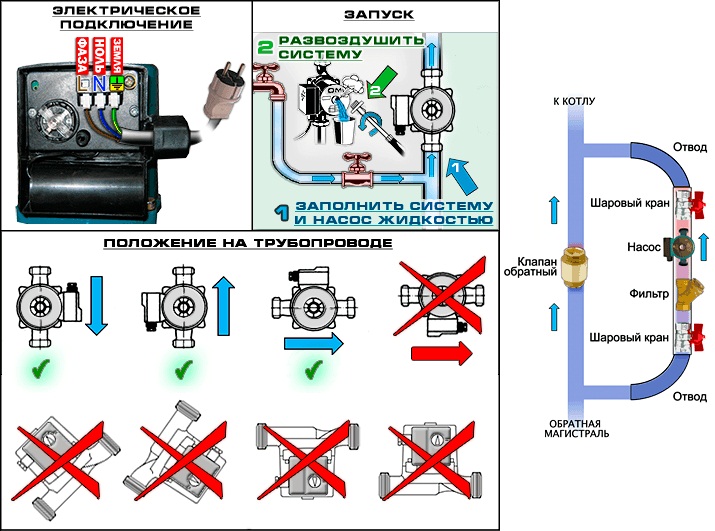

Rules for installing and connecting a circulation pump

6 bolts connecting the shell of the pump part and the motor housing are unscrewed with a ring wrench. When the shell is removed, access to the drainage holes will appear. The impeller remains on the motor rotor. With the help of a narrow flat-type screwdriver, a shirt is prying off, which serves for the impeller and motor compartment. The actions taken will bring the rotor shaft and the impeller out of the stator cup.

Pros and cons of choice

Modern heating systems most often operate on the principle of natural circulation. But sometimes there is a need for forced circulation of the coolant. And then there is the question of choosing the right pump. In this case, the choice depends on many factors, the most important of which is the power of the device. It should be enough to form the required feed intensity.

There are special mathematical formulas that allow you to make the necessary calculations. Finished tables are published on the Internet. They are also in the technical data sheet of the product. When choosing the pump power, the area of \u200b\u200bthe heated room and the speed that the circulation pumps are capable of producing are taken into account first of all.

By giving preference to products from Wilo, everyone receives in return a whole package of operational advantages:

- German products eliminate the possibility of heat loss, which often occurs during the evaporation process.

- All its working mechanisms are made of materials resistant to corrosion.

- The system is controlled by automation. A built-in thermostat is provided, and all functions are displayed on the LCD display. However, there is the possibility of manual switching, which allows you to control the speed of the working shaft.

- Even the most powerful models work completely silently. Almost all vilo pumps are small in size, so their installation does not take up much space.

- Connection is quick and convenient thanks to the spring terminals.

- The rotor and motor are distinguished by a multi-stage protection system, so the unit is not afraid of power surges.

The disadvantage of such installations is only one. Today, Wilo pumps can only be located where power supply problems are extremely rare. Without electricity, it is simply impossible to evaluate the advantages and quality of German equipment.

Many years of experience allows the German company Wilo to produce high-quality pumping equipment that meets the widest consumer demand. Today it is used both in the domestic sector and in industrial production. High quality and ease of installation, ease of use and the presence of a large number of technical advantages distinguish the products of the described concern from similar products. But this is not the most important thing.

German pumps can be connected not only to the heating system. They are widely used for air conditioning.The model range is represented by several dozen varieties. All devices are characterized by high performance, compact size, high power and low noise during operation.

Mechanical repair

All other parts that are not listed in the section: "Electrical Repair" are mechanical parts. If vibration or noise occurs in a running pump, to determine the source of their occurrence, it is necessary:

- Smoothly stop the boiler.

- Remove the front panel of the housing and lower the control box.

- Close the cold water, supply and return taps.

- Drain water from the boiler system through the drain cock.

- Unscrew the pump air vent lock to completely drain the water from the system. After draining all the liquid, tighten the retainer until it stops.

- Remove the terminal with the starting capacitor.

- Unscrew the fixing screws and dismantle the block: motor-turbine.

- Inspect bearings, impeller, pump cavity for oxidation, contamination, foreign objects, damage. If bearing wear is observed or the motor shaft scrolls with effort, then they must be replaced with others, for example, with fluoroplastic ones. All dirt from the turbine, internal compartments of the housing, sealing rubber should be removed.

- Install the repaired mechanism in place and fix.

- Insert terminal with capacitor.

- Open the return, supply and cold water taps.

- Using the make-up tap, check the tightness of the pump, if it does not leak, then the coolant should be added to the system up to 1.2 bar.

- Start the pump in circulation mode and check its condition.

- In positive results, set the temperature control knob of the heating circuit to the desired position.

The service life of the Wilo circulation pump and other components of the boiler can be extended if a complete maintenance is carried out before each heating season.

The possible causes and ways to eliminate the overheating of the coolant in double-circuit, automatic and semi-automatic gas heating boilers are described.

This article describes five practical ways to de-icing a coaxial air duct.

The principle of operation is considered, the main signs and causes of a malfunction are shown, methods for diagnosing and repairing a fan (exhaust fan) of a gas boiler.

The main causes of pressure changes in a closed heating system are listed, effective ways to stabilize the coolant pressure are given.

Let's figure out what to do if the geyser with a semi-automatic ignition system does not light up, the principle of operation of the ignition system, the reasons.

Latest arrivals

E.syboxmini is the world's smallest electronic pressure booster!

Happy Independence Day of Ukraine!

EVOTRON wet rotor circulation pumps with frequency control

Vulver company at Aqua-Therm Kiev 2015

GENIX is a new lifting station for the collection and automatic pumping of fecal sewage

Submersible 4″ motor DAB

Centrifugal pump DAB K-HA

Welcome to New Rock!

Help the guys who are defending our Motherland!

Accumulators GWS

WARNING, FAKE!

The season is in full swing!

Autumn offer

New series of DAB filters for front filtering

Vertical centrifugal pumps NKV 32, NKV 45 series

Representatives of the Wolver company visited the 18th international exhibition for water treatment, water treatment, recycling and waste disposal, IFAT 2014.

Horizontal variable speed pump KDNE MCE/P

Horizontal frequency-controlled pump KDNE MCE/C

Cavitation is a risk factor

KE horizontal variable speed pump

Dab monoblock pumps with frequency control NKM-GE/NKP-GE MCE/C

Centrifugal pumps with built-in pre-filter - EUROPRO

EVOPLUS SAN - glandless circulation pump with electronic control for hot water systems

ERHARD ROCO Premium - the innovative Butterfly Valve

EVOPLUS D – Glandless double circulation pump with electronic regulation

DABDAB sewage pumpsAqua-Therm KievHousehold pumping stationsGate valves with rubberized wedgesewage pumpsPumping stationCirculation pumps DABhousehold pumping stationwater supplyselection of a pumping stationchoice of a borehole pumpwhere to buy a pump for waterdeep pumps for wellswhy do you need a check valvehow to choose a circulation pumpbuy a pump for a wellbuy pumps dabbuy a check valvebuy a circulation pumppump Dabpump for sewage Dab stationpumping equipment DABpumping stations DABpressure booster pumping stationsdab pumps ukrainepumps for heating systemswaste water treatmentsubmersible pumps dabsubmersible pumps for wellssubmersible well pumpsselection of a pumping stationpumping equipment saledab pumping equipment salepumping equipment sale Ukraineself-priming dab pumpsborehole pumps dabpressure booster stationspressure booster for homefaecal pumpprice trough pumps DAB centrifugal pumps for wells

Basic problems and solutions

In cases where vibration appears during operation of the device, extraneous noise occurs, the pressure in the system changes, their cause should be determined and, if possible, the malfunctions should be eliminated.

When turned on, the pump hums, but the shaft does not rotate:

- the shaft jammed due to a long period of inactivity. Remove the protective cap on the motor housing and turn the shaft with a flat screwdriver;

- if foreign objects get in, disassemble the pump and clean the impeller, after that replacing the cleaning filter, which is installed in front of the device;

- power supply problems (insufficient mains voltage).

When turned on, the device does not work:

- there is no mains voltage. Electrical wiring and protective automation are checked;

- the fuse has blown. Replaced with a new one.

Automatic shutdown of the device after a short period of operation:

accumulation of limescale in the stator glass. The glass and the rotor of the electric motor are being cleaned.

During operation, the pump makes a lot of noise:

- dry operation with air in the system. Release the air and make sure that the pump shell is filled with liquid;

- cavitation. Pressurize the fluid line.

Excessive pump vibration:

critical condition of thrust bearings with heavy wear. Bearings should be replaced.

Reduced head and flow compared to manufacturer's specifications:

- power failure or phase change resulting in power loss or reverse rotation of the impeller. Phase check (three-phase motors) and capacitor replacement (with single-phase power supply);

- the pipeline has a high resistance to the movement of fluid (hydraulic resistance). Clean (replace) the filters, check the shut-off valves, if necessary, increase the diameter of the pipes.

Automatic shutdown of the pump by an external protection system:

malfunction of the electrical components of the device. Check connection terminals (oxidation, short circuit), capacitor (replacement), control unit.

Repair

It is better to repair your faulty pump at a service center if the warranty period has not yet expired. Some models are non-separable or partially disassembled, which implies repair work in the form of replacing entire blocks or the entire device.

Testing the electrical box of the circulation pump

Testing the electrical box of the circulation pump

In the absence of a guarantee and the possibility of disassembling the pump, minor repairs are carried out independently.

According to the above signs, the causes of malfunctions are eliminated, and repairs are carried out if the design of the pump allows it to be disassembled.

Operating elements of the control unit that can cause failure of the pump and must be replaced:

- capacitor;

- connection block (terminals);

- speed controller.

Since the capacitor has a small capacitance, its performance can be checked using the C-meter that is built into the multimeter. If a discrepancy is found with the nominal values, this part should be replaced with a new one.

It is important not to reverse the polarity of the connection and check the voltage compliance. In a conventional single-phase electric motor, capacitors are installed that are approved for connection to the network up to 450 V

If the speed controller breaks down, it is replaced with a new one, observing the correct connection of the terminals.

Terminals must always be clean, dry, free from overheating and deposits. If the above problems are identified, they should be replaced with new ones, similar or the same if possible.

During post-warranty operation, problems with support bearings are possible. It is better to replace them in a specialized workshop.

To prevent the formation of scale on the impeller and siltation of the stator cup, high-quality filters should be installed and the prepared liquid should be used in closed heating heating systems. If these conditions are met, the pump will work in ideal conditions and will not bring repair problems for a long time.