What to choose basalt wool or glass wool

In the building materials market, mineral insulation provides ½ of the total sales of goods in this category. Their advantages over organic-based insulation have ensured their popularity and high rating in the field of construction work. The most common types of insulation are glass wool and stone (basalt wool).

Today we will tell you about the properties of these products, the pros and cons of their use, and which of the heaters is best suited for a particular type of construction.

glass wool

The starting material for these products is cullet (80%), natural sand, limestone, borax, dolomite. Raw materials melted at a temperature of 1500 degrees are placed on a centrifuge in a chamber and inflated with steam. After being treated with a polymer spray, the pulp enters the conveyor for the alignment procedure.

The further process is the polymerization of the material at a temperature of 250 degrees and cooling. The finished insulation is cut, rolled into rolls and goes on sale.

- fire safety level 400-700 degrees, after which the material begins to fuse and loses its performance;

- insulation resistant to aggressive environment protects metal surfaces of structures from corrosion;

- the long fiber of glass wool makes it flexible and elastic, which allows it to be used for geometrically complex structures;

- high level of sound insulation;

- small volume and the ability to restore shape after compression simplifies the transportation process; affordable cost.

Among the disadvantages is the tendency of the material to shrink due to the crystallization of the fibers. But this process begins after a long period of time from the start of operation. Working with insulation requires full compliance with safety rules, since microparticles from brittle fibers can irritate the skin or mucous membranes.

https://youtube.com/watch?v=eHT165_JaYA

Basalt wool

Insulation obtained by melting basalt rock. The production technology is similar to the production of glass wool. The material obtains certain properties due to special binding additives and additives.

- fire safety level 700-1000 degrees;

- service life up to 50 years with the preservation of all operational properties;

- the vertical arrangement of part of the fibers protects the material from shrinkage;

- insulation fibers freely pass water vapor without absorbing them;

- the material is chemically passive and allows protecting structures from corrosion;

- the technological process allows the production of insulation with different rigidity, these can be rolls with soft material and plates with increased rigidity;

- insulation has good heat and sound insulation properties.

The disadvantages of the material include the fact that it cannot be compressed like rolls with glass wool during transportation

What to choose?

These mineral heaters have many similar characteristics. But there are also differences. Products based on basalt stone are distinguished by a longer service life. A building with such insulation does not shrink, and for several decades it will maintain excellent thermal insulation without the need to replace the material.

When building buildings in noisy areas of the city and near highways, the question arises of reducing the noise level in the room. The ideal indicator for our body is 25 dB. According to sanitary standards, the daytime indicator should be within 45 dB, and the nighttime indicator should not exceed 35 dB. Stone wool absorbs noise better, so it is more suitable for areas with heavy traffic or entertainment centers.

According to its characteristics, stone wool is in a better position, but in terms of cost, it is much more expensive.Therefore, in terms of recommendations, we can give advice - be guided by the purpose of insulation and the period of operation of the premises.

For temporary premises, country houses, cheaper glass wool is suitable. It will perfectly cope with all functions, and its service life will come to the end of the operation of the building.

Residential premises - apartments and houses are best insulated with basalt wool. Its durability, the ability to use it for any part of the house from floor to ceiling, technical characteristics are more suitable for such premises. Its safety is also important - the absence of particles that cause injury to the skin and eyes. When carrying out repair work in insulated areas, you do not have to worry about the health of your loved ones.

«>

What is better to insulate with foam

This material proved to be very good, in those places where the humidity of the air is quite high, but insulation is required.

- Styrofoam will not be affected by contact with wet ground, so they can perfectly insulate foundations, as well as various engineering structures underground. Dozens of years will pass, and the insulation will remain the same as in the very beginning. It is often used in the construction of multi-layer foundations as a middle layer. It turns out a very reliable and high-quality foundation.

- When building houses, without basements, on a monolithic foundation, it is also convenient to use expanded polystyrene. Slabs of this material are laid on a leveled area, and then a layer of concrete is poured on top of them. The plates themselves can be either one row or several. After the concrete has hardened, the walls of the house begin to be erected.

- So that the foundation of the house does not freeze, it is very effective to insulate with foam plastic not only its vertical, but also its horizontal part. Styrofoam plates are placed along the foundation. Then they fall asleep, if necessary, additionally laying a waterproofing layer. This method of insulation reliably protects the foundation from frost.

- The walls of houses (both inside and outside) can also be effectively insulated with polystyrene foam. It is best if these walls are block or brick. A high heat-insulating effect is achieved when using expanded polystyrene for insulation of interior spaces, while the formation of a dew point is not observed.

- For roofs of non-ventilated type (warm, flat roofs), the brand of expanded polystyrene PSBS is used. A waterproofing layer must be placed on top. For cold roofs that are ventilated, thermal insulation is carried out differently. Styrofoam isolate the inside of the roof, without fail leaving space for ventilation. This prevents water vapor from condensing.

- Floors and ceilings between floors are also well insulated with foam boards. A layer of insulating material is placed under them, and on top they are poured with concrete.

- A variety of packaging is also produced from expanded polystyrene, and it is also used for thermal insulation of refrigerators, freezers and special isothermal vans.

PROPERTIES OF MINERAL WOOL

We figured out the properties of glass wool, now consider the features of mineral wool. No wonder it is so often used in construction.

Mineral wool is probably the most popular building insulation in recent decades. However, it has been used for so long that it is difficult to remember.

Previously, mineral wool had many advantages and disadvantages. Weak density, the ability to shrink slightly, the inability to withstand direct loads, etc., could be written down as disadvantages.

She also experienced contact with water not in the best way. Plates or rolls, just like fiberglass, absorbed moisture, accumulating it inside. Here, however, the moisture had a different effect.

Installation of mineral wool is done by hand and without special tools

Because of it, the insulation became cold and damp, and then completely began to rot or mold.Fortunately, almost all of these shortcomings have been eliminated through the invention of new production technologies.

ADVANTAGES AND DISADVANTAGES

Modern basalt wool is an extremely reliable heat-insulating material. In terms of thermal conductivity, it is even better than fiberglass. Basalt wool also weighs less than its glass wool counterpart, but here the difference is not so significant.

Moreover, modern manufacturers produce various samples of basalt wool. There are both heavy slabs for thermal insulation of a flat roof or walls, and light, air slabs that are mounted without problems in slopes and weigh almost nothing.

Therefore, you can easily choose an option that will be better suited for a particular situation. Moreover, the variety of heaters on the market is so significant that you can even get confused when buying.

Modern samples of basalt wool are not afraid of water. Their absorption rate is 1-2%, which is a very good indicator. In fact, the part of the insulation lowered into the water will not absorb a drop of liquid. It will simply drain from the material as soon as you pull it out of the water.

In a fire, basalt mineral wool also does not burn. This is already its unique feature. Moreover, studies by builders have shown that basalt wool can be safely burned with a gas burner. And it will burn only in the place of direct contact with fire.

Any damage from exposure to high temperatures is not observed at all. You can put your hands on the second side of the stove, and you won’t feel the temperature rise at all.

Also note that basalt insulation is not eaten by rodents or insects. It's also much easier to work with. Roughly speaking, cotton wool is completely safe for humans, and you can lay it with your own hands.

As for the minuses, here we can only note the high price. Indeed, the price of basalt wool is at a very decent level. In fact, it is considered the highest of all competitors.

Installation process of fiberglass insulation

The second point is the undesirable use of mineral wool boards for warming baths, bathrooms, etc. Of course, the water absorption of modern wool is at a very low level, but with wet steam, things are different.

It’s better not to take risks here, because in the aggressive conditions of the bath, cotton wool will still be prone to gradual accumulation of liquid.

Now let's bring together all these pros and cons, forming a complete list of parameters.

Main advantages:

- Convenience and ease of installation;

- Light weight;

- Environmental friendliness, safety for health;

- Does not absorb water

- Vapor permeable;

- Has a high density;

- Does not burn in fire;

- Excellent thermal conductivity.

Main cons:

- High price;

- It is not advisable to use for warming the bath.

SO WHICH IS BETTER TO BUY?

As you can see, glass wool is different from basalt wool, although their standard indicators are almost the same.

But if we start a tight comparison, then mineral wool is still better in terms of thermal conductivity and density

It does not shrink, does not absorb water so much and, most importantly, is absolutely safe for humans.

On the side of glass wool is its low price and optimal properties.

If we talk about specific solutions, then we recommend taking basalt wool. It is better than fiberglass insulation in almost every way. And the price, though higher, but fully justifies the money spent.

If you do not have enough money, then you can turn to glass wool, but here you already have to be careful.

Shrinkage susceptibility

Shrinkage means slipping or caking of the insulation after some time. If the tendency of the material to shrink is high, then voids without insulation may form and the thermal insulation of the building will deteriorate.

Here, the difference between basalt wool and fiberglass mineral wool lies in the improved structure of the first.Part of the basalt wool fibers is located vertically, which prevents it from caking throughout the entire service life. What can not be said about glass wool, which, if properly installed, can last for a long period, but will still shrink over time. Most of all, glass wool embedded in horizontal structures undergoes shrinkage, where, in addition to caking, material slippage can occur.

What is better to insulate with mineral wool

- For wooden houses, you do not have to choose which is better - polystyrene foam or mineral wool. "Breathing" wooden walls cannot be insulated with polystyrene foam - this will negate their useful properties. Therefore, they are insulated with mineral wool. And in buildings built from other materials, partitions, floors, ceilings, ceilings are sheathed with mineral wool. If the outer walls are insulated, then a ventilated facade of a suspended type is made. Vapor barrier membranes are an integral part of such a design.

- Mineral wool insulate attics, attic rooms and ceilings of houses, pitched roofs. At the same time, be sure to leave space for ventilation.

- Brick houses with a small number of floors, in which the middle thermal insulation layer is mineral wool. It is also used for three-layer panels made of concrete, reinforced concrete, as well as sandwich panels in a metal shell.

- They are used in those places where it is necessary to provide good protection against strongly heated objects, since basalt wool can withstand temperatures up to 1000 0C.

- Frame buildings of any type, it is better to insulate with mineral wool. In addition, it is also used for soundproofing. Moreover, this material is well suited for horizontal, and for vertical, and for curved surfaces.

- Cotton wool from mineral fibers, released in the form of soft plates, can be wrapped around pipes of heat, water, gas mains. It also isolates industrial equipment at enterprises.

Basalt wool

Basalt thermal insulation is made from gabbro-basalt ore. The maximum temperature that basalt insulation can withstand is +1200°C. There are a large number of sizes, densities and shapes of this insulation.

Advantages

Since basalt wool is made from stone, it is non-combustible. Due to this and the high maximum operating temperature, it is used in places where it is necessary to protect the structure from the effects of high temperatures. For example, basalt is great for insulating places where a chimney passes through an attic floor.

Basalt insulation does not shrink, and also has excellent vapor permeability. Therefore, it is recommended to use it for wooden structures. In addition, basalt insulation does not absorb water from the air and is not eaten by rodents.

Flaws

Basalt insulation cannot be considered environmentally friendly, although it is made from natural ingredients. To improve consumer qualities, chemical additives are added to it, which at high temperatures can release harmful volatile substances.

Basalt is not of interest to rodents as food, but they can live in it. As a result, it is necessary to install additional protection against their penetration inside.

Basalt wool does not absorb moisture from the air, but when water hits the surface, it quickly draws it in. Therefore, it cannot be used to insulate foundations, basements and blind areas. Also, basalt cannot be considered a good sound insulator, since it only retains airborne noise, and skips shock.

For heaters with low density, wind protection is required, as they are blown through. It can also be blown through at the joints, so the plates must be laid with a run. If it is necessary to lay thermal insulation with a layer of 100 mm, then it is better to do this in 2 layers of 50 mm each.

Basalt insulation does not fit snugly in places where it cannot be placed at an angle of 90 °.Therefore, it is not considered the best option for domed or similar frame structures. When working with basalt wool, you also need to use protective equipment, as it emits dust.

https://youtube.com/watch?v=ivHaQo3exks%3F

glass wool

Fiberglass insulation is made from cullet, as well as sand, dolomite, soda. Compared to basalt wool, glass wool has fibers 2 or even 4 times longer, making it stronger and more resilient. Therefore, after pressing down, this thermal insulation restores its porosity, even with a minimum material density of 11 kg/m 3 .

Advantages

Glass wool insulation has the following positive qualities:

- Resistant to chemicals, do not cause metal corrosion;

- Do not shrink;

- Frost-resistant;

- They have low weight and low hygroscopicity;

- Absorb sound well.

Flaws

At temperatures above the maximum, glass wool loses its elasticity and shape, which is why it is not recommended to use it in places with elevated temperatures, such as near chimneys. When exposed to constant fire, it burns out.

https://youtube.com/watch?v=cFmkO5JgVXs%3F

The difference between glass wool and stone wool

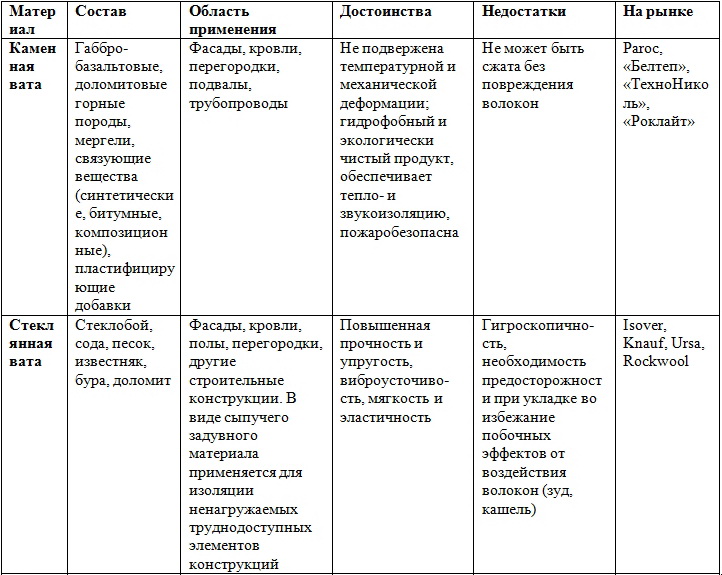

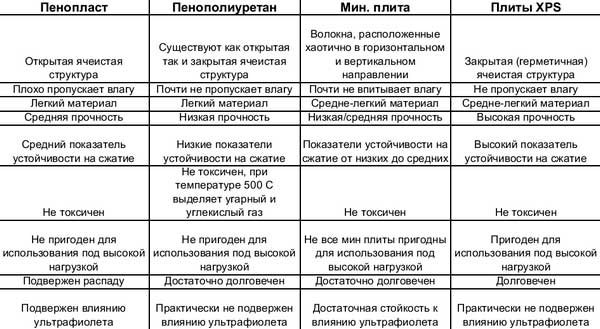

Table of characteristics of glass wool and stone wool.

It is worth noting another important difference between glass wool and stone wool. Glass wool fibers are arranged parallel to each other and are longer than the fibers that stone wool contains (they are much shorter, but arranged in a randomly interlaced manner)

This gives increased elasticity and flexibility to fiberglass products, the ability to produce products of very low density (10-30 kg / m³), but the inability to achieve high rigidity and density, which materials based on stone fiber have.

Stone wool products, on the contrary, have higher compressive strength characteristics and low bending strength characteristics. In order to achieve higher compressive strength characteristics, which are required, for example, in flat roof construction, glass wool manufacturers increase the content of organics (synthetic binders), which increases the combustibility group. In this regard, glass wool occupies a niche of cheap and light insulation, and mineral wool occupies the segment of flat roofs and hinged, plaster facades.

In terms of thermal conductivity, all of the above types of material are endowed with values of the same order, and for effective heaters made using modern technologies, this indicator is in the range of 0.033 - 0.043 W / m • ° C for products made of glass wool and mineral wool. For products made of expanded polystyrene 0.028 - 0.040 W/m•°C. At the same time, air has the lowest thermal conductivity of 0.026 W/m•°C.

Table of the main heat-insulating materials.

These values of thermal conductivity of the material are given in the dry state, which are measured in the factory laboratories at 10°C or 25°C. It is worth considering that under operating conditions with a certain humidity absorbed from the air, the thermal insulation of insulated building structures will have increased thermal conductivity coefficients. For products made of glass wool and mineral wool based on mineral wool, these figures are 15-20% higher than those measured in dry conditions. The thermal conductivity indicators for expanded polystyrene products under operating conditions are practically no different from those in dry conditions.

The heat transfer resistance of a heat-insulating layer depends on the thermal conductivity of the material. Therefore, the use of materials with lower thermal conductivity makes it possible to reduce the thickness of thermal insulation, reduce the total amount of material and, accordingly, the financial costs of its purchase.

Summing up, it should be noted that when choosing between mineral wool or glass wool, it is worth deciding in advance on the budget that can be allocated for thermal insulation.Mineral wool is more expensive than glass wool, so if you have a limited or insufficient budget, you should opt for glass wool. What to choose - mineral wool or glass wool - is up to the buyer, since it is impossible to give an unambiguous answer here. The choice will depend on many different factors.

Dependence on the density of the material and the place of insulation

A material with a certain density has a specific purpose. So basalt insulation with a density of 25-30 kg / m 3 is intended for thermal insulation of floors. He should not experience any burden. 35 kg/m 3 is used for the roof, 45 kg/m 3 can be installed vertically. Materials with a density of 50-60 kg/m 3 are used in layered laying, and 70-80 kg/m 3 are mounted in ventilated facades.

For plaster facades, it is necessary to purchase plates with a density of 140-150 kg / m 3, and for flat roofs with a load - 160-180 kg / m 3.

When choosing a material, it should be taken into account that the denser the insulation, the higher its price, since more raw materials were used for production. But at the same time they have the same thermal characteristics.

https://youtube.com/watch?v=4MLsqSnjaw8%3F

Mineral wool or basalt thermal insulation what to choose

In terms of installation, both materials are worthy of attention. Mineral wool insulation and basalt slabs can be laid on horizontal and vertical surfaces. But it is more difficult to work with stone wool, as it is denser, not so elastic and brittle. But, unlike mineral wool, it does not lose functionality even when wet at 30%, does not shrink, and is suitable for thermal insulation under plaster and screed.

Mineral heaters shrink, are not so resistant to dust and moisture, poorly remove moisture accumulated inside, require additional protection with special vapor barrier membranes. Only some samples of mineral heaters are suitable for a device for finishing with plaster or under a screed.

In terms of operation, glass wool is more convenient. The insulation includes an acrylic base, is more elastic and practically does not clog the room with dust. Many brands have a real resemblance to natural cotton.

In conclusion, it remains to be noted that basalt wool, despite some shortcomings, is better than mineral analogues, which once again confirms the analysis of characteristics reflected in the price. When choosing mineral heaters, you should give preference to proven brands with high density indicators.

Thermal conductivity

Thermal conductivity is the ability of a material to transfer thermal energy from a warm part of a material to a colder part. When it comes to insulating walls or floors, the lower the indicator, the longer the external cold will not be able to penetrate into the room, and therefore the heating costs will be reduced. In the summer heat, thermal conductivity has the opposite effect and helps to keep cool inside the house.

Due to the fibrous structure, the transfer of heat through mineral wool depends on the thickness of the filaments. Glass wool with fibers of 5-15 microns has a thermal conductivity index of 0.038-0.046 W / (m * K). And basalt wool, with fibers with a cross section of 3-5 microns, starts its minimum value from 0.033 W / (m * K). Since the basalt-based insulation has thinner threads, the heat transfer through them takes longer, which makes it a leader in this characteristic.

Making a choice between glass wool and basalt wool

Menu

In order not to make a mistake in choosing a heater, you need to have an accurate idea of the various types of this material available on the modern building materials market. What is better, more economical, and most importantly more efficient for your needs: glass wool or basalt wool? This question can be answered accurately and structured when you have decided exactly where exactly you will use this or that material for insulation.If you are an amateur in this matter and do not have much experience in the process of insulation, it is better to consult a competent specialist who will definitely help you with advice and tell you how not to make a mistake. With the right choice and high-quality installation, the thermal insulation properties of the object will be equal to all existing norms and rules that must be followed during construction work.

What is better, glass wool or basalt wool? You can get an unambiguous answer after we understand in detail all the features and specifics of the material, as well as its main properties and methods of installation.

Raw materials

Requirements for raw materials, according to DSTU B V.2.7-94-2000 (TOS 4640-93).

Metallurgical blast-furnace slag is one of the main raw materials for the production of mineral wool. Their chemical composition is represented by the following most important oxides, % by weight:

SiO2 — 35…40;

А12О3 - 7…17;

Fe2O3 + FeO - 0.5 ... 3;

CaO - 31 ... 47;

Мg0 - 5…11;

MnO - 0.4 ... 2.2.

The slags are charged with acid additives with a high content of SiO2 and Al2O3 in order to reduce the basicity modulus of the charge Mo to a value of no more than 0.8 (or the acidity modulus of Mk to a value of at least 1.25), determined by the formulas:

Cupola slags are characterized by an increased content of acidic oxides and a reduced content of basic oxides, wt %: SiO2 – 40…46; А12О3 - 10…18; Fe2O3 + FeO - 5 ... 15; CaO - 20 ... 34; MgO - 1.5 ... 8. Basicity modulus Mo=0.35…0.72 (Mk=1.37…2.82). They can be used as a one-component raw material, as well as an acidifying additive to more basic slags. They have a low melting point.

Open-hearth slags are basic slags containing CaO + MgO - 42 ... 54%, SiO2 + A12O3 - no more than 40%; Mo=1.3…2 (Mk=0.49…0.76). They are characterized by an increased content of Fe2O3 + FeO - 8 ... 24%. They can be used as an additive to very acidic raw materials in order to increase the mobility of the silicate melt and the performance of the melting unit due to the high content of basic oxides and as a melt, which lowers the melting temperature due to the increased content of iron oxides.

Slags from non-ferrous metallurgy, as a rule, are mostly suitable for the production of mineral wool. They have a diverse chemical composition, but mainly belong to acidic and ultra-acidic slags, have Mo=1.1…0.3 (Mc=0.9…3). Viscosity of slag melts from nickel, tin, zinc, lead productions at a temperature of 1250...1350°C is quite acceptable and amounts to 0.13...0.8 Pa•s. Slags from copper smelting are much more viscous - 20 Pa • s at a temperature of 1350 ° C, and therefore their additional charge is necessary.

Ashes from power plants are very diverse in terms of chemical composition. The ash from oil shale and brown coal is less acidic than the ash from coal combustion.

Rocks are most suitable in the form of igneous rocks of the gabbro-basalt group and metamorphic rocks and marls with a similar chemical composition. It should be noted that the reserves of such raw materials in our country are practically unlimited. The chemical composition of rocks used for the production of mineral fiber varies within the following limits, % by weight: SiO2 – 45…65; А12О3 - 10…20; Fe2O3 + FeO - 10 ... 15; CaO — 5…15; МgО — 5…15; N2O + K2O - 1 ... 3.

Wastes of silicate and ceramic industries are widely used in the production of mineral wool in the process of additional charging of the main raw material as an acidifying additive with a content of SiO2 + A12O3 - 70 ... 85%.

Otherwise, the resulting silicate fiber has low mechanical strength and is unstable against water due to its high content of CaO.

Electrothermophosphoric slags contain approximately the same amount of CaO and SiO2 (about 41 ... 44%), Mo = 1.09 ... 1.21 (Mk = 0.82 ... 0.91), must be charged with acidic additives (sand, ash, cupola ultra-acid slags etc.).

Stocks of raw materials that make it possible to produce mineral wool from a one-component charge without additives are very limited, so most plants operate on a two-component charge. The charge must provide the required melt viscosity and fiber durability.

According to the existing standard, the acidity modulus of mineral wool must be at least 1.5 for the highest and not less than 1.2% for the first quality category. With an increase in the acidity modulus, the durability of mineral wool increases, as its chemical resistance and, in particular, water resistance increase. . The water resistance of mineral wool is characterized by pH; mineral wool belongs to the highest category of water resistance at pH

The pH index of the hydrolytic resistance of mineral wool increases with an increase in the content of acid oxides SiO2 and A12O3 in it. However, an increase in the amount of acid components of the charge leads to an increase in viscosity, which entails a decrease in productivity and worsening conditions for fiber formation. In this regard, when choosing the composition of the charge, it is necessary to look for the optimal solution. On the one hand, avoid too high viscosity in order to avoid disruption of the process; on the other hand, to prevent a low content of acid oxides in the charge to the detriment of the durability of mineral wool.