Washing methods

To date, it is customary to distinguish four technological methods for cleaning the heating system.

To perform chemical cleaning yourself, you must have the following tools and materials on hand:

- washing solution, which may include mineral or organic acids, as well as all kinds of solvents and alkalis;

- container for draining liquid;

- pump;

- hoses.

The procedure is carried out as follows:

- water is drained from the heating system;

- acid solution is poured;

- a special pump is connected to the system, which pumps the cleaning liquid throughout the heating circuit for several hours;

- the waste liquid is drained and clean water is pumped.

An important point: the used acid solution is strictly forbidden to drain into the sewer. If it is not possible to dispose of it yourself, then you can purchase special means of neutralization.

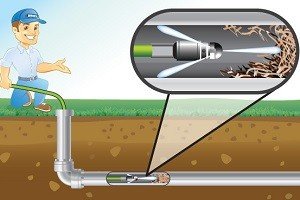

The principle of cleaning in this way is that water is supplied under pressure to a nozzle that generates thin jets of water. With the help of these jets, all grease, rust and scale are removed from the working area.

It should be noted that although this method of flushing pipes is quite effective, due to its high cost, it is used too little.

Pneumohydropulse flushing of the heating system. In order to perform this type of cleaning with your own hands, you will need:

- compressor;

- outlet pipe;

- hose;

- collar;

- ball valve;

- drain container.

The order of work consists of the following steps:

- water is drained from the system;

- a branch pipe is connected to the "return";

- the compressor is connected to the outlet, and we pump up the pressure to approximately 5 atmospheres. Strong pressure in the pipes leads to the fact that all kinds of pollution break off from the walls.

- we block the outlet pipe and disconnect the compressor, and connect the hose;

- we open the valve, and as a result, all contaminants come out under pressure.

It should be noted that for better cleaning, the pneumohydropulse procedure can be repeated several times.

And in conclusion, I would like to note that having studied our recommendations, you can more confidently flush the heating system with your own hands.

Watch a video that popularly explains the need to flush the heating system and the features of the relevant work:

Types of air vents

Valves for removal of air jams are automatic and manual. Mayevsky cranes belong to the second type of air vents. They are used not only to remove air, but also to start it in order to drain the coolant from the system.

Mayevsky crane

This device is made of brass, has a simple but reliable design. The main parts of the Mayevsky crane are the body and the screw. All parts of the valve are located as tightly as possible to each other, so that the coolant cannot escape. Open the tap with a special key, screwdriver or hand.

Before removing air from the heating system, it is necessary to prepare a container for the coolant and tools. Step-by-step instructions for removing air congestion using a Mayevsky crane:

- If the heating system is operated by means of a circulation pump, then it should be switched off for the time of air discharge.

- With a key, screwdriver or hand, the valve is turned 1 turn counterclockwise. Immediately, a hiss of air coming out of the radiator will be heard.

- As soon as the coolant began to flow out, it means that the air plug is removed, the Mayevsky tap is closed back.

Automatic air vent

This device independently removes air from the heating system. Mounted either vertically or horizontally. Consisting of brass body, float, exhaust valve and articulated arm. To prevent the coolant from flowing through it, the air vent is equipped with a protective cap.

The principle of operation is as follows: if there is no air in the chamber, then the exhaust valve is closed. As it enters the float goes down. As soon as the chamber is completely filled, the outlet valve opens and the air is expelled to the outside. The float then closes the outlet valve again.

Air separator

This device consists of a metal case, an air vent, a drain cock and a tube with a mesh. Unlike conventional air vents, the separator itself takes air out of the water. Passing through the grid, the coolant swirls, due to which air bubbles are formed. As a result, they rise up, and the gases are removed through the air vent. In addition to air, the separator separates sand, rust and other impurities. The sludge is removed through a drain cock located on the outside at the bottom of the housing.

What is the difference between supply and return heating

Heating was invented to ensure that the buildings were warm, there was a uniform heating of the room. At the same time, the design that provides heat should be easy to operate and repair. A heating system is a set of parts and equipment used to heat a room. It consists:

- A source that creates heat.

- Pipelines (supply and return).

- heating elements.

Heat is distributed from the starting point of its creation to the heating block with the help of a coolant. It can be: water, air, steam, antifreeze, etc. The most used liquid coolants, that is, water systems. They are practical, since various types of fuel are used to create heat, they are also able to solve the problem of heating various buildings, because there are really many heating schemes that differ in properties and cost. They also have high operational safety, productivity and optimal use of all equipment as a whole. But no matter how complex heating systems would be, they are united by the same principle of operation.

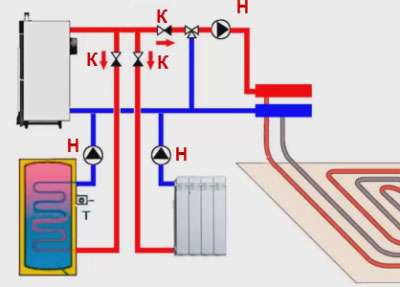

Briefly about the return and supply in the heating system

The water heating system, using the supply from the boiler, supplies the heated coolant to the batteries, which are located inside the building. This makes it possible to distribute heat throughout the house. Then the coolant, that is, water or antifreeze, after passing through all available radiators, loses its temperature and is fed back for heating. The simplest heating structure is a heater, two lines, an expansion tank and a set of radiators. The conduit through which the heated water from the heater moves to the batteries is called the supply. And the conduit, which is located at the bottom of the radiators, where the water loses its original temperature, returns back, and will be called the return. Since, when heated, the water expands, the system provides a special tank. It solves two problems: a supply of water to saturate the system; accepts excess water, which is obtained during expansion. Water, as a heat carrier, is directed from the boiler to the radiators and back. Its flow is provided by a pump, or natural circulation.

Supply and return is present in one and two tubular heating systems. But in the first there is no clear division into the supply and return pipes, and the entire pipe line is conditionally divided in half.The column that leaves the boiler is called the supply, and the column that leaves the last radiator is called the return. In a single-pipe line, heated water from the boiler flows sequentially from one battery to another, losing its temperature. Therefore, at the very end, the batteries themselves will be cold. This is the main and probably the only disadvantage of such a system.

But the single-pipe option will gain more pluses: lower costs for the purchase of materials are required compared to the 2-pipe; the diagram is more attractive. The pipe is easier to hide, and it is also possible to lay pipes under doorways. Two-pipe is more efficient - two fittings (supply and return) are installed in parallel in the system.

Such a system is considered by experts to be more optimal. After all, her work fluctuates in the supply of hot water through one pipe, and the chilled water is diverted in the opposite direction through another pipe. Radiators in this case are connected in parallel, which ensures uniformity of their heating. Which one establishes the approach should be individual, while taking into account many different parameters.

Just a few general tips to follow:

- The entire line must be completely filled with water, air is a hindrance, if the pipes are airy, the heating quality is poor.

- A sufficiently high fluid circulation rate must be maintained.

- The difference between the supply and return temperatures should be about 30 degrees.

What is the difference between supply and return heating

And so, to sum up, what is the difference between supply and return in heating:

- Feed - the coolant that goes through the water conduits from the heat source. This can be an individual boiler or central heating of the house.

- The return is water that, having passed through all the radiators, goes back to the heat source. Therefore, at the input of the system - supply, at the output - return.

- It also differs in temperature. The supply is hotter than the return.

- Installation method. The conduit that is attached to the top of the battery is the supply; the one that connects to the bottom is the return line.

Actions for prevention

In working condition, monitor the level of heating of the engine. If it seems too high for you, then it is better to remove the pump and contact the point of sale with a request to replace the unit. The same can be done in the case of a discrepancy between the force of pressure

Also, to protect pumping equipment from sudden failure, it is recommended to carry out preventive maintenance of the unit, which will include the following actions:

- Regular external inspection of the pump housing and its careful listening in the operating mode. So you can check the performance of the pump and the tightness of the housing.

- Ensure that all external pump fasteners are properly lubricated. This will make it easier to disassemble the pump if repairs are needed.

- It is also worth observing some rules when installing the pump unit for the first time. This will help to avoid repairs in the future:

- So, when you first connect the pump to the heating network, you should turn on the unit only if there is water in the system. Moreover, its actual volume must correspond to that indicated in the technical passport.

- It is also worth checking the pressure of the coolant in a closed circuit here. It must also correspond to that stated in the technical specifications of the unit.

- In working condition, monitor the level of heating of the engine. If it seems too high for you, then it is better to remove the pump and contact the point of sale with a request to replace the unit. The same can be done in case of a mismatch in the pressure force.

- Also, make sure that there is an earth connection between the pump and the terminals when connecting the pump. Here, in the terminal box, check the absence of moisture and the reliability of fixing all wiring.

- A working pump should not give even minimal leaks.Particularly noteworthy are the junctions of the inlet and outlet pipes of the heating system with the pump housing.

Unbalance and installation

Another reason why it doesn't circulate water in the system heating, is an incorrectly carried out imbalance during the repair or redevelopment of the apartment. This is affected by the uncontrolled installation of new radiators and underfloor heating.

Batteries on some floors continue to function normally, on others they will remain cold, since they do not receive coolant. Although the masters will easily balance the distribution of water across all risers, the system will not work in several apartments.

If some tenants removed the thermostats when replacing heating equipment, then heat will not flow into their neighbors' dwelling. To eliminate this problem, it is necessary to eliminate the thermostats in all apartments. You can increase the heat supply if you follow the example and also replace all the radiators. Bimetallic or aluminum batteries will harmoniously fit into modern heating systems. You must first obtain permission to replace devices, since you cannot do this yourself.

In a private house, batteries located closer to the boiler heat up more than others. To restore balance, you need to close the adjustment valves and limit the access of the coolant to nearby radiators. But sometimes a new battery does not heat up. If the whole system worked fine before its installation, then the problem lies in improper installation. When welding several polypropylene pipes, the master overheated the product, due to which its inner diameter decreased. The specialist must redo all the work for free. All structural elements must be securely and efficiently fastened.

How to protect the pump from malfunction

It is advisable to always maintain the required volume of heat-carrying water in the pipes. Otherwise, the pump will work for wear and tear, both in case of excess water volume, and in case of its shortage.

In order to insure and avoid breakage of rather expensive pumping equipment, it is recommended to follow some basic rules for the operation of equipment of this type:

- Do not turn on the pump without the presence of a coolant in a closed circuit. That is, if there is no water in the pipes of the heating system, then you should not “torment” the pump. So you will provoke an early breakdown of equipment.

- It is advisable to always maintain the required volume of heat-carrying water in the pipes. Otherwise, the pump will work for wear and tear, both in case of excess water volume, and in case of its shortage. For example, if the pump can distill the amount of water from 5 to 105 liters, then the need to work with volumes from 3 to 103 liters will already wear out the working units of the unit, which will lead to its failure.

- In the event of a long downtime of the pump (during the off-season of heating), it is necessary to run the unit once a month in the operating position for at least 15 minutes. This will avoid oxidation of all movable elements of the pump unit.

- Try not to exceed the coolant temperature above 65 degrees Celsius. A higher rate will negatively affect the working and movable parts of the structure.

- At the same time, check the pump housing for leaks more often. If even the slightest leak is observed somewhere, you should immediately identify the malfunction and carry out maintenance of the pump.

Heating systems with natural circulation

The natural circulation heating system was widely used even in the pre-war period due to its efficiency, simplicity and reliability. Most often, this type of heating system is used in summer cottages, as well as in country houses due to frequent power outages at such facilities. Such systems are conditionally divided into two types - with lower and upper water supply.To determine with the choice of the type of heating system, it is necessary to consider their differences, characteristics and scope.

Schematic diagram of heating with natural circulation of the coolant

Heating systems with natural circulation

No circulation in the heating system, what are the reasons

In the absence of it, you will regulate the temperature of the batteries not only in your room, but throughout the riser. It is unlikely that the neighbors will be delighted with such actions.

Read more: temperature controllers in the heating system.

The simplest and cheapest version of the regulator is the installation of three valves: on the supply, on the return and on the jumper. If you cover the valves on the radiator, the jumper must be open.

There is a huge abundance of various thermostats that can be used in apartment buildings and private homes. Among the wide variety, each consumer can choose for himself a regulator that will suit him in terms of physical parameters and, of course, in terms of cost.

Consequences of a cold return

Scheme for heating the return

Sometimes, with an incorrectly designed project, the return flow in the heating system is cold. As practice shows, that the room does not receive enough heat during a cold return, this is still half the trouble. The fact is that at different supply and return temperatures, condensate can form on the walls of the boiler, which, when interacting with carbon dioxide released during the combustion of fuel, forms acid. She then can disable the boiler much ahead of time.

To avoid this, it is necessary to carefully consider the design of the heating system, special attention must be paid to such a nuance as the return temperature. Or include additional devices in the system, for example, a circulation pump or a boiler, which will compensate for the loss of warm water

Radiator connection options

Now we can more than confidently say that when designing a heating system, the supply and return must be ideally thought out and configured. With the wrong design, you can lose more than 50% of the heat.

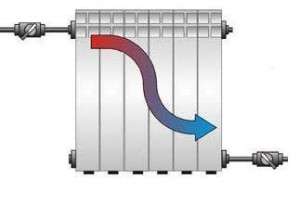

There are three options for inserting a radiator into a heating system:

- Diagonal.

- Lateral.

- Lower.

The diagonal system gives the highest efficiency and is therefore more practical and efficient.

The diagram shows a diagonal inset

How to regulate the temperature in the heating system?

In order to adjust the radiator temperature and reduce the difference between the flow and return temperatures, a heating system temperature controller can be used.

When installing this device, do not forget about the jumper, which must be in front of the heater.

Installation of the circulation pump what should be paid attention to

To install the circulation pump yourself, use the following recommendations:

- to extend the life of the entire system, install a filter in front of the circulation pump to clean the liquid. the filter must be installed on the suction pipe;

- do not choose for the heating system a circulation pump of greater power and productivity than required. Otherwise, there is a risk of encountering additional unpleasant noise during its operation;

- Never turn on the pump before filling the heating main with water and removing air from it, this can lead to equipment failure;

- install the pump in an area as close as possible to the expansion tank;

- when installing the pump in a closed heating system, if possible, install the pump on the return. This is due to the fact that this section of the pipeline has the lowest temperature.

Circulation pump installation

Tip: before starting the heating system, it is necessary to rinse it with water to remove various foreign particles.Do not forget that even short-term idle operation of the circulation pump in the absence of fluid in the system can result in the failure of the pump itself and other elements of the system.

Almost all circulation pumps on the market today are equipped with a connection with automatic adjustment of boilers for heating. This function provides the owners with the opportunity to regulate the air temperature in the heated object by changing the speed of water movement in the heating system. In order to take into account the level of heat consumption in the premises, special meters are installed, thanks to which heat losses arising from the wear of the mains are controlled. The heating scheme itself is not subject to any changes.

You can familiarize yourself with the installation method of the circulation pump yourself by watching the video:

Coolant circulation in a combined branched heating system

Let's start the analysis of the circulation of the coolant with a complex system - then you will deal with simple circuits without problems.

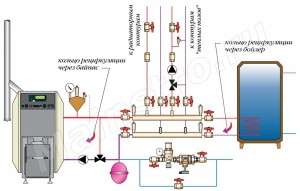

Here is a diagram of such a heating system:

It has three circuits:

1) boiler - radiators - boiler;

2) boiler - collector - water heated floor - boiler;

3) boiler - indirect heating boiler - boiler.

Firstly, the presence of circulation pumps (H) for each circuit is mandatory. But this is not enough.

In order for the system to work as we want it: the boiler is separate, the radiators are separate, check valves (K) are needed:

Without non-return valves, let's say we turned on the boiler, however, the radiators "for no reason" began to warm up (and it's summer in the yard, we just needed hot water in the plumbing). Cause? The coolant went not only to the boiler circuit, which we now need, but also to the radiator circuits. And all because we saved on check valves that would not let the coolant through where it is not needed, but would allow each circuit to work independently of the others.

Even if we have a system without boilers and not combined (radiators + water heated floor), but “only” branched with several pumps, then we put check valves on each branch, the price of which is definitely less than reworking the system.

Return in the heating system

Return flow in the heating system - installation and installation methods

The return is a coolant (water or antifreeze) in the heating system, which, having passed through all the radiators, loses temperature and is fed back into the boiler for heating. The heat carrier occurs in a two-pipe and in an improved one-pipe heating system.

Principle of operation

The principle of operation of a single-pipe system is that hot water is supplied from the boiler and flows sequentially from one radiator to another, gradually cooling down. Thus, in the outermost rooms, at the end of the chain, the batteries will give out less heat. If this system is slightly improved so that two pipes crash into the passing pipe from each radiator - one with supply, the other with return, and thermal valves are installed on each radiator, then it will be warmer in the outer rooms. The two-pipe system is more thought out - two pipes are connected in parallel (supply and return). The slightly cooled water leaves through the second pipe, which is located at a slight slope towards the boiler.

Heating

If the temperature between the supply water and the return water differs so much that it can cause “dew” on the walls of the boiler combustion chamber, then the boiler will not work for a long time. In the process of combustion of fuel materials, CO2 is released, which, when combined with dew drops, forms an acid corrosive “water jacket” of the boiler furnace. In order to extend the life of the boiler, they try to initially think over the heating system so that the “dew” does not fall out, i.e. try to reduce the temperature difference between the two pipes.Most often, this is achieved by including a hot water boiler in the heating system or by heating the return coolant. The boiler is installed next to the boiler. It is fixed on a short heating ring and set so that hot water, after passing through the main distribution manifold, immediately enters this boiler and then goes back to the boiler.

The return flow in the heating system can be heated by two pipes, between which a bypass is made, and a circulation pump is installed on it. A check valve must be installed behind such a pump, otherwise it can push through the recirculation circuit. For the circulation pump, you should select a power corresponding to one third of the power of the main pump (if there are several, then from the sum). In general, the circulation pump allows you not to make slopes in the pipes to ensure the movement of the coolant, and also allows you to reduce the diameter of the pipes used.

Purchase from Docker Chemical GmbH Rus.

Coarse filter

As mentioned above, one of the reasons that there is no circulation of the coolant may be the accumulation of debris in the pipeline. In order to completely avoid this, again, we do not save on pennies, but put a coarse filter in front of each device:

With the help of a filter, it is easier to catch dirt than to correct the consequences of clogging of the pipeline or boiler heat exchangers.

Conclusion! We put coarse filters in front of each device of the heating system (pump, boiler, etc.) and in front of each plumbing device. We DO NOT save pennies to "buy" problems. Arrows are embossed on the filter housing, indicating the direction of movement of the coolant or water in the water supply ...

The filter needs to be cleaned regularly. And it is very simple to do this: close the valves before and after the filter - unscrew the plug (1) on the filter - remove and rinse the mesh under the tap - insert it into place and tighten the plug. Everything. Not that pipes change

These are the simple “body movements” you need to make in order to never complain that there is no circulation in the heating system. Good luck.

no circulation in the heating system

The return in the heating system is the coolant that has passed through all the heating radiators, lost its primary temperature and is already cold and is fed into the boiler for the next heating. The coolant can move both in a two-pipe and in an improved one-pipe heating system.

A single-pipe system implies a sequence of connections for heating radiators. That is, the supply pipe is connected to the first radiator, from which the next pipe goes to the second radiator, and so on.

If a single-pipe heating system is improved, then its design will be something like this: there is one pipe along the perimeter of the entire room, into which you can insert the supply and return pipes of each radiator. In this case, it is possible to install a control valve on each battery, with which you can very successfully regulate the air temperature in a given room.

A big plus of this option is the minimum number of pipes in it. And the minus is the temperature difference between the first radiator from the boiler and the last one. This problem can be eliminated with the help of a circulation pump, which will drive all the water through the system and heating much faster, and thus the coolant will not have time to lower the temperature.

The two-pipe version is a wiring of two pipes. One pipe is the supply of hot coolant, the second pipe is the return pipe in the heating system, through which the already cooled water from the radiators enters the boiler. Such a system allows almost parallel connection of all radiators, which makes it possible to flexibly configure each radiator separately without affecting the operation of the others.

Air locks

Cold batteries are usually caused by air preventing water from flowing freely.

Air lock is formed for several reasons.

:

Oxygen bubbles accumulate in one of the batteries or at the top of the heating system. Because of this, the lower part of the radiators will be hot, and the second half cold. And also during the operation of the equipment there are gurgling sounds. In multi-storey buildings in the uppermost apartments, the boilers completely stop working.

In old apartment buildings, many pipes have long since expired. Therefore they can cause accidents and reduce the level of heat

. Microelements contained in the coolant are deposited inside the pipelines. They impede the normal circulation of water. The correct solution would be to replace the products, but this is not always possible.

Scale layers form on the inner surface of the boiler, which reduces the pressure in the system. This problem leads to the use of hard water, saturated with minerals and salts. Special reagents must be added to the equipment, which soften the qualities of the coolant.

Corroded or improperly connected pipes cause leakage. If it is located in a prominent area, then it is easy to seal the hole with sealants. It is more difficult to deal with a problem hidden in a wall or floor. In this case, you will have to cut off the entire branch, fix the problem and mount a new section. In addition to sealants, you can use special parts to clamp the pipeline, corresponding to its diameter. If it is not possible to purchase such devices, then it is enough to make a clamp. The place of leakage is covered with a piece of soft rubber and tightly fixed with wire.

If a leak is detected on the radiator or its junction with the pipe, the hole is wrapped with a strip of cloth, after soaking it in construction moisture-resistant glue. Sometimes cold welding is used. To avoid such problems, before the start of the heating season, the entire system is inspected for damage. Be sure to start the boiler and check the quality and reliability of its work.

Troubleshooting in a two-pipe heating system continued

First of all, shut off the coolant supply to the radiator and leave the return line open. Open the bleeder, wait for the air to escape, close the bleeder and open the coolant supply. As a rule, this is enough.

In the event that this method did not work, and we are talking about an apartment building, it is better to call a specialist. For private houses, there is another option. First you need to turn off the heating supply, open the drain at the highest point of the system and squeeze out all the air with back pressure.

Each heating system may have its own characteristics, and therefore there is a high probability of atypical problems. These include incorrectly selected pipe diameters, incorrect distribution of the coolant, poor throughput, lack of pressure, malfunctions of the circulation pump or expansion tank. In any case, only a specialist will be able to fully understand all the nuances, therefore, in case of difficulty in solving the problem, it is better to seek help.

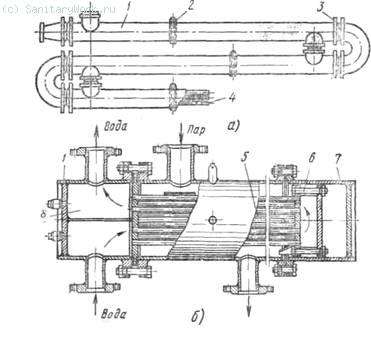

§ 87. Schemes of hot water supply systems

A schematic diagram of a hot water supply system includes an installation for heating cold water to a temperature not exceeding 75 ° C and a network of distribution pipelines. For this purpose, high-speed instantaneous water heaters are used. In such water heaters, water flows at a significant speed through the heating tubes, which, in turn, are heated by water from the heating network passing inside the water heater body and washing them.

When preparing hot water in the central heating system in a closed circuit, high-speed water heaters OCT 34-588-68 (coolant - water), OCT 34-531-68 and OCT 34-532-68 (coolant - steam) are used.

Rice. 174.

Possible breakdowns and ways to eliminate them

necessary to fix the problem. By the way, it is recommended to protect the pump from power surges by installing a reliable stabilizer. Such a move will also protect the pump from burning a fuse, which fails as a result of constant pressure drops in the network.

So, if, nevertheless, trouble happened to your circulation pump, and it refuses to work, then we will try to repair the unit with our own hands.

Important: but if you are not sure of your abilities or do not have the appropriate tool at hand, then it is better to contact a specialized center

If the pump makes a hum, but the impeller does not rotate

The reasons may be the following:

- The presence of a foreign object in the area of the impeller;

- The rotor shaft was oxidized due to a long idle time of the unit;

- Violation of the power supply to the terminals of the mechanism.

In the first case, you need to carefully remove the pump from the heating system and unwind the housing in the area of the impeller. If a foreign object is found, remove it and rotate the shaft by hand. When assembling the pump in the reverse order, it is necessary to install a reliable filter on the nozzle.

If de oxidation takes place, then it is well cleaned, all movable elements of the working unit are lubricated and the pump is assembled in the reverse order.

If the problem is in the quality of the power supply, then you will have to check the voltage with a tester. First, in all sections of the cable and if a break or malfunction is detected, completely replace the latter. Then, if the cable is in order, check the voltage at the terminals. If the tester shows infinity, a short circuit has occurred. If it shows less voltage, then the winding has broken. In both cases, the terminals are replaced.

If the unit shows no signs of life at all

This can happen if there is no voltage in the network. Using a tester, check the voltage and, if necessary, fix the problem.

By the way, it is recommended to protect the pump from power surges by installing a reliable stabilizer. Such a move will also protect the pump from burning a fuse, which fails as a result of constant pressure drops in the network.

If the pump starts but then stops

The reasons may be:

- The presence of scale between the moving elements of the unit;

- Incorrect connection of the pump near the terminals.

In the first case, you will have to disassemble the pump and check it for scale. If limescale is found, remove and lubricate all joints between the rotor and the stator.

If there is no scale, then check the tightness of the fuse on the unit. You should remove it and thoroughly clean all the clamps. Here it is worth checking the correct connection of all wires in the terminal box by phase.

If the pump makes a loud noise when turned on

The reason for this is the presence of air in the closed circuit. It is necessary to release all air masses from the pipes, and mount a special assembly in the upper part of the pipeline to prevent the formation of air pockets.

Another reason could be wear on the impeller bearing. In this case, you need to disassemble the body of the unit, check the bearing and, if necessary, replace it.

If the pump makes noise and vibrates

Most likely, the matter is in insufficient pressure in the system. It is necessary to add water to the pipes or increase the pressure in the area of the inlet pipe of the pump.

If pressure is still low

Here it is worth checking the direction of rotation of the working unit in the pump housing. If the wheel turns incorrectly, then a mistake was probably made when connecting the device to the terminals by phases in the case of a three-phase network.

Another reason for the decrease in pressure may be too high viscosity of the coolant.Here, the impeller experiences a lot of resistance and does not cope with the tasks. You will have to check the condition of the strainer and clean it if necessary. It would also be useful to check the cross section of the pipes of the inlet and outlet and, if necessary, set the correct parameters for the operation of the pump.