Installation, adjustment, operation, precautions, actions in case of breakdown

The installation of the regulator in the hot water supply system should be done on a flat, easily accessible section of the pipe, which will simplify the repair and maintenance work associated with regulating its operation. Fixing occurs due to flanges in accordance with GOST 12815. Temperature control is carried out using a direct-acting valve or an electronic regulator. The operating conditions for different models are different, but they all agree that the ideal conditions for the operation of this unit is an air environment with a temperature of 5 to 10 degrees Celsius and a relative humidity of not more than 75% at 25 ° C. There should not be too much or too little difference between the forward and return pipes.

In most cases, the temperature regulator of water in the DHW system stops working when there is insufficient pressure, which is often found in modern cities. You can fix this by installing pumps. The danger during repair and maintenance is primarily a rather significant amount of heated water in the system, so you should be careful when servicing or replacing it. It is worth remembering that installation and repair should be carried out only if there is no pressure in the direct and reverse pipelines.

Various operating modes and modifications

DHW regulators are composed of two different modifications. The first of them makes it possible to use the device only as a temperature controller for hot water, while the second, in addition to the main function, makes it possible to protect the system from emptying. The first modification is correspondingly simpler and includes only a control valve, its drive and a control device. At a given temperature, all moving parts of the device are in a stationary state, and when it is exceeded, the volume of the cylinder of the regulating device changes and the shutter of the actuating device moves. In contrast to it, on the ‘protective’ modification, a universal direct-acting pressure regulator is additionally installed - URRD, which protects against pressure drops. With this scheme, the pressure in the return pipeline is less than in the local heating system. Due to this, during the pressure drop, the balance of the acting forces is disturbed, and the valve closes. When the pressure normalizes, the automatic regulator will automatically switch to the state of maintaining the required temperature.

Device Mounting Recommendations

Thus, using accessible and functional regulators in the heating system, it is possible to achieve significant results in matters of energy saving and to achieve a smooth distribution of heat from heaters in a house or apartment.

The regulation of the heating battery depends on the heating system installed in the apartment. If you cannot do it yourself, it is best to invite specialists who will do everything at the highest level.

Installing a DHW temperature controller

An automatic temperature controller ensures rational heat consumption and stable hot water temperature.

OTOS is ready to perform a full range of works on the installation of a water temperature controller in a DHW heating substation.

- We will develop and approve the project

- We will supply equipment and materials

- Install a water temperature controller

- Let's start the DHW system and set up the regulator

- We will conclude a maintenance contract

The project for the installation of the regulator is carried out by certified specialists with many years of experience. All projects are developed individually, and the selection is accompanied by a detailed calculation.

Installation of the temperature controller in the hot water system will be performed by an experienced team using modern tools and materials. Installed equipment, materials and work performed are covered by a two-year warranty.

How does the regulator maintain the temperature of the water?

The regulator valve is installed on the supply pipeline of the heating network in front of the heat exchanger (boiler), and the temperature sensor is installed at the outlet of the heated water from the heat exchanger.

The sensor measures the temperature of the heated water at the inlet to the hot water supply system and transmits a control signal to the control valve drive to increase or decrease the flow of the heating coolant. If the set temperature is exceeded, the regulator shuts off the heating flow, and opens it if it is not enough.

Types of water temperature controllers

Direct acting temperature controller

The temperature sensor of such a regulator is a cartridge filled with gas and connected by an impulse tube with a bellows drive. The gas heats up in the temperature sensor (canister) and expands, and, accordingly, the pressure in it and in the drive increases - the drive bellows expands and presses on the regulator stem, blocking the flow. On cooling, the opposite happens.

Direct acting temperature controllers operate without external energy sources, but have a limited temperature range and cannot be programmed to maintain different temperatures depending on the day of the week and time of day.

Programmable temperature controller

It consists of a sensor, a controller, an electric actuator and a control valve. The sensor transmits temperature data to the controller, which compares the measured temperature with the set setting and, if it deviates, generates a control signal for the electric drive of the closing or opening control valve.

The programmable regulators are powered by an external network, maintain the water temperature with greater accuracy and can provide different temperatures depending on the day of the week and time of day.

How much can you cut your hot water bills?

Excessive heat consumption in the DHW system, the water heater of which is not equipped with a temperature controller - can reach 30%

. At the same time, during the absence of water intake and, accordingly, heat removal, the hot coolant from the supply pipeline of the heating network flows into the return one, which is not allowed under the conditions of heat supply in district heating networks and entails a fine and an increase in heat losses from pipelines.

Installing a DHW temperature controller

Varieties of heating system regulators

Several types of thermostats are used for heating systems:

- mechanical;

- electronic;

- electromechanical.

With their help, you can control the temperature and maintain a comfortable indoor climate. Regardless of which regulator will be used, each of them has advantages and disadvantages.

Electronic regulators

The electronic thermostat consists of 3 main elements:

processes and transmits the signal

The advantages of electronic thermostats are:

- high precision;

- ease of adjustment and control of heating systems.

Electronic regulators are used to control the heating system of an apartment or house and regulate the operation of air conditioners, as well as other systems that are responsible for maintaining and creating a comfortable microclimate in the room.

Electronic sample thermostats can be easily mounted in a smart home system and monitor the temperature of heaters and rooms.

Mechanical heating controllers

A mechanical type thermostat for a radiator consists of:

without the use of external energy

The principle of operation of a mechanical regulator is quite simple - the temperature wheel is set to the desired level using manual control.

Mechanical regulators, in addition to the adjustment wheel, may have an on and off button, such regulators are controlled and turned on only manually.

Electromechanical regulators

One of the simplest regulators is considered electromechanical. Its main element is considered to be a relay, which can be of several types, but a regulator with a relay is used in the heating system, in which some elements expand at the time of heating.

This type of regulator is used in oil coolers and boilers. where the relay is a cylindrical tube filled with sensitive fluid. The tube is in a small tank of water that is heated.

The principle of operation of the temperature controller

The thermostat for heating radiators consists of a thermostatic head and a valve, the latter acting as a so-called actuator. The head, in turn, consists of a cylinder filled with a working substance that is sensitive to temperature fluctuations. Actually, thanks to this, the thermostat performs its function.

When the temperature rises, the volume of the working fluid increases, and if it decreases, then vice versa. During this, a pressure rod is set in motion, which is connected to the cylinder. The thermostatic head is mounted on the valve. When expansion / contraction occurs, the rod releases or compresses the locking cone located under the spring (this cone is necessary to close / open the hole through which the coolant is supplied).

The regulator can operate on a liquid or gaseous working substance, according to this parameter, in fact, all devices are divided into two large groups. Gas-filled thermostats are more sensitive to temperature changes, but liquid-filled thermostats more accurately respond to pressure surges in the device, so that the temperature can be controlled with maximum accuracy.

Note! The principle of operation of the regulator is the same for all heating systems - both one- and two-pipe. The only difference is the resistance of the valves: in the first case, it is significantly lower than in the second.

Control method

Adjustment of work is carried out in two ways: mechanical, as, for example, in the model of equipment, as well as electronic, as in.

In the first case, the water temperature is set using a screw regulator, and in the second - through a keypad. Note that with electronic control, all the set parameters are reflected on the LCD display, which is located on the front panel, which is very convenient for monitoring the operation. In the event of a breakdown, a special code is displayed on the screen, the decoding of which is most often in the instructions. So, if a problem occurs, the master will fix it very quickly.

Main areas of use, types and examples of specific models

Such devices are actively used in plumbing and water heating systems, in the automotive industry, at boiler houses of each type and heating stations. In addition to the two main modifications, there are bellows or automobile, where the thermostat is responsible for thermal regulation.As an example of such systems, one can cite the TRZh and HND models: such as the most accessible TRZH-M1. Different models, types, modifications and configurations of automatic regulators have their advantages and disadvantages and are selected depending on the situation. The material of manufacture (cast iron or steel) is important. Below is a table of parameters of the P-2.T model, taken for clarity.

Classification of thermostats

There is no generally accepted classification, so let's try to divide the thermostats for the hot water supply system conditionally.

According to the principle of operation of control systems

-

Pneumatic or hydromechanical, direct action.

These are the simplest controllers. They use bellows filled with a liquid, a gas that changes its volume depending on temperature. The bellows is then lengthened or shortened and actuates the actuator. This is how regulators on radiators work.

An outdated system, but due to the ease of tie-in, it is still used today. Another advantage of such regulators is their independence from the power supply, which they simply do not need. Most often, they also lack a control unit.

-

Pneumohydromechanical with indirect action pipelines

. They also most often use bellows sensors. But impulse pipelines and network water pressure are used to transmit and amplify the signal from them. Unlike the previous variety, they can work on more powerful hot water systems with high pressure pipelines. -

electromechanical

e. They already have actuators with an electric drive (motor or solenoid) and have a control box. Intermediate relays can be installed to communicate them with the sensor. -

Electronic

. The most common variety today. In them, the operation of the system is controlled by an electronic circuit. It can be analog (almost never occurs) or digital. Modern thermostats for hot water supply usually include microcontrollers in their electronic circuit and, thanks to software control, they are very easy to reconfigure.

According to the scheme of installation of thermostats

Schemes of installation of regulators are determined by inserts of sensors and actuators. The control unit, if any, as is clear, is mounted in any convenient place.

At the point of insertion of the sensor

There are several options:

- Insert at the outlet of hot water from the heat exchanger. This is the most common method, it is prescribed in almost all manuals for the operation of thermostats. Moreover, the second method described below is impossible with a DHW system without recirculation, since there is no return there. The disadvantage is that you need to take into account the cooling on the way to the consumer and slightly overestimate the setting temperature.

- Inset on the return line of hot water pipelines. The method is rarely used, but only it can ensure that the set temperature is met at all points of water analysis.

- Insertion on the supply of network water. It is used when installing the simplest regulators, in which the actuator is located in the same housing as the sensor. A supply tie-in is usually used when the heating medium and hot water in the boiler move countercurrently and the temperature of the latter at the outlet is almost equal to the supply temperature.

- Inset on the return line of network water. It is used if the water and the coolant move in the same direction in the boiler, in which case the hot water at the outlet will be heated to the return temperature.

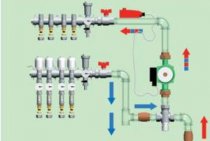

By places of insertion of executive devices

There are four schemes for installing thermostatic actuators:

- A two-way (faucet valve valve, etc.) actuator is mounted on pipelines of network water pumped to the boiler. The actuator blocks the cross section of the return or supply. This is the simplest tie-in scheme most commonly used.

- An actuating two-way device is installed on the network water bypass in front of the boiler and, when opened by bypassing part of the flow past, reduces the flow through the heat exchanger. So they crash the least.

- A three-way valve or similar fitting with a drive crashes. It simultaneously bypasses part of the flow through the bypass and presses the flow to the heat exchanger. The most profitable option, as it provides effective regulation and minimally affects the modes of other nodes of the heating network.

- Two two-way locking devices are installed on the supply or return of the coolant and bypass. The system works in the same way as with a three-way valve (being its imitation). Requires a more complex control scheme. The scheme is rarely used.

Additionally, you can watch the video in this article, which talks about such systems. Next, we will analyze several industrially produced and currently used temperature controllers, as well as one device for self-assembly.

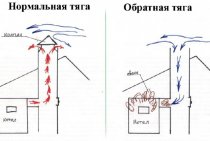

Protection system

It usually includes three main elements:

- ionization flame control electrode, responsible for the supply / shutdown of fuel supply when the burner is attenuated;

- draft sensor that blocks operation if there is no normal draft in the chimney;

- a hot water heating sensor that turns off the column if the water temperature reaches the maximum mark, which is dangerous for the heat exchanger to burn out.

These are the main elements of column protection, but there may also be additional ones, for example, a safety valve through which excess water is removed when the pressure in the system is exceeded, which is necessary to avoid malfunctions; a sensor that prevents the column from turning on if the water pressure in the system is critically low, and others.

Note that many new generation speakers can function properly even with low water pressure in the system. For example, geysers from and work properly even at a pressure of 0.1 or 0.2 bar. Do not hesitate, even if there is a slight pressure in the tap, the burner will work and the water will heat up.

Water heater protection system ensures safe use. Fears about a gas leak that could poison people, or an explosion of a column when the water is turned off prematurely, are a thing of the past.

Now you know how modern gas water heaters differ from water heaters that can still be seen in Khrushchev apartments. After getting acquainted with the main characteristics, you will have less doubts about choosing a column. If you still have questions, you can contact our managers by phone 8-800-555-83-28. We work to ensure that your purchase of a water heater is really pleasant and useful.

__________________________________________________________________________

Performance

When choosing and buying a geyser, it is very important to pay attention to its performance. It will depend on this whether the equipment will be able to fully serve you. This value can be 6-11 l/min, 12 or 14 l/min, and it usually depends on the burner power, which is 11-19 kW, 22-24 kW or 28-30 kW, respectively.

The more intense the flame, the greater the performance. To service one faucet, a column with a minimum power is sufficient, but if hot water is needed in the bathroom and in the kitchen and, perhaps, the second toilet in the house, you will need equipment that can heat at least 12 l / min

This value can be 6-11 l/min, 12 or 14 l/min, and it usually depends on the burner power, which is 11-19 kW, 22-24 kW or 28-30 kW, respectively. The more intense the flame, the greater the performance. To service one faucet, a column with a minimum power is sufficient, but if hot water is needed in the bathroom and in the kitchen and, perhaps, the second restroom in the house, you will need equipment that can heat at least 12 l / min.

Expert tip: It is best to choose a column with a capacity slightly larger than required. Running the column constantly at maximum power can cause rapid wear.

Installing the heating temperature controller step by step instructions

First, prepare everything you need to work:

- grinder or electric jigsaw;

- sanitary paste;

- spanners;

- pipe clamps.

All this must be prepared in advance, so as not to be distracted during the installation process. The installation itself is extremely simple - the procedure consists of four main stages.

First, prepare the battery for installation work. Turn it off, drain all the working fluid. If there is a valve, then remove it.

Note that in single-pipe systems, there is a mandatory bypass - a special jumper, thanks to which the liquid will circulate through the line even when one of the devices is turned off. In this case, you will not be able to disturb the heating of other rooms in the house.

Installation of a thermostat. In this case, you will use a threaded connection, and the thread itself must be sealed with sanitary flax, having soaked the latter with paint in advance. First, screw the device into the radiator hole, which is intended to enter the working fluid. Do not overdo it with pressure, otherwise you may damage the device.

Note! On the valve you can see the marking made in the form of an arrow. Make sure that it points in the direction in which the coolant will move.

Install a thermostatic element - a device that determines the temperature of the air in the room. Its other function is to control the operation of the locking mechanism. Fix it only horizontally! Also, make sure that the heat generated by the battery does not directly affect the thermal sensor.

But if, for one reason or another, horizontal installation is impossible, then we advise you not to do it “anyhow”, but to purchase a special device with an external temperature sensor. Such a device can be installed two meters from the heating radiator, and sometimes even more.

There are a number of requirements regarding the installation of a temperature sensor. Here they are.

- The device should be installed at least 80 centimeters from the floor surface, since cold air, as we remember from physics lessons, accumulates from below. And if the sensor comes into contact with this air, then its readings may be inaccurate.

- Do not cover the temperature sensor with curtains, furniture and other interior items.

- Avoid being exposed to direct sunlight.

- Finally, do not allow the device to be exposed to direct streams of heated air, which, it is worth noting, can come not only from the battery, but also from various household appliances.

Note! If the sensor is remote, then its fastening is carried out with brackets

It is also important that the mounting location is chosen correctly.

If all these requirements are met, the heating temperature controller will work properly and efficiently.

Set up the thermostat and prepare it for operation. After turning on the heating system for the first time, set up and calibrate the device. Do this in full accordance with the manufacturer's instructions for a particular model, as this process may differ for different devices. Although there is a general rule: you can start setting up only after each of the heaters in the system has warmed up well.

As you can see, there is nothing complicated in mounting the temperature controller. Having understood its device and having done everything as stated in the instructions, in the future you will be able to control the intensity of heating the room, due to which energy resources will be spent extremely rationally. And this, in turn, will help to significantly save on heating.

Heating systems and temperature control

Heating systems can be of several types. water, steam, air and combined. Temperature controllers can be installed on any of them.

common variant

Electric heating is convenient, practical, safe and reliable. The temperature is controlled according to the set and actual temperature.

Mechanical regulators are very easy to use and are much cheaper than their electronic counterparts. Regulating mechanisms are installed on heating devices to the coolant supply line. The principle of operation of a mechanical regulator is very simple, because the sensor is built into the valve, and the temperature is adjusted by increasing and decreasing the coolant in the radiator.

On the issue of installing automatic hot water temperature controllers in MKD

Almost every year, by the beginning of the heating season, the following situation develops. The resource supplying organization does not issue readiness certificates for the autumn-winter period due to the failure of the HOA, housing cooperative, managing organizations to fulfill warranty obligations for the restoration of heat exchange equipment according to the design or installation of automatic hot water temperature controllers.

It should be recalled that in accordance with paragraph 9.5.1 of the Rules for the technical operation of thermal power plants, approved. By order of the Ministry of Energy of the Russian Federation of March 24, 2003 No. 115, the installation of an automatic hot water temperature controller in the hot water supply system is mandatory. Operation of DHW systems with a faulty water temperature controller is not allowed. According to Part 9. Art. 29 of the Federal Law "On Heat Supply" No. 190-FZ of July 27, 2010, the use of centralized open heat supply systems (hot water supply) for the needs of hot water supply, carried out by taking the heat carrier for the needs of hot water supply, is not allowed from 01.01.2012.

According to the Omsk branch of TGC No. 11, in half of the apartment buildings in Omsk, hot water systems are not equipped with automatic hot water temperature controllers at all. In addition, it is necessary to install about 1300 heat exchangers (at least 118 units per year) by 2022.

The absence of a heat exchanger or thermostat installed on the DHW system and, as a result, the failure to fulfill warranty obligations, in my opinion, cannot be attributed to the negligence of the operating (management) organizations.

In accordance with Part 1 of Art. 36 of the Housing Code of the Russian Federation, owners of premises in an apartment building own, on the basis of common shared ownership, common property in an apartment building, namely: mechanical, electrical, sanitary and other equipment located in this house outside or inside the premises and serving more than one premises.

Consequently, the decision to install the specified equipment and finance the work falls within the competence of the general meeting of owners of premises in an apartment building, held in accordance with the procedure established by the Housing Code of the Russian Federation.

A common situation is when at a general meeting, when considering the issue of financing the costs of acquiring and commissioning equipment, the owners of the premises refrain from making a decision or even vote only for priority repairs, for example, the roof of a house.

But nevertheless, the requirements of the legislation must be fulfilled, as well as to receive acts of readiness for the autumn-winter period.

I think that with the joint organization of the management company, the HOA and the heat supply organization to widely inform the owners of the premises, the situation may change in a positive direction.

As one of the possible options, the organization of a general meeting of owners of premises with the involvement of a representative of the resource supply organization, to the heat source of which the apartment building is connected, for competent consideration of emerging issues of citizens.

Principle of operation and device

The DHW regulator operates on the principles of mixing two water streams of different temperatures from the supply and return pipelines, with the formation of a third stream with the required temperature, which is directly sent to the consumer's hot water supply system. The device itself consists of a body and a working part, the main component of which is a bellows-tight cylinder, usually filled with benzene or paraffin and maintaining the desired temperature balance. It is the temperature-sensitive element of the system, its expansion or contraction leads to a change in the amount of mixed hot water, and, accordingly, an increase in cold water. The regulator is automatic and non-volatile, it does not require additional human control.

Heating temperature controllers model range and prices

Immediately make a reservation that there are a lot of manufacturers and we do not intend to consider each of them. Let's talk only about the most popular models.

Teplolux MCS 300

- Remote control and management of underfloor heating via the Internet

- Control from one mobile device all warm floors in an apartment, country house or country house. Replace classic wall thermostats with the MCS 300 and control your comfort from your smartphone screen.

- separate operating mode for each thermostat

- event programming for each room during the day, days of the week

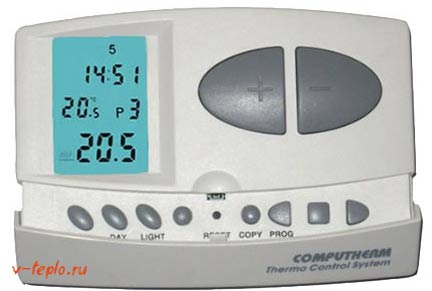

The Computherm Q7 model, also of an electronic type, with a temperature range of +5 - +35 C, costs about 1400-1800 rubles.

The price is 1400-1800 rubles.

Temperature controller - Veria Control T45

A more expensive regulator is the Veria Control T45, which has the same range as the previous model.

The price is 4300-4400 rubles.

Terneo RTP mechanical heating temperature controller

Mechanical regulators are cheaper. For example, the Terneo RTP model with a temperature range of +10 - +40 C.

The price is 1050-1100 rubles.

Although there are more expensive mechanical devices. So, Legrand Etika 672630 costs as much as 7750-10600 rubles.

As you can see, you always have to pay more for quality, and our case is no exception. But we note that mechanical models are still simpler and, accordingly, cheaper. Now let's find out how to properly set the heating temperature controller.

Do you want to know more about thermostats for heating radiators?

Our installation instructions and a large overview of models with their technical characteristics Read more here

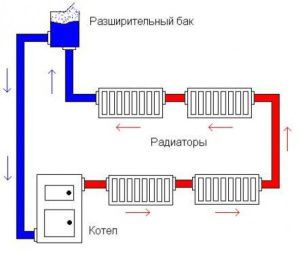

Open heating system

Open heating system

If an open-type heating system is being filled in a private house, then the procedure for performing the work is somewhat different. The peculiarity lies in the fact that the pressure in the pipes is equal to atmospheric. Therefore, the main element of control is an expansion tank installed above other heating devices.

In this case, the procedure for filling the heating system is as follows:

- The old coolant is drained and the pipes are cleaned.

- On all heating devices, the Mayevsky tap opens.

- The flow of liquid to fill the heating system can be carried out through the return pipe.

- As soon as all the air is out of the system, the water level in the expansion tank is checked. It should be 2/3 full.

It is noteworthy that with the help of a hand pump used to fill the heating system, it is also possible to add a coolant.

Excessive pressure is not allowed for an open heating system. Otherwise, it may lead to incorrect temperature operation.