The device and principle of operation of the Neva Lux boilers

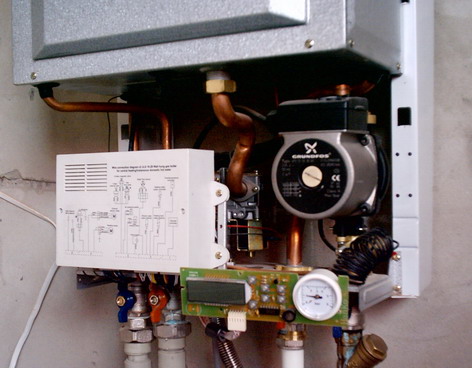

Neva Lux gas boilers are presented in two variations - wall-mounted and floor-standing, we will consider their device using some models as an example. Neva Lux 8618 is a single-circuit heating boiler, the installation method is wall-mounted, it has a low level of energy consumption, a fairly high efficiency of 91%, a power of 18 kW. It can heat a room ranging from 30 to 180 square meters.

Works both from natural, and from liquefied gas. It is small in size, equipped with a water-cooled combustion chamber, and can be connected to a room thermostat, which is convenient to use. Equipped with an overheating (boiling) protection device, a thermostat against overheating of the gas exhaust device. It can be connected to both a chimney and a turbo nozzle.

Neva Lux 8224 is a double-circuit gas boiler designed for heating a room up to 240 meters2, as well as for heating water for household needs, with a throughput of 14 liters per minute. Its power is 24 kW, it is equipped with a closed combustion chamber.

The installation method is wall-mounted, equipped with a built-in 6-liter expansion tank, which makes it possible to connect the boiler to a heating circuit of 70 liters. The design provides for two heat exchangers, copper for the heating circuit, and the second, made of stainless steel, for hot water supply.

Powered by natural or liquefied gas, for ease of use it has a display that reflects the current and set temperature in the coolant.

Neva Lux 7224 - installation method wall-mounted, double-circuit apparatus is designed to heat a room up to 240 m2, water throughput for domestic needs is 14 liters per minute. It can work on natural gas and liquefied gas, the efficiency is 92%.

Equipped with a bithermic heat exchanger, thanks to which it is possible to reduce the final cost of heat. It is equipped with an electronic self-diagnosis system, and a small display is installed on the body to indicate readings.

Neva Lux 7023 - wall-mounted, designed for space heating up to 250 meters2, as well as heating service water 13 liters per minute. It works not only on natural gas, but also on liquefied gas; for ease of use, you can connect a room controller.

The removal of smoke is forced, with the help of a built-in fan, the air for burning the fire is blown from the street. Equipped with a closed combustion chamber, has a coaxial heat exchanger, an expansion tank with a volume of 6 liters.

Neva Lux 8023 - is a double-circuit wall-mounted boiler that has the ability to provide heat to a room whose area does not exceed 240 m2. The circulation of liquid in the system is forced, using a pump, equipped with a closed combustion chamber.

Smoke removal occurs thanks to the exhaust fan. The power of the device is 23 kW, two heat exchangers are provided, the heating circuit is paramount, made of high-alloy stainless steel.

Error E8 no traction

The column turns off after 2..5 minutes of operation. Re-enabling becomes possible only after cooling - 2..3 minutes.

Reason #1.

No draft in the chimney

. Clean the chimney.

Reason number 2.

Soot on the heat exchanger

. Increased accumulation of soot on the heat exchanger, which prevents the passage of carbon monoxide into the chimney. The column needs to be serviced to correct the problem.

Reason number 3.

Thrust sensor faulty

. The thrust sensor works on a break. Over time, the sensor becomes very sensitive to vibrations and can turn off the column during heating. Therefore, with this error, the sensor will be checked for operability.

Error E1 - no flame

Ignition clicks for about a minute burner does not ignite. The electronic control unit does not see the presence of a flame and the column goes into emergency mode.

Reason #1.

The presence of air in communications

. D

After a simple column, or after its installation, the operation of the pilot burner will occur only after the removal of air. It is necessary to purge the system by constantly turning on the column. Since ignition lasts no more than a minute, after completion you should reopen the water tap until ignition occurs.

Reason number 2.

Lack of gas in the cylinders or the tap on the downstream to the dispenser is closed

. P

fully open the shut-off valve. Check LPG bottles. Replace if necessary.

Reason number 3.

No contact between unit and flame sensor

. It is necessary to carry out maintenance of the contacts coming out of the electronic unit, if necessary, clean, tighten for a good connection, replace the worn ones.

Reason number 4.

Flame sensor outside the flame zone

. Adjust the position of the flame sensor so that its electrode is in the gas combustion zone. Make sure that the electrode does not touch other metal components. Clean the electrode from carbon deposits.

Reason number 5.

The gap between the spark plug and the igniter is broken

. From constant heating and cooling, the nozzle of the pilot burner is deformed, which increases the gap to the spark plug. Once every two years, or during regulated maintenance, the gap should be adjusted to 4 ... 5 mm.

Error codes displayed

The following error codes are displayed:

Error 01. This error indicates an unsuccessful ignition. The boiler does not turn on:

Error 02. Overheating of the coolant. The boiler does not work:

Error 03. No traction:

Error 04. Low water pressure in the circuit:

Error 05. Failure of the temperature sensor of the heating system:

Error 06. Failure of the DHW temperature sensor:

- sensor malfunction;

- open or short in the electrical circuit between the sensor and the electronic board.

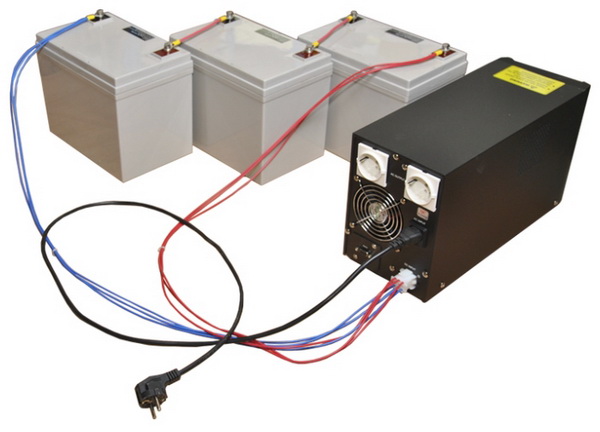

If the electronic board was accidentally flooded with water. It is necessary to turn off the boiler from the network and dry the board with warm air from a hair dryer. Sometimes there may be a malfunction in the electronics. To reset to the original position, press the RESET button. If it does not help, then disconnect the boiler from the network for a few minutes and turn it on again.

If you smell gas, find and repair the leak immediately.

If you cannot fix the leak yourself, it is recommended to call the gas service on the emergency number 104.

In chapter Service, care and repair

to the question Boiler Neva Lux 8224. Constant error 03. Condensate accumulates in the tubes of the pressure switch. How to fix this problem. given by the author Vladimir

the best answer is Need more detailed information about where it is located, external temperature, fuel (gas or diesel), winter or summer, etc. And condensate from what (water, gas)? What can be done to prevent condensation from collecting in the Pitot tubes? The Neva Lux 8224 boiler turns off every year in January, showing error 03. Of course, I eliminate the condensate and start the boiler until the next accumulation of condensate, but this problem is pretty annoying.Help!

Answer from Yotas Shabanov

1. Check whether the make-up valve is completely closed.2. If the make-up valve is closed to the stop, it is possible that the make-up valve is not hermetic. Replace the make-up valve.3. Check if the secondary heat exchanger is leaking.4. Also check if the pressure sensor and the connectors of its contacts are working. Another option: slightly opening the plug on the right side at the top so that warm air enters the combustion chamber and condensate does not form in the pressure switch tubes.

In the section on the question Boiler Neva Lux 8224. Constant error 03. Condensation accumulates in the pressure switch tubes. How to fix this problem. given by the author Vladimir

the best answer is Need more detailed information about where it is located, external temperature, fuel (gas or diesel), winter or summer, etc. And condensate from what (water, gas)? What can be done to prevent condensation from collecting in the Pitot tubes? The Neva Lux 8224 boiler turns off every year in January, showing error 03. Of course, I eliminate the condensate and start the boiler until the next accumulation of condensate, but this problem is pretty annoying. Help!

Answer from Yotas Shabanov

1. Check whether the make-up valve is completely closed.2. If the make-up valve is closed to the stop, it is possible that the make-up valve is not hermetic. Replace the make-up valve.3. Check if the secondary heat exchanger is leaking.4. Also check if the pressure sensor and the connectors of its contacts are working. Another option: slightly opening the plug on the right side at the top so that warm air enters the combustion chamber and condensate does not form in the pressure switch tubes.

The Neva Lux geyser from a domestic manufacturer is a technically complex product. The entire cycle of operation from turning on the column to heating the water is controlled by automation, which eventually fails. For a better idea of the malfunction, the company's engineer placed on the front panel indicator a window in which one or another error code is displayed during an emergency stop. Let's consider them in more detail.

ATTENTION!

Maintenance operations for the repair of geysers, associated with the dismantling of its gas or water communications, must be carried out by qualified craftsmen. Self-repair can have the opposite effect, in the raft before buying a new device.