Painting walls from heat blocks

Before you start painting the walls, you need to seal the seams with a sealant, we have already talked about this a little higher. The sealant will provide effective waterproofing, as well as serve as part of the decorative finish.

When the walls of the house are erected, it remains only to paint them. The appearance of the house is limited only by your imagination.

Heatblocks do not need cladding; after construction, they can simply be painted. Painting of external walls occurs in stages:

- First, the walls are primed. A primer is needed to improve adhesion (adhesion of the coloring element to the wall). For example, VERNOV VD-AK-0110 deep penetration primer is quite suitable.

- then you can start painting. You can choose any color - pastel colors, shades of beige and peach color look good on heat blocks. For example, you can use facade acrylic paint on a water-dispersion basis VERNOV VD-AK-103.

- many homeowners of heatblock houses paint corner blocks in contrasting colors to create the illusion of complex geometry and a more interesting look.

An example of a finished house from heat blocks

We talked about the stages of building houses from heat blocks, the features of laying heat blocks and the basic rules that must be observed during construction. To summarize:

- When laying heat blocks on glue or cement mortar, try to ensure that the binder does not get into areas with foam.

- Styrofoam joints are foamed with mounting foam.

- Every 2 or 3 rows of laying heat blocks, a reinforcing mesh must be laid.

- When constructing buildings above one floor, it is recommended to install a monolithic reinforcing belt.

- Iron corners of the lintel for openings are preferable to other types of lintels.

Heat blocks installation:

The article was prepared by the Cheboksary Construction Plant

What else to read?

Tags: reinforcing belt, armored carcass, armored belt, house from heat blocks, masonry walls, laying heat blocks, multilayer blocks, painting heat blocks, building a house, heat block, Teplosten, heat-efficient block, thermoblock

Popular Articles

TOP-5 mistakes of customers during repair. Experience of professionals

Views: 23 548

Which interior doors are better - choose the material

Views: 4 398

TOP 7 mistakes when leveling the floor

Views: 12 962

Advantix Vario Viega shower channel, easy installation and versatility

Views: 12 747

Flexible shingles - an easy way to update the roof of a house

Views: 12 512

Do-it-yourself kitchen renovation

Views: 11 737

Construction of a swimming (bathing) pond

Views: 11 286

The device of a garden fountain at their summer cottage

Views: 11 003

Do-it-yourself warming of the loggia. Detailed guide

Views: 55 438

Varieties of plates and sheets for wall, floor and ceiling cladding

Views: 21 562

Unusual wooden houses

Views: 10 417

Installation of electrical distribution board

Views: 62 055

How to build a country toilet with a hozblok

Views: 10 365

Attachments, nozzles and accessories for drills

Views: 29 272

We build interior partitions with our own hands

Views: 42 405

Types of cables, wires and cords

Views: 30 335

10 myths about frame houses

Views: 24 834

How to make a scratching post and cat house

Views: 55 714

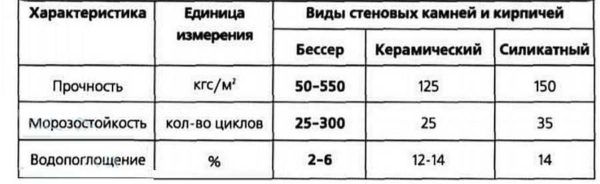

Criteria for selecting building blocks

There can be three goals: structural, structural and heat-insulating, heat-insulating. Simply put, you just need to build something, insulate it, or both.

In order to choose the right block, you need to look at the brand. So the brand of expanded clay M - 50-150. This means that the material can withstand a load of 50 to 150 kg per square centimeter, this is a very high strength.

For example, a foam block is marked with an indicator of 0.25-12.5, which means that it will be a mistake to build load-bearing walls from it. On the Internet, you can find summary tables of the strengths of building blocks and make the calculations necessary for specific needs.

The second criterion is the attitude to different temperatures

It is worth paying attention to the frost resistance of the material: any building block is able to withstand a limited number of cycles of complete freezing and thawing, after which it will begin to collapse. Even in high latitudes, the walls do not completely freeze through, so the indicator is conditional

The level of frost resistance (Mrz) 35 (so many full frosts will withstand) is sufficient, most lightweight concrete blocks reach it. For ceramic models, the indicator is 50.

The ability of a material to absorb moisture

Concrete is inferior to brick here, so walls made of any kind of blocks need external facade finishing (cladding, plaster, siding, etc.). Therefore, the finishing procedure should not be postponed for a year, until the start of the new summer season.

Do I need to take into account the shrinkage of a house or cottage from building blocks?

A lot here depends on the foundation: for the construction of low-rise buildings, a monolithic strip foundation is usually laid out from building blocks, which is relatively inexpensive and strong enough. The material also plays a role: aerated concrete and foam concrete are most susceptible to shrinkage, while expanded clay concrete, ceramics and wood concrete successfully cope with this challenge. In any case, it is necessary to follow the masonry technology, in particular, do not forget about its reinforcement with a special metal mesh or alternative material (plastic, for example) around the entire perimeter of the walls. This procedure will become something like a screed and prevent cracks on the walls.

Advantages

Due to its "layering" any multiblock has a number of advantages over any traditional building materials. First, strength. All layers of the multiblock are fastened together not only with binding solutions, but also with strong reinforcing bars. This achieves high strength and durability of the multilayer structure.

Secondly, ease. It has already been noted above that due to the special composition of the bearing part, the multilayer block has a much lower weight compared to traditional materials. Accordingly, their dimensions will be small. A modern building, built of multilayer blocks, has a thickness of external walls of the order of 3-3.5 cm. Therefore, such a structure does not require digging a deep and fortified foundation.

Thirdly, thermal insulation. Modern heat-retaining materials allow the structure to have high insulating characteristics. For comparison, the thickness of conventional insulation, laid on the finished walls of the house, will be at least 2-4 cm. The thickness of the entire wall, built of building multi-layer blocks, will be only about 3.5 cm. and in standard insulated buildings.

Moisture proofing and stability

Modern thermal insulation materials are sensitive to steam and moisture. Constant contact with a humid environment gradually destroys the insulating layer and reduces its characteristics. In multiblocks, the layer is reliably protected by the cladding. The outer layer is designed in such a way that the thermal insulation retains its properties for many years.

They are also characterized by resistance to corrosion, fungus and mold. The three-in-one design consists of chemically inert substances that interact poorly with aggressive environments.

Climate and comfort

Buildings built using multi-layer blocks will last for many years even in the most difficult climatic conditions.Concrete blocks retain their performance characteristics in a wide temperature range, and special technologies for creating a facing layer make it resistant to various mechanical damage.

Using three-layer building blocks, you can significantly speed up the process of building your own house, thereby saving time and money. In addition, a building built from multiblocks will ultimately cost much less than the same building built from classic building materials with subsequent insulation.

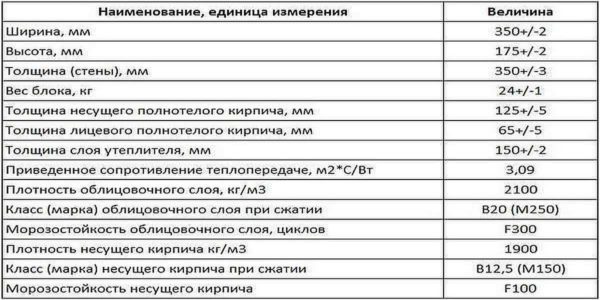

Thickness of layers in blocks

What thickness of concrete layers should be in a warm block to ensure the strength of the wall for the entire service life? It is known that experts recommend using heat blocks with an inner layer thickness of at least 180 mm for two and three-story houses.

For a one-story building with a non-residential attic, it is permissible to use blocks with a thickness of the inner concrete layer and 130 mm, but subject to reinforcement with masonry mesh (every fourth layer), openings, as well as the creation of a reinforced concrete belt under the ceilings.

The compressive strength characterizes the entire block as an integral product - there are M35, M50, M75. When determining the characteristics, all layers are taken into account, even the foam.

It is necessary to distinguish between the strength of the concrete from which the block is made, and the strength of the block itself. The compressive strength of the concrete from which the block is made will be greater than that of the block as a whole.

An increase in the width of the insulation leads to a thinning of the inner bearing layer of concrete. Ensuring strength, reliability and durability is the main criterion when choosing blocks. Therefore, it is impossible to reduce the thickness of concrete in pursuit of better heat saving.

This is interesting: A house made of expanded clay concrete blocks pros and cons: we explain in detail

Heat-efficient Balaev blocks

A relatively new building material resembling heat blocks. Products have a three-layer structure:

Cement, lead and expanded clay are used as the main components. In the manufacture, vibrocompression technology is used in combination with the clamping method. The result is a fundamentally new building material.

The author of the development was Alexander Balaev together with his sons. The idea of creating a block came to the inventor after a fire in the White Horse club, when more than 150 people died.

Presentable appearance. The front part imitates natural stone.

Absolute fire safety. Blocks do not ignite even when exposed to high temperatures for a long time.

Long operation. They can last up to 100 years (according to the inventor).

Practicality. Due to the unique structure, an optimal microclimate is maintained indoors at any time of the year.

Convenience. If necessary, they can be easily cut with a regular saw.

The material appeared on the market in 2009, so it did not have time to show up on the negative side. However, the obvious disadvantages can already be attributed to the high cost.

Advantages of heat blocks

The production of heat blocks is becoming massive due to the numerous advantages of this material:

- high strength. Blocks are able to withstand a tensile load of up to 2 tons per square meter. cm;

- durability. The heat block is able to maintain its operational properties for 100 years;

- excellent soundproofing properties. The material is able to protect against noise 52-54 dB;

- excellent decorative qualities;

- insulation and finishing are carried out together with the construction of walls, which reduces construction time;

- the heat loss of the building is reduced, which reduces heating costs;

- 1 degree of fire safety, which complies with building codes.

Pressed cement blocks from sand concrete besser blocks

Another type of hollow building blocks is made of sand concrete. The same technology is used to make full-bodied ones, but they have low thermal efficiency.But the wall is practically a monolith, it is difficult to break through it, the bearing capacity is high. But such a house, in order to be warm, will have very thick walls, which will increase the cost of the foundation.

What blocks are best for building a house? If strong walls are a priority, then vibropressed ones are out of competition

The process of forming vibropressed blocks is as follows: a mixture of cement and sand is diluted with water. The solution is poured into molds, which are then processed on a vibrocompression table. That is, the solution is simultaneously subjected to vibration and pressure. This gives it increased strength and allows you to make the walls thin and the voids significant. All this makes it possible to reduce weight, as well as increase thermal performance. This technology has been used in America for a long time. Budget houses are built from such a building block. It's called a besser block.

Advantages and disadvantages of vibropressed blocks

The main advantage of this technology is the processing by vibration with simultaneous pressure. Concrete stone is very durable and uniform. There are no voids, inhomogeneities, the characteristics and properties are stable, the walls are even and smooth. And this processing gives you the opportunity to control the size. Of all the blocks that are poured into molds, this one has the best geometry.

Sand concrete blocks: the main characteristics of corpulent

Further on the properties: high frost resistance - from 50 cycles (up to 300), strength - M100 or higher. The thermal conductivity of hollow blocks is 0.9 W / m² C, which is much lower than required, so either the wall must be thick or it must be insulated. It absorbs moisture, but in small quantities, it is not afraid of getting wet. There are no data on the thermal conductivity of a solid block. It must be understood that they are extremely disappointing.

When building walls from hollow vibrating blocks, reinforcement is recommended. And they do both vertical and horizontal. For the vertical, rods are used, which would be good to connect with releases from the foundation. And the horizontal reinforcement is a metal mesh. This is not a requirement, but it makes for stronger walls.

What blocks are best for building a house? For beauty, these

Of the "clean" shortcomings - a fairly large weight and small size of the stone. This is when compared with blocks of lightweight concrete. Accordingly, the foundation for heavy weight needs a more powerful one, which leads to an increase in the cost of it.

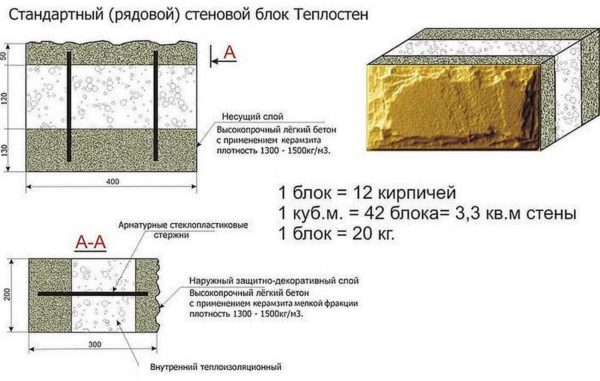

Heat block

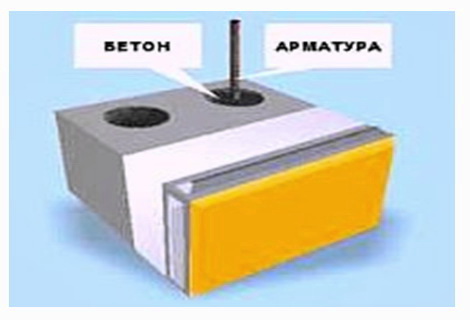

A heat block was made on the basis of vibrocompression technology. This is a multilayer structure, in the middle of which there is polystyrene, and on the sides there is a cement-sand vibrocompressed composition. Moreover, one side is front, painted in mass and, as a rule, textured, and the second is a full-bodied building stone that carries the load. To increase the reliability, the structure is fastened with reinforcing rods.

Perhaps the most energy efficient option. As long as it's not too popular

That is, the heat block is a “three in one” material. Immediately, the wall is being built, and its thermal insulation and decoration. The idea is very interesting and tempting. But, as usual, the novelty raises concerns - how will such a pie behave over time? How secure are these walls? In general, while people are in no hurry, although these blocks are better for quickly building a house.

Here the characteristics are not so difficult to find. Apparently, because thermal conductivity pleases

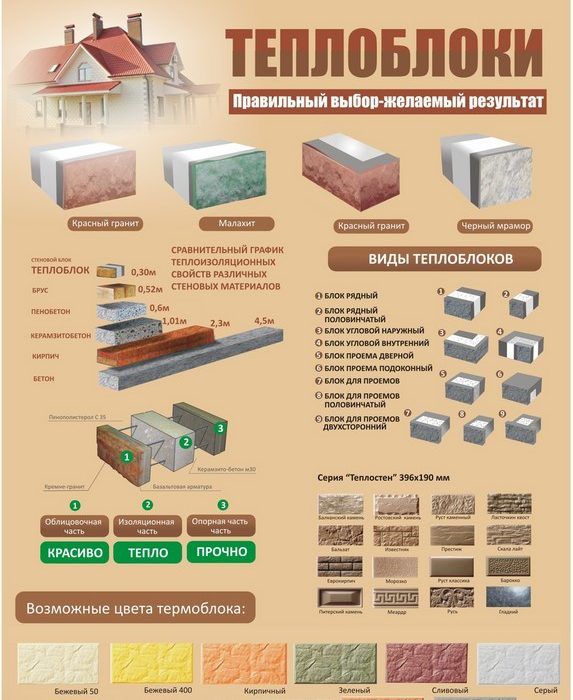

Types of heat blocks

- According to the material of the bearing part.

The bearing part of the heat block can consist of expanded clay of several grades of different strength: M50, M75, M100. Depending on the number of floors of the building and the current load, the appropriate brand of expanded clay is selected.

According to the material of the inner part of the heat block.

The insulating filling of the heat block is made of ordinary expanded polystyrene and extruded, which, with the same dimensions, retains heat much better.

According to the design of the carrier layer.

Heat blocks can be both solid and with voids inside the bearing layer of the structure for additional reinforcement of the wall. Reinforcement is installed in the voids and poured with concrete mortar.

By size.

Typically, blocks are produced in several sizes: 400x400x190, 400x300x190 and 200x400x190. The latter is used mainly in the construction of unheated attics or houses located in a warm climate. The size of the inner polystyrene liner can be from 120 to 200 mm.

This article talks about houses from blocks of thermal walls.

And here is an article that discusses all the pros and cons of heat blocks.

Dimensions

Building insulated blocks are available in standard sizes: 40 cm length; 20 cm - height. Depending on the insulation used, its thickness varies. For calculations, you can take the average value of the thickness - 30-35 cm. Such dimensions and low weight make the blocks very convenient for building walls. This building material is laid in exactly the same way as standard brickwork. Therefore, even builders with little experience do an excellent job of building walls without any special instructions.

After the erection of the walls of the building, no additional work on insulation and waterproofing is required. The load-bearing wall inside the room is finished with plasterboard panels or covered with a layer of plaster. Blocks based on lightweight concrete make it possible to erect buildings up to three floors high without the use of a frame.

Thanks to the exact geometry of this building material, the walls erected from it will have strict proportions. Since the seams between the blocks will be about 5 mm, and there will be no cold bridges in the walls. Insulated heat blocks can be drilled and sawn, however, such a multiblock will be too tough for rodents.

Application features

The use of warm blocks is still experimental.

Research Institute "Teplosten", which are considered the developers of this technology, recommend using the spatial reinforced concrete frame of the building together with the blocks. And the blocks themselves can be with a total thickness of 300 mm (with reduced strength characteristics).

But the construction of a spatial reinforced concrete frame, although not so expensive, complicates the construction process, many construction organizations simply avoid such problems, preferring classical masonry.

Most manufacturers recommend using wider blocks. Making of them external and internal load-bearing connected walls, together with the ceiling, form the power frame of the building (according to the project).

Polystyrene concrete

The block is a monolithic structure, where the main component is high-quality cement. Quartz sand, foamed polystyrene, plasticizers are used as a filler, which increase the strength and frost resistance of finished products.

The best thermal insulation on the market. Allows to save on heating of internal rooms in the winter period.

High strength. The material is highly resistant to compression and bending, has virtually no shrinkage.

Excellent vapor permeability. The walls of such blocks have the ability to "breathe", which is guaranteed to prevent the appearance of mold.

Ease of installation. The blocks are easily subjected to additional processing, have a large size and the correct geometry.

Frost resistance. The product is able to withstand up to 150 freeze / thaw cycles without losing its original properties.

Direct dependence of quality from the manufacturer. Violation of manufacturing technology leads to the formation of internal microcracks.

Difficulties in interior design. The surface of the block has poor adhesion with plaster solutions.

The porous structure "does not hold" nails and self-tapping screws.

Polystyrene concrete blocks are considered non-combustible material, but when exposed to high temperatures, they begin to release phenol, a substance harmful to human health.

Reinforcement

Reinforcement of blocks can be done using reinforcing mesh, filling it with masonry glue. You can reinforce every third or fourth row of masonry. Internal partitions with load-bearing walls are connected with the help of strobes, which can be made with a chisel, chasing cutter or perforator. Sometimes fiberglass or steel embedded elements are used. The base of the insulated block is easily processed with dowels or standard nails. With expected heavy loads, injection dowels can be used.

The cost of a house built from insulated three-in-one building materials can be compared with popular houses built using Canadian technologies. Only a house made of heat blocks turns out to be much more environmentally friendly and durable, and in terms of its operational characteristics, it can belong to the premium class of capital structures.

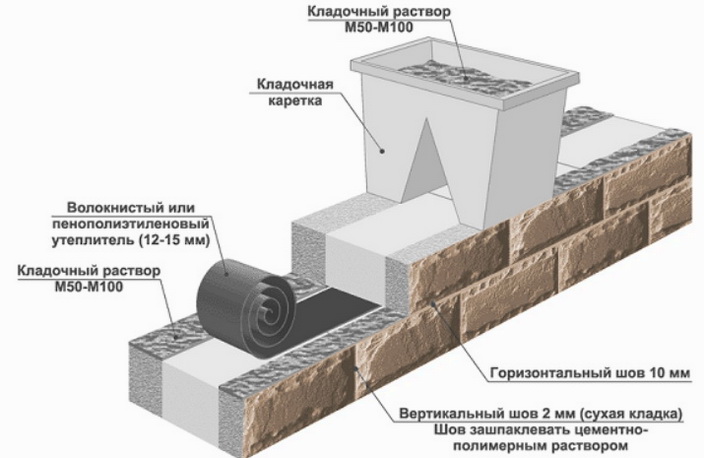

How to perform masonry

When laying, it is recommended to fill with glue (mortar) vertical and horizontal seams between concrete parts. (any masonry adhesive is used, for example, under a tile). And the seams between the foam parts are ordinary polyurethane foam. When using a solution on the foam, you can put a tape flexible insulation.

Some manufacturers produce blocks with holes in a thick inner layer specifically for creating vertical reinforcement with steel bars, and a spatial reinforced frame directly in the blocks.

Seam issue

A feature of the use of heat blocks is the absence of external plaster and the jointing of through masonry joints. In this case, it becomes necessary to very carefully and reliably overwrite all the seams between the blocks from the outside. Why use the same masonry adhesive, and on top of it facade primers or silicone sealant.

It is necessary to monitor the condition of these seams throughout the operation of the building. When the wall is soaked with precipitation, water can enter through small cracks in the seams into the wall. What threatens it with frosty destruction, loss of thermal and strength qualities, penetration of moisture into the house, destruction of the mounting foam in the seams.

Walls made of this material with a relief surface on the outside are additionally painted with facade paints with any vapor permeability, usually in light colors, which creates additional protection for the structure.

The technology of protecting the wall from the outside by grouting through joints between the bearing elements seems unreliable.

Unlike aerated concrete or porous ceramics, which are also laid with through seams, but for which an external protective finish of the wall is always provided, lightweight plaster for the facade

Durability

The presence of the synthetic Styrofoam substance between the mineral carrier layers also raises questions. Styrofoam service life is not so longlike minerals. Presumably, this insulation will gradually decompose, compact, crumble, etc. And here this layer is a binder and can take loads….

After all, the predicted service life of the foam and mineral wool insulation on the wall is only 35 years, after which it is necessary to conduct another energy audit of the building and change the heaters that have become unusable. Even clinker brick cladding in a three-layer wall can be dismantled brick by brick to replace the insulation. But in this case ... The durability (100 years or more) of walls made of heat blocks is in doubt.

Blocks made entirely of mineral substances, where foam glass acts as a heater, "eternal" and vapor barrier, are clearly the preferred option. But they are much more expensive.

The use of mineral wool in blocks, which not only has a short service life, but also absorbs water like a sponge, also raises many questions.

According to the project

It is possible to use heat blocks (three-layer concrete blocks with an average layer of insulation) only in accordance with a project made specifically for this wall material.

Based on the calculations, the optimal design of the heat block will be selected, as well as reinforcement, a spatial frame formed by walls and ceilings.

You should not use the services of drawing up specifications and orders for heat blocks based on any house project offered by manufacturers of this material.

Pros and cons

The pros and cons of heat blocks, as well as how walls are laid from this material, can be found in this film

General description of heat-efficient blocks

A heat block is a modern material that consists of several layers:

- concrete. The basis of the block, its bearing part;

- insulation. Usually, regular or extruded polystyrene foam is used;

- finishing. It can be one- or two-layer with decorative lining.

This material can be made in the form of light expanded clay concrete blocks or from ordinary heavy concrete. The first option, due to its low weight, is used more often in private construction.

Heatblocks are characterized by a wide range of applications. It is used for cocking external load-bearing walls or partitions. This material may only be used in the construction of one- or two-story private houses.

Distinctive features

With the help of a simple but unique design, the heat block is much superior to other wall building materials in terms of technical parameters and has a number of distinctive features:

- The ability to keep warm for a long time.

For example, the cost of heating housing from heat blocks will be 4 times more than from brick. To obtain the same coefficient of thermal insulation as a wall of heat blocks 40 cm thick, you need to build a wall of foam concrete 60 cm thick, expanded clay concrete - 100 cm, brick - 230 cm, and concrete - 450 cm.

High speed of construction of buildings.

A heat-block house is being built many times faster than a brick house. It takes about a month to build a large two-story house from such blocks. This affects the ease of installation of blocks, and the lack of work on insulation and facade decoration.

Laying walls from heat blocks on a special glue.

High service life.

A well-built house can last more than 100 years without a major overhaul.

Good fire protection.

Does not require protection from mice and rats, insects, mold and rot.

There is no need for fine finishing of the facade of the house.

Saving money on materials and transport.

When laying heat-efficient blocks, cement, sand and water are not used. Thus, there is a saving not only on materials, but also on their delivery. And since the heat block is much lighter than other similar materials, then the foundation for the foundation of such a house will be laid much less. In addition, the decorative layer of the block saves a significant amount of money on the exterior decoration of the facade, which sometimes comes out equal in cost to the entire structure of the house.

Equipment for the production of heat blocks

Equipment for the production of heat blocks is selected taking into account the technology that will be used to implement the production process.

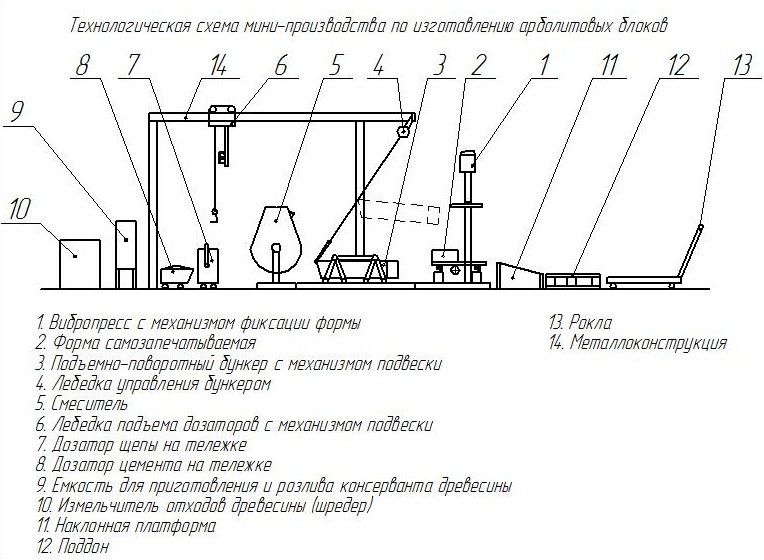

Making material at home

The production of such building material as heat blocks can take place at home. For this, you do not need to purchase an automated line. It is enough to purchase simpler equipment, the cost of which is significantly lower.In this case, its installation and operation is facilitated, which is important when organizing production on its own.

Some experts recommend using an ordinary concrete mixer, and pour the prepared solution into home-made forms. But do not expect high performance and excellent quality. The fabricated material will not be sufficiently compacted, which will adversely affect its strength characteristics. Without a specially equipped thermal chamber, the drying process of heat blocks can take up to 8 hours.

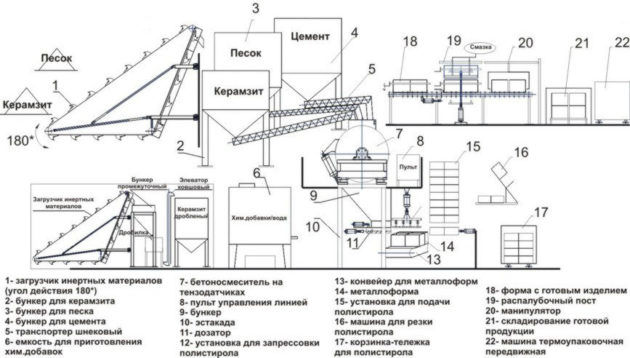

Production of heat blocks on an industrial scale

If you plan to release the material on an industrial scale, it is advisable to purchase an expensive line from specialized companies. It is recommended to choose vibropress equipment, where most of the processes are automated. Such lines will make it possible to produce material with maximum efficiency, which will differ in low cost.

The average cost of imported professional equipment for the production of heat blocks with a capacity of 20 cubic meters. m per day will be 70,000 dollars. At the same time, the final price of the line may change up or down depending on its equipment and other factors.

Composition of industrial scale production line

To complete the line for the production of energy-efficient material, which is lined with artificial stone, it is necessary to purchase the following equipment:

- bunkers for storage of raw materials;

- concrete mixer for the preparation of a building mixture;

- vibropress for compaction of a freshly prepared solution;

- vibrating chair for blocks;

- forms for obtaining material of a given shape and size;

- tables;

- units for cutting insulation into pieces of the desired size;

- formwork and a unit for its removal from finished blocks;

- steam generator and steaming machine;

- loader for moving finished materials and raw materials for their manufacture;

- shelving for efficient storage.

The cost of the line from different manufacturers

For the manufacture of heat blocks, it is necessary to purchase a production line, which can have completely different equipment, which affects its cost. The following models are popular among buyers:

- "Condor". Plant productivity 50-60 blocks per hour, 270 thousand rubles;

- automated line "Foreman" with molds and a drying chamber. The cost ranges from 350 thousand to 1 million rubles;

- "Kremnegranit" allows you to make material lined with porcelain stoneware. The average price of the unit is 300,000 rubles.

To equip home production, you need to invest at least 150,000 rubles. This amount includes the cost of purchasing a vibrating table, a concrete mixer, cassette molds and rubber liners. Formwork, racks and tables can be made independently from improvised materials. This will significantly reduce the initial investment for opening a home workshop for the production of heat blocks.

Related video: The process of production of heat blocks

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Brief conclusion

Ideal building materials do not exist in nature. Therefore, when choosing building blocks, you need to focus not only on the price of the product, but also on the scope and technical characteristics.

We recommend that you take a responsible approach to choosing a manufacturer: if a block is manufactured in violation of the technological process, the efficiency will be reduced to zero.

Modern building technologies are increasingly offering blocks of various materials instead of brick as a wall material. They differ in size, properties and price. Each of the types of blocks has its own area of preferred application, but all of them are able to replace bricks, both in residential and industrial construction.

In order to choose the right blocks, which in each case will show only their positive characteristics, it is necessary to compare them according to the main parameters. The physical and chemical properties of materials determine their behavior in the wall under load and largely affect the microclimate in the house.

The article will consider the main types of blocks that are used in private and industrial construction: aerated concrete; foam concrete; ceramic; arbolite; expanded clay concrete.

The analysis will concern not only the properties of a particular block, but also their interaction with other types of building materials, the complexity of preparatory and finishing work, the need to strengthen the structure, and the service life. An attempt to determine which blocks are best for building a house will be based only on objective data, without bias in advertising of one kind or another.