What determines the choice of diameter

The choice of the diameter of the PP pipeline depends on:

- purpose of application;

- pressure force;

- load;

- number of water sources.

As a rule, the inlet pipe has a diameter of 32 mm. For wiring, PPT 16-20 mm are used. At the same time, the inner diameter of the pipes directly depends on the thickness of their walls, therefore this parameter is one of the most important when constructing a water supply system. For the most accurate representation, there is a special correspondence table.

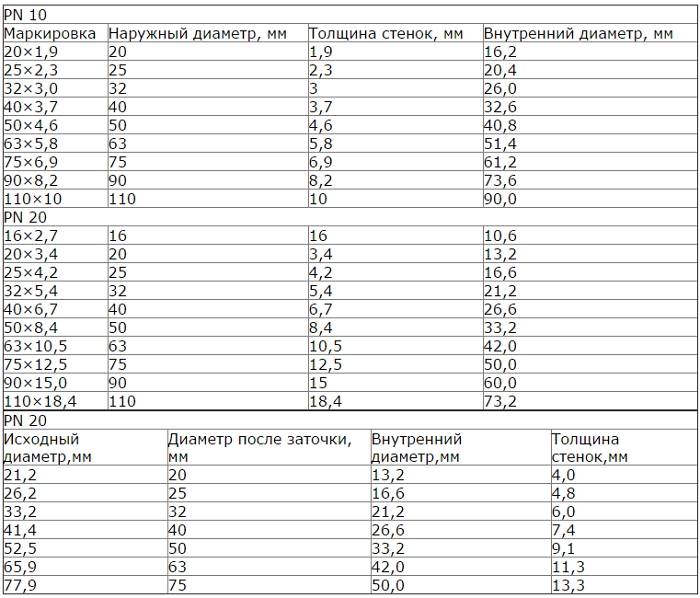

Diameter of polypropylene pipes table:

For the plumbing system, most often, pipes with an outer diameter of 21 to 25 millimeters are used, which is similar to standard steel pipes with a diameter of ½ and ¾ inches. For risers, products with a diameter of 32 to 40 millimeters are used.

Among polypropylene pipes there are several types of diameter:

- 16-1200 mm;

- 16-32 mm in the case of household products;

- 40-50 mm for internal sewerage.

The maximum possible pipe diameter is 110 mm. However, it is used only in the case of arranging the sewers of large apartment buildings.

The maximum pressure at which a particular polymer pipe can be used is indicated in the marking. For example, the inscription PN10 means that the product must be operated at a pressure of no more than 10 bar, PN20 - no more than 20 bar. In addition, the marking indicates the temperature in degrees.

Polypropylene tubes have a high coefficient of expansion: when the temperature changes during the use of the line, the dimensions of the PPT change noticeably.

The inner diameter depends on the permeability of the water supply. The following factors influence the level of patency:

- internal section (the smaller it is, the weaker the flow);

- total pressure inside the system;

- deposits inside the pipes (depending on the service life of the product);

- the number of transitions, turns and joints;

- the composition of the PPT raw materials (with a smoother surface, the pressure and permeability will increase);

- the total length of the pipeline (with a large length, the permeability decreases).

The diameter and wall thickness directly depend on the purpose of the application and the class of the pipe. To find out the exact diameter, there is a special calculation based on the measurement of hydraulic parameters. The main purpose of this calculation is to obtain the most accurate diameters.

During the calculation, all aspects must be taken into account, including the structure of the system and the working pressure. For example, pipes for a heating system are significantly different from products for cold water supply. In most cases, for trouble-free operation of the line without failures, it is necessary to use pipes with a large cross section, which will increase costs several times. If you ignore the need for a large cross section, then the pressure will noticeably decrease.

If a house or apartment is being equipped

When creating a project for a standard private house or apartment, there is no need for accurate calculations. The number of plumbing fixtures will be minimal, while the difference in price for pipes of different diameters will differ minimally, which will practically not affect the budget.

If you look at the faucet hose, you can see how small their diameter is, that is, through what minimum holes water enters the sink. Taking into account the fact that the cross section of the polypropylene pipe will be much larger, it will always be enough, since this particular hose will be the bottleneck in this case. That is, the patency of the entire system will rest against its narrowest point.

That is why the owners of private houses and apartments do not carry out complex calculations, but simply purchase a 20 mm polypropylene pipe, while saving their precious time.In the vast majority of cases, with a standard number of washbasins, sinks, bathtubs and other plumbing fixtures, such a pipe will suffice with a large margin.

We hope everyone figured out what diameter polypropylene pipes are measured by. Selecting them will not be difficult. As practice shows, it is often possible to simply purchase the simplest and cheapest pipe - the result will be a high-quality and properly functioning water canal.

Varieties of plastic

Connection of plastic pipes.

Several varieties of plastic plumbing products are widely known. They are based on different types of chemicals:

- PVC pipes are produced on the basis of polyvinyl chloride. Polypropylene pipes are marked with the letters PP, polyethylene - PE, made of cross-linked polyethylene - PEX. Metal-plastic are marked PEX-AL-PEX. PVC pipes are used for hot and cold water supply systems, sewage systems, and are used in the food industry. To connect them, special fittings are used;

- PP polypropylene pipes consist of a working layer, a foil layer and a protective layer, which are connected to each other thanks to perforated foil. Such puff structures have a diameter of 16-125 mm. Connected by thermoplastic welding. Are applied in systems of supply with drinking water, in pipelines of heating and transmission of compressed air;

- PEX pipes are made using cross-linked polyethylene. They have high strength. Are applied to installation of systems of heating and water supply. Mounted with compression fittings. Are applied in systems of snowmelt and at the equipment of heat-insulated floors;

- widely used metal-polymer pipes have an additional layer of aluminum foil inside. This layer can significantly reduce the coefficient of linear expansion of the product. When bent, they retain their shape.

Polypropylene pipes are usually supplied in lengths of 4 m and are completed with fittings. Fittings include tees, adapters, elbows, combo couplings, Americans, flange collars, combs, electrofusion couplings, water sockets, crosses and plugs.

Diameters of polyethylene pipes.

The next indicator is the diameter. It is external and internal. Polypropylene pipes are produced with an internal diameter of 5 mm or more. This indicator allows you to calculate the amount of substance that can pass through the pipe per unit time. The outer diameter must be known to prepare a niche for laying the pipeline. for selection of connecting fittings.

- small diameter pipes - from 5 to 75 mm. They are used for the installation of plumbing and heating systems in private houses and apartments. The most popular in multi-storey residential buildings with a diameter of 32 mm;

- average diameter - 80-315 mm. They are used for sewerage systems, water supply in homes, for the transportation of various chemical liquids;

- 400 mm and above refers to the classification of large diameter. Such pipes are used to supply large volumes of cold water and for the installation of ventilation systems. The wall thickness of various polypropylene pipes can be 1.9-18.4 mm. For heating systems, thick walls should be chosen.

Diameters have standard designations. When choosing a suitable diameter, you need to consider:

- interior. This is the main characteristic for the selection of connecting fittings;

- outer - subdivided into small size - 5-102 mm; medium - 102-406 mm; large - 406 mm or more. Sometimes the diameter may be indicated in inches.

The inner diameter is an important characteristic. This value helps to choose the right pipes for the installation of a variety of thermal systems in everyday life and at work. You can calculate it yourself using the formula: d=sqrt((3.14xQ)(vxdt)). Symbols stand for:

- d is the desired inner diameter;

- Q is the value of heat flow in kW;

- V is the average coolant velocity in meters per second;

- dt is the temperature range;

- sqrt is the square root.

Polypropylene pipes with a diameter of 110 mm are used in production conditions. 63 mm - for the transport of chemicals and compressed air, as well as for connection to the boiler room in heating systems. 25 mm - for connecting radiators to a common heating system.

The risers of 5-storey houses are made of pipes 25 mm in diameter. For buildings with 9 or more floors, a diameter of 32 mm is used. Intra-apartment wiring is carried out with a diameter of 20 mm. Large diameter pipes are used to supply cold water to several houses. 500 mm or more is suitable for the installation of a main water supply system that supplies water to an entire urban area.

Installation of polypropylene pipelines is carried out using a minimum set of tools. You will need:

- roulette;

- scissors for cutting polypropylene;

- welding electrical appliance;

- corners;

- couplings;

- cranes.

Scissors can be replaced with a hacksaw for metal. The standard welding device is equipped with a set of nozzles for welding polypropylene pipes with a diameter of 20 to 50 mm.

Diameters of polypropylene pipes correspondence from external to internal

Polypropylene products differ from other types in their relatively low cost and ease of installation. In addition, pipelines made of this material are not subject to corrosion and deposits, do not conduct electricity, have an aesthetically attractive appearance and leak very rarely. If such a nuisance happens, then it is associated with errors made during installation.

In addition to in-house water pipes and heating systems, polypropylene products are used in ventilation systems, sewage systems, external water supply pipelines, industry and agriculture.

Classification of polypropylene pipes:

- PPH - this is the first type, made from homopolypropylene, has increased strength, is used in systems for cold water, ventilation, in industry

- PPB is the second type, made from a block copolymer, used in ventilation and cold water systems, as well as in underfloor heating.

- PPR - the third type (the most common), made from a random copolymer, used for cold and hot water, in radiator and underfloor heating

- PPs is a special type that allows the temperature of the internal environment up to 95 degrees.

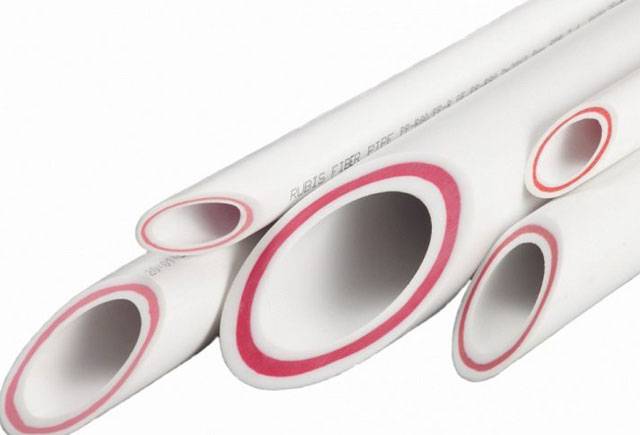

Polypropylene products are also divided into reinforced and non-reinforced. Aluminum foil or fiberglass can be used as reinforcement. The foil may be located near the outer surface or in the middle of the wall.

Diameters of polypropylene pipes: dependence of wall thickness

Before designing a pipeline, you need to know what diameter of polypropylene pipes will be used. There is a complex hydraulic calculation. His goal is to choose such a size for each site in order to save money when buying. The calculation takes into account the working pressure and the structure of the system. A large cross section, of course, does not harm, but it will be very expensive. If the cross section is too small, the pressure will decrease.

What are the diameters of polypropylene pipes? From 16 to 1200 mm! However, for domestic water supply and heating systems, products with a size of 16 to 32 mm are used, for internal sewerage - 40, 50 mm or polypropylene pipes with a diameter of 110 mm. The maximum diameter of polypropylene pipes is relevant when installing external sewer pipelines for very large houses or entire neighborhoods.

When designing an internal cold water supply system, the choice of size depends on the length of the pipeline and the number of water supply points. The supply pipe most often has a size of 32 mm; for indoor wiring, the outer diameter of polypropylene pipes is 16 - 20 mm.

No less important is such an indicator as wall thickness. The internal diameters of polypropylene pipes depend on it. The table will help you understand the variety of sizes:

Cross-country classification

Additionally, pipes are classified by patency.The internal size of polypropylene pipes indicates how much water they can pass in a certain period of time. The external dimensions of the PP pipe in this case do not matter. This suggests that the wall thickness can be any - only how strong the pipes will depend on this parameter.

How to correctly calculate the patency of pipes

To calculate the inner diameter of PP pipes, you need to use the following formula:

D = √(4 - Qcommon — 1000/π∙V), where:

Qcommon – limiting total water consumption;

V is the speed of water movement.

If the pipes are thick, then the speeds are assigned a value of 1.5-2 m / s, for thin pipes, this value, as a rule, is 1.2 m / s. That is, the smaller the cross section of the pipe, the higher the surface / clearance ratio. In other words, in a thin pipe, almost the entire volume of water will slow down against the walls.

PP pipes with sections of 10-25 mm are selected if the speed of water movement is small. But if the V values are large, then the pipe sections must be at least 32 mm.

In any case, it is desirable to proceed from the highest speeds, since polypropylene has very smooth walls. If a water supply system is installed, then in this case the friction of water on the inner surface of the pipes will be minimal.

The exact values of the patency and cross-section of pipes are of great importance only in the case of designing a plumbing system in multi-storey buildings. If you do not use the table of sizes of polypropylene pipes, and choose a pipe with a section smaller than the prescribed one, then during periods with peak water consumption, residents will simply be left without water.

However, you may want to take a pipe with a margin

In this case, it is worth paying attention to the feasibility of such a decision from an economic point of view. Larger diameter pipes will require more expensive fittings.

As a result, costs can rise significantly. If desired, this can be prevented, the main thing is to use a rational approach.

PP pipes of large cross sections are not advisable to use in places where there will be enough thin pipes, again for the purpose of saving. The fact is that when you drain cold water from a tap for a long time, with a large section of the pipe and more water will be spent before the water becomes hot. If there is no water intake, then a significant part of the heat from hot water will simply dissipate idle.

It is recommended to organize a circulating water supply system, so that it is not necessary to drain the water each time until it becomes hot. If this is a private house, then you only need to install a simple circulation pump, as well as purchase and equip the system with an additional pipe through which water will return to the boiler.

There is a huge assortment of polypropylene pipes for heating and not only on the market. If you are making a water supply riser, then polypropylene pipes with a cross section of 25 mm are suitable if it is a five-story house, and 32 mm for houses from nine to sixteen floors. In this case, when determining the diameter, it is worth considering the exact number of plumbing fixtures that will be used in this system.

Large-section polypropylene pipes are most often used to supply cold water to one or more houses. Polypropylene is not used for laying pipes in heating mains, since it does not like hot water. In addition, this is a place where a large load will act on the pipes, from which soft polypropylene can simply be damaged.

With cold water, everything is much simpler - due to its low temperature and low pressure in the system, cast iron is increasingly being abandoned in favor of polypropylene when equipping water pipes. Quite often you can find systems with a conditional diameter of polypropylene pipes of 500 mm or more, which feed entire small areas.

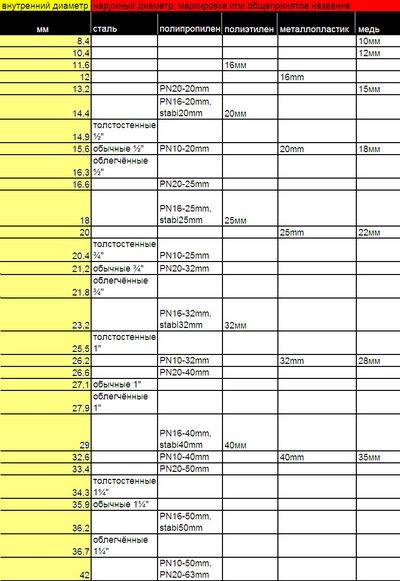

The ratio of the passage diameters of pipes made of different materials. Sample PivotTable

Very often, installers and locksmiths confuse pipe diameters. I had to see how a locksmith from the housing office insisted that during the alteration the diameter of the pipes in the central heating should not be narrowed, while demanding that everything be passed as 25 metal (34), but the installers understood this as 25 polypropylene.

Do not forget that it is the inner diameter that is important in pipes, because it is it that determines their throughput.

Below is an approximate summary table of pipes of different diameters and different materials. The most common materials and diameters are taken.

How to use the table: on the left, the vertical column shows the inner diameter, for example, we find 15.6mm, this inner diameter corresponds to an ordinary steel pipe 12. polypropylene PN10 with a diameter of 20mm, 20mm metal-plastic and 18mm copper.

By the way, an ordinary pipe in 34 corresponds to PN20 polypropylene with a diameter of 32 mm, which is considered to be an inch.

Polypropylene and metal-plastic pipes information about Wavin pipes from 20 to 40 mm in diameter was used

Copper pipes used GOST 2005, up to 15 mm in diameter, the wall thickness is taken 0.8 mm, up to 28 mm - wall thickness 1 mm, over 28 -1.2 mm

Steel pipes used an old GOST of the 75th year.

Uponor polyethylene pipes - PEX with pressure up to 10 bar for heating and plumbing.

Pipes that are very close in ID are grouped under the nearest value.

Perhaps such a table will be useful in the calculations.

Polypropylene pipes and their main diameters

Previously, only cast iron and galvanized steel pipes were used for the installation of various pipelines. They were replaced by products made of polypropylene. They differ from cast iron in a high degree of reliability, lightness, durability, low cost. Polypropylene pipes do not conduct electricity. This quality makes them indispensable when connecting washing machines. A completely smooth inner surface prevents debris from accumulating inside them.

Advantages of plastic pipes: durability, corrosion resistance, poor thermal conductivity.

Polypropylene has a high anti-corrosion resistance. Gas and chemical liquids can be transported through such pipes. Polymeric materials are not afraid of temperature changes. They do not burst from freezing in winter, they are able to withstand high temperatures. Craftsmen from such products assemble frames for gazebos and greenhouses. The diameter of polypropylene pipes is different. The properties and applications of these products largely depend on it.

How to choose the right diameter for a home line

For pipes made of polypropylene, which will be used in apartment buildings, all calculations of the pipeline for water supply and sewerage must be done with great care and attention. Accordingly, the higher the water consumption by the residents, the larger the diameters of the polymer products used.

As a rule, in apartment buildings the following sizes of diameters of polypropylene pipes in mm are used:

- for risers of 5-storey buildings Ø25 mm;

- wiring inside buildings - Ø 20 mm;

- for risers of houses of 9 or more floors, PPT Ø 32 mm is used.

For each specific apartment or private house, there is no need to accurately calculate the diameter of the water pipes, since there are not so many fence points in such premises. Pipes in this case are selected according to a given specification and have a larger section than the diameter of the mixers.

The diameter of polypropylene pipes for water supply in an apartment or in a house is selected taking into account the following features:

- with a pipeline length of up to 10 m, a diameter of 20 mm is preferable,

- for pipelines 10-20 m - diameter 25 mm,

- with a length of more than 30 m - a diameter of 32 mm.

For risers choose products of 32 mm or more.

If necessary, the calculation of a home pipeline can be done using a simple formula, which initially requires only the exact value of the water flow and the total internal flow rate of the liquid.We select the inner diameter of polypropylene pipes by elementary calculation with the initial data:

- the speed of fluid movement along the line;

- water consumption.

The diameter of polypropylene pipes for the water supply of an apartment or a private house is calculated by the following formula:

In an apartment and a house, it is recommended to install pipes for heating with a clear diameter of 20 mm, and for a water supply system, the minimum section size should be 16 mm. It is not worth exceeding this size, so as not to lose compliance with the specifications. As for pipes with the largest possible diameter (over 500 mm), there is no need for them at all.

Based on all of the above, you can easily decide on the choice of a polypropylene pipe for water supply in each case, and make an independent calculation of its diameter, based on a simple formula and data from the table.

Where are polypropylene pipes used

Polypropylene pipes appeared on sale not so long ago, however, they are already very popular.

There are a number of advantages that distinguish them from the background of analogues:

- the material is not subject to oxidation;

- can be used in environments with aggressive conditions;

- low cost;

- do not conduct electricity;

- pipes are easy to lay;

- look great on the outside.

It should be noted that PP pipes can be used not only as an internal water supply.

Additionally, they can be used to equip:

- Ventilation systems. Even the large outer diameter of polypropylene pipes keeps them light, without creating large loads on wooden frame partitions and plasterboard sheathing, for example.

- Sewers. The material is not afraid of aggressive substances.

- External plumbing with cold water supply.

Since polypropylene is not as strong as cast iron, it needs protection in some places. If pipes are laid under roads, it is better to build a reinforced concrete box.

The advantages include the fact that deposits do not accumulate on the inner walls of pipes made of polypropylene. Due to its elasticity, such pipes will not be damaged by frost.

Varieties of polypropylene pipes

Polypropylene pipes are divided into types according to the composition of the raw material and the pressure at which they are used.

Classification of polypropylene pipes (PPT) according to the composition of raw materials, namely, according to the degree of modification of the main polymer with various additives used:

- PPR (PPRS, PPR) - pipes of this type are made from a static copolymer of foam propylene with a crystalline structure of molecules. These products are resistant to temperature fluctuations from -170 to +1400C, as well as shock loads, so they are often used for plumbing, heating and sewage systems. Diameter size from 16 mm to 110 mm.

- PPH - in these products, to give increased impact strength, modifying additives are mixed with polypropylene: nucleators, fire retardants, antistatic agents. This type with a large diameter is used for outdoor plumbing, drainage, ventilation. And for the heating device, these products are not suitable, because they have a low melting point.

- PPB (block copolymer) - this type of raw material has a structure of blocks of homopolymer micromolecules that differ in composition and structure, which alternate with each other in a certain order. Ultimately, the products acquire an increased degree of impact resistance, so they are used for underfloor heating and cold water supply systems.

- PPs (polyphenyl sulfide) - this highest class of polymer with a special molecular structure has increased resistance to stress and overheating, is very wear-resistant and durable. PPs are used for cold and hot water supply, ventilation, heating systems. The diameter of these polypropylene pipes varies from 20 to 1200 mm.

At the same time, the configurations, as well as the outer and inner diameters of polypropylene pipes, are strictly regulated by GOST.

In the marking of pipes made of polypropylene, there are designations N25, N 20, N10, etc. This indicator allows you to evaluate the resistance of PPT to the pressure of the liquid that is in them.

There are such types of polypropylene pipes by pressure, which determines what diameter to choose a product:

- PN10 (N10) - with a working pressure on the wall of 1.0 MPa and a polymer thickness of 1.9 to 10 mm. Are applied to the device of systems of heat-insulated floors, cold water supply with heating to +45 °C. The diameter of pipes of this type: outer - 20 ... 110 mm, inner - 16 ... 90 mm.

- PN16 - this type of product is rarely used, has a pressure on the wall of 1.6 MPa. Is suitable for cold and hot water with heating of the heat carrier up to +60 °C.

- N20 (PN20) - products with a working pressure on the wall of 2.0 MPa and a thickness of 16 ... 18.4 mm. The most demanded polymer for hot and cold water supply with heating temperature up to 80 °C. Execution: outer diameter - 16 ... 110 mm, inner - 10.6 ... 73.2 mm.

- N25 (PN25) - polypropylene with a working pressure on the wall of 2.5 MPa and reinforcement with aluminum foil. They are perfect for arranging hot water supply systems, heating with a liquid temperature up to +95 ° C. The multi-layer structure of these products contributes to high resistance to thermal and shock loads. The diameter of pipes of this type is 13.2 ... 50 mm, the outer one is 21.2 ... 77.9 mm.

There are also glass fiber reinforced PPTs. Such lines do not delaminate during operation, and when assembling a water pipe, they save time on cleaning cuts during welding. Polypropylene pipes reinforced with fiberglass mesh are resistant to deformation, have an extended service life, and provide quick and easy installation.

Use of reinforcement

Reinforcement is one of the ways to give pipes special mechanical properties.

Reinforcement is as follows:

- Aluminum foil layer. It can be both external and located inside.

- fiberglass layer. As a rule, it has an internal location.

Thanks to the reinforcement, the pipes are more durable, and their thermal expansion becomes smaller.

Experts recommend paying attention primarily to the reinforcement of the fiberglass layer. This type of pipe never loses its mechanical strength and does not delaminate, and their installation does not require stripping.

This type of pipes never loses its mechanical strength and does not delaminate, and cleaning is not required for their installation.

Pipe classification

Polypropylene pipe device.

- PN 10. They have the usual strength. These are polypropylene pipes with thin walls. The range of their application is quite wide. They are highly resistant to high and low temperatures. They can be used for installation of underfloor heating and plumbing systems. Their outer diameter - 20-110 mm, inner - 16.2-90 mm, wall thickness - 1.9-10 mm;

- PN 20. This model is universal. It is applied to installation of systems of ventilation and hot water supply. They can be used for underfloor heating systems. The inner diameter is 10.6-73.2 mm, the outer diameter is 16-110 mm, the wall thickness is 1.6-18.4 mm. In the cold they become brittle;

- PN 25. Polypropylene pipes reinforced with aluminum foil or fiberglass. They are very durable. They are used for installation of central heating systems, external plumbing, air supply systems under high pressure. Inner diameter - 13.2-50 mm, outer - 21.2-77.9 mm, wall thickness - 4-13.3 mm.

The numbers 20, 10 and 25 are the designation of the maximum allowable pressure in kg / cm².

Advantages

- durability. They serve 3-5 times longer than steel and cast iron. Their service life is 50 years or more;

- anti-corrosion resistance. Polypropylene does not enter into electrochemical reactions;

- this plastic is a clean material in terms of ecology;

- it has poor thermal conductivity. This prevents condensation on the surface of the water supply;

- products are light weight. It is 9 times lower than the weight of metal analogues;

- the movement of water occurs almost without noise;

- installation and installation of systems is extremely simple;

- they can be laid inside and outside the building;

- internal parts of pipes made of polypropylene, which are in direct contact with water, fully comply with all sanitary standards of Russia, the USA, Germany, England, Belgium, Spain and Italy;

- their outer surface does not need to be painted.

The disadvantages of a pipeline made of polypropylene include:

- each type of polymer material requires the use of different mounting technologies;

- they cannot be used for fire fighting purposes;

- not all products can be used for the installation of hot water and heating systems.

All polypropylene pipes are available in different colors. They are white, black, gray and green. The color itself means nothing. Exception - black color protects somewhat better from ultraviolet radiation.